What Is a Ceramic Base PCB and Why It Matters in Electronics

A ceramic pcb uses advanced ceramic materials like aluminum oxide or aluminum nitride. These materials offer high thermal conductivity and strong electrical insulation. You benefit from devices that stay cool and reliable.

Material | Characteristics |

|---|---|

Aluminum oxide | Good thermal conductivity, electrical resistance, cost-effective. |

Aluminum nitride | Superior thermal conductivity, excellent insulation. |

Beryllium oxide | Exceptional thermal conductivity, but regulated. |

A ceramic base pcb factory like LT CIRCUIT leads in building ceramic pcbs for demanding electronics. |

Key Takeaways

Ceramic PCBs provide excellent thermal conductivity, keeping electronic devices cool and enhancing their reliability.

These boards offer strong electrical insulation, preventing unwanted current flow and protecting sensitive components in high-voltage applications.

Ceramic materials are highly durable, making them ideal for use in harsh environments, ensuring long-lasting performance in demanding electronics.

Ceramic PCB Properties

Ceramic pcb technology gives you unique benefits in electronics. You see these benefits in three main areas: thermal conductivity, electrical insulation, and mechanical strength. LT CIRCUIT uses advanced ceramic materials and manufacturing processes to deliver high-performance ceramic pcbs for demanding applications.

Thermal Conductivity

You need your electronic devices to stay cool, especially when they handle high power. Ceramic pcb materials like alumina and aluminum nitride offer outstanding thermal conductivity. This property helps your devices manage heat efficiently and maintain reliability.

Material | Thermal Conductivity (W/m·K) |

|---|---|

Alumina | 18–30 |

Aluminum Nitride | 160–200 |

Ceramic substrate options such as aluminum nitride reach thermal conductivity values up to 230 W/m·K. You get much better heat dissipation compared to traditional FR4 boards. FR4 substrates only provide thermal conductivity between 0.3 and 1.1 W/m·K. This difference means ceramic pcbs are the preferred choice for high-power electronics.

Ceramic substrates have thermal conductivities ranging from 28-35 W/(m·K) for aluminum oxide.

Aluminum nitride ceramic substrate can reach 140-180 W/(m·K).

Beryllium oxide ceramic materials offer up to 280 W/(m·K).

FR4 materials typically offer only 0.3-1.1 W/(m·K).

You benefit from ceramic pcbs because they keep your components cooler, which increases reliability and extends the lifespan of your electronics. LT CIRCUIT selects the best ceramic materials to maximize thermal conductivity in every ceramic pcb.

Electrical Insulation

Ceramic pcbs provide excellent electrical insulation. You need this property to prevent unwanted current flow and protect sensitive components. Ceramic materials like alumina and aluminum nitride deliver dielectric strengths from 10 kV/mm to over 20 kV/mm. This level of electrical isolation allows your ceramic pcb to handle high voltages without breakdown or leakage.

Ceramic pcbs maintain electrical insulation even at temperatures from 350°C to over 800°C.

The low coefficient of thermal expansion in ceramic substrate reduces mechanical stress during thermal cycling.

You get strong isolation, which means your devices work safely in harsh environments.

LT CIRCUIT uses ceramic materials with high electrical isolation ratings. You can trust your ceramic pcb to perform reliably in high-voltage and high-temperature electronics.

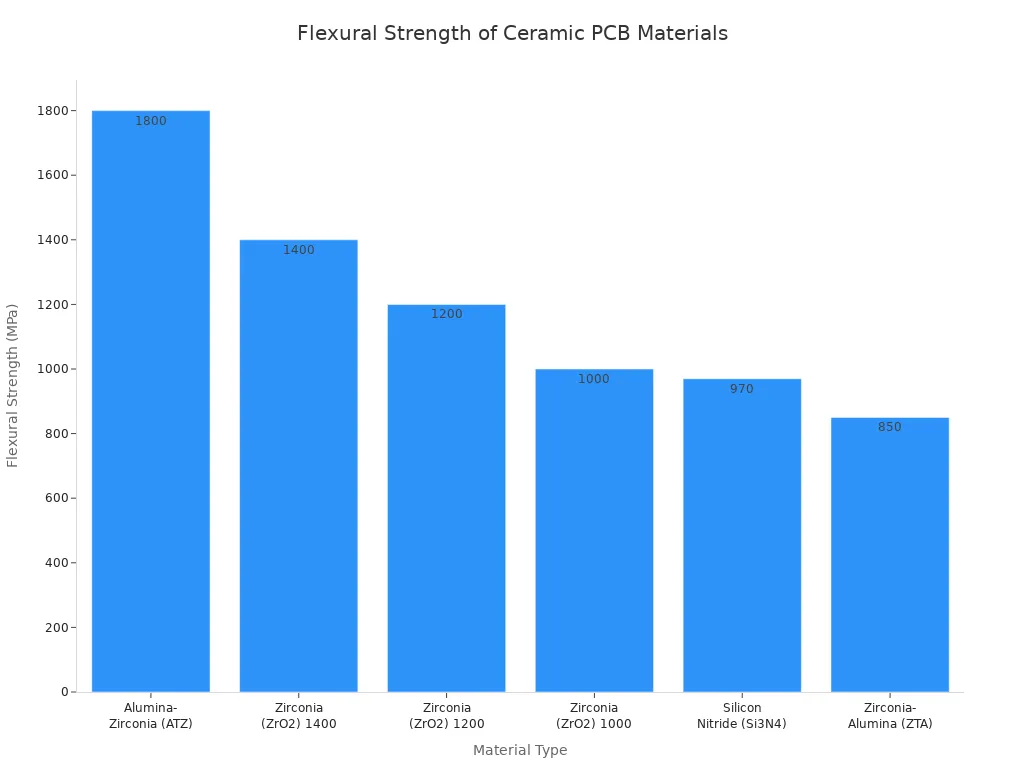

Mechanical Strength

You want your ceramic pcb to last in tough conditions. Ceramic materials offer impressive mechanical strength. Alumina-zirconia ceramic substrate reaches flexural strengths up to 1800 MPa. Zirconia and silicon nitride ceramic materials also provide high durability and resistance to wear.

Material Type | Flexural Strength (MPa) | Key Features | Best For |

|---|---|---|---|

Alumina-Zirconia (ATZ) | 1800 | High hardness, superior wear and corrosion resistance, excellent fracture toughness. | High-stress applications requiring durability and reliability. |

Zirconia (ZrO2) | 1400 | Nano-grade powder composition, high strength, outstanding wear resistance. | Applications demanding superior mechanical performance. |

Zirconia (ZrO2) | 1200 | High-purity zirconia with enhanced strength and longevity. | Precision-engineered components requiring exceptional durability. |

Zirconia (ZrO2) | 1000 | Advanced ceramic composite, reinforced with alumina platelets for enhanced toughness. | Applications needing superior fracture toughness and resilience. |

Silicon Nitride (Si3N4) | 970 | Versatile mechanical, thermal, and electrical properties. | High-temperature and high-load applications. |

Zirconia-Alumina (ZTA) | 850 | Combination of high hardness, strength, wear, and corrosion resistance. | Industrial applications where toughness and durability are crucial. |

Ceramic pcbs are rigid and provide strong mechanical support. You get reliability in static and high-reliability electronics. LT CIRCUIT uses ceramic substrate materials that resist cracking and wear, so your ceramic pcb lasts longer in industrial environments.

Tip: When you choose ceramic pcbs from LT CIRCUIT, you gain the advantage of advanced ceramic materials that deliver superior thermal conductivity, electrical isolation, and mechanical strength. Your electronics perform better and last longer.

Advantages of Ceramic PCBs

Ceramic printed circuit boards give you a clear advantage in demanding electronics. You get unmatched reliability, support for miniaturization, and strong chemical resistance. LT CIRCUIT uses advanced processes to ensure the integrity and performance of every ceramic pcb. Let’s explore these benefits in detail.

Reliability in Harsh Environments

You need your electronics to work in extreme conditions. Ceramic pcbs deliver high reliability in harsh environments like aerospace, automotive, and industrial settings. These boards handle high temperatures, strong vibrations, and rapid temperature changes without losing integrity.

Metric | Description |

|---|---|

Thermal Conductivity | AlN and SiC dissipate heat 6–10x faster than alumina and 500x faster than FR-4. |

Temperature Resistance | Ceramics can withstand temperatures over 1000°C, ideal for automotive and industrial applications. |

Electrical Insulation | Volume resistivity >10¹⁴ Ω·cm, reducing short-circuit risks in high-voltage designs. |

CTE Matching | Low CTE (4.0–5.5 ppm/°C) aligns with silicon and copper, minimizing solder joint fatigue. |

You benefit from high thermal dissipation and superior electrical insulation. These properties protect your devices from overheating and signal integrity issues. LT CIRCUIT’s quality assurance process includes thermal cycling, electrical continuity, and mechanical shock testing. These tests guarantee the integrity of ceramic pcbs in high-reliability applications.

Ceramic printed circuit boards from LT CIRCUIT power high-power electronics in 5G communication modules, power amplifiers, and satellite systems. You get consistent performance and longevity, even in the most demanding environments.

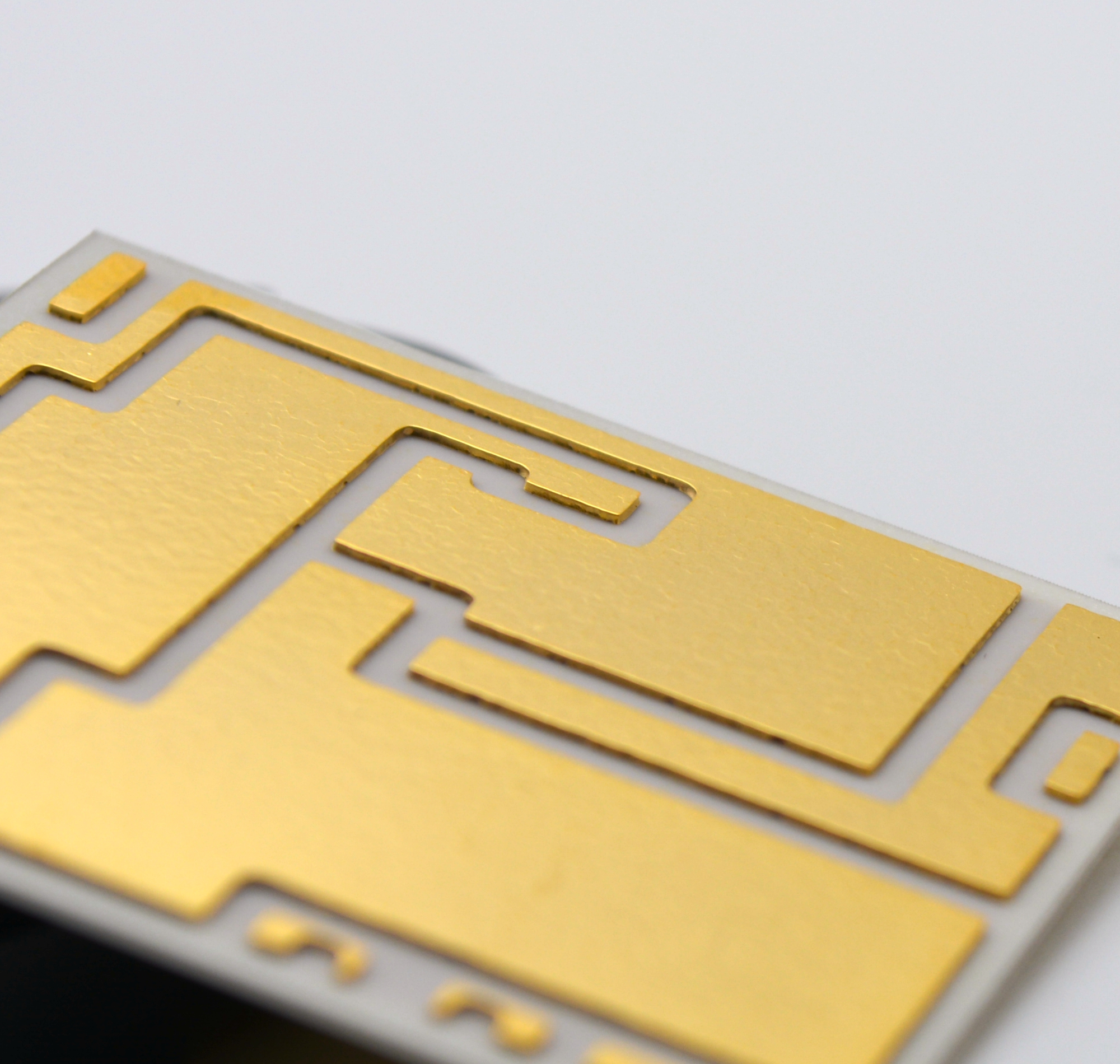

Miniaturization and High-Density

Modern electronics require smaller, more powerful devices. Ceramic pcbs enable miniaturization and high-density layouts. You can place components closer together without worrying about overheating or signal loss.

Property | Impact on Component Density |

|---|---|

Allows for closer placement of components without overheating | |

High Insulation Resistance | Reduces the risk of electrical failures in compact designs |

Low Dielectric Loss | Supports high-frequency applications with minimal signal loss |

Enhanced Durability | Ensures reliability in compact assemblies under stress |

High-Density Interconnects | Facilitates complex circuitry in smaller form factors |

You avoid signal integrity issues and maintain high performance in high-frequency circuits. LT CIRCUIT’s multi-layer ceramic pcb technology supports high-density interconnects for advanced electronics. You see these benefits in medical imaging equipment, high-power LED lighting, and solar panels.

Ceramic circuit boards help you achieve miniaturization without sacrificing reliability or signal quality. You get more functionality in less space, which is essential for high-power applications.

Chemical Resistance

You want your printed circuit boards to last, even when exposed to harsh chemicals. Ceramic pcbs offer outstanding chemical resistance. They do not corrode or degrade when exposed to acids, bases, or solvents.

Ceramic pcbs exhibit high resistance to chemicals, acids, bases, and solvents.

Ceramic substrates do not corrode or degrade when exposed to aggressive chemicals.

Ceramic materials are inherently chemically inert, providing high resistance to chemical attack.

Feature | Description |

|---|---|

Resistance to Harsh Chemicals | High temperature ceramic pcb designs withstand oils, solvents, and corrosive gases. |

Chemically Inert Coatings | Coatings prevent corrosion, enhancing durability in industrial settings. |

Sealed Edges | Sealed edges reduce maintenance needs by blocking corrosive elements. |

You benefit from the integrity and longevity of ceramic printed circuit boards in industrial and automotive environments. LT CIRCUIT’s ceramic pcbs maintain performance and reliability, even in corrosive conditions. This advantage means less maintenance and longer service life for your high-power electronics.

Note: LT CIRCUIT’s ceramic pcbs deliver unmatched reliability, support miniaturization, and resist chemical attack. You get high-reliability applications with proven integrity and performance.

Ceramic Base PCB Factory and Applications

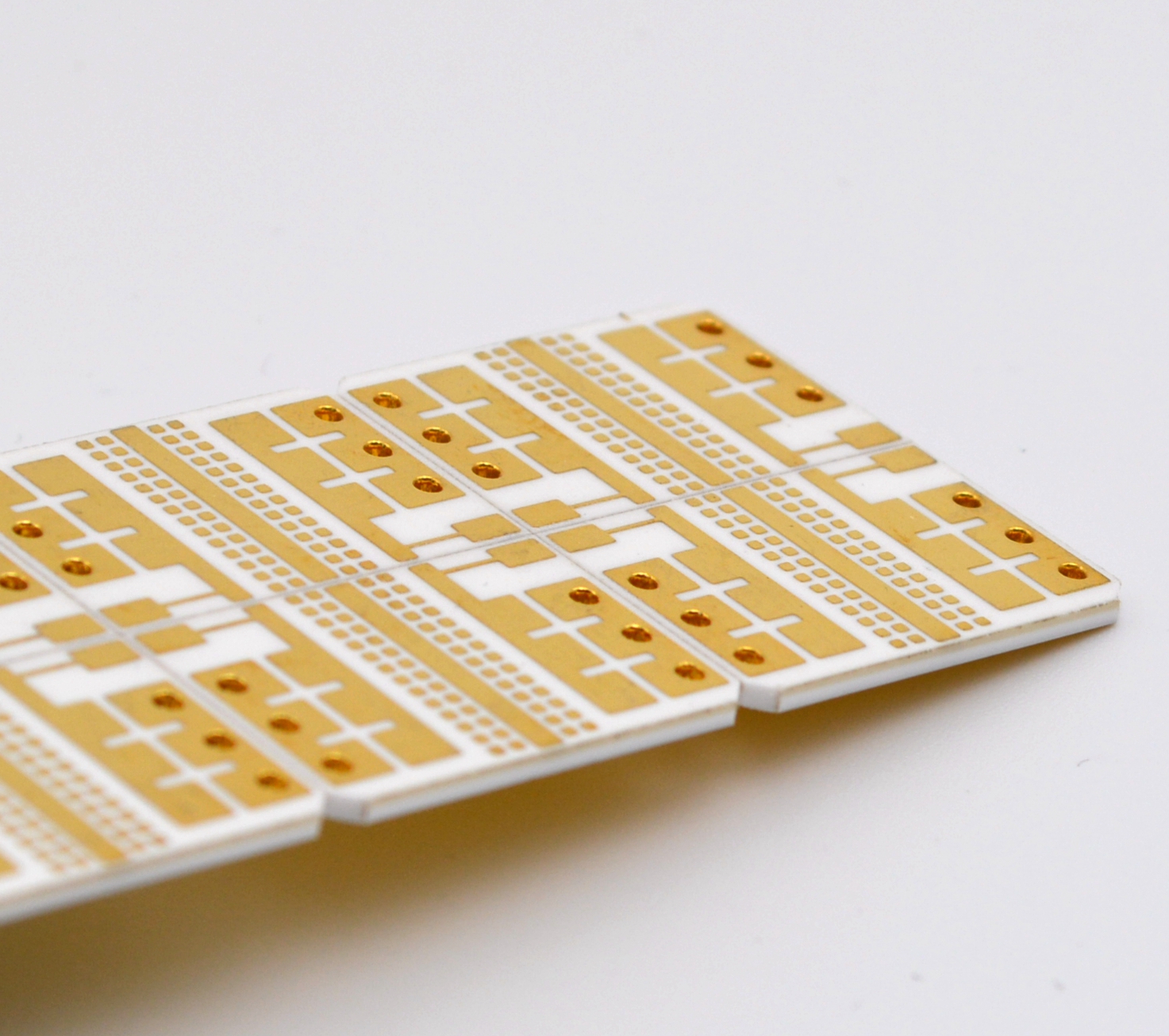

LT CIRCUIT Manufacturing Excellence

You want a ceramic base pcb factory that delivers both quality and innovation. LT CIRCUIT stands out as a leader in this field. You benefit from a facility that follows strict international standards, including ISO 9001 and IPC-6012. These certifications ensure every ceramic pcb meets high safety and quality requirements.

LT CIRCUIT uses advanced materials and strict quality control.

The ceramic base pcb factory employs cutting-edge technologies for production.

Technology | Description |

|---|---|

Laser drilling | Creates precise holes in ceramic pcbs. |

Laser Direct Imaging | Delivers accurate patterns on each ceramic pcb. |

Vacuum reflow soldering | Ensures strong, reliable solder joints. |

Automated Optical Inspection | Detects defects early in the ceramic pcb process. |

X-ray checks | Inspects internal layers for hidden issues. |

You see LT CIRCUIT’s commitment to excellence in every step. The ceramic base pcb factory serves a wide range of industries, including aerospace, medical devices, automotive, and consumer electronics. Companies trust LT CIRCUIT for reliable ceramic pcbs that perform in the toughest environments.

LT CIRCUIT’s customer base includes leaders in aerospace, automotive, IoT, and medical technology. You get proven solutions from a ceramic base pcb factory with a global reputation.

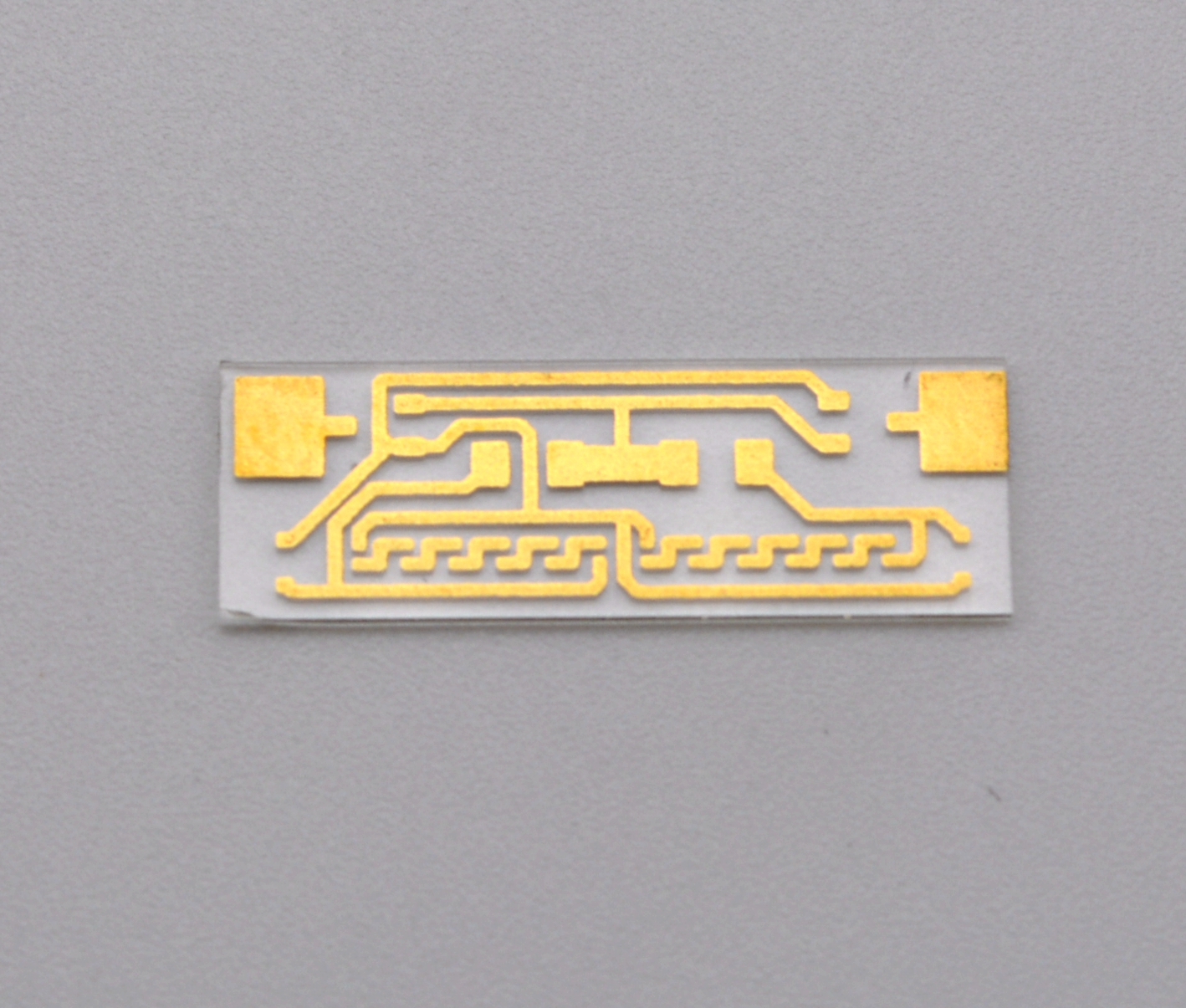

Use Cases in Electronics

You find ceramic pcbs in many advanced electronics. These boards excel in power electronics, high-frequency devices, and harsh environments. The ceramic base pcb factory at LT CIRCUIT produces ceramic pcbs for:

Power supplies, inverters, converters, and voltage regulators

RF and microwave devices, such as transceivers and amplifiers

Medical imaging systems, including MRI and ultrasound equipment

5G telecommunications, antennas, and base stations

Automotive sensors and advanced driver-assistance systems

Ceramic pcbs offer high thermal conductivity, excellent electrical insulation, and strong mechanical strength. You rely on these features for devices that must handle heat, vibration, and rapid temperature changes. Ceramic pcbs also resist moisture and chemicals, so your electronics last longer in demanding settings.

Industry | Application Example |

|---|---|

Aerospace & Defense | Avionics, radar, and satellite communication |

Medical Devices | Portable monitors, diagnostic tools, and wearable health tech |

Consumer Electronics | Laptops, gaming consoles, and smart home devices |

Automotive | Dashboards, sensors, and infotainment systems |

IoT Devices | Smart home systems and compact wearables |

You choose ceramic pcbs from a trusted ceramic base pcb factory to ensure your electronics stay reliable, efficient, and safe.

You gain many benefits when you choose ceramic pcbs for advanced electronics.

High dielectric strength and thermal conductivity keep your devices safe and cool.

LT CIRCUIT stands out for quality, innovation, and fast support.

For your next demanding project, consider a ceramic pcb for reliable, long-lasting performance.

FAQ

What makes ceramic PCBs better for high-power devices?

You get better heat management with ceramic PCBs. These boards move heat away from components quickly, so your devices stay cool and last longer.

Tip: Choose ceramic PCBs for power electronics to boost reliability.

Can you use ceramic PCBs in medical equipment?

Yes, you can. Ceramic PCBs work well in medical devices. They resist heat and chemicals, so your equipment stays safe and reliable.

How does LT CIRCUIT ensure ceramic PCB quality?

LT CIRCUIT uses strict testing and advanced tools. You receive PCBs that meet high standards for safety, performance, and durability.

See Also

Understanding How Ceramic PCBs Are Used Across Industries

The Superior Heat Dissipation Properties of Ceramic PCBs

An Overview of PCB Printed Circuit Boards and Basics

A Comprehensive Guide to Manufacturing Multilayer Ceramic PCBs

Investigating Al₂O₃ Ceramic PCBs and Their Industrial Applications