What Makes Aluminum Nitride Ceramic PCBs Unique

Experience superior performance with an aluminum nitride ceramic pcb. This advanced material sets a new standard in the industry, delivering exceptional thermal conductivity—up to 230 W/m·K—and outstanding electrical insulation. With these attributes, an aluminum nitride ceramic pcb keeps your circuits cool, ensures effective heat management, and provides reliable operation even in the most demanding environments.

Material | Thermal Conductivity (W/m·K) | Dielectric Constant (εr) | Breakdown Voltage (kV/mm) |

|---|---|---|---|

Aluminum Nitride (AlN) | 170–230 | 8.5–9.0 | >15 |

Alumina (Al₂O₃) | 24 | 9.8 | >13 |

Beryllium Oxide (BeO) | 250–300 | 6.5–7.5 | >17 |

Key Takeaways

Aluminum nitride ceramic PCBs offer exceptional thermal conductivity, reaching up to 230 W/m·K, which helps keep devices cool and enhances their lifespan.

These PCBs provide strong electrical insulation with a dielectric strength exceeding 17 kV/mm, ensuring reliable operation even in high-voltage environments.

Aluminum nitride ceramic PCBs are highly resistant to chemicals and corrosion, making them ideal for use in harsh industrial settings.

Aluminum Nitride Ceramic PCB Properties

When you look at ceramic pcbs for advanced electronics, you want to know what makes them stand out. Aluminum nitride ceramic pcbs offer a unique set of properties that set them apart from other materials. These properties make them ideal for high-performance applications where efficient heat dissipation, electrical insulation, and chemical resistance are critical.

Thermal Conductivity

You need a pcb that can handle high temperatures and move heat away from sensitive components. The thermal conductivity of aluminum nitride pcb is one of its most important properties. Aluminum nitride ceramic pcbs have a thermal conductivity range of 170–230 W/mK at 25°C. This value is much higher than most other ceramic substrate pcb materials.

Property | Value |

|---|---|

Thermal conductivity at 25 °C | 170–230 W/mK |

This high thermal conductivity allows for efficient heat dissipation, which keeps your devices cool and running smoothly. When you use aluminum nitride ceramic pcbs, you lower peak junction temperatures and improve the efficiency and lifespan of your electronics. The substrate matches well with silicon chips because of its low coefficient of thermal expansion, which is less than 4 ppm/°C. This match reduces stress and helps maintain reliability in high-temperature environments.

Material | Coefficient of Thermal Expansion (CTE) | Notes |

|---|---|---|

Aluminum Nitride | Excellent match with silicon | |

Alumina | Higher than AlN | Commonly used ceramic material |

Beryllium Oxide | Higher than AlN | High thermal conductivity |

You benefit from the thermal management capabilities of aluminum nitride ceramic pcbs in high-power devices. The thermal conductivity of aluminum nitride pcb ensures that heat moves quickly away from components, which is a key factor in aln ceramic pcb design considerations.

LT CIRCUIT uses advanced materials and manufacturing techniques to maximize the thermal properties of every ceramic substrate pcb they produce.

Electrical Insulation

You also need strong electrical insulation in your ceramic pcbs. Aluminum nitride ceramic pcbs provide high dielectric strength, with values exceeding 17 kV/mm. This property ensures that your circuits remain stable and safe, even at high voltages. The electrical resistivity at 25°C is greater than 10¹⁴ Ω·cm, which prevents current leakage and supports reliable operation.

Property | Unit | Value |

|---|---|---|

Dielectric Strength | KV/mm | |

Electrical Resistivity (25 °C) | Ω·cm | > 10¹⁴ |

Aluminum nitride ceramic pcbs maintain their electrical insulation strength even at elevated temperatures. The low dielectric loss and high insulation resistance make them perfect for RF and microwave circuits. You can trust these ceramic pcbs to deliver consistent performance in demanding environments.

Property | Description |

|---|---|

Electrical Insulation Strength | High electrical insulation strength, essential for maintaining insulation at elevated temperatures. |

Dielectric Loss | Low dielectric loss, which contributes to effective insulation performance. |

Thermal Expansion Coefficient | Matches silicon, reducing stress and enhancing reliability in high-temperature applications. |

Chemical Resistance

You want your ceramic pcbs to last, even in harsh industrial settings. Aluminum nitride ceramic pcbs offer excellent chemical resistance. They do not react with molten aluminum and resist most acids and alkalis. This resistance helps prevent corrosion and keeps the substrate strong over time.

Aluminum nitride ceramic pcbs are corrosion resistant, which helps prevent degradation in harsh environments.

Their chemical resistance ensures structural integrity and functionality over time.

This longevity makes them ideal for demanding industrial applications.

The substrate forms a protective layer when exposed to moisture, which adds another level of durability. These properties make aluminum nitride ceramic pcbs a top choice for applications where reliability and long service life are essential.

When you choose LT CIRCUIT, you get the benefits of aln pcbs engineered for maximum durability and performance, thanks to their expertise in advanced ceramic pcbs.

Aluminum Nitride PCB vs. Other Ceramic PCBs

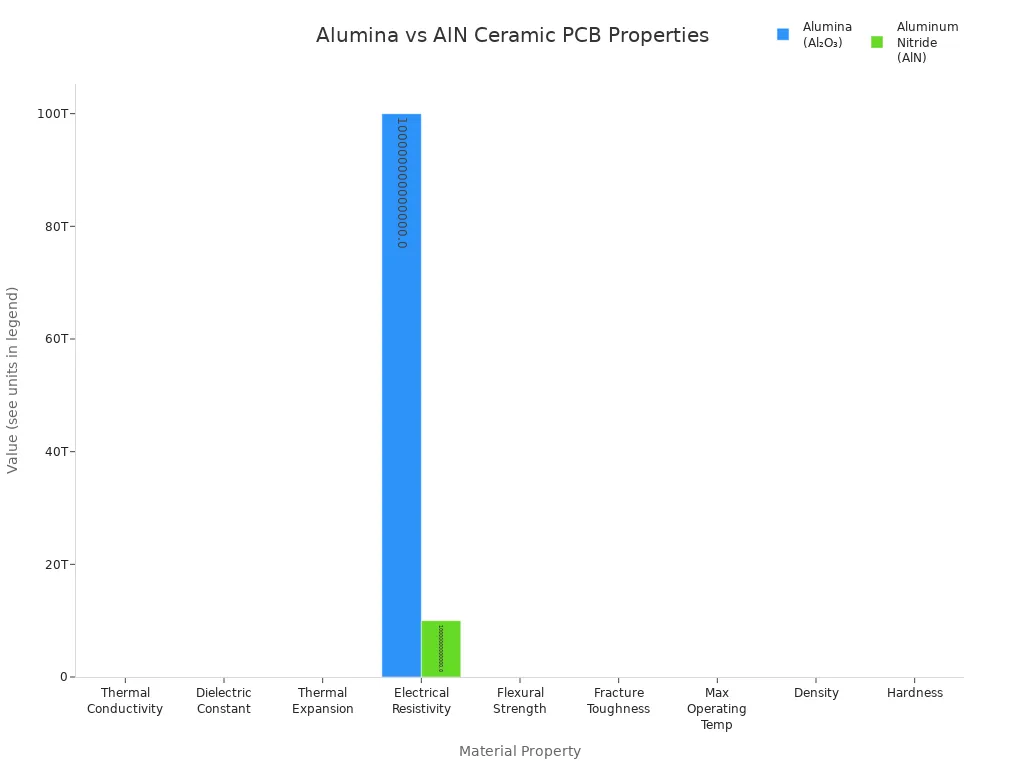

Comparison with Alumina

When you compare ceramic pcbs, you notice big differences in their properties. Aluminum nitride ceramic pcb stands out because of its thermal conductivity and heat dissipation. Alumina, another common substrate, offers good electrical insulation but falls short in thermal performance. You can see the differences in the table below:

Property | Alumina (Al₂O₃) | Aluminum Nitride (AlN) |

|---|---|---|

Thermal Conductivity | 18–30 W/m·K | 160–200 W/m·K |

Dielectric Constant | 9.5–10 | 8.5–9 |

Thermal Expansion (CTE) | ~7–8 ppm/°C | ~4.5–5.3 ppm/°C |

Electrical Resistivity | ≥10¹⁴ Ω·cm | ≥10¹³ Ω·cm |

You get much better heat dissipation with aluminum nitride ceramic pcb. This means your devices stay cooler and last longer. The substrate matches well with silicon chips, which helps reduce stress from temperature changes. You also benefit from strong electrical insulation, making your circuits safer.

Advantages in High-Power Applications

If you work with high-power electronics, you need ceramic pcbs that can handle intense heat. Aluminum nitride pcb offers thermal conductivity up to 200 W/mK, which is much higher than alumina. This property allows for rapid heat dissipation, protecting sensitive components. You also get a substrate with a thermal expansion rate close to silicon, which reduces the risk of cracks or failures.

Aluminum nitride ceramic pcb provides excellent electrical insulation, preventing short circuits.

The substrate remains stable at high temperatures, so your pcb works reliably in extreme conditions.

You see real-world benefits, like LED fixtures running cooler and lasting longer.

LT CIRCUIT uses advanced manufacturing to deliver ceramic pcbs with superior thermal properties and heat management. You can trust their innovation and quality for demanding applications.

Applications and Manufacturing

Advanced Uses

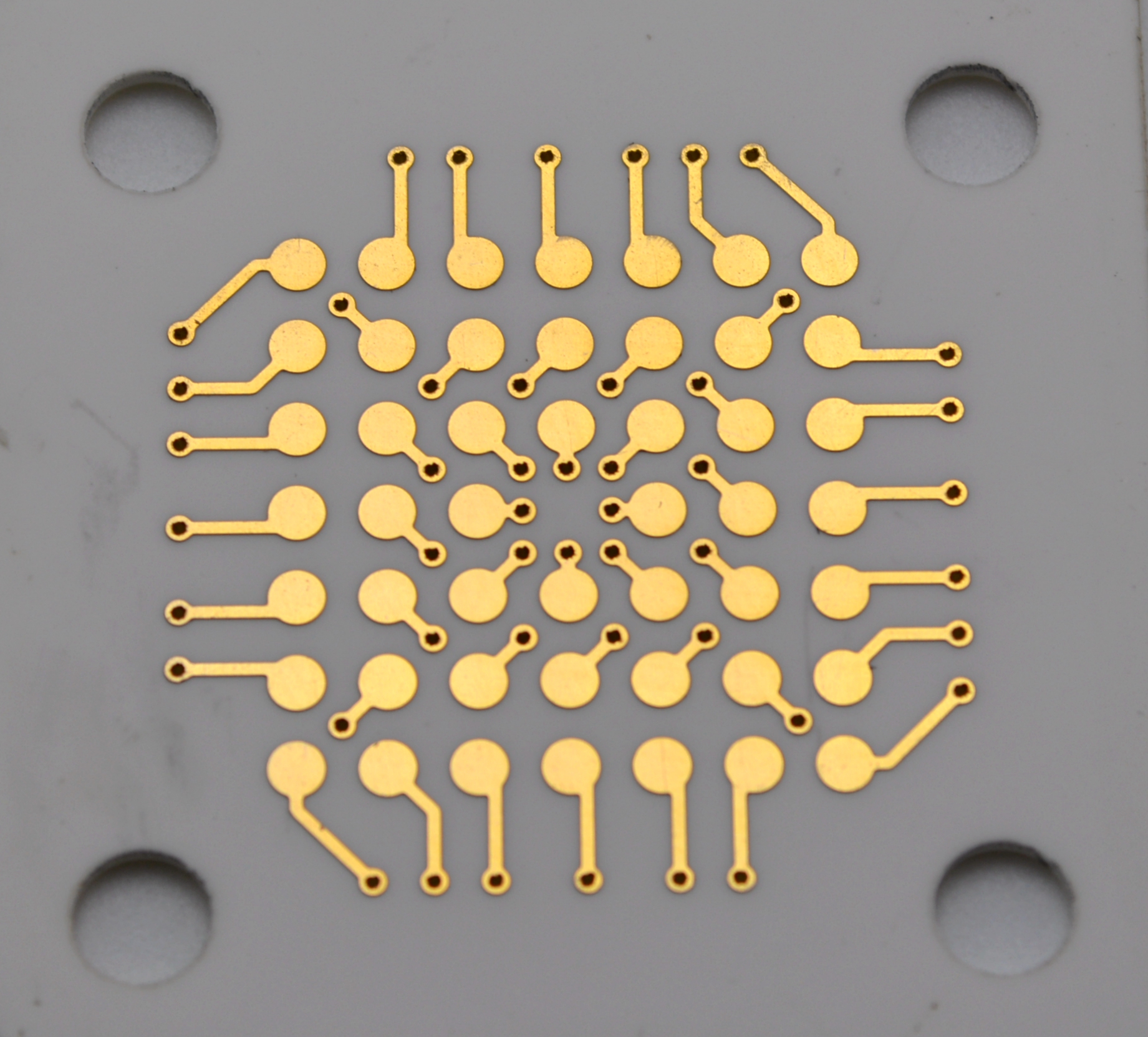

You see ceramic pcbs used in many advanced electronics because of their outstanding thermal properties and reliable heat dissipation capacity. Aluminum nitride ceramic pcbs excel in high-power and high-frequency environments. You benefit from their efficient heat dissipation and strong dielectric performance, which make them ideal for demanding applications.

High-power LED modules |

IGBT and MOSFET packages |

Power modules for EVs |

5G and RF components |

Aerospace and defense electronics |

You rely on ceramic substrate pcb for power electronics, automotive, and aerospace industries. These sectors need printed circuit boards with superior thermal conductivity and robust heat management. The thermal conductivity of aln reaches up to 170 W/mK, which supports high-power devices and reduces the risk of overheating. You also gain benefits of aln pcbs in compact designs, where efficient heat dissipation allows for smaller cooling systems.

Aluminum nitride ceramic pcb provides high mechanical strength and stability.

You get excellent electrical insulation and chemical resistance, which protect your circuits in harsh environments.

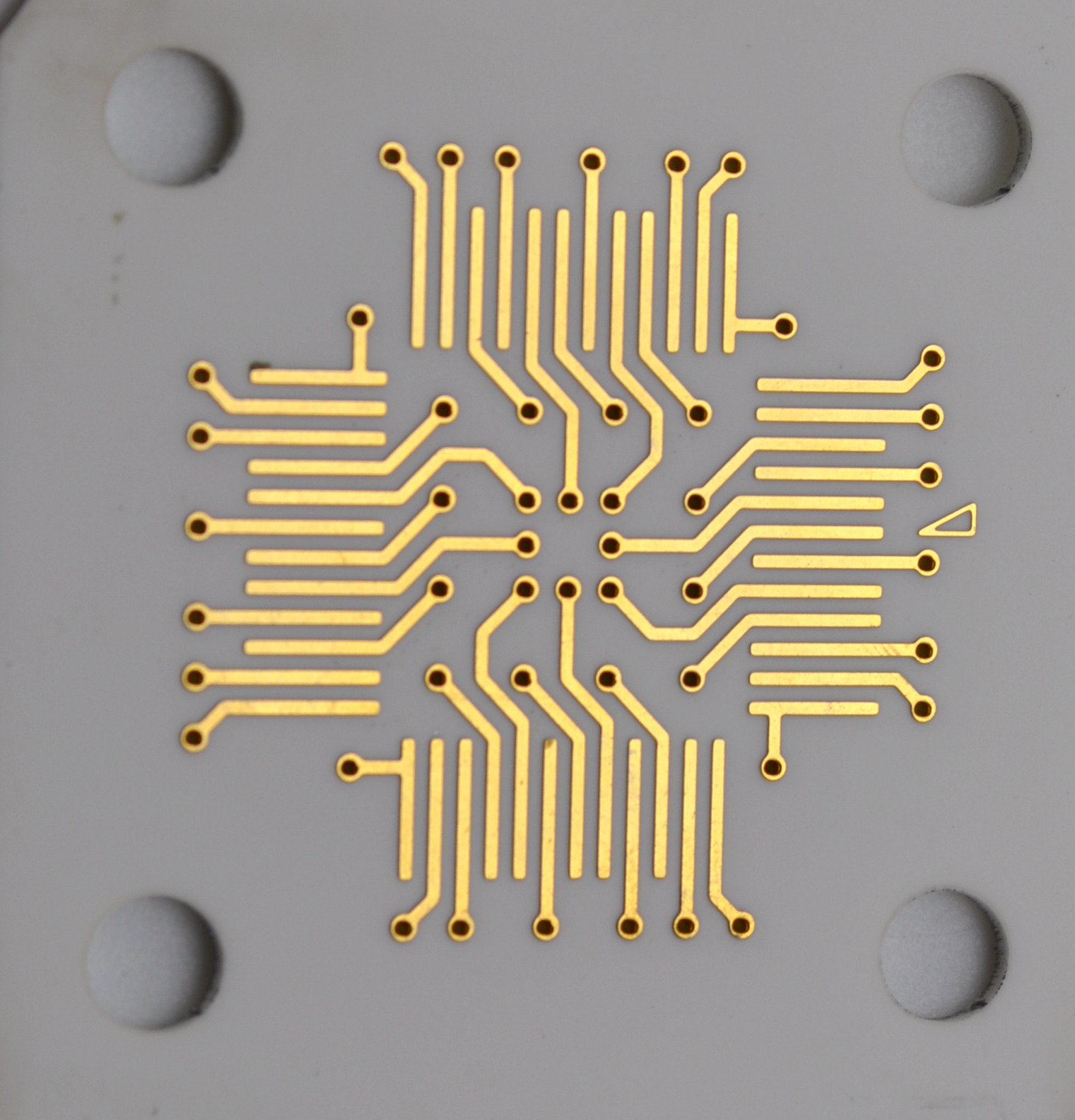

The substrate supports reliable signal transmission in RF and microwave applications.

LT CIRCUIT Manufacturing Expertise

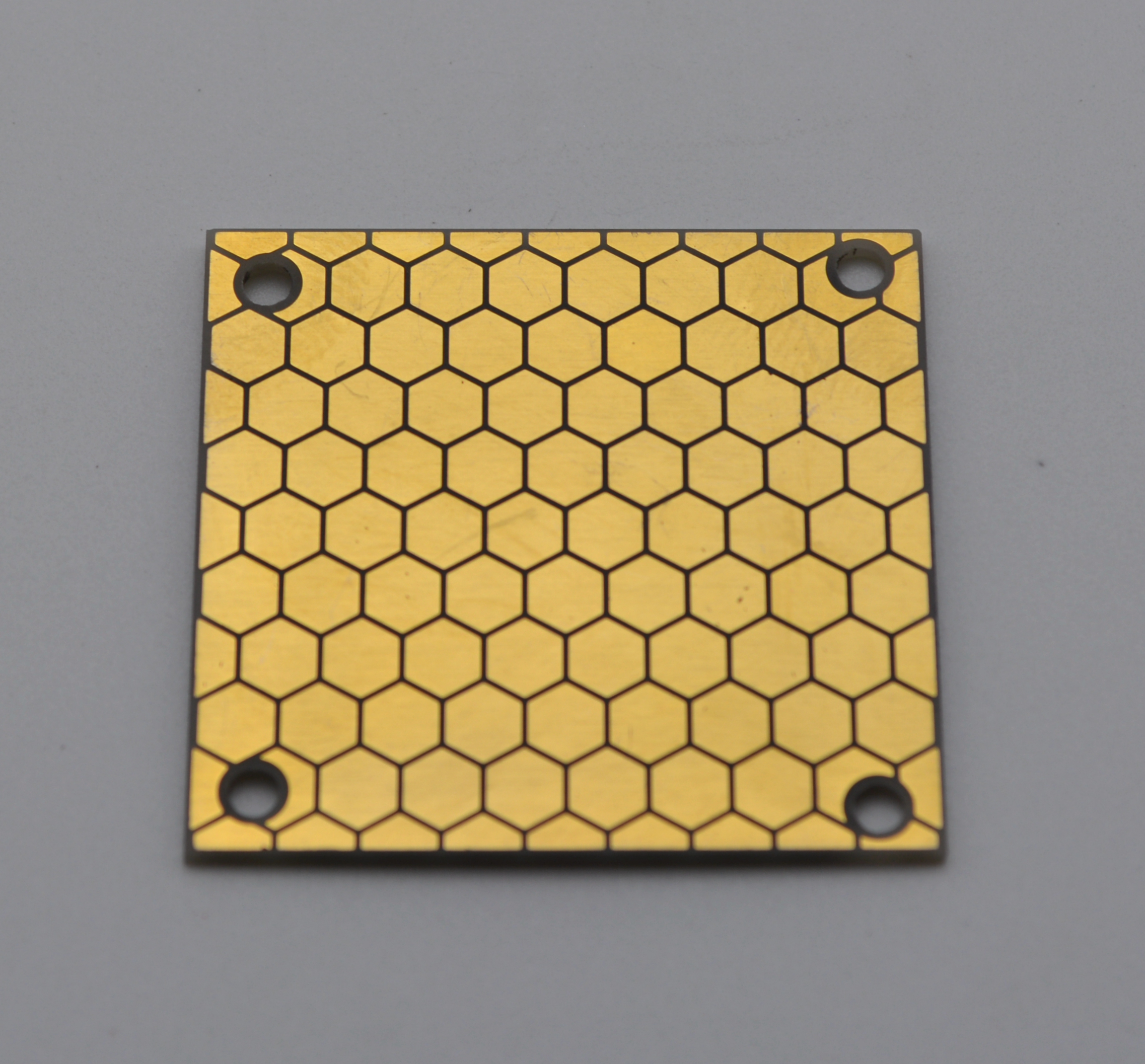

You want ceramic pcbs that meet strict quality standards. LT CIRCUIT uses advanced processes to manufacture aluminum nitride ceramic pcb. The company prepares the substrate with ceramic powder milling and tape casting. You see precise layer patterning with laser drilling and metallization. Layer stacking and lamination ensure perfect alignment and bonding. Sintering densifies the ceramic and fuses layers, while controlled cooling prevents cracks. Post-processing includes surface metallization, dicing, and rigorous testing.

Layer Patterning

Layer Stacking and Lamination

Sintering

Post-Processing

LT CIRCUIT offers customization options for ceramic pcbs, such as different solder mask colors and surface finishes. You benefit from strong design support and fast communication. The company holds ISO 9001:2015, ISO 14001:2015, and ISO 13485:2016 certifications, which guarantee quality and reliability. You can trust LT CIRCUIT for high-performance ceramic pcbs with excellent thermal management and dielectric properties.

You gain many benefits with aluminum nitride ceramic PCBs.

Superior thermal conductivity ensures rapid heat dissipation.

The substrate offers excellent electrical insulation and mechanical strength.

High thermal conductivity supports demanding applications.

Choose LT CIRCUIT for reliable solutions where thermal conductivity and performance matter most.

FAQ

What makes aluminum nitride ceramic PCBs better for heat management?

You get superior heat dissipation with aluminum nitride. Its thermal conductivity reaches up to 230 W/m·K, keeping your devices cool and reliable.

Tip: Choose aluminum nitride for high-power electronics to prevent overheating.

Can you use aluminum nitride ceramic PCBs in harsh environments?

Yes, you can. Aluminum nitride resists corrosion, moisture, and chemicals. You see long-lasting performance in industrial, automotive, and aerospace applications.

Chemical resistance

High durability

Stable operation

Does LT CIRCUIT offer customization for aluminum nitride ceramic PCBs?

You can request custom sizes, solder mask colors, and surface finishes. LT CIRCUIT supports your design needs with advanced manufacturing and fast communication. 😊

See Also

Innovative Uses of Aluminum Nitride Ceramic PCBs Today

The Superior Heat Dissipation Properties of Ceramic PCBs

Investigating Al₂O₃ Ceramic PCBs in Contemporary Industrial Applications

The Manufacturing Process of Aluminum-Based PCBs with Insulation