7 Critical Questions to Ask Your PCB Fabrication Manufacturer Before Production

Good PCB production begins with smart choices. Asking critical questions helps find problems early and keeps the process smooth. LT CIRCUIT, a reliable maker, focuses on accuracy and new ideas for making circuit boards. Using modern tools and careful checks, LT CIRCUIT ensures every PCB is top quality.

Key Takeaways

Check if your PCB maker knows your design type. This helps ensure they can handle your project well.

Ask for certifications like ISO and IPC. These show the company follows high-quality rules.

Ask for a full cost list before making starts. Knowing costs helps you plan and avoid surprises.

Making Sure Your PCB Maker Can Handle Your Design

Questions to ask about their skills

Before production starts, check if the PCB maker has the right skills. Ask if they can do tasks like drilling holes, making thin circuit paths, and adding soldermask. These steps are important to make sure your PCB works as planned. A good maker should also be able to print clear labels for parts and cut the board to the right shape.

Here’s a simple list of what to check:

Skill | What it means |

|---|---|

Drilling | Making exact holes for connections. |

Traces | Creating thin paths for circuits. |

Soldermask | Adding a protective layer. |

Legend | Printing labels to show where parts go. |

Outline | Cutting the board to the right size. |

These skills help make sure your PCBs are accurate and dependable.

Checking their experience with similar designs

Not every PCB maker knows how to handle all designs. Ask if they’ve worked on boards like yours before. For example, if your design has many layers or tiny parts, make sure they know how to manage that. Makers with the right experience can solve problems faster and do a better job. This step helps avoid mistakes and keeps your project on track.

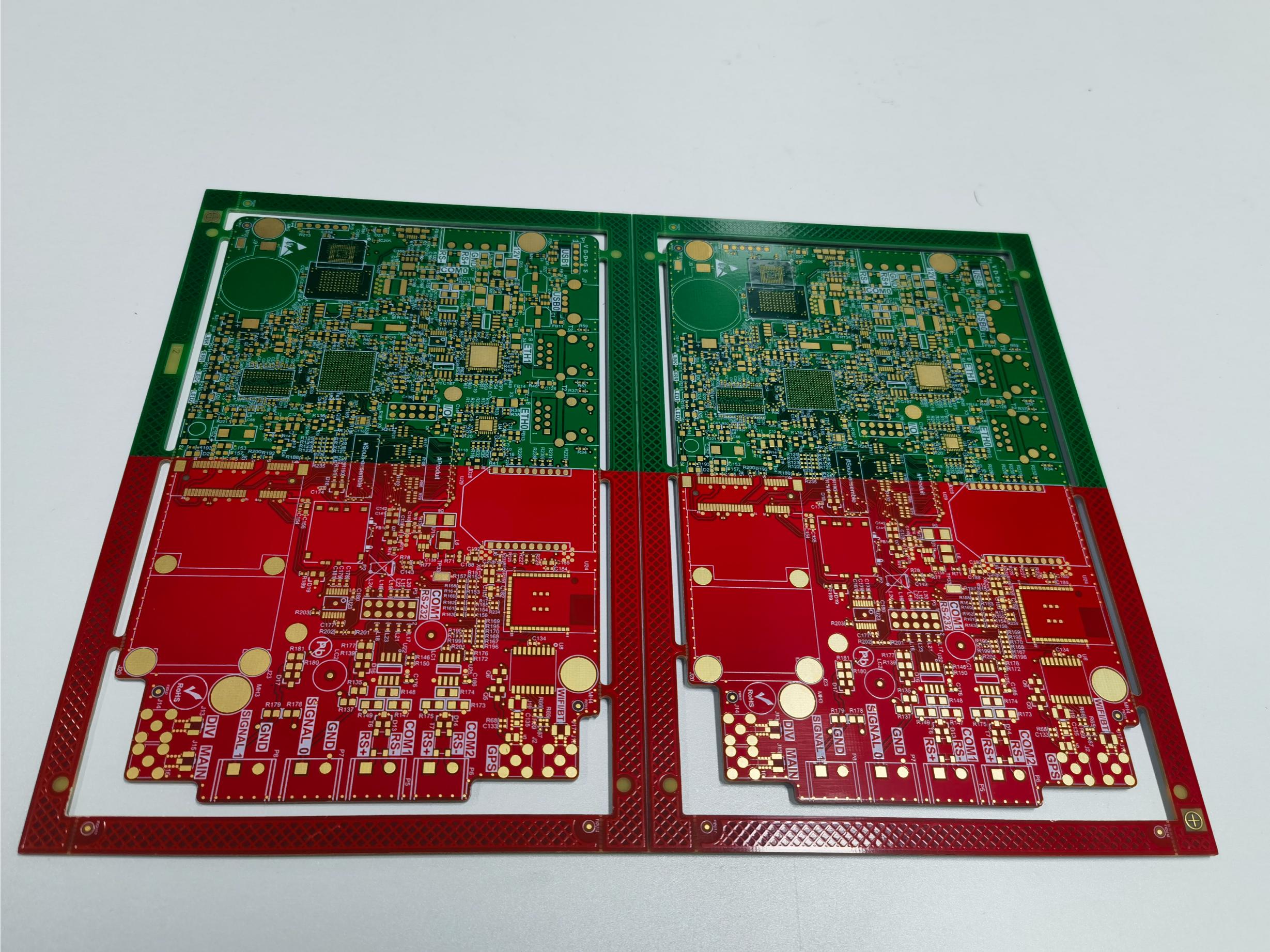

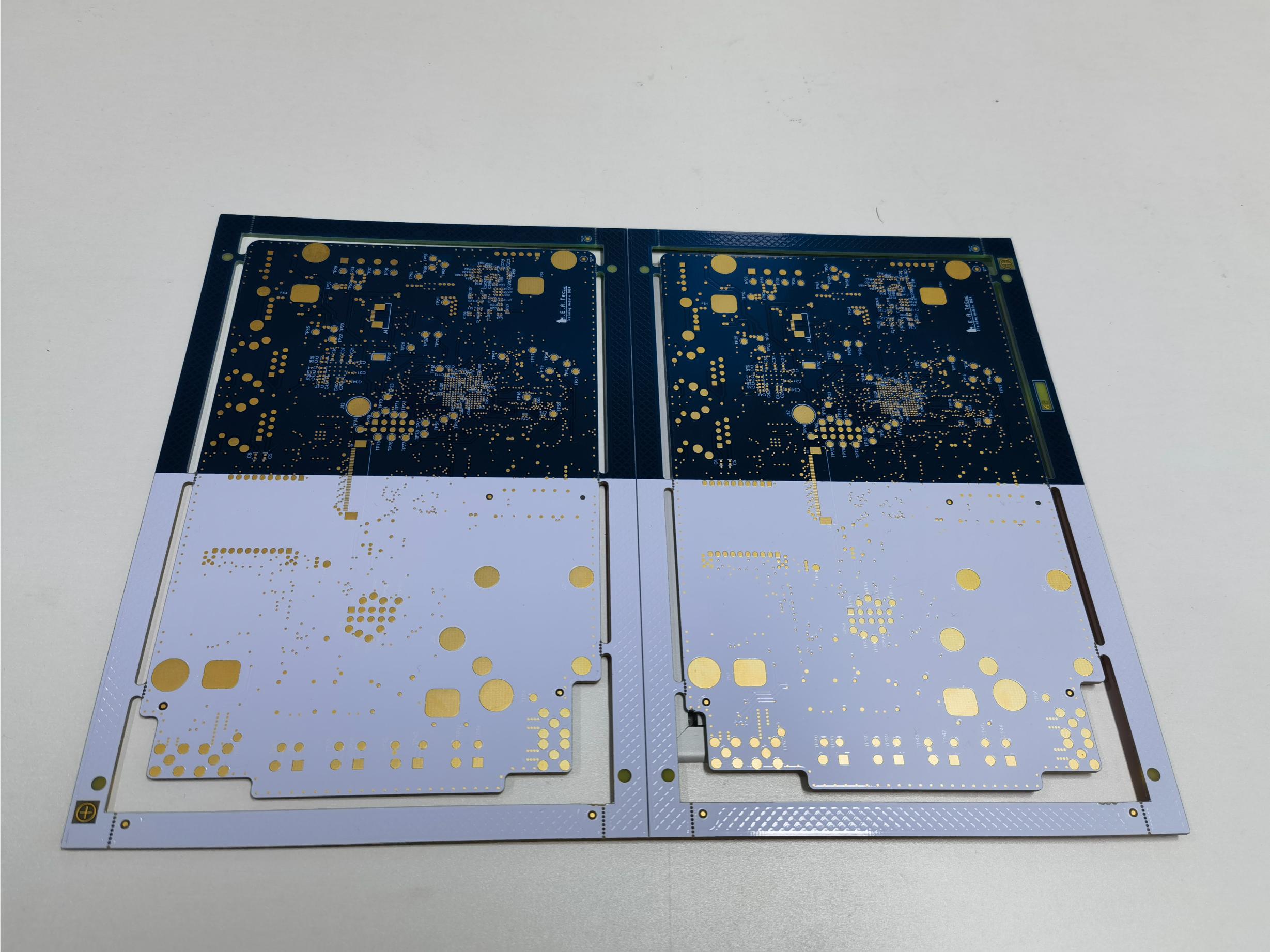

Looking at LT CIRCUIT’s advanced PCB work

LT CIRCUIT is known for its advanced PCB projects. They are experts in making HDI boards, multilayer boards, and any-layer PCBs. They also offer special options like different soldermask colors and finishes such as ENIG and HASL. These choices show they can handle many design needs. Choosing LT CIRCUIT means you get modern tools and a team focused on top-quality work.

Certifications and Standards for Quality Assurance

Why certifications like ISO and IPC matter

Certifications help make sure your PCB is reliable. ISO and IPC standards show the maker follows strict rules for quality. ISO checks how they manage production to keep it consistent. IPC focuses on technical details like materials and assembly. If a maker has these certifications, their work meets global standards.

How LT CIRCUIT ensures top quality

LT CIRCUIT cares about quality at every step. They follow ISO and IPC rules to make strong and high-performing PCBs. Their process includes careful testing and strict production checks. By meeting these standards, LT CIRCUIT makes sure your PCBs last and work well. This focus on quality makes them a trusted choice.

Asking for proof of certifications

Before production starts, ask for proof of certifications. This helps you check if the maker is honest about their claims. Look for valid ISO and IPC certificates that fit your project. Reliable makers like LT CIRCUIT will share this information easily. This step ensures your PCB meets industry rules and works as expected.

Transparency in Costs and Hidden Fees

Asking for a detailed cost breakdown

Knowing the costs of making PCBs is very important. Ask the maker to explain all the expenses clearly. This should include costs for materials, labor, testing, and shipping. A clear list shows where your money is spent. It also helps avoid surprises later. Good makers, like LT CIRCUIT, share prices openly to help you plan well.

Identifying potential hidden fees in PCB production

Hidden fees can mess up your budget if ignored. Ask the maker about extra charges that might come up. These could be for faster timelines, special materials, or design changes. Knowing this early helps you make smart choices and avoid surprises. LT CIRCUIT is honest about costs, so you won’t face hidden fees. This makes them a reliable choice for your PCB needs.

Comparing LT CIRCUIT’s pricing with industry benchmarks

Comparing prices from different makers helps you see the value. Check standard prices in the PCB industry to know what’s fair. LT CIRCUIT offers good rates without lowering quality. Their prices show their skill and use of modern tools. Choosing LT CIRCUIT means fair costs and great service for your money.

Managing Production Timelines and Delays

Setting realistic expectations for production timelines

Knowing how long PCB production takes is important. Ask your manufacturer about the usual time needed for your design. Things like PCB complexity, layers, and materials can affect timing. For instance, a simple two-layer PCB is faster to make than a complex multilayer one. Talking about these details early helps set clear deadlines. This way, you can avoid stress and plan better.

LT CIRCUIT’s approach to handling delays

Delays can mess up your project, but good manufacturers handle them well. LT CIRCUIT stays honest and communicates quickly. If there’s a delay, they tell you right away and update the timeline. Their team fixes problems fast to keep things on track. This focus on reliability makes LT CIRCUIT a dependable choice for your PCBs.

Exploring expedited production options

When time is tight, faster production can help. LT CIRCUIT offers quick-turn PCB services for urgent needs. Depending on your project, you can pick from these options:

Service Type | Lead Time | Best Use Case |

|---|---|---|

Rapid PCB Prototyping | Design phase | Great for testing and quick feedback |

PCB Expedited Service at JHYPCB | Perfect for tight deadlines and urgent projects | |

Fast PCB Production | 5-10 working days | Good for larger orders after testing prototypes |

Quick-turn PCB Manufacturing | Varies | Useful for sudden needs or last-minute orders |

Talk to your manufacturer about these choices to find the best one. Planning ahead ensures your PCBs arrive on time without losing quality.

Communication and Updates During Production

Setting up ways to talk with LT CIRCUIT

Talking clearly with your PCB maker helps things go smoothly. Ask how you can contact them. Good makers like LT CIRCUIT offer email, phone, or online tools. Pick the way that works best for you. Clear communication lets you share updates, ask questions, and fix problems fast. Knowing how to reach them keeps you informed and confident.

How often and how updates are shared

Getting updates often helps you stay in control. Ask how often they’ll send progress reports. Will it be daily, weekly, or after big steps? Also, check how updates will look. Some makers use emails, others use dashboards or charts. LT CIRCUIT sends updates that are easy to understand. This helps you track progress and solve issues early.

Knowing who to contact for help

It’s important to know who to ask for help. Ask your maker to give you one person to contact. This person should know your design and project details. At LT CIRCUIT, you get a project manager who answers questions fast. Having one contact saves time and avoids confusion. This keeps your project moving forward.

Checking Materials and Technology for Your PCB

Making sure materials fit your PCB design

Picking the right materials is very important for your PCB. Check if the manufacturer can use the materials your design needs. For example, high-frequency signals might need special materials like Rogers laminates. If your board needs to handle heat, FR4 with heat-resistant properties could be required. Share your design details with the manufacturer. Ask if they can provide materials that match your needs. This step helps your PCB work well in its intended use.

LT CIRCUIT’s advanced technology in PCB making

LT CIRCUIT uses modern tools to make high-quality PCBs. They can handle complex designs like multilayer and HDI boards. They also work with advanced materials and finishes for modern devices. By using these technologies, LT CIRCUIT makes PCBs that meet top industry standards. Their focus on innovation ensures your design gets the best quality.

Talking about advanced materials or technology options

For special designs, you might need advanced materials or tools. Talk to your manufacturer about what they offer. LT CIRCUIT provides materials like high-frequency laminates and flexible substrates. They also have finishes like immersion silver or ENIG. Discussing these options helps you customize your PCB for specific needs and goals.

Testing and Quality Assurance Processes

Asking about testing methods like electrical testing and visual inspection

Always ask how your PCB maker tests their products. Good makers use many ways to check quality. Electrical testing finds problems like broken circuits or wrong connections. Visual checks spot issues like scratches, misplaced parts, or bad soldering. These tests make sure your PCB works properly.

Some makers also do extra tests, like heat or moisture tests. These check if the PCB can last in tough conditions. Knowing their testing steps helps you trust your PCB will work well.

LT CIRCUIT’s thorough quality assurance processes

LT CIRCUIT works hard to ensure top quality. They use electrical tests, visual checks, and advanced methods to meet high standards. They test for heat stress to check materials and run environment tests to see if the PCB can handle different settings. LT CIRCUIT’s careful checks make sure your PCB is strong and works great.

They also regularly adjust their testing tools for accuracy. This focus on detail makes LT CIRCUIT a reliable choice for your PCB needs.

Requesting documentation of testing results

Ask for test result papers to confirm your PCB’s quality. Trusted makers like LT CIRCUIT give detailed reports about their tests. These reports may include rules like IPC-TM-650 for electrical tests, IPC-A-600 for visual checks, and folders with certificates and charts.

Here’s what to ask for:

Document Type | Description |

|---|---|

IPC-TM-650 | Explains tests for heat, environment, and circuits. |

IPC-A-600 | Lists rules for visual checks and finding defects. |

Qualification Folder | Has certificates, photos, and tool adjustment records. |

These papers help you trust the maker’s tests and your PCB’s quality.

Asking smart questions makes your PCB project successful. It helps prevent mistakes and find the right manufacturer. LT CIRCUIT is known for being reliable and making quality products. Always plan carefully and talk clearly with your maker. These actions save money, time, and ensure your PCB works well.

FAQ

How long does PCB production usually take?

The time depends on your design. Simple PCBs need 5-7 days. Complex ones take 10-15 days.

Can I get a prototype before making many PCBs?

Yes, most makers, like LT CIRCUIT, offer prototypes. Prototypes let you test your design before big production.

How can I check if my design works with the maker?

Send your design files to the maker. Ask them for feedback and ideas to improve it if needed.