Ceramic base PCB manufacturer advice for strong, safe boards

Choosing the right ceramic base pcb manufacturer shapes the strength and safety of your electronics. High-quality ceramic PCBs offer superior thermal management, durability, and electrical performance.

You can see Asia Pacific leads the global market:

Region | Market Share (%) | CAGR (%) |

|---|---|---|

Asia Pacific | 45 | 8.5 |

North America | 25 | 7.5 |

Europe | 20 | 7.0 |

Trusted brands like LT CIRCUIT focus on quality and expertise for reliable results.

Key Takeaways

Choose a ceramic PCB manufacturer with a strong reputation and proven expertise to ensure reliable results.

Focus on high-purity materials and thermal conductivity to enhance the performance and durability of your ceramic PCBs.

Always verify the manufacturer's quality control processes and certifications to guarantee safety and compliance in your projects.

High-Quality Ceramic PCB Criteria

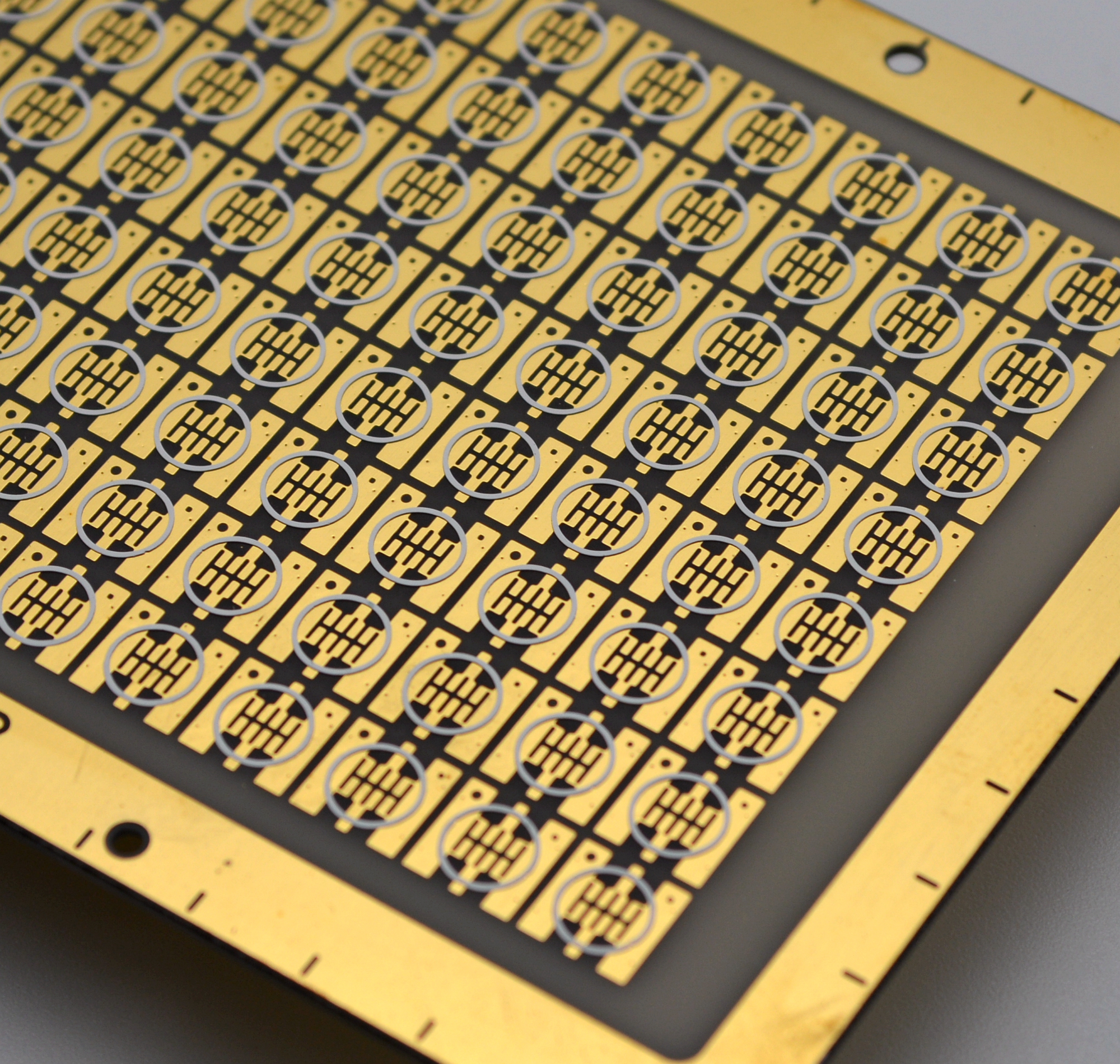

When you choose a high-quality ceramic pcb, you need to focus on several important criteria. These criteria help you ensure that your board will perform reliably in demanding environments. LT CIRCUIT uses advanced materials and strict quality controls to meet these standards.

Material Purity

You should always check the purity of the ceramic material. High-purity ceramics provide better electrical insulation and improve the overall conductivity of your board. Impurities can cause weak spots, which may lead to failures in high-stress applications. LT CIRCUIT selects only top-grade ceramics to guarantee consistent performance. This careful material selection criteria helps you avoid unexpected breakdowns and ensures your board meets industry standards.

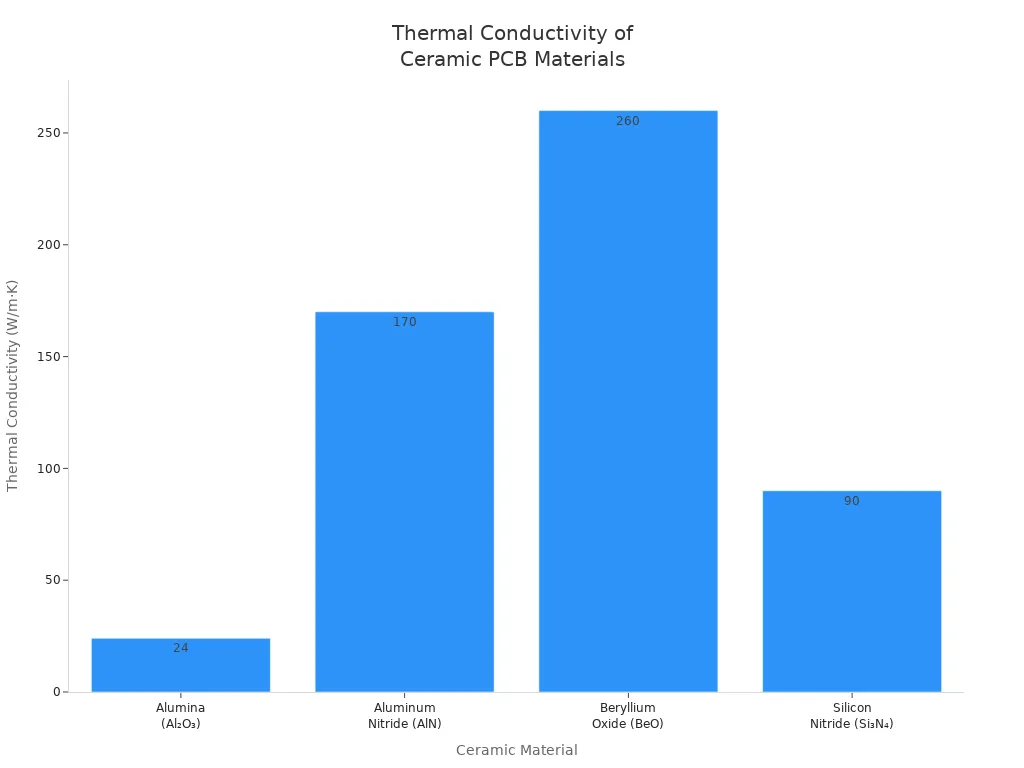

Thermal Conductivity

Thermal conductivity is one of the most critical factors for a high-quality ceramic pcb. You want your board to handle heat efficiently, especially in high-power applications. If the board cannot transfer heat away from components, you risk overheating and damage.

The minimum recommended thermal conductivity value for ceramic PCBs in high-power applications is above 18 W/mK.

Aluminum nitride ceramics can reach thermal conductivity values between 170 W/mK and 220 W/mK.

High thermal conductivity ensures your board stays cool and maintains stable performance.

LT CIRCUIT uses ceramics with high thermal conductivity to help you manage heat in your designs. This focus on thermal management protects your components and extends the life of your electronics.

Surface Finish

The surface finish of your ceramic pcb plays a big role in its electrical performance and longevity. You need a finish that protects against humidity, temperature changes, and contaminants. A good surface finish also prevents oxidation of copper traces and ensures reliable connections during assembly.

Surface finishes resist moisture and prevent short circuits.

They help your board maintain performance throughout its service life.

For high-frequency applications, the right surface finish supports signal integrity and precise impedance control.

LT CIRCUIT offers a range of surface finishes, including ENIG and immersion silver, to match your application needs. This attention to detail helps you achieve stable, long-lasting results.

Mechanical Strength

Mechanical strength is essential for ceramic PCBs used in industrial, automotive, or military electronics. You need a board that can withstand vibration, shock, and mechanical stress without deforming. Ceramic materials provide exceptional resistance to these forces, making them superior to traditional options like FR-4. This durability ensures your board remains reliable even in harsh environments.

LT CIRCUIT tests every board for mechanical strength, so you can trust your product to perform under pressure. When you select a high-quality ceramic pcb, you gain peace of mind knowing your electronics will last.

Tip: Always ask your manufacturer about their testing process and material selection. Strong, safe boards start with the right criteria.

Ceramic PCB Material Selection

Application Requirements

You should always start by matching the ceramic pcb material to your application’s needs. Different ceramic substrates offer unique strengths for various environments. For example, alumina works well for LED modules and general power boards because it balances cost and performance. Aluminum nitride is ideal for high-power electronics, such as inverters, due to its high thermal conductivity and high temperature resistance. Beryllium oxide provides the highest thermal efficiency but requires strict safety controls, making it suitable for aerospace and defense. Silicon nitride stands out in harsh environments, offering excellent thermal shock resistance and mechanical strength.

Here’s a quick comparison:

Ceramic PCB Substrate | Dielectric Constant (1MHz) | Typical Uses | Key Strengths | |

|---|---|---|---|---|

Alumina (Al₂O₃) | ≥ 24 | 9–10 | LED modules, power boards | Affordable, good all-rounder |

Aluminum Nitride (AlN) | ≥ 170 | 8.5–9 | High-power inverters, RF | High heat transfer, CTE matched to Si |

Beryllium Oxide (BeO) | 260–285 | 6.5–7 | Laser drivers, aerospace | Highest conductivity, safety controls |

Silicon Nitride (Si₃N₄) | 90 | 7.8 | EV modules, harsh electronics | Tough, thermal-shock resistance |

LT CIRCUIT offers a wide range of ceramic pcb materials and customization options, so you can select the best fit for your project.

Signal Integrity

Signal integrity depends on the dielectric properties of your ceramic substrate. You want low dielectric loss and strong electrical insulation to keep signals clear, especially in high-frequency or high-voltage resistance applications. Materials like aluminum nitride and beryllium oxide provide excellent dielectric performance and impedance control, which help reduce signal loss and distortion. Good impedance control also supports ceramic pcb assembly in RF and microwave circuits.

Tip: For high-frequency designs, always check the dielectric constant and loss tangent to ensure maximum efficiency and performance.

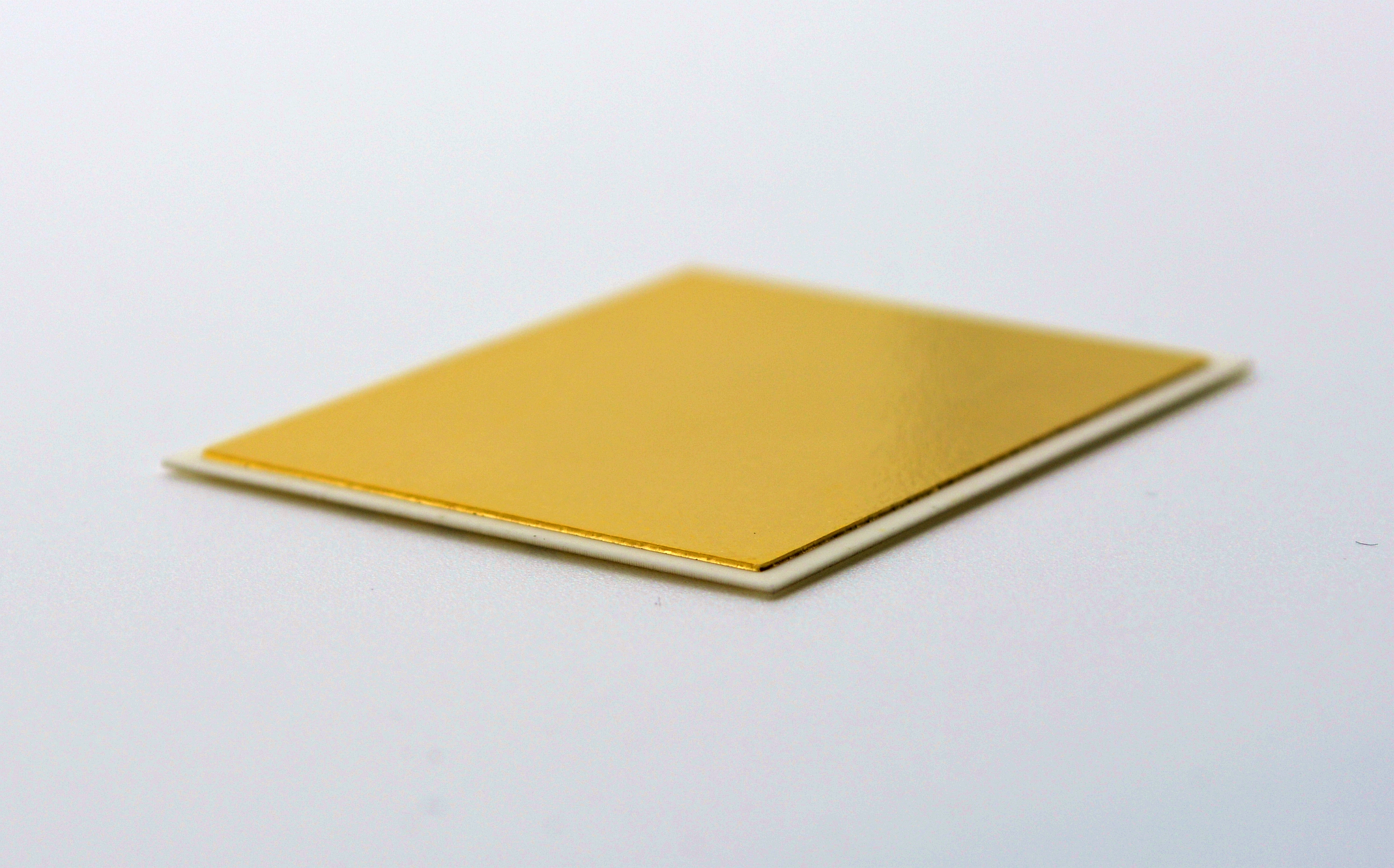

Board Thickness

Board thickness affects both mechanical strength and thermal management. Thicker ceramic boards improve heat dissipation and stability, which is vital for high-power electronics and demanding environments.

Thicker boards may enhance heat dissipation and mechanical stability, which is crucial for applications in power electronics, automotive, and high-frequency communication devices. This allows ceramic core PCBs to dissipate heat much more efficiently in high-power electronic devices, preventing performance degradation and component damage due to overheating, significantly improving device reliability and stability.

Proper thickness also helps maintain electrical insulation and supports precise impedance control during ceramic pcb assembly. LT CIRCUIT can customize board thickness to match your specific needs, ensuring your ceramic pcb technologies deliver reliable performance in any application.

Ceramic Base PCB Manufacturer Evaluation

Choosing the right ceramic base pcb manufacturer shapes the reliability and safety of your electronics. You need to evaluate several factors before making your decision. LT CIRCUIT stands out in the industry for its reputation, certifications, and customer support.

Experience & Reputation

You want a ceramic base pcb manufacturer with proven expertise and a strong reputation. Experienced manufacturers handle complex ceramic pcb manufacturing projects and deliver consistent results. LT CIRCUIT has built its reputation by focusing on advanced ceramic pcb manufacturing techniques and supporting a wide range of industries.

Use this table to compare manufacturers:

Criteria | Description |

|---|---|

Expertise and Technological Capabilities | Check the manufacturer’s skills in ceramic pcb manufacturing and their ability to manage complex designs. |

Quality Control and Material | Look for robust quality control, relevant certifications, and dependable ceramic materials. |

Customization, Design Support, and Capacity | Make sure they offer custom boards, design help, and enough production capacity for your needs. |

Cost, Customer Support, and Communication | Evaluate pricing and how well they communicate and support you during ceramic pcb manufacturing. |

A ceramic base pcb manufacturer with a strong reputation will help you avoid delays and ensure your boards meet high standards.

Quality Control

Quality control is the backbone of reliable ceramic pcb manufacturing. You need a ceramic base pcb manufacturer that uses strict quality checks at every stage. LT CIRCUIT uses advanced inspection methods to guarantee defect-free ceramic boards.

Key quality control processes include:

Visual inspection

Automated optical inspection (AOI)

In-circuit testing (ICT)

Functional testing

These steps help you receive ceramic boards that perform well and last longer. High-quality ceramic pcb manufacturing boosts assembly efficiency and increases manufacturing yields. You get durable boards that support your project’s success.

Tip: Ask your ceramic base pcb manufacturer about their quality control process. Reliable quality checks mean fewer defects and better performance.

Certifications

Certifications show that a ceramic base pcb manufacturer meets international standards. You should look for manufacturers with the following certifications:

Certification | Description |

|---|---|

ISO 9001 | Focuses on quality management systems for customer and regulatory requirements. |

ISO 13485 | Applies to ceramic pcb manufacturing for medical devices. |

IPC A-600 | Ensures acceptability of printed ceramic boards. |

IPC A-610 | Covers acceptability of electronic assemblies. |

IPC A-6012 | Addresses requirements for multilayer ceramic PCBs. |

ISO 14001 | Encourages environmental monitoring during ceramic pcb manufacturing. |

IATF 16949 | Relevant for automotive electronics. |

RoHS & REACH | Excludes hazardous substances from ceramic pcb manufacturing. |

UL Certification | Indicates flame resistance and dielectric strength. |

LT CIRCUIT holds multiple certifications, which means you can trust their ceramic pcb manufacturing to meet strict safety and quality standards.

Customer Support

Responsive customer support makes a big difference in ceramic pcb manufacturing. You need a ceramic pcb manufacturer that answers your questions quickly and helps you solve problems before they affect your project. LT CIRCUIT’s team checks new files, confirms changes, and communicates about delays or quality concerns right away.

Good customer support includes:

Fast responses to your questions

Immediate updates about changes or issues

Regular feedback to build trust

Strong support helps you avoid mistakes and keeps your ceramic pcb manufacturing project on track. You build a long-term partnership with your ceramic base pcb manufacturer when you receive reliable help and clear communication.

Note: Always test the customer support of your ceramic pcb manufacturer before placing large orders. Quick and clear communication leads to better project outcomes.

Ceramic PCB Boards Safety & Reliability

When you work with ceramic pcb boards, you need to focus on safety and reliability. These boards must pass strict tests, meet industry compliance, and show long-term durability. LT CIRCUIT uses advanced testing and quality checks to help you achieve the highest reliability for your ceramic pcb boards.

Testing Standards

You want your ceramic pcb boards to meet the best testing standards. These standards help you avoid problems like manufacturing defects, burnt components, or environmental stress. LT CIRCUIT follows industry-leading protocols to ensure your ceramic pcb boards perform well in every application.

Organization | Standards | Description |

|---|---|---|

IPC | PCB appearance acceptable standard | |

IPC-6012 | Rigid printed circuit board performance specification | |

SGS | N/A | Physical characteristics, durability, and reliability testing |

You can trust that ceramic pcb boards from LT CIRCUIT meet these standards, giving you peace of mind about their reliability.

Compliance

Ceramic pcb boards must meet strict compliance requirements, especially for medical and aerospace uses. You need to check that your boards follow these rules:

IPC Class 3 / IPC-6012 Class 3A for high-performance and critical systems

FDA Regulations (21 CFR Part 820) for medical device quality

RoHS and REACH for environmental safety

ISO 13485 for medical device quality management

These rules make sure your ceramic pcb boards stay safe and reliable in demanding environments. LT CIRCUIT designs ceramic pcb boards to meet these compliance needs, so you can use them in sensitive applications.

Durability

You want ceramic pcb boards that last. Durability means your boards resist chemicals, moisture, and mechanical stress. LT CIRCUIT tests ceramic pcb boards for:

Durability Metric | Description |

|---|---|

Resists acids, bases, solvents, and other chemicals | |

Mechanical Strength | Handles vibration, shock, and stress better than organic materials |

Moisture Absorption | Almost zero, so boards do not change shape or lose reliability |

Radiation Resistance | Works well in space or nuclear settings |

Thermal Shock Resistance | Survives extreme temperature changes |

You reduce risks like soldering issues, aging materials, or human error by choosing ceramic pcb boards with proven durability. LT CIRCUIT focuses on reliability, so your ceramic pcb boards keep working even in harsh conditions.

Tip: Always ask your supplier about their testing and compliance process. Reliable ceramic pcb boards start with strong standards and proven durability.

Selection Questions for Manufacturers

When you start your selection process for a ceramic PCB manufacturer, you need to ask the right questions. These questions help you compare options and make sure you choose a partner who meets your needs for strong, safe boards.

Sample Requests

Requesting samples is a key step in your selection. You want to see real products before making a big commitment. Follow these best practices:

Define your project requirements, including electrical and mechanical needs.

Research and compare suppliers based on experience and customer reviews.

Review technical specifications like material type, thickness, and thermal conductivity.

Request samples or prototypes to test under your actual conditions.

Check the supplier’s quality assurance and inspection methods.

Ask about pricing, lead times, and customer support.

Review warranty and return policies before making your final selection.

Tip: LT CIRCUIT’s customer support team can guide you through the sample request process and answer technical questions.

Warranty Policies

Understanding warranty policies protects you during your selection. Manufacturers usually cover defects in materials and workmanship. They will repair or replace defective boards at no cost. Exclusions often include misuse, abuse, or external damage.

Manufacturer | Warranty Duration | Coverage | Exclusions |

|---|---|---|---|

AdvancedPCB | 90 days | Defects in materials and workmanship | Misuse, abuse, cosmetic damage |

WELLER | 1 year | Defects under normal use | Neglect, unauthorized repairs |

Optimatech | Varies | Defects in materials and workmanship | Unauthorized modifications |

Always ask for clear warranty terms during your selection.

Customization

Customization options can make your selection more effective for specialized applications. Manufacturers offer choices like advanced manufacturing technologies, thick or thin film processes, and multilayer fabrication. These options help you get the right board for your project’s needs. LT CIRCUIT provides a wide range of customization, from premium materials to precision processing and strict quality control.

Note: Use LT CIRCUIT’s customer support to discuss your customization needs and get expert advice for your selection.

You can select strong, safe ceramic PCBs by following expert steps:

Description | |

|---|---|

Experience & Expertise | Choose proven manufacturers for consistent results. |

Material Quality | Use premium substrates for durability and performance. |

Certifications | Verify industry standards for safety and reliability. |

Prioritize trusted brands like LT CIRCUIT to build reliable, long-term partnerships.

FAQ

What are the main benefits of ceramic PCBs?

You get excellent heat dissipation, high mechanical strength, and reliable electrical insulation. Ceramic PCBs work well in harsh environments and high-power applications.

Tip: Choose ceramic PCBs for better performance in demanding electronics.

How do you select the right ceramic material for your PCB?

You should match the material to your application’s needs. Consider thermal conductivity, dielectric properties, and mechanical strength. LT CIRCUIT offers expert guidance for your selection.

Can you request custom sizes or shapes for ceramic PCBs?

Yes, you can request custom sizes, shapes, and thicknesses. LT CIRCUIT supports a wide range of customization options to fit your project requirements.

See Also

Essential Safety Measures When Designing PCB Circuit Boards

Understanding How Ceramic PCBs Are Used in Today's Industries

The Advantages of Ceramic PCBs for Effective Heat Management

A Comprehensive Overview of Multilayer Ceramic PCB Production

Selecting a Reliable PCB Manufacturer for Your Business Needs