Applications of Aluminum Nitride Ceramic PCBs in Modern Industries

Aluminum nitride ceramic PCBs are important in today's industries, particularly due to the application of AIN (Aluminum nitride) ceramic PCB technology. They enhance the performance of electronic components by providing excellent heat management, with thermal conductivity ranging from 120 to 200 W/mK. This capability ensures that high-power systems remain cool and operate efficiently. Additionally, they prevent electrical leakage, boasting a resistance of 10¹² to 10¹³ ohms cm, making them ideal for high-frequency applications. Many industries, including automotive and aerospace, are increasingly adopting AIN ceramic PCBs as they require robust and durable solutions.

Key Takeaways

Aluminum nitride ceramic PCBs handle heat well, with thermal conductivity of 140 to 200 W/mK. This makes them great for powerful electronic devices.

These PCBs stop electricity from leaking and work well in high-frequency uses.

Aluminum nitride PCBs are strong and last long. They can handle tough conditions like very hot or cold temperatures and corrosive places. This makes them useful in industries like cars and airplanes.

Key Properties and Advantages of Aluminum Nitride Ceramic PCBs

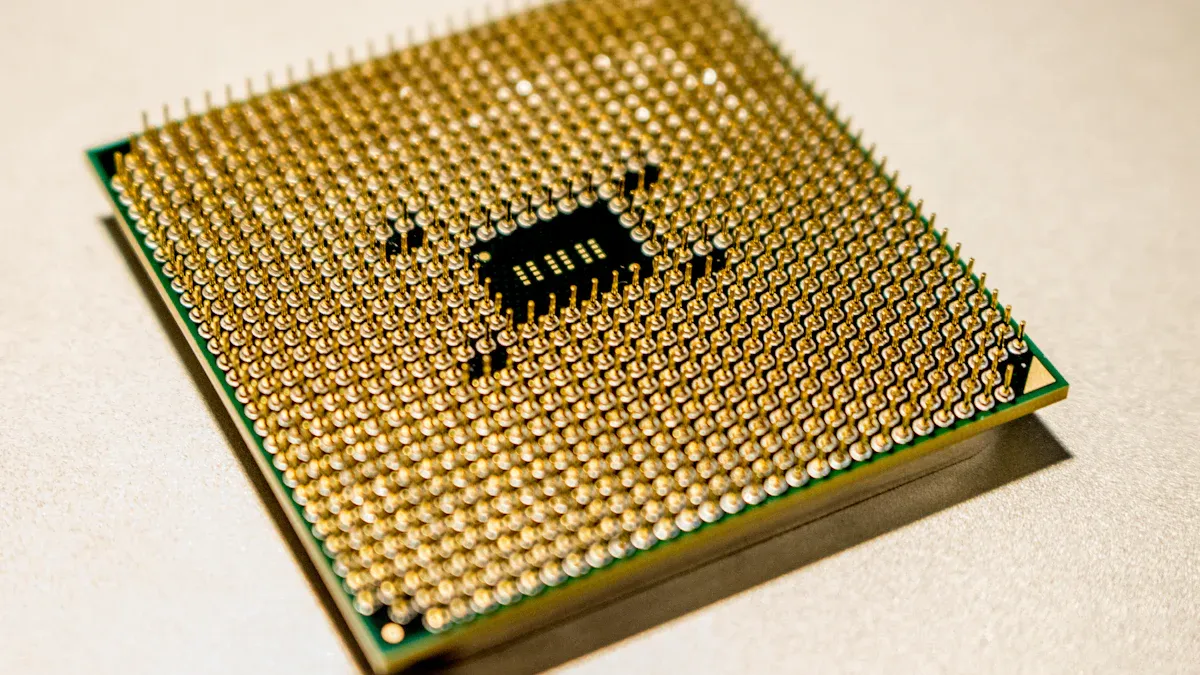

Thermal Conductivity of Aluminum Nitride PCB

Aluminum nitride PCBs are great at handling heat. Their thermal conductivity ranges from 140 to 180 W/mK. This helps electronic devices stay cool and work better. It also prevents overheating, which can damage parts and shorten their life. Compared to magnesium aluminate, which has only 25-30 W/mK, aluminum nitride is much better for managing heat.

Industries like semiconductors and LED lighting benefit a lot from this. For example, in semiconductors, aluminum nitride PCBs quickly move heat away from delicate parts. This keeps devices working well and makes them more reliable.

Property | Aluminum Nitride (AlN) | Beryllium Oxide (BeO) | Magnesium Aluminate |

|---|---|---|---|

Thermal Conductivity | 140-180 W/mK | 250-300 W/mK | 25-30 W/mK |

Dielectric Constant | ~8.9 | ~6.7 | ~9 |

Coefficient of Thermal Expansion (CTE) | ~4.5 ppm/°C | ~7.5 ppm/°C | ~7-8 ppm/°C |

This table shows how aluminum nitride beats magnesium aluminate in thermal conductivity. While beryllium oxide is better at heat transfer, it is toxic and hard to handle. Aluminum nitride is safer and easier to use.

Electrical Insulation and Reliability

Aluminum nitride PCBs are excellent at stopping electrical leaks. They have a resistance of 10¹² to 10¹³ ohms cm. This keeps electrical signals steady, even in high-frequency uses. Aluminum nitride PCBs protect circuits and keep them working properly.

Their insulation and heat-handling abilities make them perfect for power electronics. Devices like inverters and converters use them to handle high voltages and heat. This makes systems more reliable and efficient, even in tough conditions.

Durability and Resistance to Environmental Factors

Aluminum nitride PCBs are very strong and last a long time. They can handle physical stress and resist damage from acids and alkalis. This makes them great for industries like cars and airplanes.

They resist sudden temperature changes, staying strong under stress.

High thermal conductivity helps them manage heat in tough conditions.

They can handle temperatures up to 2400 °C, like in lab crucibles.

They resist corrosion, ensuring they last a long time.

These features make aluminum nitride PCBs useful in many industries. Whether in hot or chemically harsh places, they are dependable and perform well.

The Application of AIN (Aluminum Nitride) Ceramic PCB Across Industries

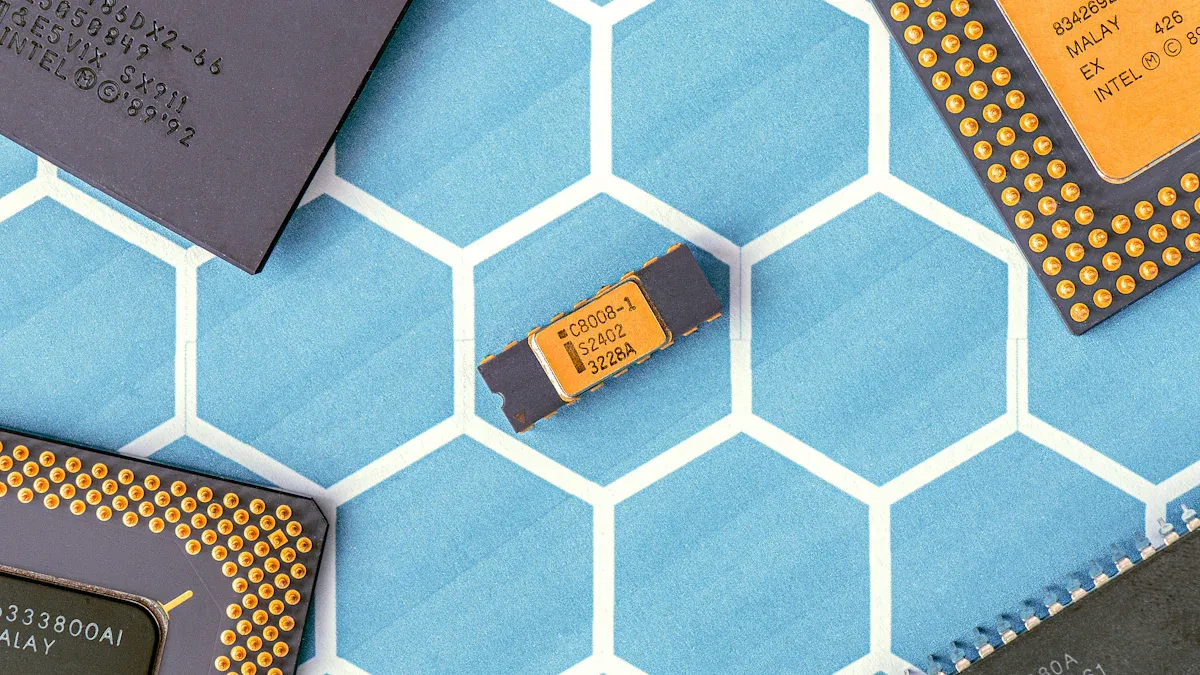

Electronics and Semiconductor Manufacturing

We use electronics daily, like phones and computers. Aluminum nitride ceramic PCBs are key to these devices. They spread heat well, with thermal conductivity of 170-200 W/m·K. This keeps parts cool and working properly. It’s about five times better than alumina, making it great for semiconductors.

The semiconductor market is growing fast, with a 6.5% yearly increase expected from 2023 to 2030. This growth needs better ways to manage heat. Aluminum nitride PCBs are used a lot in making semiconductors, making up 25% of global machinable aluminum nitride production. As chipmakers move to 2nm chips, demand for flat ceramic wafer parts has risen by 32% yearly.

These PCBs improve performance in high-frequency uses, keeping semiconductors reliable. Their strong electrical insulation stops signal problems, making them vital for high-frequency parts.

Automotive and Electric Vehicles

Modern cars rely on electronics for safety and performance. Aluminum nitride ceramic PCBs are important in electric and hybrid cars. They help cool batteries, stopping them from overheating and keeping them reliable.

In electric car systems and chargers, these PCBs improve heat control and performance. They are also used in radars and LiDAR for advanced driving systems and self-driving cars.

These PCBs handle extreme heat, making them great for engines and sensors. Their insulation ensures sensors work accurately, even in tough conditions.

Aerospace and Defense Applications

Aerospace needs materials that survive harsh conditions. Aluminum nitride ceramic PCBs are perfect here because they handle heat well and are durable. They are used in heat shields to protect parts from high heat during re-entry. Their resistance to sudden temperature changes keeps aerospace parts safe and efficient.

Industry Sector | Application | Key Benefits |

|---|---|---|

Aerospace | Heat shields | Protects parts from high heat, resists thermal shock |

Aerospace | Critical components | Prevents overheating, ensures safety and efficiency |

Automotive | Engine components | Handles extreme heat, reliable performance |

Automotive | Electric/hybrid vehicles | Manages battery heat, prevents overheating |

Automotive | Sensors | Accurate sensing, works well in tough conditions |

These PCBs are also used in defense, where reliability is crucial. Their ability to handle high-frequency signals makes them great for radars and communication devices.

Telecommunications and 5G Infrastructure

Telecommunications depend on aluminum nitride ceramic PCBs, especially with 5G technology. These PCBs are great for high-frequency signals, making them ideal for RF filters, antennas, and amplifiers.

With 5G using gallium nitride (GaN) amplifiers, aluminum nitride substrates are used more. Their thermal conductivity, over 170 W/mK, stops heat from messing up signals, ensuring top performance.

Ceramic PCBs are key for advanced telecom equipment. They support high-frequency parts and provide excellent insulation. This makes aluminum nitride PCBs better than other ceramics for telecom uses.

LED Lighting and Optoelectronics

LED lights need good heat control to stay bright and last long. Aluminum nitride ceramic PCBs manage heat well, keeping LEDs at the right temperature. This stops overheating and improves optoelectronic device performance.

These PCBs are also used in laser diodes and photodetectors. These high-frequency devices need precise heat control. Their durability and insulation make them perfect for optoelectronics, ensuring they work well in many industries.

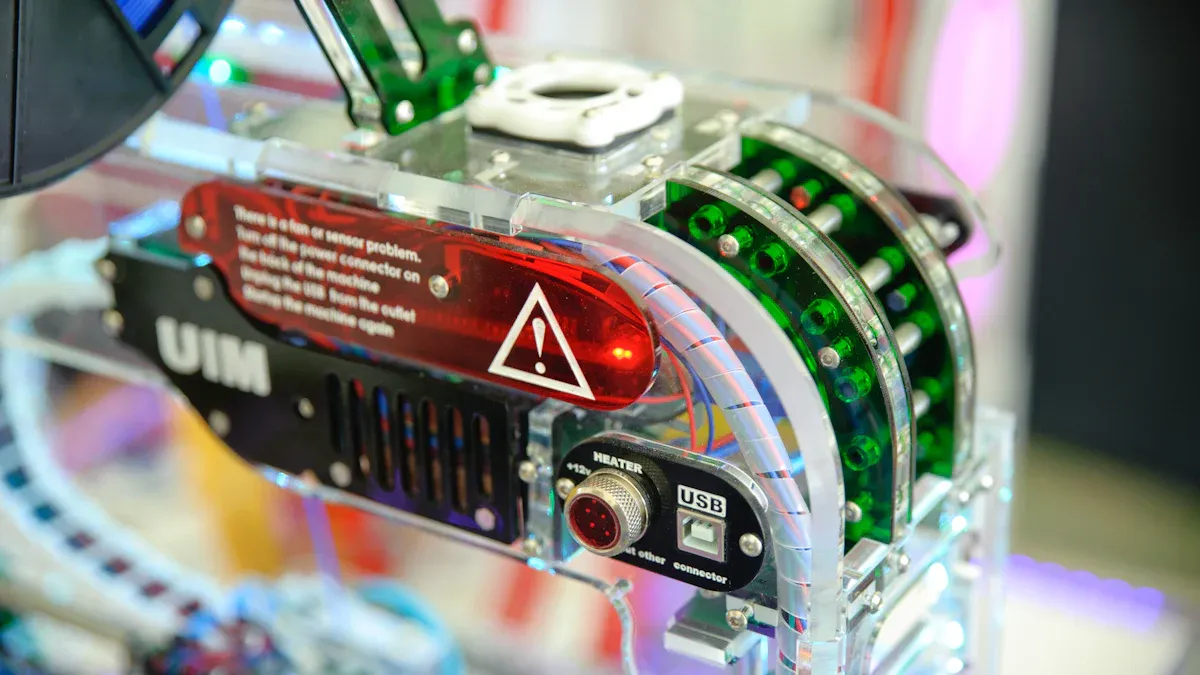

Medical Devices and Equipment

Medical devices must be precise and reliable. Aluminum nitride ceramic PCBs meet these needs by managing heat and providing strong insulation. They are used in imaging machines like X-rays and CT scanners, where heat control is important.

These PCBs are also in wearable medical devices, keeping them reliable in high-frequency uses. They can handle tough conditions, making them good for sterilization and long-term use in medical tools.

Comparison of Aluminum Nitride Ceramic PCBs with Other Materials

Aluminum Nitride vs. FR4 PCBs

Aluminum nitride ceramic PCBs are much better at handling heat. They remove heat from powerful parts faster than FR4 PCBs. This makes them perfect for systems needing great heat control. FR4 PCBs, however, only offer basic heat management.

Aluminum nitride ceramic can handle over 600°C, while FR4 stops at 150°C. This makes aluminum nitride better for places with quick temperature changes. It also keeps electrical signals steady at high frequencies, reducing signal loss. FR4 is cheaper and more flexible, so it works for simpler uses.

Metric | Aluminum Nitride (AlN) | FR-4 |

|---|---|---|

Thermal Performance | Standard | |

Temperature Resistance | Above 600°C | 130-150°C |

Electrical Properties | Better high-frequency | Standard |

Mechanical Strength | More rigid, brittle | Less rigid |

Cost | 5-20 times more | Less expensive |

Aluminum Nitride vs. Alumina Ceramic PCBs

Aluminum nitride ceramic handles heat much better than alumina ceramic. Its heat transfer ability is five to ten times higher. This makes it great for powerful devices like LEDs and chips. It also expands less when heated, so it won’t crack easily.

Alumina ceramic costs less but doesn’t insulate as well as aluminum nitride. It also doesn’t work as well in high-frequency tasks. Aluminum nitride is more reliable for jobs needing precision and strength.

Performance in High-Temperature Environments

Aluminum nitride ceramic works well in very hot places. It doesn’t crack under sudden temperature changes and stays strong. This makes it useful for planes, cars, and factories.

It can handle quick temperature shifts without breaking, lasting a long time. Its excellent heat and electrical properties make it the best choice for tough industries.

Innovations and Future Trends in Aluminum Nitride Ceramic PCBs

Advancements in Manufacturing Techniques

New ways to make aluminum nitride ceramic PCBs are changing industries. Methods like Active Metal Brazing (AMB) and Direct Plating Ceramic (DPC) improve circuit designs and metal strength. These techniques help PCBs work better in demanding tasks.

3D printing is also making production faster and easier. It creates prototypes quickly, cutting production time from weeks to days. Older methods take 3-4 weeks, but 3D printing takes only 1-2 weeks. It uses materials more efficiently, up to 95%, compared to 70%-85% before. This saves time, reduces waste, and helps the environment.

Aspect | Traditional Manufacturing | 3D Printing |

|---|---|---|

Material Utilization | 70%-85% | Up to 95% |

Production Time | 3-4 weeks | 1-2 weeks |

Prototype Cost | High | Low |

Expanding Applications in Green Energy and IoT

Aluminum nitride ceramic PCBs are becoming popular in green energy and IoT. They handle heat well, making them perfect for solar inverters and wind turbines. Their ability to work in high temperatures keeps systems reliable.

In IoT, these PCBs support devices that need fast communication. They provide strong insulation, keeping signals steady. As IoT grows, the need for durable PCBs will increase.

Key Points | Details |

|---|---|

Known for great heat transfer in powerful and fast devices. | |

Applications | Used in 5G, advanced car electronics, and LED lights. |

Demand for Advanced Materials | Needed for future tech, making AlN substrates essential. |

LT CIRCUIT’s Role in Driving Innovation

LT CIRCUIT leads in making advanced aluminum nitride ceramic PCBs. They use new methods like DPC and 3D printing to create high-quality products. Their PCBs are great at managing heat and stopping electrical leaks.

The company also cares about the environment. Efficient production methods reduce waste and pollution. This supports green energy goals. As technology changes, LT CIRCUIT stays ahead by offering top PCB solutions for modern needs.

Aluminum nitride ceramic PCBs are great at handling heat, stopping electrical leaks, and lasting a long time. These features make them important for industries like cars, airplanes, and communication systems.

LT CIRCUIT makes top-quality PCBs using advanced methods. They focus on giving you dependable products for today’s technology. Check out their products to stay ahead in your field.

FAQ

What makes aluminum nitride ceramic PCBs special?

They are great at handling heat, stopping electrical leaks, and lasting long. These features make them perfect for tough jobs in aerospace, cars, and telecom.

Can aluminum nitride ceramic PCBs survive harsh conditions?

Yes, they can handle high heat, sudden temperature changes, and corrosion. This makes them useful for defense, medical tools, and green energy systems.

Why are aluminum nitride ceramic PCBs important today?

They manage heat well and keep powerful systems working reliably. They are used in many areas like 5G networks, LED lights, and smart devices.

See Also

Understanding How Ceramic PCBs Are Used Across Industries

Utilizing Horizontal Copper Sinking Technology for PCB Manufacturing

Impact of LDI Technology on PCB Product Quality