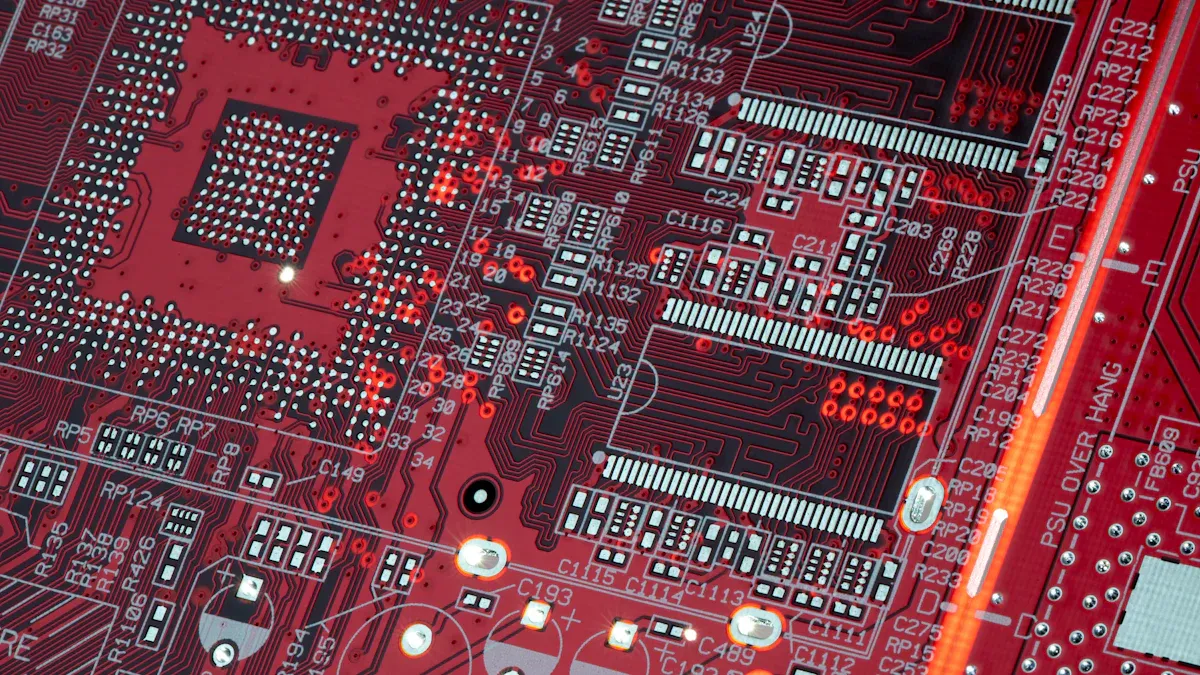

What Are the Best Materials for High-Speed PCB Designs

Choosing the right material is key for high-speed PCBs. Materials must keep signals strong, reduce losses, and handle high frequencies well. For instance, low dielectric constant (Dk) lowers signal loss. Low dielectric loss (Df) keeps signals clear. Materials with good heat transfer also help cool the PCB, making it work better.

Key Takeaways

Pick materials with low dielectric constant to keep signals strong.

Use materials with low loss tangent to avoid energy loss.

Make sure materials are stable in heat and tough conditions.

Test PCB designs with simulations to check for problems early.

Characteristics of High-Speed PCBs and Material Selection

What Defines a High-Speed PCB?

A high-speed PCB handles fast data and high-frequency signals. These PCBs are used where strong signals and good performance matter. They reduce signal loss and block interference effectively. Trace spacing and height above the plane help lower crosstalk. For example, wider gaps between traces reduce unwanted signal mixing. This improves how the PCB works. High-speed PCBs need special materials and careful designs to perform well.

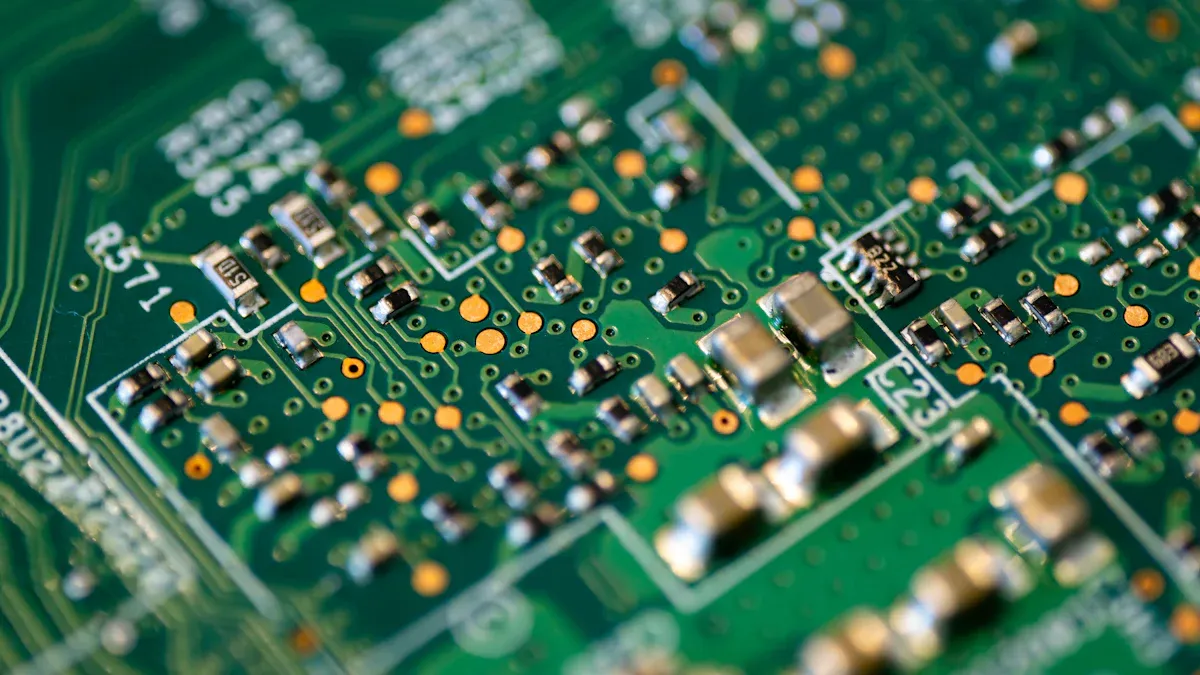

Why Material Selection is Crucial for High-Speed Designs

The materials in a high-speed PCB affect how it works. Properties like dielectric constant and loss tangent are very important. A steady dielectric constant keeps signal speed consistent. A low loss tangent reduces signal weakening. For example, PTFE is great for its electrical properties. FR-4 is strong and affordable. Surface finishes like ENIG or silver reduce signal reflections. Picking the right material helps the PCB handle fast signals better.

LT CIRCUIT’s Approach to High-Speed PCB Material Selection

LT CIRCUIT carefully chooses materials for high-speed PCBs. They focus on routing and layer stacks to improve signals. For example, they use 8-layer stacks to cut noise and boost EMC. Signal layers are placed between ground and power planes for stability. They review designs to fix routing problems and improve signal speed. This attention ensures LT CIRCUIT’s PCBs meet high-speed needs.

Key Properties of Materials for High-Speed PCBs

Low-Loss Tangent and Its Impact on Signal Integrity

When making a high-speed PCB, pick materials with a low-loss tangent. This feature helps signals stay strong by reducing energy loss. Strong signals are important for things like 5G networks and radar systems.

Here’s how low-loss tangent materials help:

5G networks use them to keep signals clear and strong.

Fast digital circuits avoid signal mixing for better data transfer.

Radar systems in cars and planes work better with these materials.

Space communication systems save power and improve signal quality.

RF tools need stable materials for accurate measurements.

Using low-loss tangent materials makes your PCB work well in high-frequency setups.

Tip: PTFE laminates are great for their low-loss tangent and electrical strength.

Dielectric Constant and Its Role in High-Frequency Performance

The dielectric constant (Dk) shows how well a PCB handles fast signals. A lower Dk keeps signals moving quickly and clearly. Materials with steady Dk values are best for high-speed designs.

Important facts about Dk:

Dk depends on the resin and how the material is made.

Low Dk values stop signal delays in fast circuits.

Changing Dk can affect signal speed and impedance.

Flat Dk values across frequencies improve PCB performance.

Choose materials with stable Dk for reliable high-speed operation.

Note: Rogers 4350B is a top choice for its low and steady Dk.

Thermal and Mechanical Stability for Reliable Operation

Thermal and mechanical stability keep high-speed PCBs working for a long time. Heat and stress can damage materials, causing problems in tough places like cars or planes.

The table below explains why stability matters:

Problem | Effect on PCB |

|---|---|

Heat damage weakens the resin, lowering strength. | PCBs may fail under stress. |

Tests show FR4-II Cu handles heat better than FR4-I Cu. | Picking heat-stable materials improves PCB durability. |

Knowing how materials break down helps choose better ones. | PCBs last longer in tough environments. |

Pick materials with good thermal and mechanical traits to keep your PCB reliable.

Tip: Use materials with high glass transition temperatures (Tg) and low thermal expansion (CTE) for better heat resistance.

Factors That Affect Material Choice for High-Speed PCBs

Frequency and Signal Speed Needs

When making a high-speed PCB, think about frequency and signal speed. Materials with low dielectric constant (Dk) and dissipation factor (Df) work best. Low Dk helps signals move faster and keeps impedance steady. Low Df reduces signal loss by stopping energy from turning into heat.

For example, car radar systems and 5G networks need materials that keep signals strong at high frequencies. These uses require accuracy, and small changes in Dk or Df can hurt performance. Picking materials with steady electrical traits helps your PCB handle fast data without losing signal quality.

Tip: Use materials like PTFE or Rogers laminates. They have low Dk and Df for great high-speed results.

Balancing Signal Quality and Cost

Cost is important when picking materials, especially for performance and budget. High-end materials like PTFE or ceramic-filled laminates give great signal quality but cost more. Cheaper options like FR-4 are good for medium-speed designs.

Think about what your design needs. If it needs high-frequency work, spending more on better materials is worth it. But for simpler designs, regular materials can balance cost and performance well.

Note: LT CIRCUIT offers PCB options that fit both speed needs and budgets. This ensures you get good value for your money.

Environmental and Manufacturing Factors

Environment and manufacturing also affect material choice. High-speed PCBs often face tough conditions like heat or humidity. Materials with good heat stability and low moisture absorption last longer in these settings.

Manufacturing is just as important. Some advanced materials need special handling, which can make production harder. For example, PTFE laminates need careful work because of their unique features. Choose materials that match your factory's abilities and the environment they’ll be used in.

Tip: Pick materials with high glass transition temperatures (Tg) and low thermal expansion (CTE) for better durability in harsh places.

Evaluating Material Performance Metrics for High-Speed PCBs

Understanding Insertion Loss and Its Implications

Insertion loss shows how much signal strength is lost in a PCB. High-speed PCBs need materials that keep this loss low. If insertion loss rises, signals get weaker. This hurts performance in things like 5G networks and radar systems.

To lower insertion loss, pick materials with low dissipation factors. These materials stop energy from turning into heat, keeping signals strong. For example, PTFE laminates work well for high-frequency circuits.

Tip: Use short traces and smooth copper to reduce insertion loss.

The Role of Return Loss in Impedance Matching

Return loss measures how well a PCB matches impedance. Bad impedance matching causes signal reflections, which harm performance. This is very important for PCBs working above 10 GHz.

Things that affect return loss:

Changes in dielectric constants can hurt impedance matching.

Signal reflections and crosstalk weaken signal quality.

Designing for low return loss improves impedance matching and reduces disruptions. Materials with steady dielectric properties help achieve this.

Tip: Use controlled impedance traces to lower return loss and reflections.

Importance of Post-Layout Simulations for Validation

Post-layout simulations check how a PCB will work after it’s made. These simulations use the real layout, including traces and parts, for accuracy.

Key Features of Post-Layout Simulation | Benefits of Post-Layout Simulation |

|---|---|

Uses actual PCB layout. | Predicts accurate performance. |

Includes parasitic effects. | Finds parasitic problems. |

Focuses on overall PCB performance. | Verifies signal and power integrity. |

Ensures design meets requirements. | Checks EMC compliance. |

Simulations find issues like crosstalk on long traces. They also ensure the PCB meets EMC rules. Orthogonal routing reduces coupling, improving signal quality.

Tip: Always simulate key high-speed signals before making the PCB.

Choosing the right materials makes high-speed PCBs more reliable. Important traits like dielectric constant and heat transfer keep signals strong and durable.

Property | What It Does |

|---|---|

Dielectric Constant | Affects how signals move and reduces signal loss. |

Thermal Conductivity | Helps spread heat and manage temperature. |

Glass Transition Temperature (Tg) | Shows how materials handle heat without breaking. |

Good materials stop problems like resin cracks and water damage. This helps PCBs last longer. Testing designs after layout finds and fixes issues. LT CIRCUIT provides custom solutions for tough projects.

FAQ

What is the most important property for high-speed PCB materials?

Low dielectric constant and loss tangent are key. They keep signals clear, reduce energy loss, and boost performance in fast circuits.

Can FR-4 be used for high-speed PCB designs?

Yes, FR-4 is fine for medium-speed circuits. For faster signals, use materials like PTFE or Rogers laminates for better signal quality.

How do post-layout simulations help in high-speed PCB design?

Simulations check performance, find problems like crosstalk, and ensure EMC rules are met. They make sure your PCB works well at high speeds.

See Also

Understanding High-Speed PCBs And Their Importance

The Importance Of High-Speed PCB Design Explained

Key Guidelines For Designing Heavy Copper PCBs