What is a 2-layer aluminum ENIG PCB and its main advantages

Discover how a 2layer aluminum enig pcb can elevate your electronics projects. This advanced 2layer aluminum enig pcb utilizes an aluminum core for superior heat management and is finished with ENIG to ensure robust solder joints. LT CIRCUIT is dedicated to providing exceptional quality in pcb manufacturing, offering durability, reliability, and outstanding performance for even the most demanding electronics applications.

Key Takeaways

A 2-layer aluminum ENIG PCB offers excellent thermal management, making it ideal for high-power applications like LED lighting and automotive electronics.

The ENIG finish enhances solderability, ensuring strong and reliable connections while protecting against oxidation.

Durability is a key advantage; the aluminum core provides mechanical strength, preventing bending and warping in harsh environments.

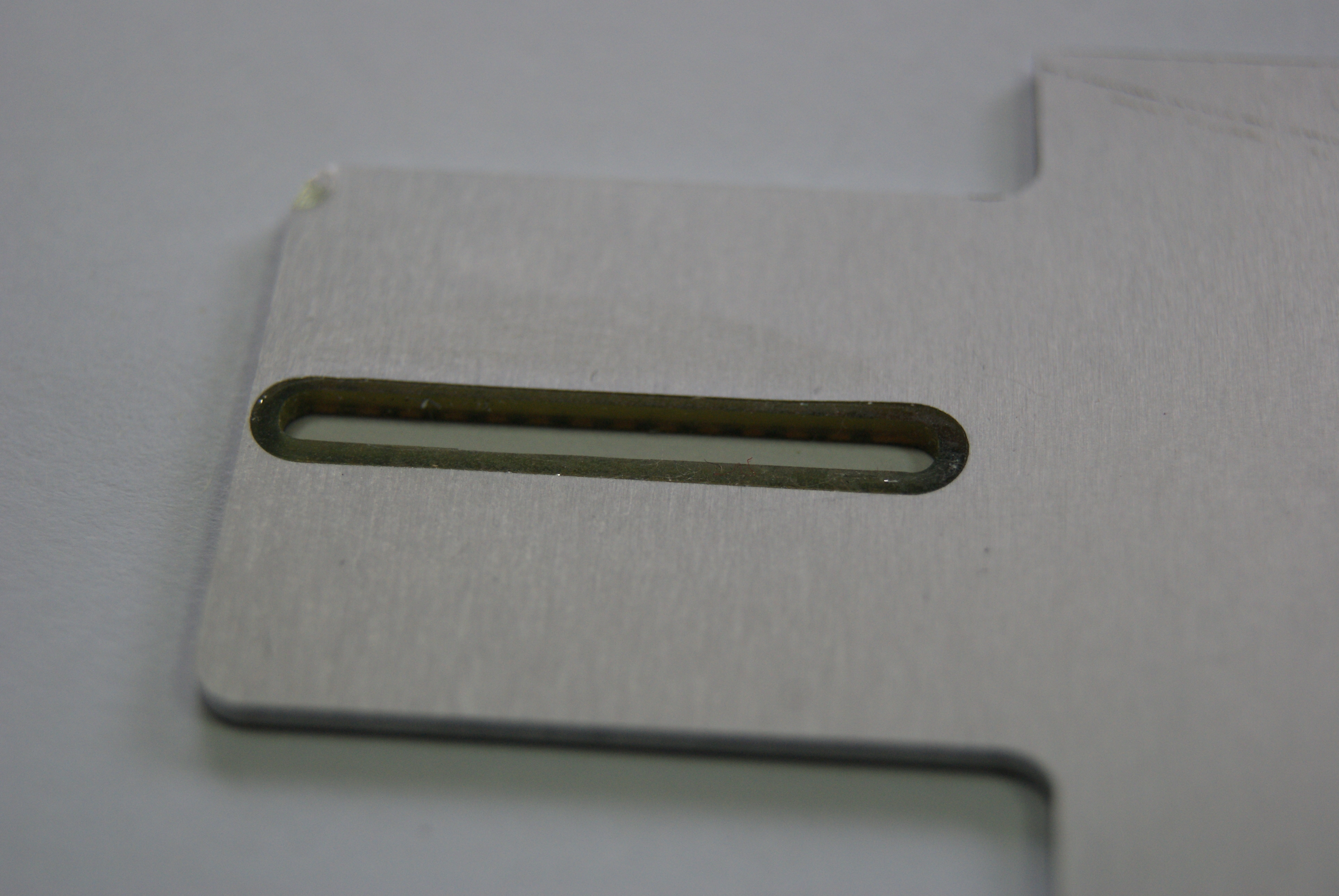

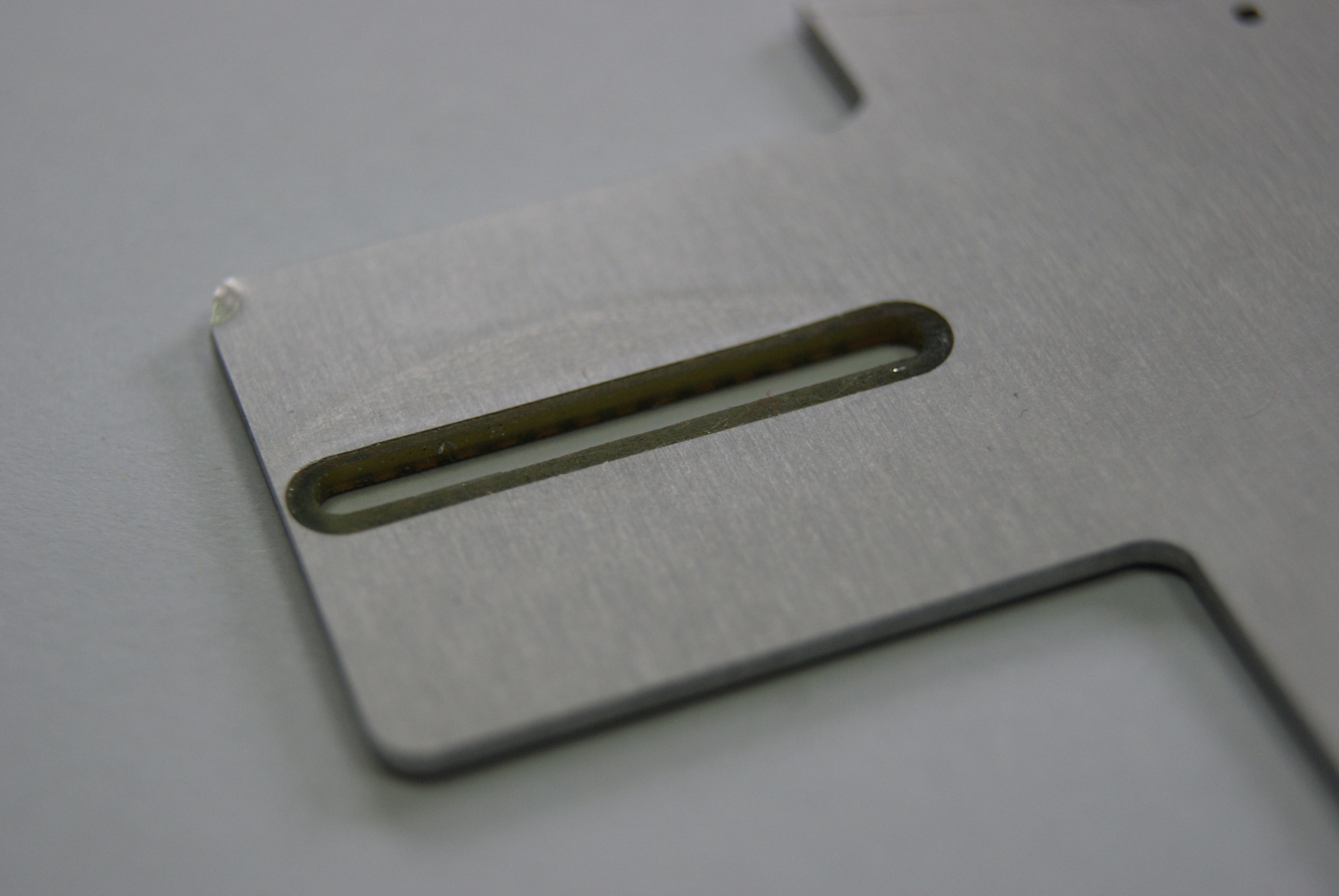

2layer aluminum enig pcb Structure

When you choose a 2 layer aluminum pcb for your project, you get a design built for strength, heat control, and reliable electrical performance. LT CIRCUIT uses advanced manufacturing to make sure every part of your aluminum backed pcb meets high standards for quality and durability. Let’s break down the main layers and features that set this metal core pcb apart.

Aluminum Core

The heart of a 2 layer aluminum pcb is the aluminum core. This metal base gives your pcb strong mechanical support and helps move heat away from sensitive electrical parts. You will notice that the aluminium core makes your aluminum backed pcb perfect for high-power LEDs, automotive electronics, and other devices that need excellent thermal management. LT CIRCUIT uses pure aluminum to ensure quality and long-lasting performance. The metal core pcb structure also helps prevent bending and warping, so your pcb stays flat and reliable.

Dielectric Layer

Above the aluminum core sits the dielectric layer. This thin, non-conductive material separates the metal base from the copper layers. You get strong electrical insulation and improved heat transfer. The dielectric layer in a 2 layer aluminum pcb is engineered for high thermal conductivity, so heat moves quickly from the copper traces to the aluminum core. LT CIRCUIT uses advanced materials to guarantee quality and consistent electrical performance. This layer keeps your electrical signals safe and stable.

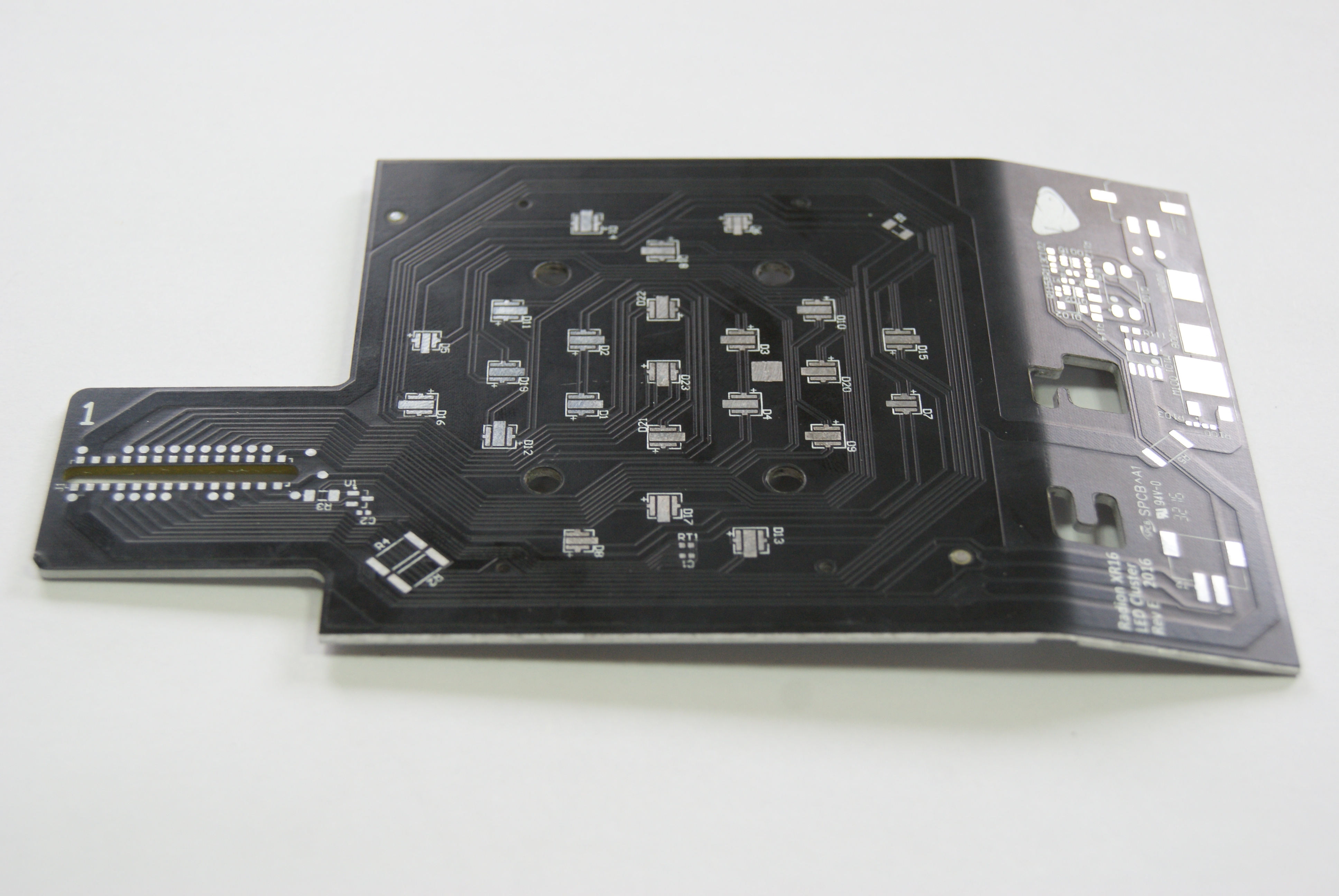

Copper Layers

On top of the dielectric, you find the copper layers. These layers form the electrical circuits that connect your components. In a 2 layer aluminum pcb, you get two copper layers, which allow for more complex routing and better electrical performance than single-layer designs. LT CIRCUIT uses high-purity copper and precise etching to create clean, reliable electrical paths. The copper layers work with the metal core pcb to deliver strong current handling and low resistance.

ENIG Finish

The final touch on your 2 layer aluminum pcb is the ENIG finish. ENIG stands for electroless nickel immersion gold. This surface finish covers the copper pads with a layer of nickel, followed by a thin layer of gold. You get a long-lasting finish that protects your pcb from oxidation and wear. The exceptional flatness of the enig surface finish makes it ideal for fine-pitch components and high-density designs. You also benefit from improved corrosion resistance and reliable electrical contact.

Tip: ENIG gives your pcb a bright, uniform look that makes visual inspection easy. You can trust the superior flatness and long shelf life to keep your metal core pcb performing well over time.

Here’s how ENIG compares to other finishes:

Feature | ENIG | Other Finishes (e.g., HASL) |

|---|---|---|

Flatness | Generally less flat | |

Compatibility | Ideal for fine pitch and high-density | Limited compatibility |

Shelf Life | Extended shelf life (up to 12 months) | Shorter shelf life |

Solderability | Excellent solderability | Varies by finish |

Heat Cycle Resistance | Can withstand multiple cycles | Limited resistance |

Visual Inspection | Bright, uniform surface for easy inspection | Varies by finish |

Corrosion Resistance | High due to nickel-gold combination | Varies by finish |

RoHS Compliance | Yes | Varies by finish |

You get a metal core pcb with a long-lasting finish and improved corrosion resistance. The ENIG process ensures reliable electrical contact and makes soldering easier. LT CIRCUIT follows strict quality standards and uses advanced testing to make sure every 2 layer aluminum pcb meets your needs.

LT CIRCUIT’s commitment to quality shows in every step. The company follows industry standards like IPC-6013, IPC-2223, and ISO 9001:2015. These standards help your pcb resist heat, bending, and electrical failures. Here’s a quick look at the certifications:

Standard | Purpose | Impact on Reliability |

|---|---|---|

IPC-6013 | Sets rules for how products should work | Helps stop failures from heat and bending |

IPC-2223 | Rules for mounting and connections | Makes sure parts fit well and stay strong |

IPC-9204 | Checks flexibility and stretching | Shows the product can bend and stretch |

IPC-9257 | Tests electrical parts | Makes sure it works right before making many |

IPC-TM-650 | Gives ways to test products | Makes testing the same every time |

ISO 9001:2015 | Quality management systems | Ensures consistent quality and reduces errors |

UL | Safety certification | Confirms product safety and compliance |

AS9100 | Aerospace quality management | Ensures high standards for aerospace products |

ISO 13485 | Medical devices quality management | Ensures compliance with medical device regulations |

When you use a 2 layer aluminum pcb from LT CIRCUIT, you get a product that meets strict quality and safety rules. You can rely on the metal core pcb structure, the advanced ENIG finish, and the careful testing to deliver strong electrical performance and durability.

Main Advantages

Thermal Management

You want your electronics to stay cool and work well. The 2 layer aluminum pcb gives you excellent heat dissipation. The aluminum core pulls heat away from your components. This keeps your pcb stable and helps prevent overheating. You can use this type of pcb in LED lighting, power supplies, and automotive electronics. The heat dissipation features make it perfect for high-power devices. LT CIRCUIT uses advanced materials to boost thermal management. You get a pcb that handles heat better than standard boards. This means your electronics last longer and perform with superior electrical performance.

Note: Strong heat dissipation protects sensitive parts and keeps your electronics running smoothly.

Durability

You need a pcb that stands up to stress and lasts a long time. The 2 layer aluminum pcb offers mechanical strength that resists bending and warping. The aluminum core adds toughness, so your pcb stays flat and reliable. You can trust this board in harsh environments. LT CIRCUIT builds each pcb with quality in mind. The mechanical strength helps your electronics survive drops, vibration, and daily use. You get a pcb that keeps working even when conditions get tough.

Mechanical strength prevents damage from physical stress.

Quality construction means fewer failures and longer life.

Aluminum core supports heavy components and keeps the pcb stable.

Solderability

You want easy assembly and strong connections. The enig finish gives your 2 layer aluminum pcb outstanding solderability. The electroless nickel immersion gold process covers the copper pads with nickel and gold. This protects the copper from oxidation. You get reliable solder joints every time. The enig finish works well with lead-free soldering and keeps your pcb safe from corrosion. Other finishes may not offer the same level of protection or solderability. You can assemble your electronics quickly and trust the connections to last.

The ENIG finish stands out because it creates a smooth, flat surface. This makes it easier to place fine-pitch components. You get better results with automated assembly. The combination of nickel and gold ensures your solder joints stay strong and resist wear.

Reliability

You want your electronics to work every time you turn them on. The 2 layer aluminum pcb with enig finish delivers reliability you can count on. LT CIRCUIT tests every pcb to meet strict standards. The aluminum core and mechanical strength help prevent failures. The enig finish protects against corrosion and keeps electrical contacts stable. You get superior electrical performance in demanding applications.

Here is a look at reliability metrics for 2 layer aluminum pcb with ENIG finish:

Finish Type | Thermal Cycles | Failure Rate | Notes |

|---|---|---|---|

ENIG | 1-2% | Susceptible to black pad defects | |

ENEPIG | >1000 | N/A | Superior choice for demanding applications |

You can use these pcbs in automotive, industrial, and LED electronics. LT CIRCUIT ensures RoHS compliance, so your products meet environmental standards. The reliability features make these boards ideal for projects that need consistent performance.

Tip: Choose a 2 layer aluminum pcb with enig finish for applications where reliability and quality matter most.

Comparison with Other PCBs

Aluminum vs. FR4

You often face a choice between aluminum and FR4 when designing electronics. Aluminum PCBs give you strong thermal management, which is essential for high-power applications. FR4 PCBs work well in general-purpose electronics where heat is not a major concern. If you build LED lighting, automotive systems, or industrial power equipment, aluminum PCBs help your electronics stay cool and reliable. FR4 suits devices that do not generate much heat.

Here is a quick comparison of typical applications:

PCB Type | Applications |

|---|---|

Aluminum PCBs | High-power LED lighting, Automotive systems, Industrial power equipment, Consumer electronics |

FR4 PCBs | General-purpose applications where heat dissipation is not critical |

Tip: Choose aluminum PCBs for electronics that need efficient heat dissipation and mechanical strength.

ENIG vs. Other Finishes

You want your electronics to last and perform well. The electroless nickel immersion gold finish, known as ENIG, offers excellent corrosion resistance and electrical performance. ENIG works best for fine-pitch components and high-density designs. Other finishes like HASL, OSP, and immersion silver have their own strengths, but ENIG stands out for reliability and shelf life.

Compare the main surface finishes:

Surface Finish | Corrosion Resistance | Electrical Performance | Additional Notes |

|---|---|---|---|

ENIG | Excellent | Excellent | Suitable for fine-pitch components |

HASL | Fair | Fair | Not RoHS compliant, cost-effective |

OSP | Good | Good | Environmentally friendly, limited thermal resistance |

Immersion Silver | Excellent | Excellent | More expensive, limited shelf life |

Studies show that solder joints on SnAg finishes with a Ni-P diffusion barrier have similar mechanical properties to those on ENIG. SnAg finishes with a chemically created Ni-P layer form more thermally stable compounds, which can improve reliability. ENIG’s electrochemically formed Ni layer increases the rate of intermetallic compound formation, which may affect long-term reliability. You should consider ENIG for electronics that require strong corrosion resistance and consistent electrical contact.

LT CIRCUIT’s solutions give you advanced materials and finishes, helping your electronics meet high standards for performance and reliability.

You benefit from 2-layer aluminum ENIG PCBs with cost-effectiveness, flat surface quality, and strong bonding capabilities.

Feature | Advantage |

|---|---|

ENIG Plating | Reliable wire bonding |

Surface Flatness | Easy component placement |

Durability | Long-lasting performance |

LT CIRCUIT supports you with certified quality, fast delivery, and expert project management for reliable, high-performance PCB solutions.

FAQ

What applications suit 2-layer aluminum ENIG PCBs?

You can use these PCBs in LED lighting, automotive electronics, and power supplies. They work best where heat management and reliability matter.

Tip: Choose aluminum PCBs for high-power devices.

How does ENIG improve soldering?

ENIG creates a smooth, flat surface. You get easy soldering and strong connections. The gold layer protects pads from oxidation.

Reliable solder joints

Supports fine-pitch components

Does LT CIRCUIT offer RoHS-compliant aluminum PCBs?

Yes, you receive RoHS-compliant 2-layer aluminum ENIG PCBs from LT CIRCUIT. These boards meet strict environmental standards for safe electronics manufacturing.

Compliance | Available at LT CIRCUIT |

|---|---|

RoHS | ✅ Yes |

See Also

Exploring Multilayer PCB Uses In Various Industries

Understanding The Differences Between PCB Types Explained

Boosting LED And Power Electronics With Aluminum-Backed PCBs

The Manufacturing Process Of Aluminum-Based PCBs With Insulation