Understanding BT Resin PCB Material and Its Properties

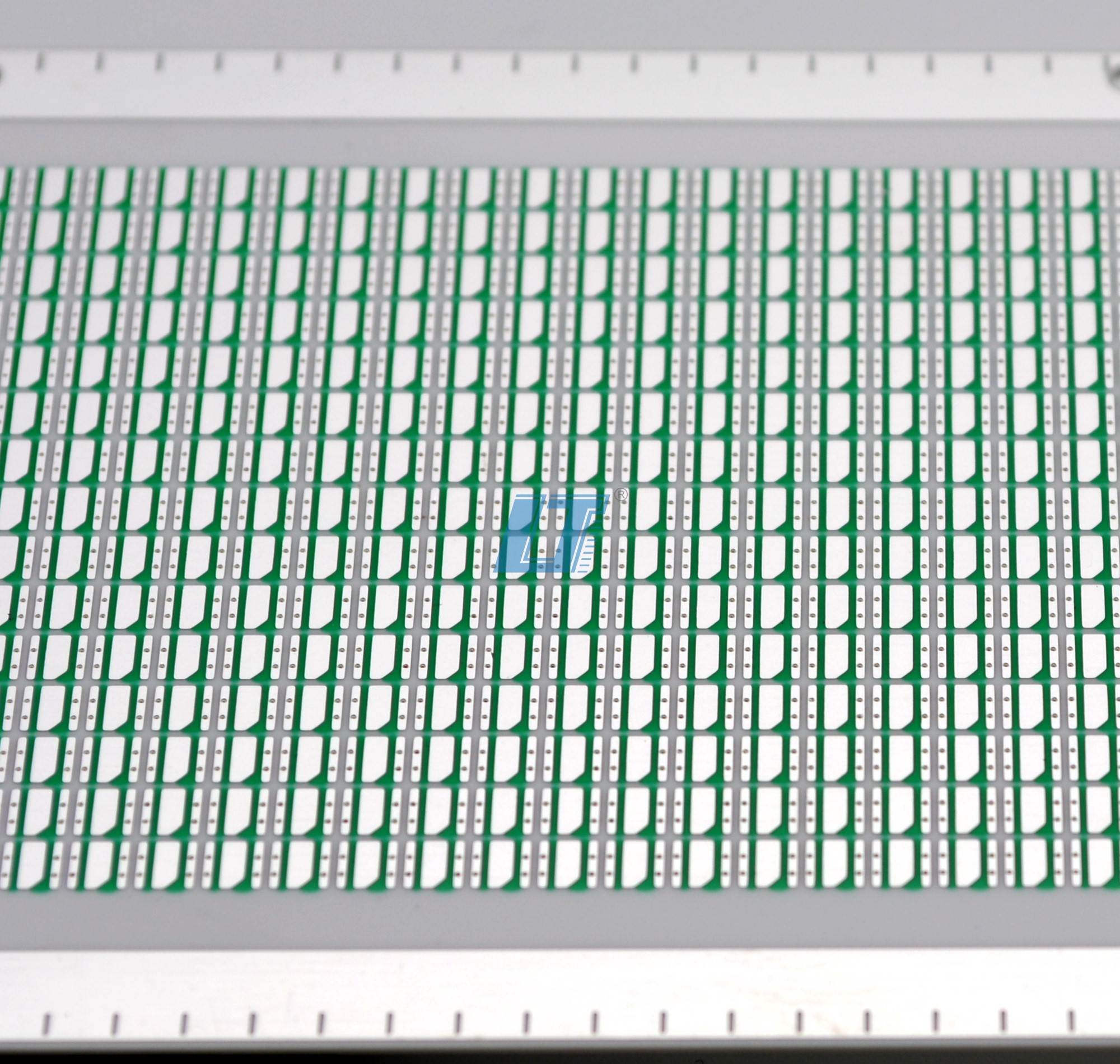

BT resin PCB material is a specialized substrate used in advanced printed circuit boards, offering superior thermal stability, excellent electrical insulation, and enhanced mechanical durability. High-performance electronics like smartphones and laptops benefit from the efficient heat dissipation and reliability provided by BT resin PCB material. At LT CIRCUIT, we utilize BT resin PCB material to deliver innovative and high-quality PCB solutions for a wide range of applications.

Key Takeaways

BT resin PCB material offers excellent thermal stability, making it ideal for high-performance electronics like smartphones and laptops.

The low dielectric constant and loss tangent of BT resin ensure minimal signal loss, supporting reliable high-frequency applications.

LT CIRCUIT provides customizable BT resin PCBs, allowing customers to select specific features to meet their project needs.

BT Resin PCB Material Overview

What Is BT Resin?

BT resin pcb material stands out in the world of advanced pcb manufacturing. BT refers to bismaleimide triazine, a unique blend of epoxy resin and BT resins. The chemical composition includes bismaleimide and cyanate ester as key ingredients. The cyanate ester contains three cyano groups that trimerize, forming a triazine ring structure. Copolymerization occurs between the maleimide group and cyano groups, creating heterocyclic aromatic rings with nitrogen atoms. This structure gives BT resin pcb material its remarkable performance in printed circuit board applications.

It includes bismaleimide and cyanate ester.

The triazine ring structure forms through the trimerization of cyano groups.

Copolymerization with maleimide groups creates strong aromatic rings.

BT-epoxy blends combine these chemical features to deliver high-performance pcb materials. LT CIRCUIT uses BT resin pcb material in its advanced products, ensuring reliability and innovation for demanding electronics.

Key Properties

BT resin pcb material offers several important properties that make it ideal for high-performance printed circuit board designs. The bismaleimide triazine epoxy structure enhances mechanical strength and stability. BT-epoxy blends show high thermal resistance, maintaining integrity at temperatures up to 180°C or more. The material absorbs very little moisture, usually between 0.2% and 2.5%. BT resin pcb material also provides excellent chemical resistance and maintains its structure under heat.

BT resin pcb material features low dielectric constant (dk), typically between 2.8 and 3.5, and low loss tangent (df), around 0.015. These properties ensure minimal signal loss and reliable electrical insulation. The coefficient of thermal expansion (CTE) remains low, which helps prevent warping and solder joint failures. Dimensional stability is another key advantage, with less than 0.05% change under varying conditions. Water absorption stays below 0.3%, much lower than standard FR-4 pcb materials.

BT-epoxy blends resist thermal cycling and show a lower risk of delamination compared to other pcb materials. They perform well in extreme environments, making them suitable for high-density interconnects and multilayer pcb designs.

Technical Data

The technical data for BT resin pcb material highlights its superior performance compared to other pcb materials. The glass transition temperature (Tg) for BT-epoxy blends ranges from 180°C to 210°C. This high Tg ensures stability during thermal cycling and assembly. The dielectric constant (dk) measures around 3.70 at 1 GHz, supporting high-frequency applications. The loss tangent (df) is 0.015, indicating low signal loss.

Property | Value | Description |

|---|---|---|

Dielectric Constant (dk) | 3.70 @ 1 GHz | Supports high-frequency signal transmission |

Loss Tangent (df) | 0.015 | Low signal loss during transmission |

Glass Transition Temperature | 180°C+ | High thermal stability |

Dimensional Change | < 0.05% | Excellent dimensional stability |

Water Absorption | < 0.3% | Low hygroscopicity |

Ion Migration Resistance | Great | Prevents ion drift, extends board life |

BT resin pcb material meets IPC-4101 specifications and strict quality criteria for advanced pcb manufacturing. The material classification addresses requirements for high frequency, high temperature, and lead-free assembly. BT-epoxy blends offer lower CTE, higher Tg, and higher decomposition temperature than standard FR-4 pcb materials.

LT CIRCUIT leverages BT resin pcb material in its HDI and multilayer pcb products. The company’s expertise ensures that each printed circuit board delivers optimal performance, durability, and reliability for modern electronics.

Applications and Advantages of BT Resin PCBs

Applications

BT resin plays a vital role in advanced pcb fabrication. Engineers select bt-epoxy blends for high-density interconnects and multilayer pcb designs. These pcb materials support demanding applications in many industries.

Network chips

Programmable logic devices

Storage chips

Mobile phone MEMS chips

Communication chips

Memory chips

LED chips

RF chips

Automotive electronics

Consumer electronics

Computing and security equipment

BT resin pcb materials excel in high-frequency and high-temperature environments. Telecommunications equipment, automotive electronics, industrial control systems, military equipment, and mobile communication devices rely on bt-epoxy for reliable performance. BT resin printed circuit boards offer superior electrical properties, exceptional thermal stability, and resistance to moisture. These features make bt-epoxy the preferred choice for advanced applications.

Advantages

BT resin pcb materials deliver outstanding strength and reliability. The table below compares key properties of bt resin and FR-4 pcb materials:

Property | BT Resin | FR-4 |

|---|---|---|

Glass Transition Temperature | Higher | Lower |

Dielectric Constant (dk) | Lower | Higher |

Heat Resistance | Excellent | Moderate |

BT resin pcb materials maintain excellent thermal stability and mechanical strength. Engineers value the low dk and df values, which support high-frequency circuits. The table below shows measured values for electrical performance:

Property | Value (1 MHz) |

|---|---|

Dielectric Constant (dk) | 3.0 |

Loss Tangent (df) | 0.005 |

BT-epoxy blends resist warping and ion migration. These pcb materials ensure reliable operation in compact, high-density circuits. BT resin printed circuit boards outperform standard options in demanding environments.

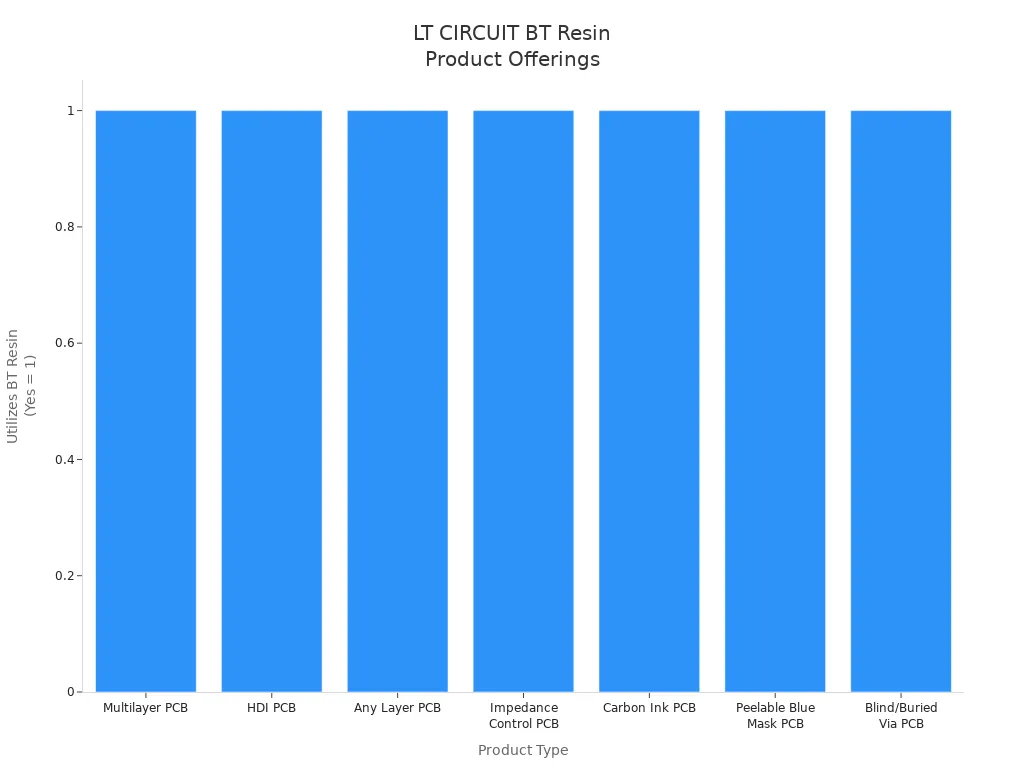

LT CIRCUIT Solutions

LT CIRCUIT offers a wide range of pcb products that utilize bt resin. The table below highlights product types:

Product Type | Utilizes BT Resin |

|---|---|

Multilayer PCB | Yes |

HDI PCB | Yes |

Any Layer PCB | Yes |

Impedance Control PCB | Yes |

Carbon Ink PCB | Yes |

Peelable Blue Mask PCB | Yes |

Blind/Buried Via PCB | Yes |

LT CIRCUIT provides customization options for bt-epoxy pcb fabrication. Customers can choose thickness, circuit layers, copper weight, and lead time. Each printed circuit board meets RoHS compliance and specific requirements for electronic circuit interconnects. LT CIRCUIT’s commitment to quality and customer satisfaction ensures reliable solutions for all applications.

BT resin PCB material offers high mechanical strength, excellent thermal conductivity, and favorable dielectric properties, as shown below:

Key Strengths | Description |

|---|---|

High Mechanical Strength | BT resins maintain reliable mechanical properties even at elevated temperatures. |

Thermal Conductivity | Composites show improved thermal conductivity, essential for heat dissipation in electronics. |

Favorable Dielectric Properties | Low dielectric constant and loss, making them suitable for high-frequency applications. |

Smartphones, high-density devices, and temperature-sensitive electronics benefit from these features. LT CIRCUIT delivers advanced PCB solutions using BT resin, meeting the needs of demanding industries.

The specialty resin market for PCBs is projected to reach $3.71 billion by 2025.

Miniaturization and high-speed digital interconnects drive demand for advanced materials.

For expert guidance and reliable performance, LT CIRCUIT stands ready to help.

FAQ

What makes BT resin PCB material suitable for high-frequency applications?

BT resin PCB material has a low dielectric constant and loss tangent. These properties help maintain signal integrity in high-frequency circuits.

Tip: Engineers choose BT resin for reliable performance in advanced electronics.

Can LT CIRCUIT customize BT resin PCBs for specific requirements?

LT CIRCUIT offers customization for BT resin PCBs. Customers select thickness, copper weight, layers, and surface finish to match their project needs.

Options include:

Multilayer designs

Impedance control

How does BT resin compare to standard FR-4 in terms of thermal stability?

Material | Thermal Stability | Glass Transition Temperature |

|---|---|---|

Excellent | 180°C+ | |

FR-4 | Moderate | 130°C–150°C |

BT resin resists heat better than FR-4, making it ideal for demanding environments.

See Also

Choosing The Right PCB Materials For Communication Devices

Utilizing Panasonic Copper-Clad Laminates In PCB Production

Top Materials For Designing High-Speed Printed Circuit Boards

Understanding The Components That Make Up Printed Circuit Boards

Exploring PCB Printed Circuit Boards And Their Fundamental Principles