Aluminum Base PCBs vs. FR4: When to Choose Metal Core for Your Electronic Design Projects

Choosing the right PCB material is very important for electronics. Aluminum Base PCBs work well in hot conditions as they spread heat easily. Their heat expansion rate is 50×10^-6 cm/cm℃, much less than FR4 PCBs at 110×10^-6 cm/cm℃. This makes Aluminum Base PCBs great for gadgets needing better heat control.

Key Takeaways

Aluminum PCBs work well for powerful devices. They handle heat great, so they’re good for LED lights and car gadgets.

FR4 PCBs are cheaper and fit regular electronics. But they don’t manage heat well, so they aren’t great for hot projects.

Pick a PCB based on your project’s heat, strength, and cost needs for better results and longer use.

Understanding FR4 and Aluminum Base PCBs

What is FR4?

FR4 is a common material used to make PCBs. It is made from fiberglass cloth and epoxy resin. This mix is strong and resists flames. FR4 gives good electrical insulation and mechanical strength. It works well for many electronic designs.

FR4 has special dielectric properties. Its dielectric strength is between 20 and 80 kV/mm. The dielectric constant ranges from 4.2 to 4.8. These features make it reliable for different uses.

Property | Value Range |

|---|---|

Dielectric Strength | 20 to 80 kV/mm |

Dielectric Constant | 4.2 to 4.8 |

Dissipation Factor | Low |

FR4 PCBs are used in everyday electronics, industrial tools, and telecom devices. They are cheap and flexible for many projects.

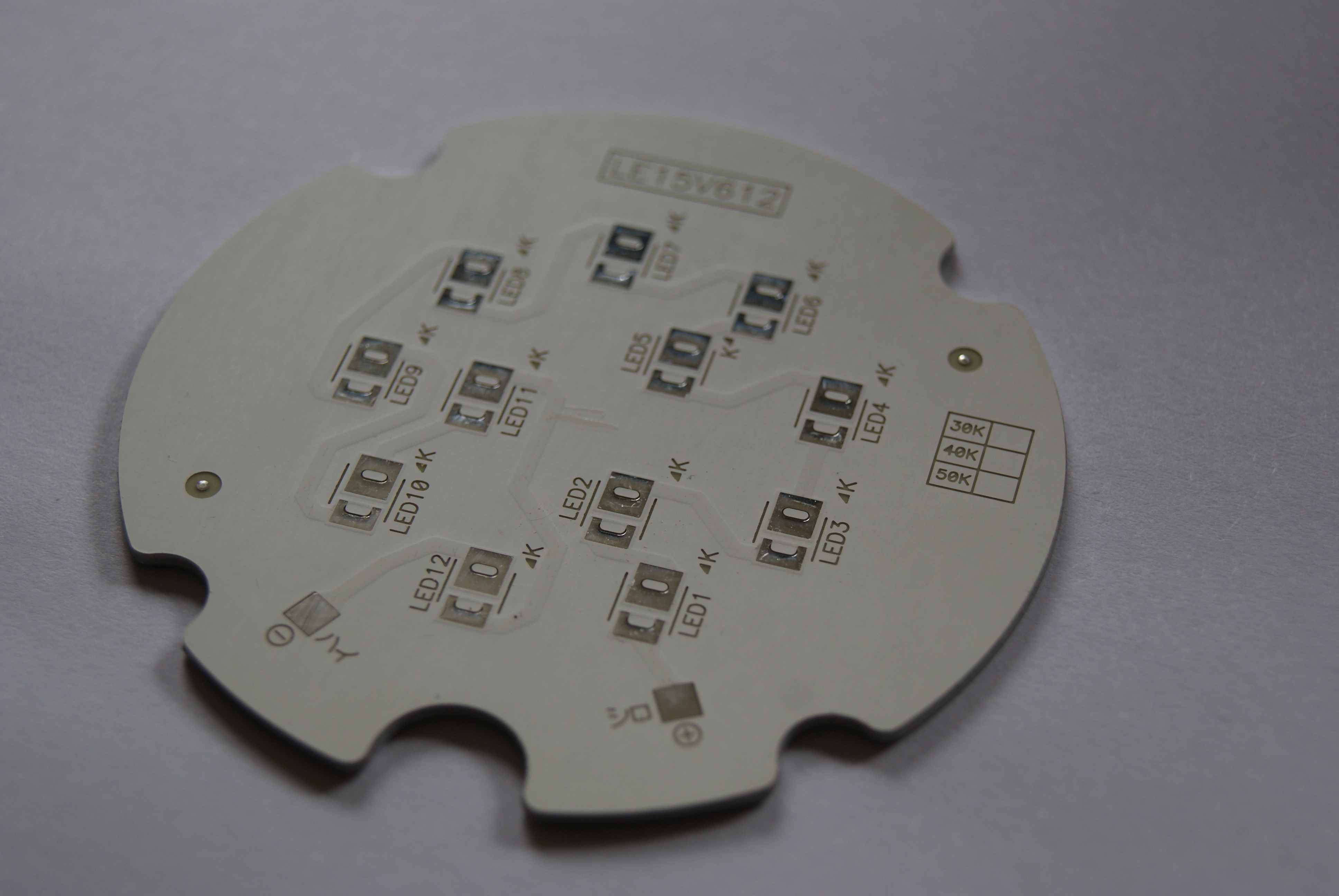

What are Aluminum Base PCBs?

Aluminum Base PCBs, or metal core PCBs, handle heat very well. They have a metal layer, usually aluminum, which spreads heat and adds strength.

The aluminum core keeps devices cool by moving heat away fast. Its thermal resistance is 4.09 × 10⁻⁴ °C/W. This makes it better than FR4 boards for heat control. Aluminum PCBs are great for LED lights, car electronics, and power systems.

Common aluminum types include:

Aluminum 1050: Used for general tasks (235 W/mK).

Aluminum 1060: Used in electronics (237 W/mK).

Aluminum 6061: Used for building structures (150 W/mK).

Key Features of FR4 and Aluminum PCBs

FR4 and Aluminum Base PCBs have different strengths and uses.

Feature | FR4 PCBs | Aluminum Base PCBs |

|---|---|---|

Thermal Conductivity | Needs extra heat sinks to manage heat. | Built-in metal spreads heat better. |

Surface-Mounted Components | Less efficient; needs tight patterns and more holes. | More efficient; fewer holes needed due to metal's heat properties. |

Board Space | Needs more space for insulation layers. | Saves space by mounting parts directly on metal. |

Electromagnetic Shielding | Basic shielding abilities. | Better shielding for high-power electronics. |

PCB Thickness | Offers many thickness choices. | Limited thickness because of the metal layer. |

Knowing these differences helps you pick the right PCB for your project.

Advantages and Disadvantages of FR4 PCBs

Benefits of FR4 PCBs

FR4 PCBs have many good features for electronics. They are strong, resist flames, and insulate electricity well. These qualities make them useful in many devices. You can find FR4 PCBs in phones, tools, and communication systems.

Another great thing is their low cost. FR4 PCBs are cheap, so they work well for projects with tight budgets. They are easy to make and widely available. Also, FR4 PCBs can have multiple layers, which helps in making complex circuits.

Limitations of FR4 PCBs

FR4 PCBs also have some downsides. They don’t handle heat as well as aluminum or ceramic materials. This makes them less useful for devices that get very hot. If your project creates a lot of heat, you might need extra cooling, which costs more.

There are also environmental issues with FR4 PCBs. They have flame retardants that can harm the environment when thrown away. FR4 PCBs are not great at moving heat, which can be a problem in fast or high-power devices.

Strong, flame-resistant, and good at electrical insulation | Poor heat handling compared to aluminum or ceramic |

Affordable and easy to use for many projects | Contains harmful flame retardants, bad for the environment |

Works in many devices like phones and tools | Struggles with heat in fast or high-power devices |

Knowing these pros and cons helps you decide if FR4 PCBs fit your project.

Advantages and Disadvantages of Aluminum Base PCBs

Benefits of Aluminum Base PCBs

Aluminum base PCBs have many benefits for high-power devices. They are great at moving heat away from parts. This keeps devices cool and stops overheating. That’s why they work well in LED lights and power systems.

These PCBs are also strong and handle stress better than FR4 boards. They can resist shaking and pressure, making them good for cars and factories. They also support high currents, up to 3000 volts, which is important for powerful devices.

Another plus is that aluminum PCBs are light and eco-friendly. Aluminum weighs less than copper and can be recycled. They are also very good at managing heat, about 10 times better than other PCBs. This makes them a smart choice for long-term use.

Performance Advantage | Description |

|---|---|

High Heat Transfer Rate | Works as a heat sink, spreading heat quickly. |

Mechanical Stability | Handles shaking and stress better than other boards. |

Lightweight | Weighs less than metals like copper. |

Environmentally Friendly | Can be recycled, helping the environment. |

Superior Thermal Efficiency | Keeps devices cool in high-power situations. |

Limitations of Aluminum Base PCBs

Aluminum base PCBs also have some downsides. Their designs are less flexible because of the metal layer. Thickness choices are limited, from 0.8mm to 4mm. FR4 PCBs, on the other hand, offer more thickness options, from 0.2mm to over 5mm.

Another issue is their cost. Making aluminum PCBs costs more than making FR4 boards. This is especially true for large orders. Also, aluminum PCBs don’t work well with high-frequency signals. This makes them less useful for devices needing very fast signal speeds.

Feature | Aluminum Base PCBs | FR4 PCBs |

|---|---|---|

Thermal Management | Great at spreading heat, up to 200°C | Not as good, max 130-180°C |

Cost | More expensive due to special processes | Cheaper for large projects |

Design Flexibility | Limited thickness (0.8mm to 4mm) | Many thickness options (0.2mm to >5mm) |

High-Frequency Performance | Not good for very fast signals | Works well with high-frequency signals |

Knowing these pros and cons helps you decide if aluminum base PCBs fit your needs.

Key Differences Between FR4 and Aluminum Base PCBs

Thermal Conductivity and Heat Management

Aluminum base PCBs handle heat much better than FR4 PCBs. The metal layer in aluminum PCBs acts like a heat sink. It quickly moves heat away from parts, keeping devices cool. This makes them perfect for things like LED lights and power systems. FR4 PCBs, however, need extra cooling tools, which can cost more.

Aluminum PCBs have high thermal conductivity, often over 200 W/mK. FR4 PCBs are much lower, around 0.3 W/mK. This is why aluminum PCBs are used in high-power devices. If your project creates a lot of heat, like car electronics, aluminum PCBs are a better choice.

Tip: FR4 PCBs can work for medium-heat projects if cooled properly.

Mechanical Strength and Durability

Aluminum base PCBs are stronger and last longer than FR4 PCBs. The metal core makes them tough against shaking and stress. This is important for cars and factory machines. FR4 PCBs are fine for low-stress uses but can break under pressure.

Here’s a quick comparison of their strength:

Feature | FR4 PCB | Aluminum PCB |

|---|---|---|

Mechanical Strength | Can warp or crack easily | |

Applications | Phones, small gadgets | Cars, heavy-duty machines |

If your project faces rough conditions, aluminum PCBs are better. For simple devices like phones, FR4 PCBs are enough.

Cost and Budget Considerations

FR4 PCBs are cheaper, making them great for tight budgets. Their cost depends on thickness, layers, and design. Thinner boards are cheaper to make and easier to produce.

Aluminum PCBs cost more but are worth it for high-power devices. They save money later by reducing the need for extra cooling. If your project needs strong heat control, aluminum PCBs are a smart investment.

Note: FR4 PCBs are good for small projects. Aluminum PCBs are better for heat-heavy designs.

Weight and Design Flexibility

Aluminum PCBs are lighter than other metal-core boards but heavier than FR4 PCBs. The metal layer adds weight but also improves strength and heat control. This makes aluminum PCBs great for powerful devices but less ideal for portable gadgets.

FR4 PCBs are more flexible in design. They come in many thicknesses, from 0.2mm to over 5mm. Aluminum PCBs have fewer options, usually between 0.8mm and 4mm. This limits their use in very thin or bendable designs.

For lightweight and flexible needs, FR4 PCBs are better. But for heat and durability, aluminum PCBs are the way to go.

Choosing the Right PCB for Your Project

When to Choose FR4 PCBs

FR4 PCBs are good for everyday electronic projects. They work well in devices like phones and communication tools. These boards are affordable and handle low to medium power needs. If your project doesn’t make much heat, FR4 is a smart choice. They are great for simple designs or when you need to save money.

FR4 PCBs also support multilayer designs. This helps create small and complex circuits. Their insulation keeps electricity flowing safely in normal conditions. But if your project makes a lot of heat, FR4 might not be enough.

Tip: Pick FR4 PCBs for portable gadgets or when cost matters most.

When to Choose Aluminum Base PCBs

Aluminum base PCBs are best for high-power and heat-heavy devices. They work well in LED lights, car systems, and power supplies. The metal layer spreads heat fast, stopping parts from overheating. This makes aluminum PCBs perfect for projects needing strong heat control.

These PCBs are tough and handle shaking or stress easily. They are great for cars and factory machines. Aluminum PCBs also manage high currents, keeping powerful devices steady. Though they cost more, their benefits last longer in heat-heavy designs.

Note: Aluminum PCBs cost more upfront but save money over time.

Factors to Consider for Heat Management and Application Needs

Think about your project’s heat and design needs before choosing a PCB. Aluminum PCBs spread heat better, with conductivity over 200 W/mK. FR4 PCBs are lower at 0.3 W/mK and need extra cooling for hot designs.

Also, consider how strong your PCB needs to be. Aluminum PCBs resist stress and vibrations, making them good for tough environments. FR4 PCBs are less durable but offer more design options for regular use.

Here’s a quick comparison to help you decide:

Factor | Description |

|---|---|

Thermal Conductivity (K) | Aluminum spreads heat 5–15× better than FR4. |

Mechanical Strength | Aluminum handles stress; FR4 is better for light devices. |

Cost | FR4 is cheaper; aluminum saves cooling costs for hot designs. |

Application Needs | Use aluminum for high-power devices; FR4 for general electronics. |

Callout: Match your PCB material to your project’s heat, power, and durability needs for the best results.

Common Uses of FR4 and Aluminum Base PCBs

Where FR4 PCBs Are Used

FR4 PCBs are used in many industries because they are strong and reliable. You can find them in electronics, cars, airplanes, and communication devices. They are great for small gadgets like phones, tablets, and smart home devices. These boards keep devices safe and working well.

Car makers use FR4 PCBs in electric and self-driving cars. They work in sensors and control systems. In airplanes, FR4 PCBs help with navigation and communication. Their flame-resistant feature makes them safer for important uses.

As technology grows, FR4 PCBs stay popular. They are affordable and work well for complex circuits in everyday devices.

Where Aluminum Base PCBs Are Used

Aluminum base PCBs are best for devices that need to handle heat. They are used in LED lights, car electronics, and industrial power systems. These boards spread heat 8–10 times better than FR4 boards. This keeps parts cool and stops overheating.

Here are some examples of how they are used:

LEDs use aluminum PCBs to stay bright and last longer by managing heat.

Car electronics, like engine controls and battery systems, use aluminum PCBs to handle tough conditions.

Industrial power systems use aluminum PCBs to manage high currents and stay strong for a long time.

These boards save money by removing the need for extra cooling parts. They are also light and recyclable, making them good for the environment.

Why Choose LT CIRCUIT for Your PCB Needs

LT CIRCUIT’s Expertise in Aluminum Base PCBs

LT CIRCUIT is skilled at making metal core PCBs. They have many years of experience and create high-quality products. Their PCBs are great for handling heat, making them perfect for LED lights, car systems, and industrial power supplies. LT CIRCUIT designs MCPCBs that manage heat well, which is important for devices that get very hot.

Many customers trust LT CIRCUIT for their PCBs. Companies like Signify (Philips) USA say, "Their quality and service is awesome. Keep it up." Normagrup Spain shares, "They have delivered the best quality of PCBs to us. We give them a thumbs up." Valon USA adds, "LT gets the job done right on. We never had any issues with our clients here."

LT CIRCUIT’s Commitment to Quality and Innovation

LT CIRCUIT works hard to stay creative and reliable. They have won awards like the CIRCUITS ASSEMBLY New Product Introduction Award and the Electronics Manufacturing Innovation Award in 2020. Their ISO/TS 16949 certification shows they follow strict rules to make high-quality products.

Award Name | Description | Date |

|---|---|---|

CIRCUITS ASSEMBLY New Product Introduction Award | Recognizes leading new products for electronics assembly. | February 2020 |

Electronics Manufacturing Innovation Award | Celebrates excellence and innovation in the electronics industry. | July 2020 |

Mexico Technology Award | Honors the best electronics manufacturing innovations in Mexico. | October 2020 |

ISO/TS 16949 Certification | Certifies quality in manufacturing processes. | January 2018 |

These awards show LT CIRCUIT’s focus on making reliable and creative metal core PCBs for modern technology needs.

Customization and Advanced Solutions by LT CIRCUIT

LT CIRCUIT offers custom options for metal core PCBs. They know every project is different, so they make PCBs to fit your needs. They help pick the right materials and improve heat control to make sure your MCPCB works well.

Their advanced tools allow for detailed designs, multiple layers, and different finishes. Whether you need a light MCPCB for small devices or a strong one for factories, LT CIRCUIT delivers great results. Their focus on customization ensures your PCB matches your project perfectly.

Tip: Working with LT CIRCUIT gives you a solution that is strong, efficient, and affordable.

Deciding on FR4 or Aluminum Base PCBs depends on your project. FR4 is better for cheaper designs, while aluminum handles heat well.

Key Takeaway: Focus on heat control, strength, and cost when choosing a PCB.

Choose LT CIRCUIT for dependable, top-quality PCBs made to fit your needs. Their skills guarantee your project will succeed.

FAQ

1. What sets FR4 and Aluminum Base PCBs apart?

FR4 PCBs are cheaper and work for many uses. Aluminum Base PCBs are better at handling heat and are stronger. They are great for devices needing high power.

Tip: Use FR4 for everyday gadgets and Aluminum for hot devices.

2. Can Aluminum Base PCBs work with fast signals?

Aluminum Base PCBs don’t do well with fast signals. The metal layer slows them down. FR4 PCBs are better for devices needing quick signal speeds.

Note: Think about your project’s signal speed before picking a PCB.

3. Are Aluminum Base PCBs good for the environment?

Yes, Aluminum Base PCBs can be recycled and are lightweight. They are eco-friendly and help reduce waste in electronic designs.

♻️ Callout: Aluminum PCBs support green projects and cut down waste.

See Also

Choosing The Right Pcb Materials For Communication Devices

Understanding Pcb Printed Circuit Boards And Their Essentials

Investigating The Thermal And Electrical Performance Of Aluminum PCBs

Enhancing LED And Power Electronics With Aluminum-Backed PCBs

The Role of Aluminum Nitride Ceramic PCBs in Today’s Industries