Aluminum-Backed PCBs: How Our Advanced Manufacturing Process Enhances LED and Power Electronics Performance

Aluminum-backed PCBs fix heat problems in LED and power devices. They spread heat well, stopping overheating and keeping performance steady. LT CIRCUIT uses a smart and careful process to make them. By using strong aluminum and strict testing, they create PCBs that control heat better and make electronics work reliably.

Key Takeaways

Aluminum-backed PCBs handle heat well, making them great for LEDs and power devices. They stop overheating, so devices work properly.

These PCBs are strong and light, offering good protection and saving money. They last longer, lowering total project expenses.

LT CIRCUIT uses advanced methods and careful testing to make top-quality aluminum-backed PCBs. This makes sure they meet rules and work well in tough conditions.

Benefits of Aluminum-Backed PCBs for LED and Power Electronics

Superior Thermal Conductivity and Heat Dissipation

Aluminum-backed PCBs are great at handling heat. This makes them perfect for LED and power electronics. They have a special layer that moves heat away from parts that can get damaged. This stops overheating and keeps devices working well.

Did you know? Aluminum can move heat 200-230 W/m·K, much better than FR-4 materials. That’s why it’s the best choice for getting rid of heat.

Here’s why aluminum-backed PCBs work better than other materials:

Thermal conduction: Aluminum quickly moves heat away from the source, faster than FR-4 boards.

Heat dissipation: Aluminum PCBs have lower thermal resistance, helping control temperature better.

Temperature control: Cooler operating temperatures help LEDs and electronics last longer.

Material | Thermal Conductivity (W/m·K) |

|---|---|

Aluminum | 200-230 |

Copper | 380-400 |

FR-4 | Much lower |

In LED systems, aluminum-backed PCBs stop heat buildup. This keeps lights bright and steady. For power electronics, they handle high heat well, making devices work reliably even in tough conditions.

Enhanced Durability and Reliability in High-Power Applications

Aluminum-backed PCBs are strong and last a long time. They’re lightweight and tough, so they work well in hard environments like factories and cars. These PCBs resist damage from impacts and shaking, keeping them safe during use.

Tip: Aluminum-backed PCBs save money over time. They last longer and cost less to make, helping your projects stay affordable.

Key benefits include:

Impact resistance: Aluminum’s strength protects the PCB from breaking, even in tough conditions.

Lightweight design: Easy to handle and install, reducing weight in cars and planes.

Cost-effectiveness: They balance good performance with low cost, making them a smart choice.

Dielectric k (W/m·K) | Aluminum Core k (W/m·K) | |

|---|---|---|

Standard LED MCPCB | 1.2 | 220 |

Automotive Power PCB | 3.5 | 225 |

High-Frequency RF PCB | 8.0 | 210 |

Whether you’re building LED lights or power devices, aluminum-backed PCBs are reliable. They handle heat and stress well, keeping devices working in many situations.

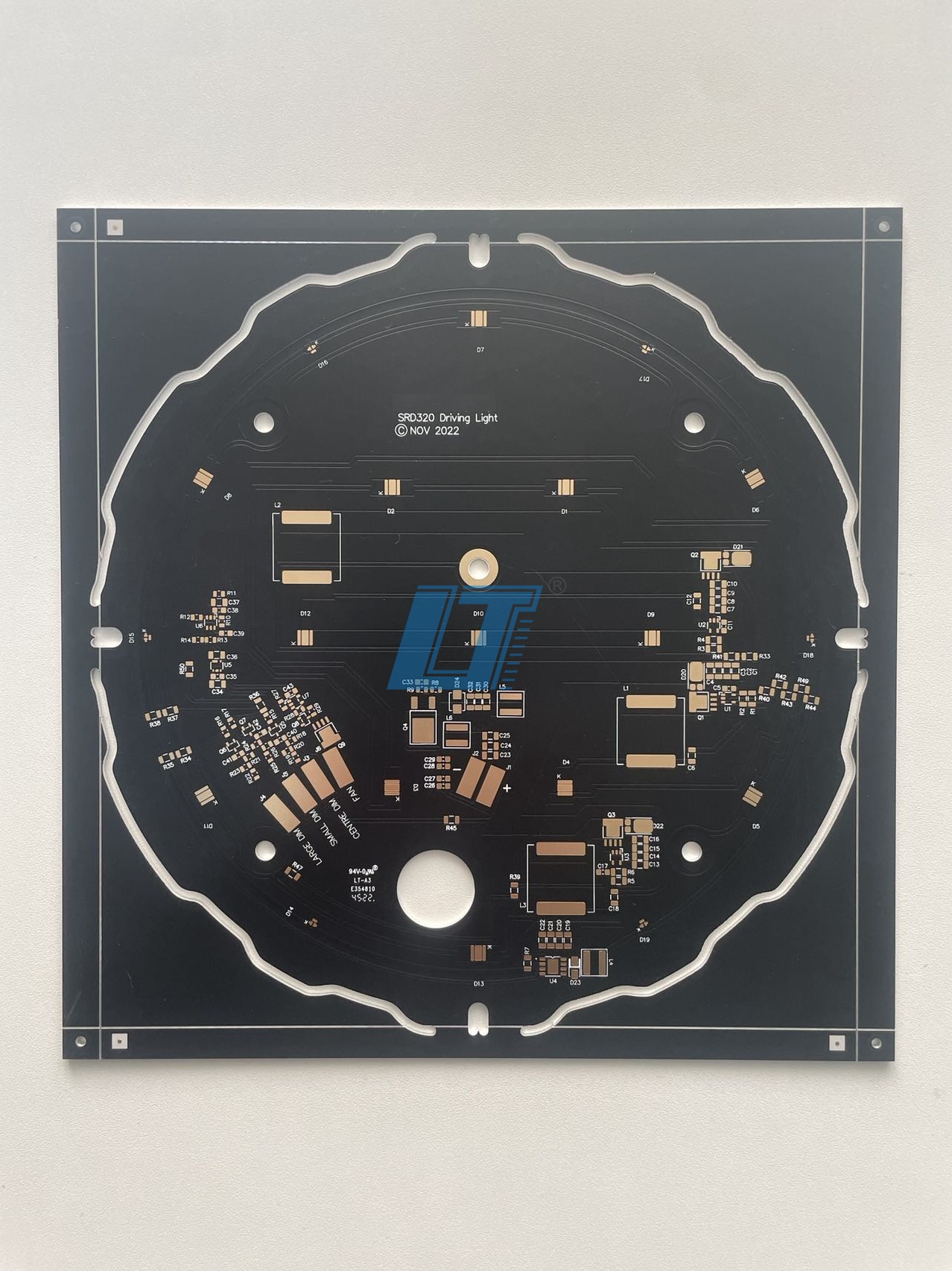

LT CIRCUIT's Advanced Manufacturing Process for Aluminum PCBs

Careful Layering and Material Choices for Aluminum-Backed PCBs

LT CIRCUIT makes aluminum-backed PCBs using smart layering and strong materials. Their process focuses on making products that work well and last long. Each PCB starts with high-quality aluminum, chosen for its ability to handle heat and stay strong. This helps your electronics work in tough conditions without overheating or breaking.

A special layer is added to move heat away from sensitive parts. This layer sends heat to the aluminum core, keeping your devices cool. LT CIRCUIT uses advanced materials with low heat resistance to improve how well heat is managed in your electronics.

Note: Aluminum-backed PCBs are built to handle heat and stay durable. They are perfect for high-power uses like LED lights and factory machines.

What makes LT CIRCUIT’s process unique:

Material choices: Strong aluminum improves heat control and keeps the PCB stable.

Layering techniques: Special layers help move heat quickly and efficiently.

Custom designs: PCBs are made to fit your needs, whether for LEDs or power devices.

This careful process ensures your aluminum-backed PCBs work reliably, even in hard environments.

Strict Testing for Better Heat Control

LT CIRCUIT checks every PCB to make sure it meets high standards. Their testing process guarantees reliable and efficient products. Each step includes tests to check heat control and strength.

Advanced tools, like 5MP cameras, inspect edges and alignment. Mechanical tests check how strong the PCBs are under pressure. These tests ensure your aluminum-backed PCBs can handle real-world challenges without losing performance.

Tip: Regular checks and audits make LT CIRCUIT’s PCBs even more dependable.

Important testing steps include:

Optical checks: Ensure edges and alignment meet industry rules.

Strength tests: Confirm the PCB can handle stress without breaking.

Copper checks: Verify leftover copper levels and key dimensions.

LT CIRCUIT’s testing results show their quality:

Metric | Value |

|---|---|

Cpk for 35μm pitch features | 2.1 |

First-pass yield on HDI layouts | 99.2% |

Copper over-etch incidents | 0.003% |

Yield for 0.2mm thick substrates | >99% |

They also use advanced methods to test heat control and reliability:

Testing Method | Purpose |

|---|---|

Automated Optical Inspection | Checks quality at key steps. |

Electrical Testing | Finds problems in circuits. |

X-ray Inspections | Looks at complex parts. |

Burn-in Testing | Tests for long-term reliability. |

Supplier Audits | Ensures materials meet standards. |

These tests make sure LT CIRCUIT’s aluminum-backed PCBs are better than industry requirements. With LT CIRCUIT, you get reliable solutions for managing heat in your devices.

Application-Specific Advantages of Aluminum-Backed PCBs

Better Performance in LED Lighting Systems

Aluminum-backed PCBs help LED lights work better. They solve heat problems, keeping power LEDs cool and efficient. The aluminum core moves heat away from hot parts fast. This keeps LEDs bright and helps them last longer. These PCBs are great for outdoor lights and factory lighting.

Using aluminum-backed PCBs means steady light and less heat damage. They stay stable, making them reliable for tough jobs. Industry studies show their benefits:

Stability Level | Best Use Cases | |

|---|---|---|

Low CTE Materials | High | Great for reliable applications |

Standard CTE Materials | Medium | Works for most uses |

High CTE Materials | Low | Needs extra design care |

Aluminum PCBs improve LED lighting performance while staying strong and dependable.

Higher Efficiency in Power Electronics

Aluminum-backed PCBs make power electronics work better in factories and homes. They handle high heat, keeping devices stable and safe. The aluminum layer spreads heat well, lowering energy use and boosting performance.

New ideas in power electronics show why aluminum PCBs are useful:

Combining many functions into one chip saves money and improves efficiency.

New microprocessors for gadgets lower costs, making automation cheaper.

Fewer parts in chips mean better reliability and less energy use.

Aluminum-backed PCBs are perfect for high-power devices. They help machines and gadgets use less energy and work reliably.

Aluminum-backed PCBs manage heat, last long, and work well. They keep devices running smoothly, even in tough conditions. LT CIRCUIT makes strong aluminum PCBs using advanced methods. Their designs fit your project needs perfectly. Use their solutions to improve your electronics with better heat control and dependability.

FAQ

Why are aluminum-backed PCBs better at handling heat?

Aluminum-backed PCBs move heat faster than FR-4 boards. The aluminum core spreads heat well, keeping devices cool and working better.

Tip: Aluminum can transfer heat up to 230 W/m·K, much better than FR-4.

Are aluminum-backed PCBs good for outdoor use?

Yes, they handle moisture and temperature changes easily. Their strength makes them great for outdoor lights and factory machines.

Note: Aluminum-backed PCBs are light but strong, making them reliable in tough places.

How does LT CIRCUIT check the quality of aluminum-backed PCBs?

LT CIRCUIT uses special tests like optical checks and burn-in tests. These tests make sure the PCBs meet standards and work well in real life.

Emoji Insight: ✅ Careful testing ensures top-quality PCBs every time!

See Also

Understanding The Steps In PCB Production And Fabrication

The Process And Advantages Of HASL PCB Manufacturing

Creating Efficient PCBs Tailored For LED Technology Needs

Analyzing Thermal And Electrical Performance Of Aluminum PCBs

Utilizing Aluminum Nitride Ceramic PCBs Across Various Industries