Understanding BT Resin PCB Materials for Modern Electronics

BT resin PCB from LT CIRCUIT utilizes advanced BT resin to provide exceptional performance for today’s cutting-edge electronics. With BT resin PCB, you benefit from excellent thermal stability, superior mechanical strength, and minimal electrical loss, making it ideal for high-frequency and demanding environments. The table below highlights how BT resin PCB outperforms other PCB materials. LT CIRCUIT is dedicated to delivering innovative BT resin PCB solutions with unmatched quality and precision for your most challenging applications.

Property | BT Resin PCB | Other PCB Materials |

|---|---|---|

Thermal Stability | Excellent thermal stability | Moderate thermal stability |

Mechanical Strength | High strength and wear resistance | Lower strength |

Electrical Properties | Low dielectric constant and loss | Higher dielectric loss |

Application Suitability | High-frequency and harsh environments | General applications |

Key Takeaways

BT resin PCBs offer excellent thermal stability, making them ideal for high-frequency applications that generate heat.

These materials provide low dielectric loss, ensuring strong signal integrity and minimal interference in advanced electronics.

BT resin PCBs are mechanically robust, suitable for demanding environments like automotive and aerospace, ensuring reliability under stress.

BT Resin PCB Overview

Definition

You encounter BT resin as one of the most advanced pcb materials in modern electronics. BT resin stands for bisphenol-T epoxy, a thermoset resin that gives printed circuit boards outstanding performance. When you choose BT resin for pcb laminates, you get a material that resists high temperatures and chemical exposure. BT resin pcb materials support high-frequency signals and maintain stability in harsh environments. You see BT resin used in printed circuit boards for telecommunications, automotive, and aerospace applications. These pcb materials help you achieve reliable operation and long service life in demanding conditions.

Composition

BT resin pcb materials combine several chemical components to create durable pcb laminates. The structure of BT resin includes bisphenol-T monomers and epichlorohydrin, which acts as a cross-linking agent. You also find bismaleimide and cyanate ester in these pcb materials. The cyanate ester contains three cyano groups that trimerize, forming a strong triazine ring structure. This unique composition gives BT resin pcb laminates excellent thermal and electrical properties.

BT resin pcb materials use a blend of additives and reinforcements to improve performance. You benefit from modified BT resin for better fluidity and heat resistance. Carbon fiber and glass fiber serve as reinforcing agents, making pcb laminates stronger and stiffer. Thermal conductivity modifiers optimize heat dissipation, while the base BT resin ensures chemical stability.

Here is a table showing the main components and additives found in BT resin pcb materials:

Component/Additive Type | Description |

|---|---|

BT resin basic type | Basic BT resin with good high temperature performance and chemical stability. |

Modified BT resin | BT resin modified to improve fluidity, processability, and heat resistance. |

Reinforcing agents | Carbon fiber and glass fiber used to enhance strength and stiffness of BT resin. |

Thermal conductivity modifiers | Additives to optimize thermal conductive properties for specific applications. |

Electrical insulation properties | BT resins provide outstanding electrical insulation, ensuring reliability in electronic equipment. |

You rely on BT resin pcb materials when you need pcb laminates that deliver top performance in advanced printed circuit boards.

Key Properties

Thermal Stability

You need printed circuit boards that can handle high temperature resistance in demanding environments. BT resin PCB materials deliver this advantage. The glass transition temperature (TG) for BT resin ranges from 170°C to 200°C. This value stands higher than the TG of FR-4, which is about 130°C to 140°C. You get better high temperature resistance with BT resin than with standard FR-4 boards. Polyimide PCBs have an even higher TG, over 250°C, but BT resin still offers a strong balance between performance and cost.

BT resin PCBs have a glass transition temperature (TG) between 170–200°C, which is higher than FR-4's TG of around 130–140°C.

Polyimide PCBs have a TG of over 250°C, making them superior in thermal stability compared to both BT resin and FR-4.

In summary, BT resin offers better thermal stability than FR-4 but does not reach the levels of polyimide.

You can trust BT resin PCBs for high-frequency applications that generate heat. These boards maintain their structure and function even when exposed to high temperature resistance. This property ensures your devices stay reliable in telecommunications, automotive, and aerospace settings.

Tip: When you design for high-frequency applications, always consider the thermal stability of your PCB material. BT resin gives you a dependable option for environments where heat is a concern.

Electrical Performance

You want your electronic devices to transmit high-speed signals with minimal loss. BT resin PCB materials help you achieve this goal. The dielectric constant of BT resin PCB is 3.70 at 1 GHz. This low dielectric constant supports excellent signal integrity and reduces signal attenuation. Your circuits can handle high-frequency performance without interference or data loss.

The dielectric constant of BT resin PCB is 3.70 at 1 GHz.

This low dielectric constant contributes to excellent electrical properties.

It ensures signal integrity and minimizes signal attenuation in high-performance applications such as telecommunications and high-speed computing.

You also benefit from a low electrical loss (Df) value of 0.015. This means your signals remain strong and clear, even in complex, high-frequency applications. You can rely on BT resin PCBs to deliver consistent signal integrity in advanced devices.

Note: For applications that demand high-frequency performance, such as 5G networks or advanced computing, BT resin PCBs provide the electrical stability you need.

Mechanical Strength

You need your PCB to withstand physical stress, vibration, and shock. BT resin PCB materials offer excellent mechanical strength, making them ideal for rugged environments. The unique composition of BT resin, combined with reinforcing agents like glass fiber, gives your board the durability to support electronic components securely.

Advantage | Description |

|---|---|

The inherent strength and stiffness of BT substrate material provide mechanical support for electronic components, reducing the risk of damage due to vibration, shock, or mechanical stress. |

You can use BT resin PCBs in automotive, aerospace, and industrial applications where reliability matters most. The excellent mechanical strength ensures your circuits remain intact and operational, even under harsh conditions.

BT resin PCBs deliver excellent mechanical strength for demanding environments.

You can count on these boards for applications that require both high temperature resistance and mechanical durability.

Reminder: When you select a PCB for rugged or mobile devices, always check for excellent mechanical strength. BT resin PCBs give you the confidence to build products that last.

BT Resin PCB vs Other Materials

FR-4 Comparison

You often see FR-4 as the standard material for printed circuit boards. FR-4 works well for general electronics, but BT resin PCB offers you several advantages. When you need better thermal properties and lower moisture absorption, BT resin stands out. The table below shows how BT resin PCB compares to FR-4:

Property | BT Epoxy | FR-4 |

|---|---|---|

Thermal Properties | Better thermal properties | Standard thermal properties |

Moisture Absorption | Low moisture absorption | Higher moisture absorption |

Common Applications | Automotive, mobile devices | General electronics |

You should also consider cost.

FR-4 is more cost-effective and widely used for general applications.

BT resin PCBs are generally more expensive than FR-4 PCBs due to their specialized formulation and performance benefits.

When you design thin PCB boards, you notice the dielectric constant for thin pcb designs is lower in BT resin, which helps with signal integrity in high-frequency circuits.

Polyimide Comparison

You may choose polyimide for its high thermal resistance, but BT resin PCB gives you unique benefits in high-frequency applications.

BT epoxy resins provide high thermal resistance, making them suitable for high-frequency applications.

They exhibit excellent electro migration resistance, which is critical for reliability in RF/microwave applications.

Insulation resistance is superior, ensuring better performance in high-frequency circuits.

You find BT resin PCBs preferred in telecommunications and RF modules. They help minimize signal loss, which is crucial for high-speed signals in technologies like 5G. BT resin's thermal stability supports devices in environments with fluctuating temperatures.

Ceramic Comparison

You may use ceramic PCBs for extreme thermal conductivity. Ceramic PCBs reach up to 170 W/m·K, while BT resin PCB ranges from 0.2 to 0.4 W/m·K.

Type of PCB | Thermal Conductivity (W/m·K) |

|---|---|

Ceramic PCB | Up to 170 |

BT Resin PCB | 0.2 – 0.4 |

Ceramic PCBs suit applications needing rapid heat dissipation. BT resin PCBs offer you a balance of thermal stability, mechanical strength, and electrical performance for most high-performance electronics.

High-Performance Applications

Telecommunications

You rely on BT resin PCB materials for high-performance applications in telecommunications. These boards support high-frequency signals and maintain signal integrity, which is essential for modern wireless networks. You see improvements in reliability and data transmission speed when you use BT resin PCBs in high-performance devices. The table below shows how BT resin PCB enhances telecommunications equipment:

Performance Aspect | Description |

|---|---|

Thermal Stability | BT resin materials can withstand extreme temperatures, ensuring reliability in challenging conditions. |

Signal Integrity | Designed to minimize signal loss, maintaining high signal integrity for seamless communication. |

High-Frequency Performance | Enhanced capabilities for high-speed data transmission, crucial for modern wireless applications. |

You can trust BT resin PCB to deliver consistent performance in base stations, routers, and 5G modules.

Automotive

You need high-performance materials for automotive electronics. BT resin PCB supports advanced driver-assistance systems, infotainment units, and engine control modules. These boards resist vibration and heat, which helps your vehicle’s electronics work reliably. You benefit from stable operation in harsh environments, such as under the hood or in outdoor conditions. BT resin PCB enables high-performance applications that demand durability and precision.

Aerospace

You face strict requirements for weight and thermal management in aerospace electronics. BT resin PCBs conduct and dissipate heat efficiently, which protects sensitive components from overheating. This thermal management extends the life of your high-performance devices and ensures stable operation during flight. The unique thermal properties of BT resin prevent chips from overheating, which keeps your systems reliable under heavy loads. You achieve high-performance results in avionics, satellite systems, and navigation equipment.

Consumer Electronics

You see BT resin PCB driving miniaturization in consumer electronics. These boards manage heat in compact devices, which allows you to design smaller and more efficient products. You benefit from excellent electrical insulation and mechanical stability, which supports high-density layouts. The lightweight and compact nature of BT resin PCB makes it ideal for smartphones, wearables, and portable high-performance applications. You create innovative devices that meet modern demands for speed and reliability.

Selecting BT Resin PCB with LT CIRCUIT

Application Needs

When you select a BT resin PCB for your project, you need to match the material to your application’s requirements. Start by looking at the operating frequency range. High-frequency circuits need materials that keep signal loss low and maintain signal integrity. You should also consider impedance control, which helps your signals stay clear and accurate.

Thermal management is another key factor. If your device generates a lot of heat, you want a PCB that can handle it without losing performance. Mechanical properties matter too. Strong boards last longer and resist damage during assembly or use. Cost and availability play a role, especially if you have a tight budget or need fast delivery. Environmental considerations, like resistance to moisture or chemicals, help your PCB survive in tough conditions.

Operating frequency range

Signal integrity and impedance control

Thermal management

Mechanical properties

Cost and availability

Environmental considerations

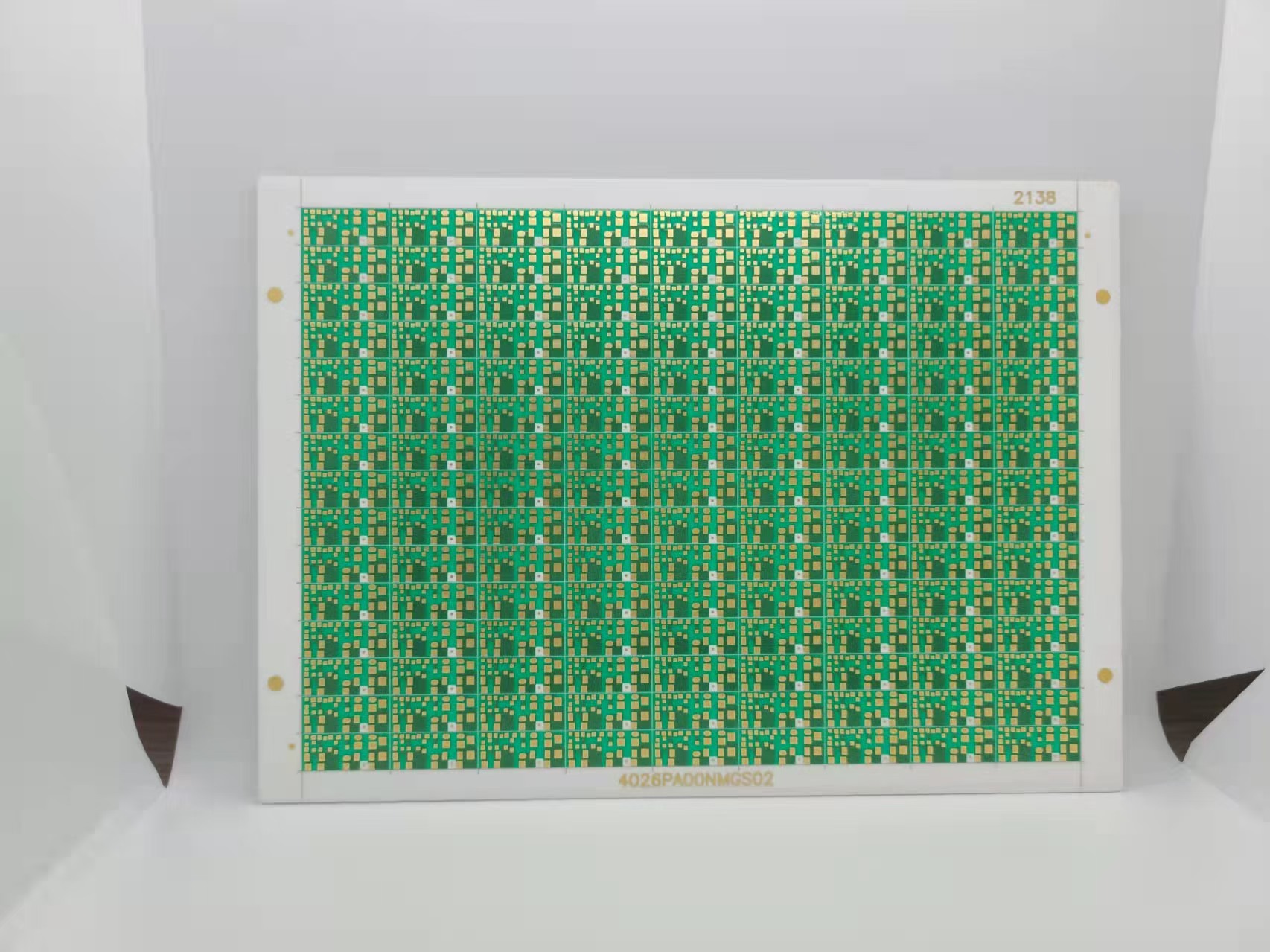

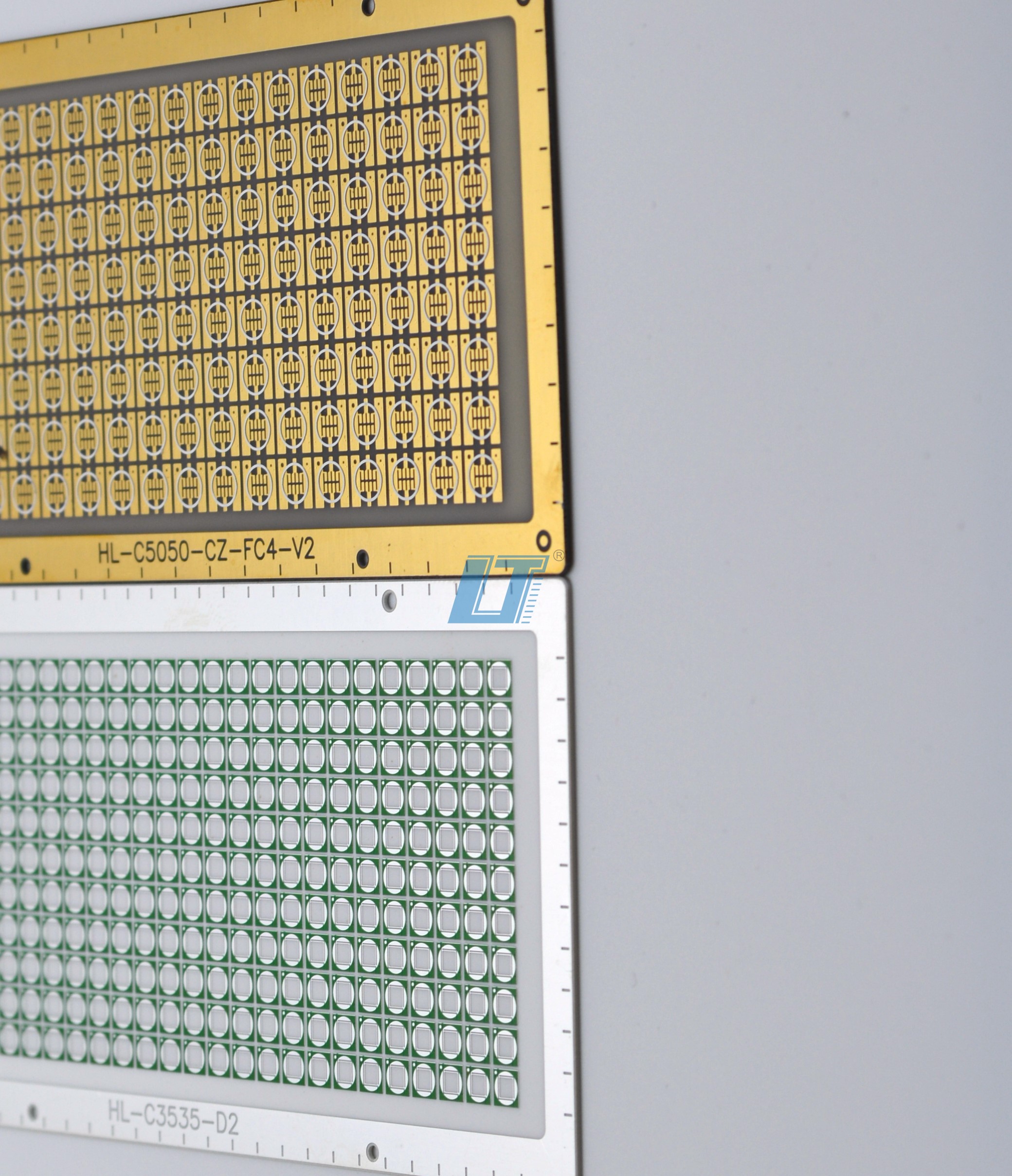

LT CIRCUIT offers a wide range of BT resin PCB solutions. You can choose from different copper weights, thicknesses, and trace spacings to fit your needs. For example, you might need a 1oz copper weight or a 0.2mm thickness for compact designs. LT CIRCUIT’s BT resin PCBs work well in processor platforms, microelectronics, and chip board assemblies. You can even request features for flexible substrates or rigid-flex pcb designs if your application demands them.

Feature | Description |

|---|---|

Copper Weight | 1oz Copper Weight Package Substrate PCB |

Thickness | 0.2mm |

Temperature Resistance | Operates effectively in high-temperature environments up to 150°C |

Minimum Trace Spacing | 0.1mm, enabling complex circuit configurations and high-density interconnections |

Minimum Hole Size | 0.2mm, supporting sophisticated microelectronic components |

Industry Applications | Tailored for Processor Platform PCBs, Microelectronics Circuit Layers, and Chip Board Assemblies |

Tip: Always match your PCB’s features to your application’s needs for the best performance and reliability.

Design Tips

You want your BT resin PCB to perform at its best. Focus on design considerations that support high-frequency and high-density layouts. Keep trace lengths short and use controlled impedance routing to maintain signal quality. Choose the right copper weight and board thickness for your application. For flexible pcbs or designs that need to bend, ask LT CIRCUIT about options for flexible substrates.

Here are some design considerations to keep in mind:

Use minimum trace spacing and hole sizes to fit more components on your board.

Plan for thermal management by placing heat-generating parts away from sensitive circuits.

Select surface finishes that match your assembly process and end-use environment.

For rigid-flex pcb designs, combine rigid and flexible layers to save space and improve durability.

Note: Early collaboration with LT CIRCUIT’s engineering team helps you optimize your design for manufacturability and performance.

Manufacturing Process

The manufacturing process for BT resin PCBs requires precision and expertise. You need accurate drilling for small holes and careful heat management to prevent defects. LT CIRCUIT uses advanced techniques to address common challenges, such as wire bonds breaking or layers coming apart. The team mixes BT epoxy with other resins to improve properties and applies strict quality control at every step.

Manufacturing Challenges | LT CIRCUIT Solutions |

|---|---|

Wire bonds breaking | Innovations in BT epoxy to enhance properties |

Metal mixing | Mixing BT epoxy with other resins |

Layers coming apart | Strict quality control measures |

Solder joints getting tired | Careful heat management and monitoring during production |

You benefit from:

Precise drilling for small holes and fine features

Heat management to protect solder joints and components

Monitoring for signal issues during production

Quality checks throughout the manufacturing process

LT CIRCUIT’s commitment to quality ensures your BT resin PCB meets the highest standards. You get reliable boards for demanding applications, whether you need multilayer, HDI, or custom solutions.

Cost Factors

When you plan your project, you need to understand what drives the cost of BT resin PCB production. Material cost is a major factor. BT resin and high-quality copper foils add value but also increase the price. The number of layers and the complexity of your design affect the manufacturing process and cost. Larger and thicker boards use more material and require specialized processing.

Surface finishes and special features, such as impedance control, can raise the cost. If you order a large volume, you benefit from lower per-unit costs. Shorter lead times may add extra fees. Meeting strict quality and certification requirements also impacts the final price.

Cost Driver | Description |

|---|---|

Material Cost | The cost of BT Resin and other materials like copper foils and prepreg sheets. |

Layer Count and Complexity | Higher layer counts and complex designs increase manufacturing costs. |

Board Size and Thickness | Larger and thicker boards require more materials and specialized processing, raising costs. |

Surface Finish and Special Features | Premium finishes and features like impedance control add to the overall cost. |

Manufacturing Volume | Larger production runs lower per-unit costs due to economies of scale. |

Lead Time and Turnaround Time | Shorter lead times can incur additional fees, affecting overall costs. |

Quality and Certification Requirements | Meeting specific standards can increase manufacturing costs due to quality control measures. |

Remember: Work with LT CIRCUIT to balance your design considerations, performance needs, and budget. The team helps you choose the right options for your application and guides you through the manufacturing process.

You gain many advantages with BT resin PCB materials. These boards offer strong thermal stability, electrical performance, and mechanical strength.

The market expects about 7% CAGR growth, fueled by the expanding electronics industry.

LT CIRCUIT helps you achieve reliable results in demanding environments. Consider BT resin PCBs for your next high-performance project.

FAQ

What makes BT resin PCB better for high-frequency circuits?

You get low dielectric loss and stable signal transmission. BT resin PCB supports high-speed data and reduces interference in advanced electronics.

Tip: Choose BT resin for reliable performance in 5G and RF devices.

Can you customize BT resin PCBs with LT CIRCUIT?

Yes, you can request custom thickness, copper weight, and surface finishes. LT CIRCUIT offers flexible options to fit your project needs.

How does BT resin PCB handle heat in demanding environments?

You benefit from excellent thermal stability. BT resin PCB resists high temperatures and keeps your circuits safe during heavy use.

Reliable in automotive, telecom, and aerospace settings

See Also

Choosing The Right Materials For Communication PCB Designs

Top Materials For Designing High-Speed Printed Circuit Boards

Understanding The Components That Make Up PCBs

Industrial Rigid PCB Production: Key Materials And Standards