Top Benefits of Mixed PCB Assembly Combining SMT and THT Technologies

Mixed Assembly PCB combines SMT and THT technologies. SMT offers speed and precision, while THT enhances the strength and durability of the boards. This mixed assembly approach is particularly effective in compact environments, accelerating production and enabling versatile designs. Engineers are currently utilizing this method for applications in automotive and medical devices.

Key Takeaways

Mixed PCB assembly uses SMT and THT to make products stronger. This method lowers errors and builds better connections, helping items last longer.

Mixed assembly offers flexible designs as a big advantage. It uses SMT for compact layouts and THT for strong links, fitting many industry needs.

Mixed PCB assembly saves money by being efficient. Machines work faster, and less waste cuts costs, making it a good option for companies.

What is Mixed PCB Assembly?

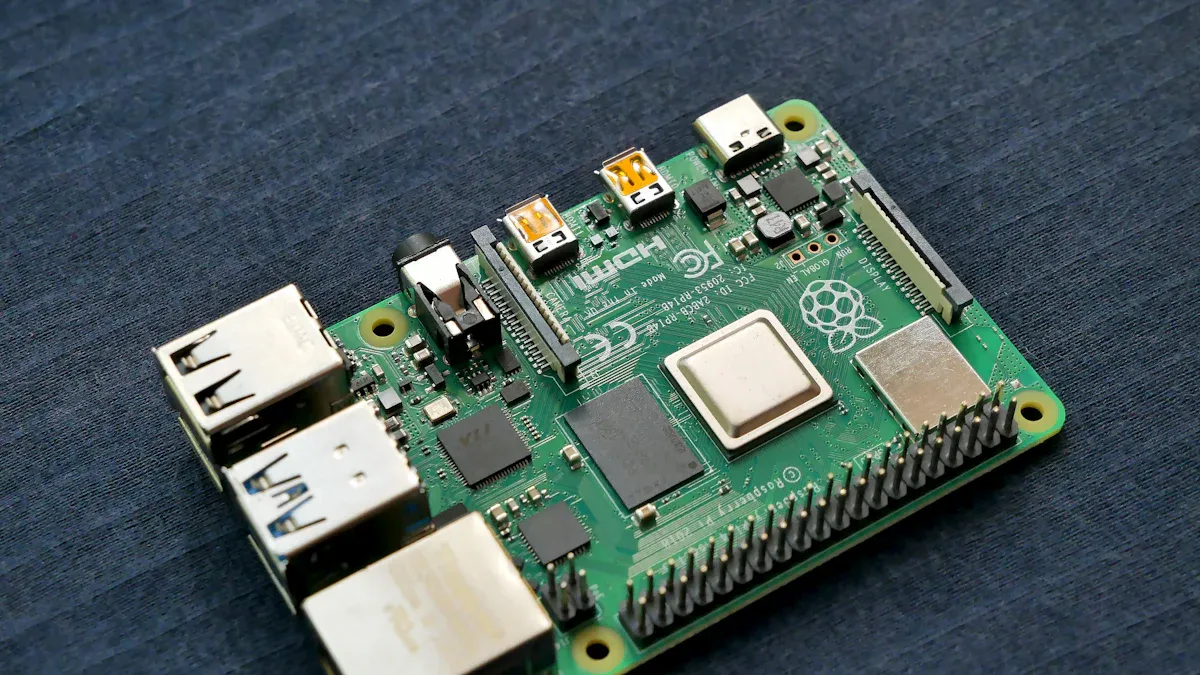

Mixed PCB assembly uses surface mount technology (SMT) and through-hole technology (THT) together. This method combines the best features of both to make printed circuit boards that work well and fit different needs.

Overview of SMT Technology

SMT changed how PCBs are made by placing parts directly on the board's surface. This skips drilling holes, making it quicker and easier. SMT parts are tiny, allowing for smaller and more packed designs. Machines handle the assembly, saving time and reducing mistakes, which makes devices more reliable.

Performance Metric | Description |

|---|---|

SMT boosts efficiency with smaller designs and more parts in less space. | |

Signal Distortion | Shorter paths mean less signal distortion and better performance. |

Production Speed | Machines speed up production and lower mistakes, improving efficiency. |

Circuit Density | Tiny parts allow tighter circuits, making smaller gadgets possible. |

Reliability and Performance | Shorter paths and less interference make devices work better and last longer. |

Overview of THT Technology

THT, or through-hole technology, places parts into drilled holes on the board. This creates strong connections, perfect for parts needing strength and durability. THT works well for things like connectors and transformers that handle stress or high power.

How Mixed PCB Assembly Combines SMT and THT

Mixed PCB assembly blends SMT and THT for better performance and flexibility. SMT handles small, dense parts, while THT supports bigger, stronger ones. Together, they make boards that are precise, reliable, and versatile. For instance, SMT can manage signal circuits, and THT can handle power parts. This mix meets the needs of today’s electronics.

Key Aspect | Description |

|---|---|

Includes planning, designing, making, and adding parts to the board. | |

Testing and Quality Assurance | Uses tests like optical checks and environmental tests to ensure quality. |

Design for Assembly (DFA) | Makes production easier and cheaper by planning for assembly during design. |

Key Benefits of Mixed PCB Assembly

Enhanced Reliability and Durability

Mixed PCB assembly improves reliability by using both SMT and THT. SMT parts are placed precisely, lowering assembly mistakes. THT creates strong connections, making boards tougher under pressure. This mix reduces failures, even in tough places like cars or airplanes.

Tests prove these benefits. Aging tests predict how long PCBs will last. Stress tests find weak spots early. These tests help improve designs and materials, ensuring boards work well over time. Using both SMT and THT gives a mix of accuracy and strength, making products more reliable.

Key Aspect | Description |

|---|---|

Speeds up aging to estimate how long PCBs will last. | |

Identify Weaknesses | Finds design problems and material flaws under stress. |

Improve Design and Materials | Helps make better design and material choices for stronger boards. |

Early Detection of Weaknesses | Spots problems early so fixes can be made quickly. |

Greater Design Flexibility

Using both SMT and THT allows flexible designs. SMT helps make small, dense layouts. THT works for bigger parts like connectors. This mix lets you create boards for many uses, from small gadgets to heavy machines.

During design, DFM methods make the process easier. DFM cuts down parts and speeds up assembly, saving time and money. SMT parts also align themselves, making designs more flexible and consistent across products.

Benefit | Description |

|---|---|

DFM reduces parts and time, making production easier. | |

Component Selection | Self-aligning parts simplify designs and reduce differences in products. |

Optimized Performance and Precision

Mixed PCB assembly improves performance by using SMT and THT strengths. SMT shortens signal paths, cutting distortion and boosting efficiency. THT ensures strong connections for high-power parts, improving precision.

For example, tests on NVIDIA A100 SXM chips showed hybrid assembly's benefits. These tests revealed faster operations and less data conversion, increasing efficiency. This precision makes hybrid assembly great for tasks needing high power and accuracy.

Power Consumption: Tracks energy use in watts.

Voltage: Measures electrical potential.

Current: Checks power usage and load.

Efficiency: Shows how well input power becomes output power.

Cost-Effectiveness in Production

Combining SMT and THT lowers production costs. SMT's automation speeds up production, while THT reduces waste and rework. Together, they make manufacturing faster and cheaper.

Cost studies show mixed PCB assembly saves money. By producing more while keeping quality high, businesses save without losing performance. This makes hybrid assembly a smart choice for better profits.

Benefit | Description |

|---|---|

Combining SMT and THT cuts production expenses. | |

Optimized Production Volume | Faster production reduces assembly time. |

Enhanced Reliability | High quality is maintained while lowering costs. |

Versatility in Applications

Mixed PCB assembly works for many industries. SMT's small designs and THT's strong connections fit aerospace, medical, and electronics needs. This flexibility helps meet different industry demands.

For instance, aerospace uses mixed assembly for reliable systems. Medical devices need diverse parts, and electronics benefit from better designs. This shows how hybrid assembly fits modern technology needs.

Application Area | Description |

|---|---|

Aerospace | Uses mixed assembly for reliable, high-performing systems. |

Medical Devices | Combines parts for complex medical tools. |

Consumer Electronics | Improves everyday devices with better designs and efficiency. |

Applications of Mixed PCB Assembly

Consumer Electronics

Mixed PCB assembly is important for making consumer electronics. It is used in gadgets like smartphones, tablets, and smartwatches. These devices need to be small, reliable, and do many tasks. By using SMT and THT together, manufacturers meet these needs. SMT makes tiny parts possible, while THT adds strength for connectors.

The demand for consumer electronics is growing fast. The iPhone changed how devices are designed, making them smaller and smarter. Now, people prefer portable gadgets over big computers. This trend increases the use of mixed PCB assembly to meet new needs. The market is expected to grow from $15 billion in 2023 to $20 billion by 2032. IoT devices and new packaging methods also boost this growth.

📈 Tip: Mixed assembly helps companies make high-quality gadgets while saving money.

Automotive Industry

Mixed PCB assembly is key in making car electronics reliable. Modern cars use advanced systems for safety, navigation, and entertainment. SMT allows small designs for sensors, while THT ensures strong connections for high-power parts like transformers.

Car electronics must handle tough conditions like heat and vibrations. Mixed assembly makes boards stronger, so they work well under stress. It also supports features like self-driving and electric car systems.

🚗 Note: Mixed PCB assembly helps meet the strict demands of car electronics.

Medical Devices

Medical devices need to be precise, reliable, and meet strict rules. Mixed PCB assembly combines SMT for small designs and THT for strong connections. This method is used in pacemakers, scanners, and imaging tools.

Certifications prove the quality of medical PCBs. The FDA checks manufacturing, and ISO 9001 ensures good design. IPC-A-600 and IPC-6012 class 3 confirm high-quality boards. ISO 13485 focuses on safety, and IEC 60601 ensures clinical standards. These rules make sure medical PCBs are safe and effective.

🩺 Tip: Mixed assembly ensures medical devices are accurate and long-lasting.

Telecommunications Equipment

Telecom devices depend on mixed PCB assembly for better signals and power use. SMT allows dense designs for parts like amplifiers. THT adds strength for connectors and power modules.

This mix is used in routers, base stations, and satellites. It improves signal quality, reduces interference, and ensures reliable performance. As faster networks are needed, mixed PCB assembly becomes more important.

📡 Note: Mixed PCB assembly ensures telecom devices work reliably and efficiently.

LT CIRCUIT’s Expertise in Mixed PCB Assembly

Advanced Manufacturing Capabilities

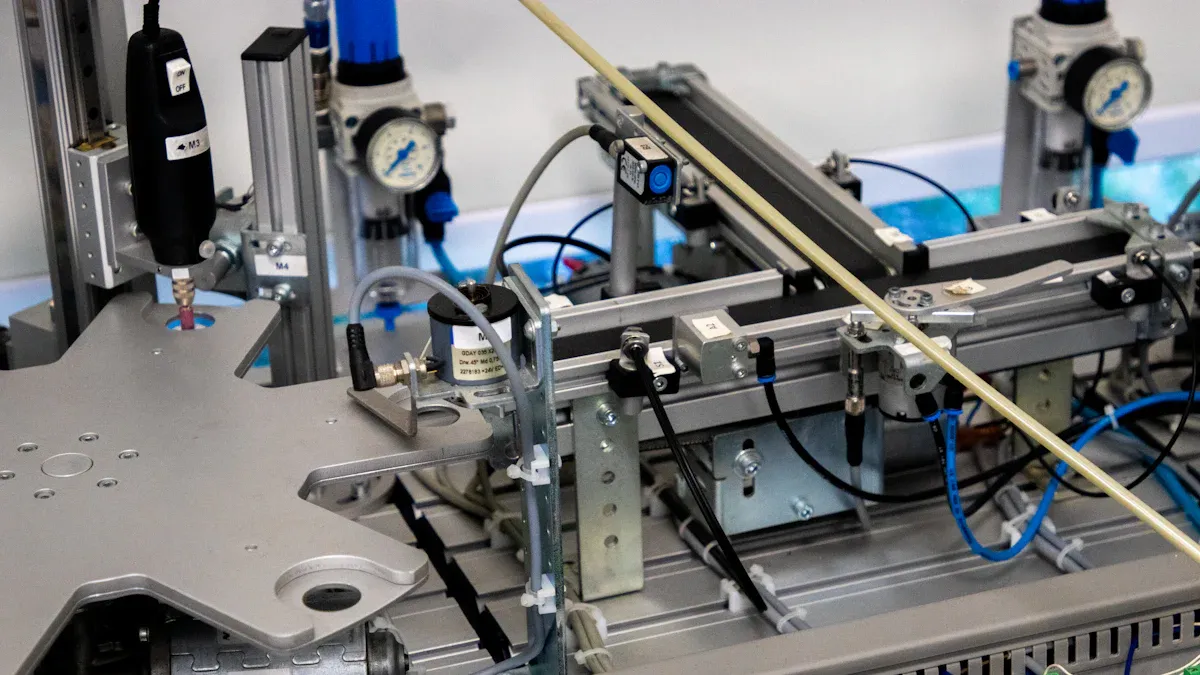

LT CIRCUIT uses modern tools for mixed pcb assembly. Their advanced machines ensure accuracy and fast production. Automated systems handle both SMT and THT smoothly. This reduces mistakes and speeds up the process.

Their factories can manage complex designs with ease. They create boards with dense circuits and strong parts. Innovation is their priority, so every board meets today’s industry needs.

🚀 Tip: Modern tools help make boards faster without losing quality.

High-Quality PCB Solutions

LT CIRCUIT focuses on making high-quality boards. Their boards are strong and work well, even in tough conditions. They use top materials and strict tests to ensure great performance.

Their mixed assembly combines SMT for small designs and THT for strong parts. This mix makes products more reliable. Whether for gadgets or cars, LT CIRCUIT delivers dependable boards.

Customization and Testing Services

LT CIRCUIT lets you customize boards to fit your needs. You can pick solder mask colors, finishes, and lamination types. Their team works with you to design the perfect board.

Testing ensures every board works as it should. Tests like flying probe and E-tests find problems early. These checks make boards more reliable and prevent failures. LT CIRCUIT delivers boards you can trust.

🛠️ Note: Custom options and tests help create reliable, custom boards.

Design and Manufacturing Considerations for Mixed Assembly

Component Placement Strategies

Placing parts correctly is key in mixed PCB assembly. SMT parts work best in tight spaces needing small layouts. THT parts are better for areas needing strength, like connectors. For example, transformers need THT because they require strong bonds.

Automated tools help place parts with great accuracy. These tools reduce mistakes and make work faster. AI and machine learning improve this by spotting patterns humans might miss. Keeping testing tools in good shape ensures they work well. Training testers on new tech also keeps results accurate.

💡 Tip: Use clear testing rules to check part placement carefully.

Layout Types for Mixed Assembly

The PCB layout affects how well it works and is made. Mixed assembly needs careful planning to fit SMT and THT parts together. SMT fits dense layouts for small designs. THT needs space for drilled holes and bigger parts.

Try different setups to meet customer needs. This makes production flexible and avoids last-minute changes. Creating ready-to-use data helps adjust to different orders without losing quality.

📐 Note: A good layout saves time and makes products more reliable.

Importance of DFM and DFT Processes

DFM and DFT are important for mixed PCB assembly. DFM makes designs simple, cutting costs and waste. This speeds up production and gets products to market faster. DFT adds testing steps to designs, lowering the chance of failures.

Using DFM ideas improves supplier teamwork and lowers costs. For example, simpler layouts make manufacturing easier and improve quality. DFT, like automated tests, finds problems early, making products more reliable.

🛠️ Tip: Keep designs simple to balance making and testing for best results.

Challenges and Solutions in Mixed PCB Assembly

Managing Complexity in Mixed Assembly

Mixed PCB assembly uses both SMT and THT technologies. This can make the process tricky. SMT parts are small and need precise placement. THT parts need drilled holes and manual soldering. Mixing these methods can lead to mistakes during assembly.

Machines help make this easier. Automated tools place SMT parts accurately. Robotic arms help with soldering THT components. Using Design for Assembly (DFA) ideas also helps. Planning layouts for both methods reduces problems. Good teamwork between design and production teams keeps things running smoothly.

🛠️ Tip: Automated tools and DFA ideas make assembly easier.

Heat Management Techniques

Heat can harm parts during assembly. SMT parts are tiny and can’t handle high heat. THT parts often deal with more power and create heat. Without good heat control, parts can break or stop working.

Thermal vias and heat sinks help manage heat. Thermal vias move heat away from sensitive areas. Heat sinks spread heat out to keep parts cool. Using materials that handle heat well also helps. During soldering, temperature settings protect parts from overheating.

🌡️ Note: Managing heat keeps your PCB safe and working longer.

Ensuring Quality and Consistency

Quality checks are very important in mixed PCB assembly. Parts must be placed, soldered, and tested correctly. Without regular checks, mistakes can cause the final product to fail.

Different inspections improve quality. Material checks ensure parts are good before assembly. Solder Paste Inspection (SPI) checks solder joints. Automated Optical Inspection (AOI) finds placement mistakes. X-ray inspections spot hidden problems. Functional tests make sure the PCB works as it should.

Purpose | |

|---|---|

Material Checks | Makes sure parts are good before assembly starts. |

Solder Paste Inspection (SPI) | Checks solder paste for strong connections. |

Automated Optical Inspection (AOI) | Finds mistakes in part placement and soldering. |

X-Ray Inspection | Spots hidden problems in solder joints. |

In-Circuit Testing (ICT) | Tests electrical features to find issues. |

Functional Testing | Confirms the PCB works correctly under real conditions. |

✅ Tip: Regular checks and tests keep your PCB high-quality and reliable.

Mixed PCB assembly combines SMT and THT for great results. This method improves reliability, allows flexible designs, and boosts performance. It works well for many industries.

Main Benefits:

Faster production and easier teamwork.

Quick testing and more room for new ideas.

Technology | Performance Benefits | Key Features | |

|---|---|---|---|

THT | Very strong in harsh environments | Handles high power well | Strong connections, fewer solder problems |

SMT | Reliable with small parts | Best for fast signal transfer | Compact layouts, shorter signal paths |

LT CIRCUIT provides top-quality, affordable solutions for today’s electronics. Using mixed assembly helps you keep up with advanced technology needs.

FAQ

What is the main advantage of mixed PCB assembly?

Mixed PCB assembly uses both SMT and THT strengths. This makes boards more reliable, flexible, and better for many uses.

Can mixed PCB assembly reduce production costs?

Yes, it can save money. SMT works fast with machines, and THT reduces waste. Together, they make production quicker and cheaper.

Which industries benefit most from mixed PCB assembly?

Industries like cars, medical tools, gadgets, and telecom gain a lot. Mixed assembly gives them strong, precise, and flexible designs.

💡 Tip: Mixed PCB assembly keeps up with changing needs, making it a smart choice for the future.

See Also

Utilizing Horizontal Copper Sinking Technology in PCB Manufacturing

Addressing PCB Design Challenges for SMT Processing Needs

Advantages of LDI Exposure Machines for HDI PCB Circuits