How Aluminum-Based PCBs with Insulation Holes Are Made

Aluminum-based PCBs with insulation holes play a crucial role in electronics, offering effective heat management while ensuring electrical separation. The insulation holes prevent short circuits, enhancing the safety and performance of devices. With excellent heat dissipation properties, aluminum-based PCBs are ideal for cooling applications. LT CIRCUIT specializes in manufacturing durable aluminum-based PCBs with insulation holes, adhering to the highest industry standards.

Key Takeaways

Aluminum PCBs with insulation holes improve safety and work better. They stop short circuits and handle heat well.

Picking good materials for aluminum PCBs is very important. Quality materials help them last longer and work efficiently without wasting money.

Drilling and filling insulation holes carefully make strong connections. This stops electrical problems and makes PCBs safer and stronger.

Preparing Aluminum PCB Laminates in Manufacturing

Picking aluminum, copper, and dielectric materials

The first step is choosing the right materials. Aluminum is picked for its strength and ability to handle heat. Copper layers help carry electricity, while dielectric materials keep parts insulated.

Tip: Using good materials makes your aluminum-based pcb with insulation holes work better and last longer.

Different materials affect how the pcb works. For example:

Signal quality depends on the dielectric material's properties.

High-frequency uses need materials with low loss, but these cost more.

Uneven materials can cause timing problems in fast circuits.

Choosing the best mix of aluminum, copper, and dielectric materials is key to balancing cost and performance.

Cleaning and getting the aluminum ready

Before adding layers, the aluminum must be cleaned. This step removes dirt and makes the surface smooth. Cleaning can involve chemicals or polishing to get rid of grease and rust.

A clean surface helps the layers stick better. It also lowers the chance of layers peeling off later, making the pcb stronger.

Adding dielectric and copper layers to the aluminum

Laminating is an important step in making aluminum pcbs. Dielectric layers are added first, then copper foil. Heat and pressure are used to bond them together.

Research shows plasma treatment improves how well layers stick. Rougher surfaces and better wetting make the bond stronger. For example:

Plasma treatment for 20 seconds gives the best peel strength.

Flexible pcb cores show strong bonds, holding up to 2.61 N in tests.

Note: Strong bonds between layers make aluminum core pcbs reliable, even in tough conditions.

This process builds a strong base for circuits, making it a key part of aluminum pcb manufacturing.

Circuit Creation and Insulation Hole Drilling

Making circuit patterns on copper layers

Making circuit patterns is an important step in PCB production. First, a light-sensitive coating is added to the copper. UV light shines through a mask to create the design. After that, unwanted copper is removed, leaving the circuit pattern.

Tip: Automated optical inspection (AOI) helps find mistakes in designs.

AOI uses smart technology to check for errors in circuits. It works better than manual checks and ensures designs are accurate. This is especially useful for complex PCB designs.

Step | Details |

|---|---|

Removes extra copper using wet etching methods. | |

Temperature Control | Keeps etching at 30–32 °C for best results. |

Post-Etch Cleaning | Rinses with clean water and dries to avoid rust. |

These steps make sure the circuit patterns are clear and work well.

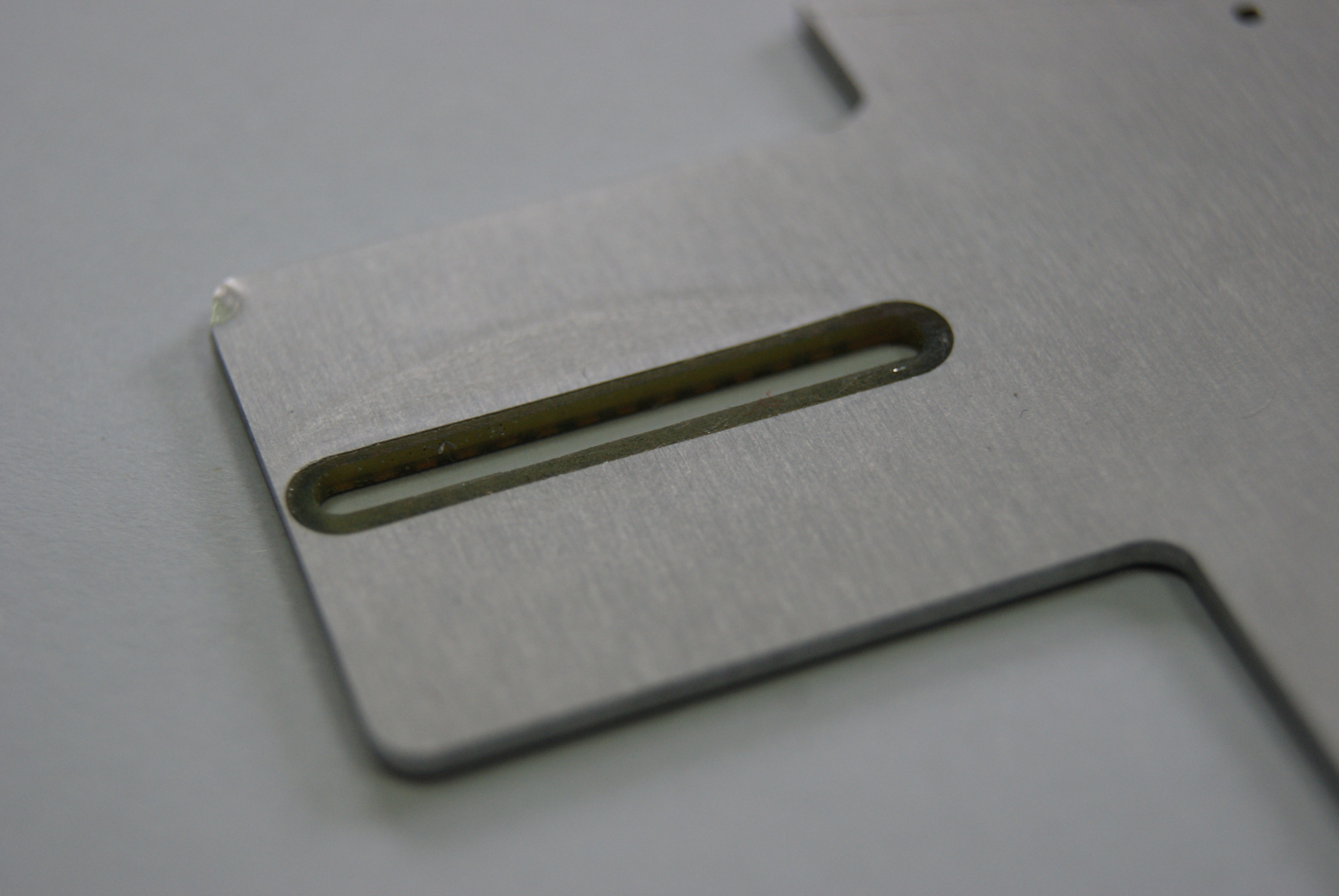

Drilling insulation holes carefully

Drilling holes is a tricky part of making PCBs. Lasers are used for tiny holes because they are very precise. Bigger holes are drilled mechanically but need careful setup to avoid problems.

Note: X-ray checks confirm holes are in the right spots.

Plasma cleaning improves the hole walls for better material sticking. These methods are important for reliable PCBs used in tough jobs like aerospace.

Drilled holes connect layers in the PCB.

Good hole placement avoids assembly issues.

Exact hole sizes are needed for press-fit parts.

Laser drilling is more accurate than mechanical drilling.

Smooth hole walls help with copper coating and electricity flow.

Careful drilling makes insulation holes strong and reliable.

Filling holes with insulating material

After drilling, holes are filled with special insulating material. This keeps circuits separate and improves heat control. The material must handle high voltage and prevent electrical problems.

Tip: Nanofluids improve insulation and reduce electrical risks.

The filling process checks the material’s thickness and safety levels. Studies show nanofluids increase voltage resistance by 20 kV rms. This lowers the chance of electrical failure and boosts PCB performance.

Test | Result |

|---|---|

Voltage Resistance | Nanofluids raise voltage resistance by 20 kV rms. |

Safety Testing | Flash points are checked to ensure safe use. |

Fluid Thickness | Measured to keep filling smooth and effective. |

Filling holes with good insulating material makes PCBs safer and longer-lasting.

Surface Finishing and Quality Assurance in Aluminum PCB Manufacturing

Adding solder mask and silkscreen for protection and labels

Solder masks keep copper circuits safe from rust and damage. This layer stops short circuits and makes the PCB last longer. Silkscreen printing adds labels to help with assembly and fixing problems.

Rules like IPC-HDBK-840 and IPC-SM-840 guide how solder masks and silkscreens are applied. These rules make sure materials are strong and reliable. Following them helps aluminum PCBs work well in tough conditions.

Surface finishes like HASL, ENIG, and OSP

Surface finishes protect copper and make soldering easier. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

Finish | Time Limit | Flux Type | |

|---|---|---|---|

Lead HASL | 265°C ±10°C | 45-90 seconds | Standard ROSH |

ENIG | 280°C ±5°C | 30-60 seconds | No-clean needed |

OSP | 250°C ±8°C | 15-30 seconds | Aggressive fluxes |

ENIG is great for its smooth surface and rust resistance. It lasts a long time and is eco-friendly. HASL is cheaper, while OSP works best for short-term use.

Checking insulation holes for accuracy and strength

Testing makes sure insulation holes meet quality standards. X-ray and electrical tests check hole placement and material quality.

Standard | Details |

|---|---|

Explains what affects insulation resistance in PCBs. | |

IPC-579 | Focuses on testing small plated holes for reliability. |

These rules help check the heat and electrical safety of aluminum PCBs. Following them ensures your PCB is safe and works well.

Making aluminum PCBs with insulation holes needs many careful steps. Each part, like picking materials and finishing surfaces, helps them work well. These PCBs are great at keeping electricity safe and managing heat. Tests show the process is very accurate, like getting 99.2% success on HDI designs. Surface smoothness stays below Ra <0.4μm, following ISO 4287-1 rules. These numbers show how much care goes into making good PCBs. LT CIRCUIT makes sure every PCB meets strict rules. Their PCBs are strong and work great in modern devices.

FAQ

What are insulation holes in aluminum-based PCBs?

Insulation holes keep circuits apart and help heat escape. They stop short circuits and make the PCB work better in tough jobs.

Why is aluminum used as the base material?

Aluminum spreads heat well and lasts a long time. It handles heat, making it great for hot devices like LEDs and power tools.

How does LT CIRCUIT ensure PCB quality?

LT CIRCUIT uses smart methods, careful checks, and top materials. These steps make sure their PCBs are strong and meet high standards.

See Also

Investigating Thermal and Electrical Performance of Aluminum PCBs

Understanding the Materials Used in Printed Circuit Boards

Perfecting PCB Production Techniques with Press-Fit Hole Methods

Enhancing LED and Power Electronics with Aluminum-Backed PCBs