Exploring the Applications of Ceramic PCBs in Modern Industries

Ceramic PCBs change how electronics work in tough conditions. The application of ceramic PCB is particularly beneficial for industries needing strong and reliable tools. They have unique features that make them important:

They spread heat well, keeping devices cool and steady.

They are strong and can handle stress in rough places.

They keep signals clear, even for high-speed uses.

Ceramic PCBs allow small designs without losing any features. These qualities make them key for cars, planes, and communication industries.

Key Takeaways

Ceramic PCBs handle heat well, so they work great in powerful devices like electric cars and factory machines.

They are strong and can survive tough conditions, making them dependable for industries like space travel and phone networks.

Ceramic PCBs allow small designs while keeping all features, which is important for today’s electronics in many areas.

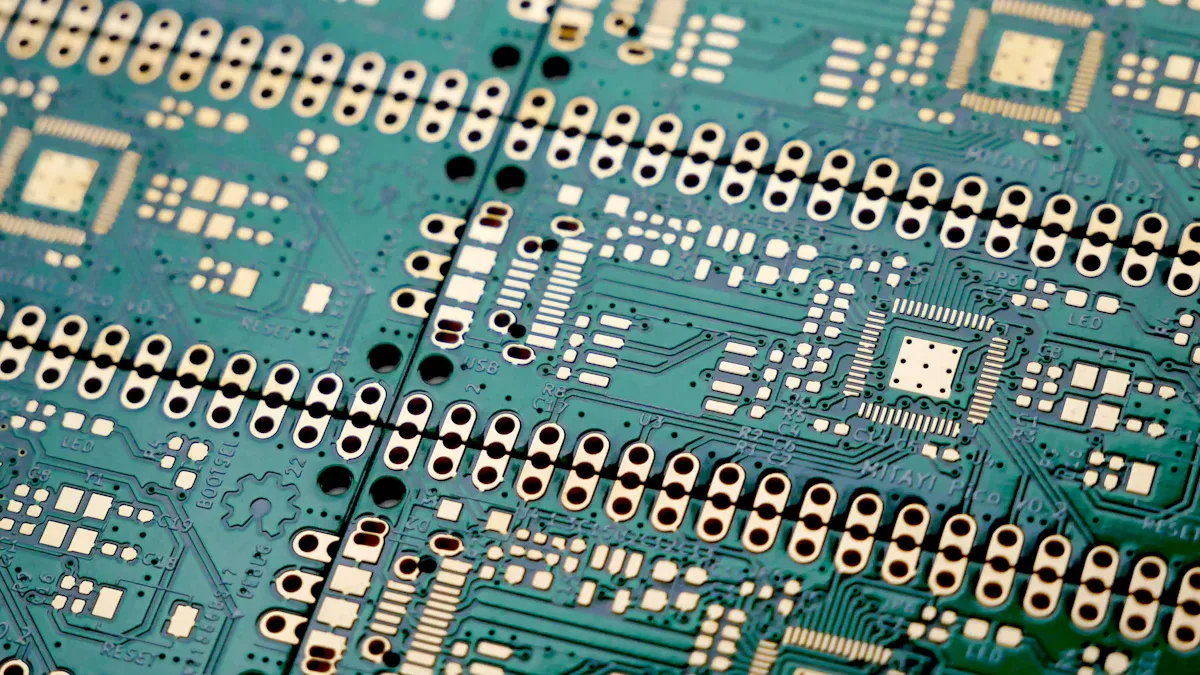

Overview of Ceramic PCBs

Ceramic PCBs are changing the electronics world. Their special design and materials make them great for tough jobs. Let’s look at their types, features, and why they are better than regular PCBs.

Types of Ceramic PCBs

Ceramic PCBs come in different types for specific uses. Here’s a simple list:

Thick Film PCB: Uses thick layers for circuit designs.

Thin Film PCB: Best for small, detailed circuits with thin layers.

DPC PCB: Copper directly bonded for great heat control.

DBC/DCB PCB: Double-sided with strong bonding for better durability.

AMB PCB: Uses Active Metal Brazing for excellent heat transfer.

LTCC PCB: Low-Temperature Ceramic, great for radio frequency parts.

HTCC PCB: High-Temperature Ceramic, works well in hot places.

These types are used in cars, planes, and communication tools for top performance.

Unique Properties of Ceramic PCBs

Ceramic PCBs are special because of their amazing features. These include:

Property | What It Does |

|---|---|

Thermal Conductivity | Spreads heat well, perfect for powerful devices. |

Electrical Insulation | Stops electrical shorts, making circuits safer and stronger. |

Durability | Handles stress and tough conditions, ideal for factories and planes. |

These features help ceramic PCBs work even in the hardest situations.

Why Ceramic PCBs Are Preferred Over Traditional PCBs

Ceramic PCBs are better than regular PCBs in many ways. Here’s a comparison:

Feature | Ceramic PCBs | Regular PCBs (FR4) |

|---|---|---|

Heat Control | Low heat spreading (0.3-0.5 W/m·K) | |

Strength | Very strong and stress-resistant | Breaks easily under pressure |

Electrical Safety | Great insulation with low signal loss | Weaker insulation |

Ceramic PCBs are used in electric cars, medical tools, and space systems where reliability matters most.

Applications of Ceramic PCBs Across Industries

Ceramic PCBs are changing many industries with their amazing features. They manage heat well, are strong, and stop electrical problems. These qualities make them perfect for powerful and fast devices. Let’s see how they are helping different fields.

Automotive Industry: Better Engines and LED Lights

In cars, ceramic PCBs improve how vehicles work and last. They are used in engine controls to handle heat and keep things running smoothly. They also help LED lights stay cool and shine brightly.

EV Battery Systems: These boards lower heat stress and guide electricity safely.

Car Electronics: They make sensors and control systems more reliable for safety.

Ceramic PCBs help car electronics work well, even in tough conditions. This makes them very important for modern cars.

Aerospace and Defense: Strong in Tough Places

Planes and defense tools need electronics that work in hard conditions. Ceramic PCBs are great because they are strong and handle heat well. They are used in airplane systems and military radars.

Tests like HALT and thermal cycling prove ceramic PCBs can survive tough environments. These tests check if the boards meet strict aerospace and defense needs.

Ceramic PCBs are also used in satellites. They keep signals clear and work well for communication and navigation.

Telecommunications: Perfect for Fast Signals

Telecommunication needs fast and strong electronics. Ceramic PCBs are the best choice here. They spread heat well and are tough enough for hard conditions.

Uses: These boards are in wireless devices, radars, and 5G systems.

Flexible Design: They allow small, detailed circuits for fast communication.

Ceramic PCBs in telecom and 5G systems ensure they work well for a long time.

Medical Devices: Accurate and Safe Tools

Ceramic PCBs are helping medical tools work better. They are safe for the body and handle heat well, making them great for sensitive devices.

Title | Authors | Year | Summary |

|---|---|---|---|

Design of Ceramic Packages for Acoustically Coupled Implantable Medical Devices | M. Schuettler, et al. | 2010 | Talks about using ceramics in safe implant packages. |

Ceramic Packaging in Neural Implants | N/A | 2020 | Explains ceramics in brain implants for better power use. |

These boards are key for accurate and reliable medical devices.

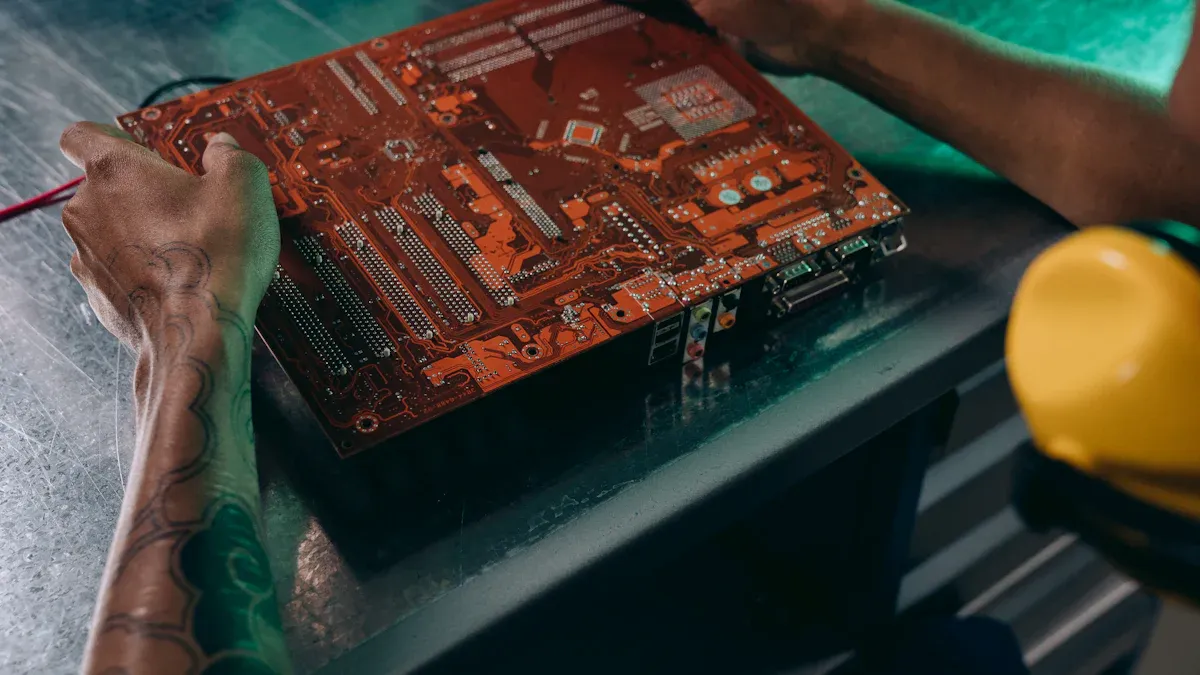

Industrial Applications: Helping Robots and Machines

In factories, ceramic PCBs are used in robots and machines. They handle high power and resist damage, making them perfect for these jobs.

Motor Drives: DBC ceramic PCBs improve heat control and insulation.

Power Modules: These boards make factory machines work better and last longer.

Ceramic PCBs help industrial tools stay strong and work well in tough places.

New Tech: Electric Cars and Power Systems

New technologies like electric cars need ceramic PCBs. These boards handle high power and control heat well.

EV Batteries: They lower heat stress and make batteries safer.

Power Systems: Special ceramic boards improve energy use and reliability.

As technology grows, ceramic PCBs are becoming more important for advanced electronics.

Advantages of Ceramic Substrate PCBs

Great at Handling Heat

Ceramic PCBs are excellent at controlling heat. This makes them perfect for powerful devices. They quickly move heat away from parts, stopping overheating. This is very useful in things like power modules and LED lights. Too much heat can make these devices fail or work poorly.

Ceramic PCBs expand less when heated compared to regular materials. This lowers stress on parts and keeps them safe. They work well with materials like silicon, making them reliable in tough conditions.

For instance, ceramic PCBs manage power in electric cars and machines. They spread heat well, helping devices last longer and work steadily.

Strong and Long-Lasting

Ceramic PCBs are made to be tough. They can handle vibrations and impacts without breaking. They keep their shape even in extreme conditions, reducing the chance of failure.

These PCBs also resist water, chemicals, and harmful gases. This makes them great for harsh places like space systems or factory machines. Tests like vibration and heat cycling prove they are durable and dependable.

Durability Features | Benefits |

|---|---|

Keeps Shape | Reduces stress during temperature changes, improving reliability. |

Protects from Damage | Blocks moisture and gases, ensuring steady performance. |

Tested for Strength | Shows they last long under tough conditions. |

Clear Signals for Fast Devices

Ceramic PCBs are best for high-speed electronics. They lose less signal, keeping communication clear and strong. This makes them ideal for 5G, radios, and satellites.

Their special design reduces interference and keeps signals accurate. This is very important for industries like telecom and aerospace, where precision matters a lot.

Using ceramic PCBs improves performance in fast devices. They also stay durable and manage heat for long-term use.

Future Trends in Ceramic PCB Technology

New Ideas in Ceramic Substrate PCBs

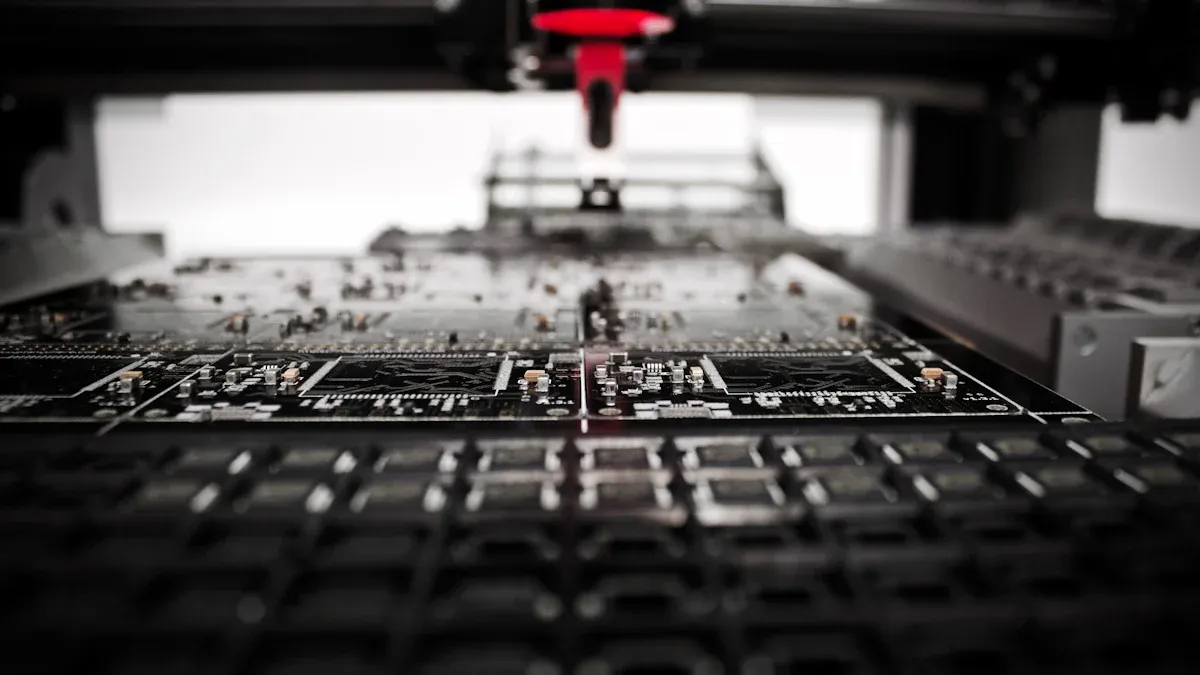

The future of ceramic PCBs is full of exciting changes. New methods like laser cutting and 3D printing are improving how these boards are made. These techniques allow for more detailed designs to fit modern electronics. Smaller devices are also shaping the future. Ceramic PCBs now support more circuits without losing quality.

Eco-friendly ideas are also important. Ceramic PCBs can be recycled, helping reduce electronic waste. This supports global efforts to protect the environment. With these changes, ceramic PCBs will perform better and help create greener technology.

Trend | What It Means |

|---|---|

More ceramic PCBs are needed for fast 5G and IoT devices. | |

Eco-Friendly Focus | Recyclable ceramic PCBs match global goals for less waste. |

Better Manufacturing | Laser cutting and 3D printing improve how ceramic PCBs are made. |

Smaller, Denser Circuits | Ceramic PCBs now fit more circuits into smaller spaces. |

New Uses in Growing Industries

Ceramic PCBs are being used in many new industries. In renewable energy, they help manage power in solar panels and wind turbines. They handle heat well, making them perfect for these systems. In electric cars, ceramic PCBs keep batteries and power parts working safely.

Other industries also benefit. Aerospace uses ceramic PCBs in satellites and planes because they are strong and reliable. Telecommunications relies on them for stable signals in 5G systems. The military uses ceramic PCBs in radars and missiles because they resist heat and insulate electricity.

Aerospace: Helps manage heat in satellites and planes.

Military: Used in radars and other high-tech tools.

LEDs: Keeps LED lights cool and working well.

Car Electronics: Makes car systems safer and more stable.

Telecom: Improves signal strength in communication devices.

LT CIRCUIT’s Role in Ceramic PCB Progress

LT CIRCUIT is a leader in making ceramic PCBs. They use advanced tools to create strong and precise boards for industries like aerospace, cars, and telecom. Their products are built to handle tough jobs and last long.

LT CIRCUIT also cares about the environment. They use recyclable materials and eco-friendly processes. The company invests in research to find new ways to improve ceramic PCBs. Whether for green energy or medical tools, LT CIRCUIT offers reliable and innovative solutions.

Ceramic PCBs are changing industries with their special features. They are used in cars, planes, communication, medical tools, and factories. These boards handle heat, resist shaking, and allow small designs, making them very useful.

Where They Are Used | Benefits of Ceramic PCBs |

|---|---|

Hot Places | |

Strong and Durable | Handles shaking without breaking |

Radio Systems | Allows smaller circuits for low-frequency signals |

LT CIRCUIT is helping this change by making advanced ceramic PCBs. They focus on quality to give strong and dependable products for modern needs.

FAQ

Why are ceramic PCBs good for hot environments?

Ceramic PCBs work well in heat because they spread it quickly. This keeps devices steady and working properly in tough conditions. 🔥

Are ceramic PCBs used in medical tools?

Yes, ceramic PCBs are safe and dependable. They are great for imaging machines, implants, and other medical tools needing accuracy and safety. 🏥

How does LT CIRCUIT make sure ceramic PCBs are high quality?

LT CIRCUIT uses smart methods and strict tests. They focus on making strong and precise ceramic PCBs for many industries. ✅

See Also

Utilizing Horizontal Copper Sinking Technology for PCB Manufacturing

Importance of Vacuum Two-Fluid Etching Machines in Precision PCB Creation

Explore Cutting-Edge Techniques for HDI PCB Prototyping Now

Impact of LDI Technology on PCB Product Quality

Advantages of LDI Exposure Machines for HDI PCB Circuit Production