Discover the Benefits of 2-4 Layer Aluminum MCPCBs for Demanding Thermal Applications

For high-power applications, you need dependable solutions that deliver superior performance. The 2-4 layer metal core pcb mcpcb aluminum board is an excellent choice, as its aluminum core and multi-layered structure efficiently dissipate heat from critical components. This advanced design enhances thermal performance and extends the lifespan of your devices. LT CIRCUIT offers reliable 2-4 layer metal core pcb mcpcb aluminum solutions tailored for your most demanding projects.

Key Takeaways

2-4 layer aluminum MCPCBs provide superior thermal conductivity, ensuring effective heat dissipation and preventing overheating in high-power applications.

These boards support high component density, allowing for efficient use of space while maintaining reliable performance through advanced thermal management.

Aluminum MCPCBs offer excellent mechanical strength and stability, making them ideal for demanding environments and extending the lifespan of electronic devices.

2-4 Layer Metal Core PCB MCPCB Aluminum

Structure and Composition

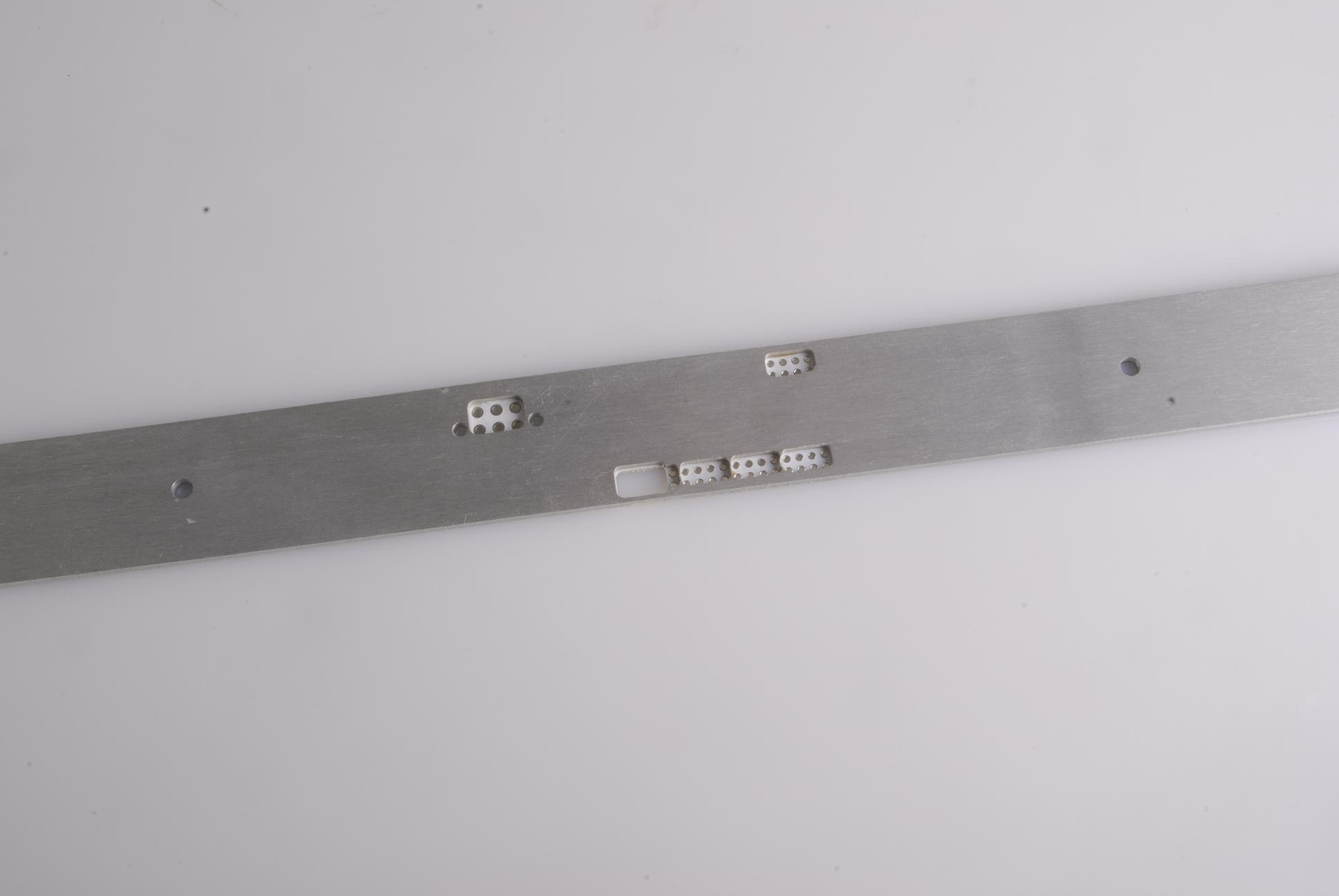

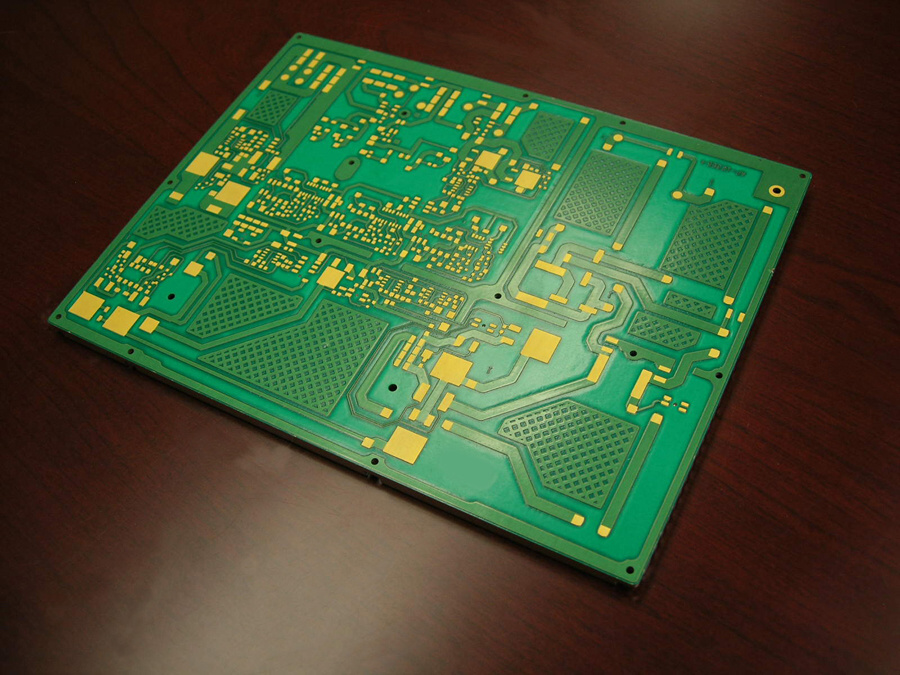

When you explore 2-4 layer metal core pcb mcpcb aluminum boards, you see a unique structure that sets them apart from standard pcb options. These aluminum pcbs use a solid aluminum core, which gives them strength and excellent thermal properties. You find multiple layers stacked together, allowing for complex circuit routing and robust pcb design. This structure supports high-power applications and ensures reliable performance.

You can review the typical layer configurations and thicknesses in the table below:

Layer Configuration | Thickness Range |

|---|---|

Various sizes and thicknesses depending on application requirements | |

Double-Layer | Aluminum thickness from 0.8mm to 3.8mm |

LT CIRCUIT uses advanced manufacturing techniques to produce these aluminum pcbs. The company follows strict standards, such as IPC-6012 and UL 796, to guarantee quality and safety. These standards help prevent warping, ensure solder joint integrity, and verify electrical performance. You benefit from a product that meets high expectations for durability and reliability.

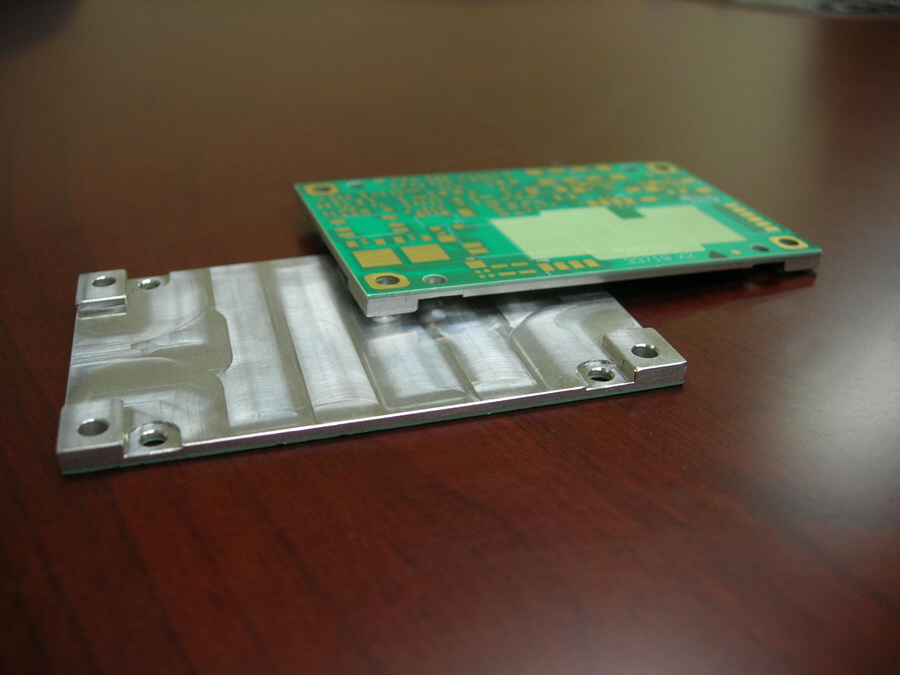

Thermal Management

You need effective thermal management in high-power applications. The aluminum core in these pcbs acts as a powerful heat sink. It rapidly transfers heat away from sensitive components, which improves device performance and extends lifespan. Aluminum pcbs offer superior thermal conductivity compared to traditional single-layer boards. This means you get better heat dissipation and lower operating temperatures.

Aluminum pcbs use a metal substrate to boost thermal conductivity.

They provide better heat dissipation than single-layer mcpcb boards.

You can rely on them for high-power and high-temperature applications, which leads to improved reliability.

When you choose a 2-4 layer metal core pcb mcpcb aluminum board from LT CIRCUIT, you invest in a high-power aluminum pcb design that delivers consistent power, excellent performance, and long-term value for demanding applications.

Key Benefits for High-Power Applications

Superior Thermal Conductivity

You need reliable thermal management in high-power applications. Aluminum pcbs deliver outstanding thermal conductivity, which helps you maintain safe operating temperatures in power electronics. When you use aluminum mcpcb boards, you get enhanced heat dissipation. This feature protects your devices from overheating and improves overall performance. You see aluminum pcbs used in power inverter systems because they transfer heat away from components quickly. This process extends the lifespan of your equipment and keeps your power systems stable.

Aluminum pcbs enhance thermal management in power electronics.

You benefit from efficient heat dissipation, which reduces the risk of overheating.

The durability of aluminum pcbs ensures reliable performance in harsh environments.

LT CIRCUIT offers high-power aluminum pcb design options that maximize thermal performance aluminum pcb design. You can select from multiple pcb layers and custom thicknesses to match your specific power requirements. These solutions help you achieve optimal thermal dissipation and maintain high current carrying capacity.

High Component Density

You often need to fit many components into a small space for high-power applications. Aluminum pcbs support high component density without sacrificing performance. When you place components close together, you risk creating hotspots. Aluminum mcpcb boards solve this problem by providing superior heat dissipation and thermal resistance. You can use thermal vias to transfer heat away from densely packed areas, which keeps your devices cool and reliable.

High component density can create hotspots due to increased heat.

Effective component placement prevents concentrated heat buildup.

Thermal vias in aluminum pcbs improve heat dissipation.

Metal-core pcbs offer better thermal management than standard boards.

LT CIRCUIT gives you robust pcb design choices for high-power systems. You can customize your aluminum pcb to include advanced thermal features, such as optimized via placement and specialized materials. These options help you handle high current and maintain consistent performance in demanding applications.

Mechanical Strength

You need strong and stable pcbs for high-power applications. Aluminum pcbs provide excellent rigidity and dimensional stability. When you compare aluminum mcpcb boards to ceramic and FR-4 pcbs, you see that aluminum offers better thermal conductivity and less thermal expansion. This stability protects your devices from mechanical stress and ensures long-term performance.

Aluminum mcpcb boards deliver good rigidity and thermal conductivity.

Metal core pcbs dissipate heat more effectively than FR-4 boards.

Aluminum pcbs experience less thermal expansion, which improves dimensional stability.

LT CIRCUIT supplies high-power aluminum pcb design solutions that combine mechanical strength with advanced thermal features. You can rely on these boards for robust pcb design in power electronics, industrial devices, and other high-power applications. The company provides customization options to meet your unique requirements, including multiple pcb layers and specialized finishes.

Tip: When you choose aluminum pcbs from LT CIRCUIT, you invest in reliable performance, superior heat dissipation, and long-lasting durability for your high-power systems.

MCPCB Aluminum vs. Other PCB Types

Performance Comparison

You often compare aluminum pcbs to traditional FR-4 boards when you need robust pcb design for high-power applications. Aluminum mcpcb boards stand out because they offer excellent thermal conductivity and greater mechanical strength. You see that aluminum pcbs transfer heat away from components much faster, which keeps your high-power systems running safely. FR-4 pcbs do not handle heat as well, so they may not suit demanding power applications.

Here is a table that highlights the main differences:

Feature | Aluminum MCPCB | FR-4 PCB |

|---|---|---|

Thermal Conductivity | Excellent thermal conductor | Relatively poor thermal conductor |

Coefficient of Thermal Expansion | 50×10^-6 cm/cm℃ (lower) | Higher than aluminum |

Layering | Strictly three layers | Can be single, double, or multi-layer |

Mechanical Strength | Greater strength and rigidity | Lower strength compared to aluminum |

Applications | Suitable for high-temperature use | Not ideal for high heat dissipation |

You also consider cost and manufacturing differences. Aluminum pcbs have lower material costs but higher manufacturing costs due to machining challenges. Copper core pcbs cost more for materials but are easier to manufacture and offer better high current carrying capacity.

PCB Type | Material Cost | Manufacturing Cost | Suitability for High-Power Applications |

|---|---|---|---|

Aluminum Core | Lower | Higher due to machining challenges | Good for heat dissipation |

Copper Core | Higher | Lower due to ease of manufacture | Better for high current capacity |

Aluminum pcbs provide environmental benefits. You help reduce energy use and emissions when you choose aluminum for your pcb design. Aluminum can be recycled efficiently, and its lightweight nature lowers transportation energy needs.

Application Examples

You find aluminum pcbs in many high-power applications. These boards support robust pcb design in consumer electronics, LED lighting, and industrial devices. You see aluminum pcbs used in power supplies, automotive lighting, and communication equipment. Their superior thermal performance and mechanical strength make them ideal for high-power systems.

Aluminum pcbs improve energy efficiency in LED lighting by managing heat.

You use aluminum pcbs in industrial power modules for reliable performance.

Their lightweight design helps reduce transportation costs and emissions.

You find aluminum pcbs in consumer electronics where compact design and heat management matter.

Aluminum pcbs support high current carrying capacity in power conversion devices.

LT CIRCUIT supplies aluminum pcbs for these demanding applications. You benefit from advanced design options and reliable performance in every high-power system.

You gain reliable thermal management and durability with 2-4 layer aluminum MCPCBs, making them ideal for high-power electronics. The market for these boards will grow as energy-efficient technologies expand. LT CIRCUIT offers advanced solutions with key advantages:

Description | |

|---|---|

Superior Thermal Conductivity | Efficient heat dissipation for reliability |

Durability | Long-lasting performance in tough environments |

Electromagnetic Shielding | Protection from interference |

Innovation in Materials | Advanced materials for high standards |

Application Versatility | Used in many industries |

FAQ

What makes aluminum MCPCBs better for heat management?

You get faster heat transfer with aluminum MCPCBs. The metal core acts as a heat sink, keeping your devices cooler and more reliable.

Can you customize aluminum MCPCBs for specific projects?

Yes, you can choose layer count, thickness, and finishes.

LT CIRCUIT offers tailored solutions for your unique requirements.

Where do you use 2-4 layer aluminum MCPCBs?

Application | Benefit |

|---|---|

LED lighting | Improved heat control |

Power electronics | Enhanced durability |

Industrial devices | Stable performance |

See Also

Understanding Thermal And Electrical Performance Of Aluminum PCBs

Diverse Applications Of Multilayer PCBs In Various Industries

Enhancing LED And Power Electronics With Aluminum-Backed PCBs

Comprehensive Guide To Heavy Copper Multilayer PCB Production

High TG FR4 Laminate PCBs For Extreme Temperature Performance