Exploring BT PCB and Its Essential Characteristics

Bismaleimide triazine PCB (BT PCB) gives you high thermal stability, strong electrical insulation, and impressive mechanical strength.

You find BT PCB important for advanced electronics because of its reliable properties.

Definition | Classification |

|---|---|

Bismaleimide triazine PCB (BT PCB) is a high-performance circuit board known for its exceptional thermal stability and mechanical strength. | BT PCBs are classified among high-performance circuit board materials due to their excellent mechanical strength, heat resistance, and reliability in harsh environments such as automotive, aerospace, and telecommunications. |

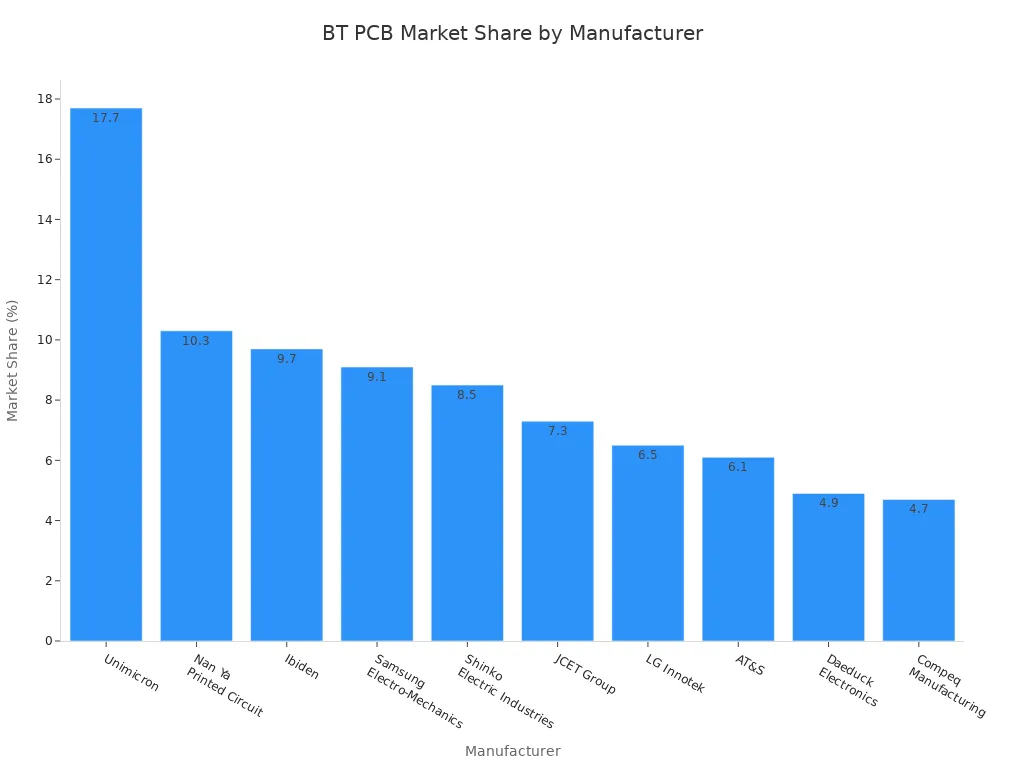

The PCB market for BT PCB is expected to grow rapidly, with a projected compound annual growth rate of 13.4% from 2024 to 2031.

You see BT PCB used in many high-reliability devices because its properties support demanding applications.

Key Takeaways

BT PCB offers high thermal stability, making it ideal for advanced electronics that operate in extreme temperatures.

Its superior electrical properties ensure minimal signal loss, enhancing performance in high-speed applications.

BT PCB's mechanical strength provides durability against physical stress, ensuring reliability in demanding environments like automotive and aerospace.

BT PCB Features

Thermal Stability

You rely on BT PCB for its high thermal stability, which sets it apart from many other printed circuit boards. This high-performance substrate can withstand extreme temperatures, making it a top choice for high-reliability and heat resistance in advanced electronics. When you use BT PCB, you benefit from a material that resists thermal expansion and maintains its shape and function even during rapid temperature changes.

Here’s how BT PCB compares to other PCB materials:

Metric | BT PCB (ITEQ IT-180) | Other PCB Materials (FR4, Polyimide) |

|---|---|---|

Glass Transition Temperature (Tg) | Higher | Lower |

Mechanical Strength | Superior | Varies |

Moisture Absorption | Lower | Higher in some cases |

Thermal Conductivity | Enhanced | Moderate to low |

You see that BT PCB offers a glass transition temperature much higher than standard FR-4, which means it can operate at temperatures up to ~200°C. This property ensures reliability under harsh conditions, especially in environments where thermal management is critical. You also notice that BT PCB absorbs less moisture, which helps maintain its performance over time.

Tip: BT PCB’s enhanced thermal conductivity and reduced dimensional expansion help you achieve better thermal management and stability in high-frequency applications.

When you choose BT PCB, you gain:

Improved reliability in extreme environments

Reduced dimensional expansion at high temperatures

Enhanced stability of plated through holes

Better thermal stress resistance in temperature cycling applications

These properties make BT PCB the preferred option for devices that demand high-reliability and heat resistance, such as automotive and aerospace electronics.

Electrical Properties

You need your PCB to deliver superior electrical performance, especially when working with high-speed signal transmission and high-frequency applications. BT PCB stands out because it maintains excellent electrical insulation, even under extreme conditions. This ensures that your circuits remain stable and efficient, reducing the risk of signal loss or interference.

Let’s compare some key electrical properties:

Property | BT-Epoxy | FR-4 |

|---|---|---|

Coefficient of Thermal Expansion (CTE) | Lower than FR-4 | Higher than BT-Epoxy |

Glass Transition Temperature (TG) | 180 °C | Lower than 180 °C |

Decomposition Temperature | 325 °C | Lower than 325 °C |

Moisture Absorption | Low | Higher |

High | Moderate |

You benefit from BT PCB’s low dielectric constant (3.38–3.50 at 100 kHz) and low dielectric loss (0.0102–0.0107 at 100 kHz). These properties support high-speed signal transmission and minimize signal attenuation, which is essential for modern communication and computing devices.

When you design high-frequency circuits, you should:

Keep trace lengths short and avoid sharp bends

Minimize the number of vias to reduce capacitance and inductance

Route differential pairs closely together for consistent impedance

Use uniform trace width and spacing to control impedance

Select low-loss materials for better signal integrity

BT PCB’s electrical properties make it ideal for high-frequency applications, where signal clarity and reliability matter most.

Mechanical Strength

You expect your PCB to handle physical stress without losing performance. BT PCB delivers outstanding mechanical strength, which is vital for devices exposed to vibration, shock, or repeated thermal cycling. This strength comes from its unique resin system, which provides both rigidity and flexibility where needed.

Here’s how BT PCB compares to other substrates:

Material | Mechanical Durability | Thermal Stability | Moisture Absorption |

|---|---|---|---|

BT PCB | Better | Improved | Lower |

FR-4 | Moderate | Standard | Higher |

Polyimide | Best | Excellent | Lower |

You see that BT PCB offers a Young’s modulus of 4.06 GPa, which means it resists bending and deformation. This property, combined with its low moisture absorption, ensures reliability under harsh conditions and supports lead-free soldering processes.

Note: BT PCB’s mechanical durability and thermal stability make it a smart choice for applications that require both strength and long-term reliability.

You find BT PCB used in automotive, aerospace, and telecommunications because its mechanical and thermal stability and mechanical strength support demanding environments. Its properties ensure your devices last longer and perform better, even when exposed to challenging conditions.

Applications and LT CIRCUIT Solutions

Industry Uses

You see bt pcb used in many advanced industries. Telecommunications companies rely on bt-epoxy for high-frequency performance and thermal stability. Advanced computing systems need minimal signal loss and strong thermal stability, which bt pcb delivers. RF modules and 5G technology also depend on bt-epoxy for high-speed performance and reliable signal transmission. The table below shows how different sectors use bt pcb and their specific requirements:

Industry Sector | Specific Requirements |

|---|---|

Telecommunications | High-frequency performance, thermal stability |

Advanced Computing Systems | Minimal signal loss, thermal stability |

RF Modules | High-frequency performance, minimal signal loss |

5G Technology | High-speed performance, minimal signal loss |

Chip manufacturers use bt-epoxy to support miniaturization and increased chip density. You benefit from bt pcb’s ability to withstand thermal cycling, moisture, vibration, and mechanical stress. These properties help maintain electrical integrity and efficient signal transmission.

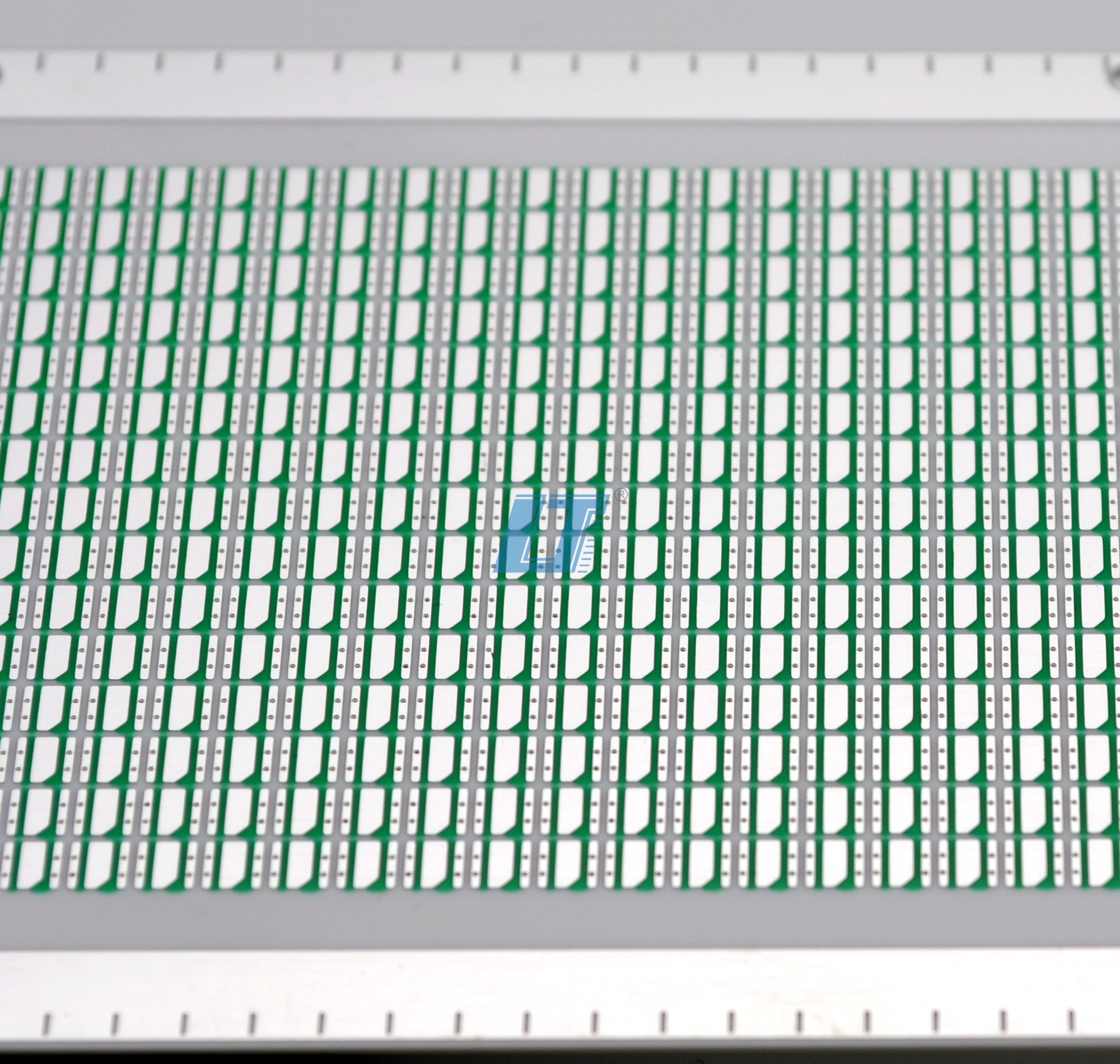

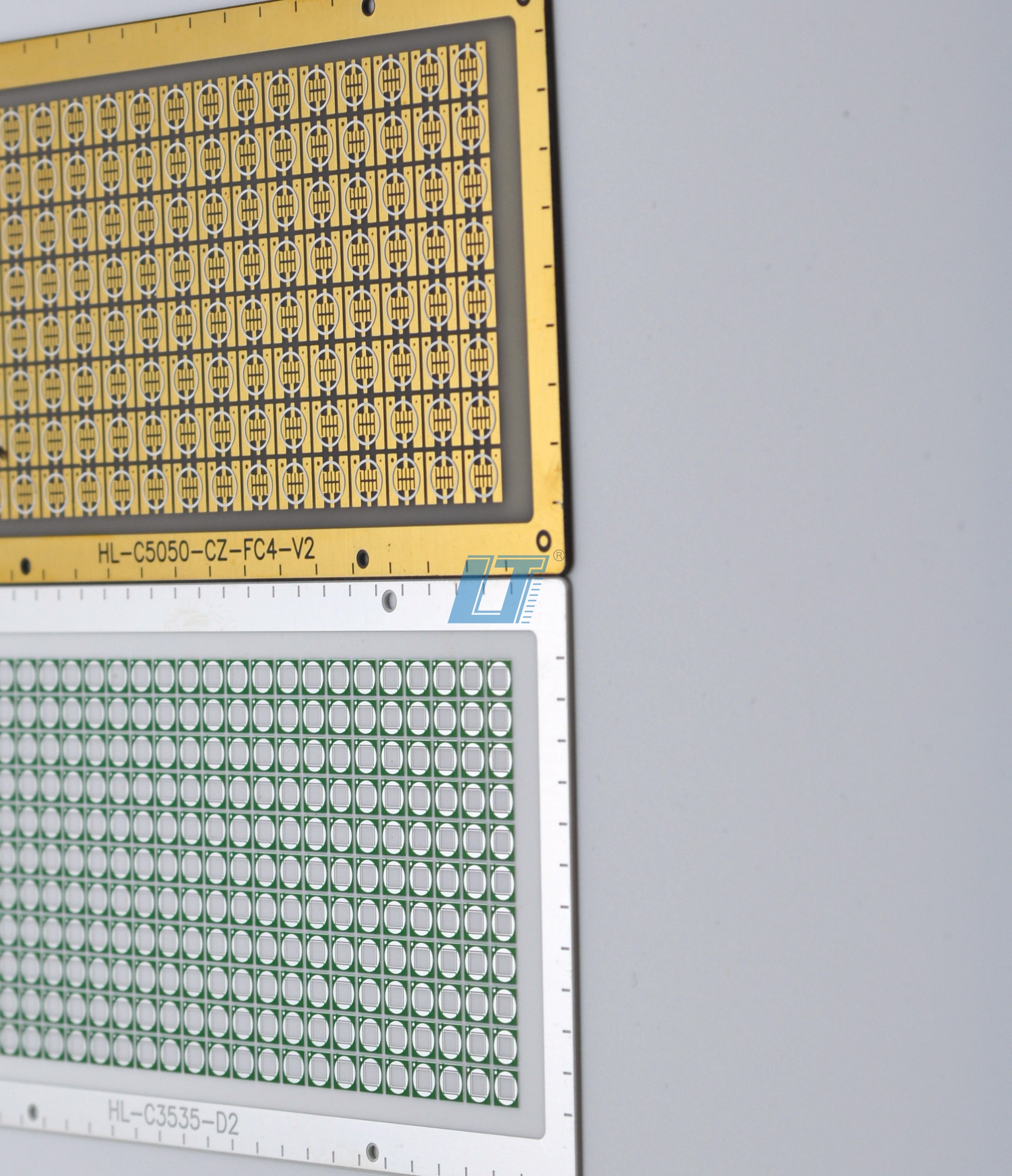

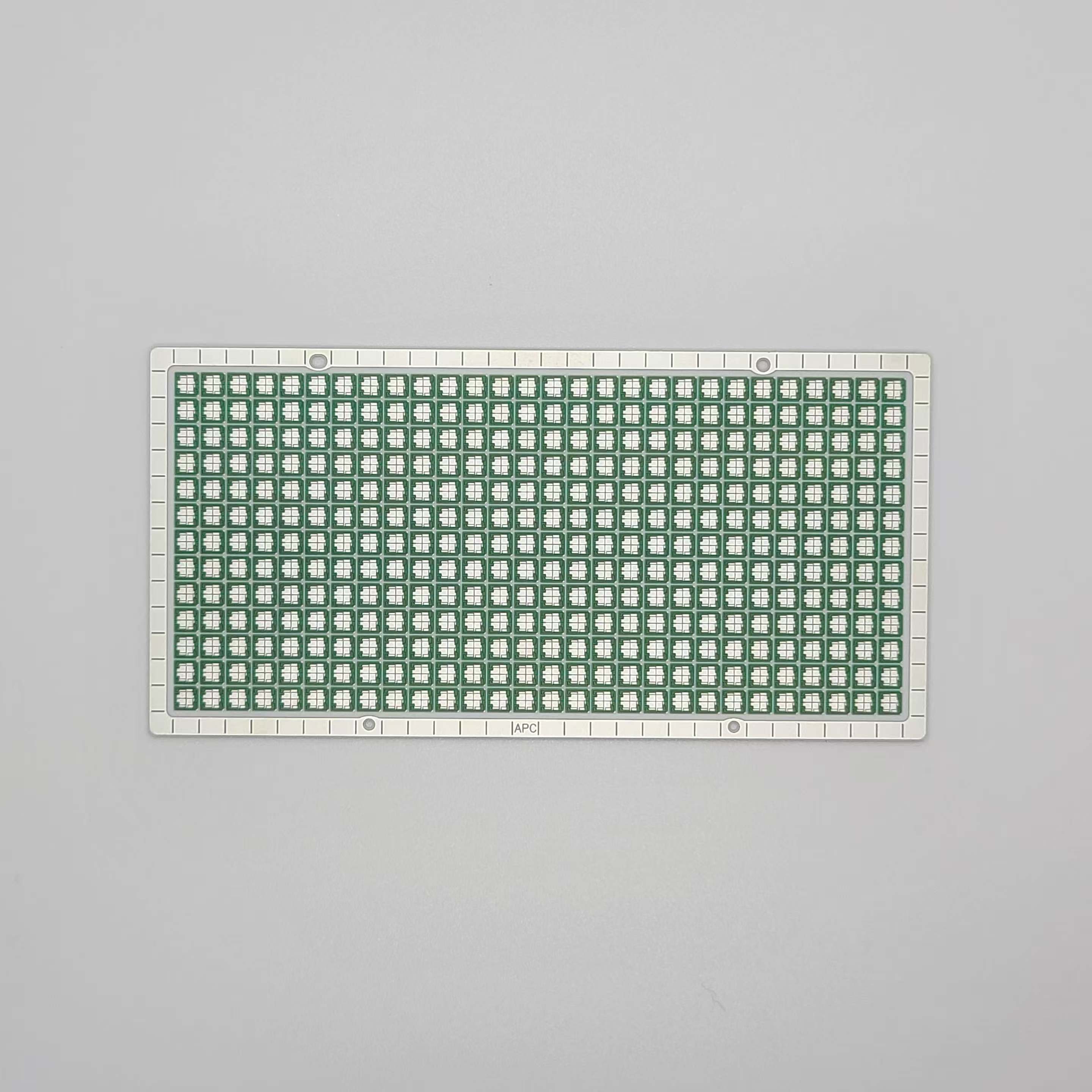

LT CIRCUIT Expertise

You want a partner who understands bt pcb and bt-epoxy. LT CIRCUIT leads in advanced pcb solutions, offering innovations in bt-epoxy materials that improve water resistance, strength, and electrical performance. LT CIRCUIT uses new manufacturing techniques to enhance the quality of bt pcb for computers, 5G, and mobile devices. You get durable bt-epoxy that resists harsh chemicals and water, extending the lifespan of your pcb in automotive and aerospace applications.

LT CIRCUIT ensures quality through strict inspections and certifications. You benefit from:

Quality Assurance Method | Description |

|---|---|

Class II and Class III Inspection | Adherence to stringent industry standards for high-reliability applications. |

X-Ray Inspection | Advanced technology for thorough inspection of hidden solder joints and internal structures. |

RF Testing | Specialized testing for radio-frequency applications. |

Automated Optical Inspection | Detects defects such as solder bridges, missing components, and misalignments. |

Functionality Testing | Comprehensive tests for electrical performance, signal integrity, and overall functionality. |

Certifications | ITAR Registered, IPC Member, RoHS Compliant, UL Approved, AS9100D/ISO9001:2015 Certified, etc. |

Manufacturing Considerations

You face challenges when manufacturing bt pcb for high-frequency applications. Common issues include transmission line effects, signal integrity problems, and electromagnetic interference. You need specialized design and processing methods to overcome these challenges. LT CIRCUIT uses advanced technologies for bt-epoxy customization:

Minimum hole size of 0.2mm for high-density circuit designs

Maximum operating temperature of 150°C for demanding environments

Robust ceramic base for thermal stability and electrical insulation

ENIG surface finish for excellent solderability and corrosion resistance

Ideal for high-density and high-frequency microelectronics

LT CIRCUIT meets important certifications and quality standards, including US UL, ISO9001, TS16949, and CQC. You can trust LT CIRCUIT to deliver reliable bt pcb with superior bt-epoxy properties for your most critical projects.

You choose bt pcb for advanced electronics because its properties support high reliability and performance. When selecting bt pcb, you consider these factors:

Design affects signal integrity.

Manufacturing process determines pcb quality.

Environmental conditions test bt pcb stability.

Assembly ensures bt pcb reliability.

Testing confirms bt pcb performance.

LT CIRCUIT delivers high-quality bt pcb for your most demanding projects.

FAQ

What makes bismaleimide triazine pcb a high-performance substrate?

You get a high-performance substrate because bismaleimide triazine pcb offers high thermal stability and mechanical strength. These properties support reliability under harsh conditions and high-frequency applications.

How does bt pcb improve high-speed signal transmission?

You benefit from bt pcb’s superior electrical performance and low dielectric loss. This helps maintain signal clarity and conductivity, which is essential for high-speed signal transmission in advanced printed circuit boards.

Can you use bt-epoxy for lead-free soldering processes?

Yes, you can use bt-epoxy for lead-free soldering processes. Its high thermal stability and mechanical strength ensure reliability and thermal management during assembly.

See Also

Understanding PCB Printed Circuit Boards And Their Essentials

Essential Knowledge For Designing Multi-Layer PCB Layouts

Defining High-Speed PCBs And Their Unique Characteristics

Exploring Flexible PCBs And Their Important Uses

Diverse Applications Of Multilayer PCBs In Various Industries