How Ceramic Base PCB Manufacturers Stack Up on Quality and Price

To achieve the best results in the PCB industry, it’s essential to partner with ceramic base PCB manufacturers that consistently deliver high-quality products at competitive prices. Ceramic base PCB manufacturers provide solutions with superior thermal conductivity and reliability, making them the preferred choice for advanced PCBs and critical printed circuit boards. Leading ceramic base PCB manufacturers such as Kyocera Corporation, Murata Manufacturing, Rogers Corporation, NGK Spark Plug, and Maruwa dominate the global market, each bringing unique strengths in manufacturing and innovation.

Manufacturer | Market Share (%) | Notes |

|---|---|---|

Kyocera Corporation | N/A | Major player in ceramic-based PCBs |

Murata Manufacturing Co., Ltd. | N/A | Focus on innovation and R&D |

Rogers Corporation | N/A | Known for advanced manufacturing processes |

NGK Spark Plug Co., Ltd. | N/A | Engaged in strategic partnerships |

Maruwa Co., Ltd. | N/A | Develops new applications for ceramics |

LT CIRCUIT distinguishes itself among ceramic base PCB manufacturers in the PCB industry by offering high-quality products and advanced ceramic solutions. Whether you prioritize top performance, cost efficiency, or a balanced approach, you’ll find recommendations from leading ceramic base PCB manufacturers that align with your needs.

Key Takeaways

Choose ceramic base PCB manufacturers that prioritize quality and innovation. This ensures you receive reliable products that meet your project needs.

Consider thermal conductivity and electrical performance when selecting a manufacturer. High-quality materials improve heat management and signal integrity.

Look for customization options and strong customer support. This helps you get PCBs tailored to your specific requirements and ensures effective communication.

Compare prices based on design complexity and material type. Understanding these factors can help you find cost-effective solutions without sacrificing quality.

Always check manufacturers' certifications and quality control processes. This guarantees that your PCBs meet industry standards and perform reliably in demanding applications.

Leading Ceramic Base PCB Manufacturers

Industry Leaders Overview

When you look for the best pcb manufacturers, you want to know who leads the market. The top ceramic base pcb manufacturers include Kyocera Corporation, Murata Manufacturing, Rogers Corporation, NGK Spark Plug, Maruwa, and LT CIRCUIT. These companies have built strong reputations in the pcb industry. They stand out because they focus on innovation, quality, and customer satisfaction.

You can use several criteria to compare these pcb manufacturers. The table below shows the most important factors:

Criteria | Description |

|---|---|

Expertise and Technological Capabilities | Check the manufacturer's skill in pcb production and their ability to handle complex designs. |

Quality Control and Material | Look for strong quality control, certifications, and reliable materials. |

Customization, Design Support, and Capacity | See if they offer custom boards, design help, and enough capacity for your needs. |

Cost, Customer Support, and Communication | Compare prices, and see how well they support and communicate with customers. |

These criteria help you find pcb manufacturers that match your project needs. Each company brings something unique. For example, Kyocera and Murata focus on advanced technology. Rogers Corporation is known for its manufacturing processes. NGK Spark Plug and Maruwa develop new uses for ceramics.

LT CIRCUIT’s Position in the Market

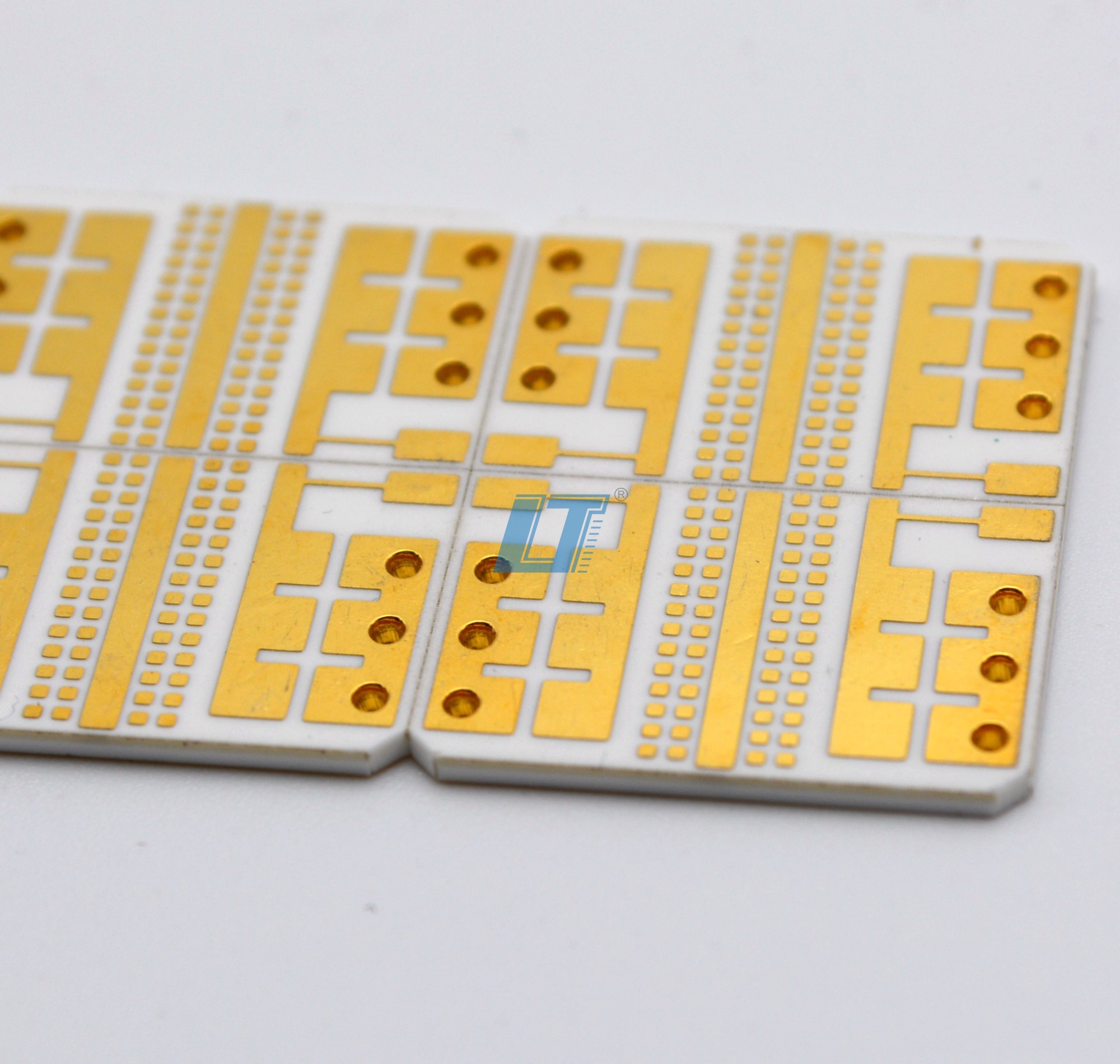

LT CIRCUIT stands out among pcb manufacturers for its commitment to quality and innovation. You will find that LT CIRCUIT uses advanced materials and strict quality control to deliver reliable pcb products. The company offers a wide range of solutions, including HDI and multilayer boards. LT CIRCUIT also provides strong design support and customization options, making it easy for you to get the right pcb for your application.

Many customers choose LT CIRCUIT because of its excellent customer service and fast communication. The company’s focus on meeting customer needs has helped it earn a trusted place in the pcb industry. If you want a manufacturer that balances quality, technology, and support, LT CIRCUIT is a top choice.

Ceramic PCB Fundamentals

Key Features and Benefits

Ceramic PCBs stand out in the pcb industry because they offer unique advantages for advanced pcbs and demanding applications. You can see how these features compare in the table below:

Feature/Benefit | Description |

|---|---|

Moves heat away from components, reduces the need for extra cooling, and prevents hotspots. | |

Thermal Shock Resistance | Handles quick temperature changes without damage, perfect for thermal cycling. |

Extended Temperature Range | Works in high-temperature places where other materials might fail. |

Superior Dielectric Properties | Keeps signal loss low, improves signal quality, and boosts power efficiency at high speeds. |

Frequency Stability | Stays consistent across many frequencies, which is important for modern communication. |

Mechanical Durability | Strong mechanical properties help the board last in tough environments. |

Dimensional Stability | Holds its shape under heat, lowering the risk of cracks and making the board more reliable. |

Hermetic Properties | Blocks moisture and protects against corrosion. |

Applications | Used in automotive, aerospace, industrial, and military fields where reliability matters. |

You benefit from these features when you need printed circuit boards that must perform in harsh or high-power environments. Ceramic materials help your pcb last longer and work better, especially when heat and reliability are critical.

Why Manufacturer Choice Matters

Choosing the right ceramic pcb manufacturer affects how well your product performs in real-world situations. Different industries rely on ceramic pcbs for their unique strengths:

Aerospace and avionics systems need thermal stability and reliability in extreme temperatures.

Automotive electronics depend on high thermal conductivity and low expansion rates to keep electric vehicles and hybrids running safely.

Industrial and power electronics require strong thermal management and electrical insulation, especially in solar inverters.

Military and defense applications demand durability in harsh conditions to ensure mission success.

LED lighting and high-power semiconductors use ceramic pcbs for excellent heat dissipation, which helps extend the life of the components.

When you select a manufacturer with proven expertise, you get printed circuit boards that meet strict standards. This choice helps your products succeed in the most challenging environments.

Quality Factors in Ceramic Base PCB Manufacturers

Thermal Conductivity

When you compare quality among ceramic base PCB manufacturers, thermal conductivity stands out as a key factor. High thermal conductivity helps your printed circuit boards manage heat efficiently. This is vital for advanced pcbs in high-reliability sectors like automotive and aerospace. You want your pcb manufacturers to use materials that move heat away from components quickly. The table below shows typical thermal conductivity values for ceramic substrates used by leading manufacturers:

Ceramic Substrate Material | Thermal Conductivity (W/mK) |

|---|---|

Aluminum Nitride (AIN) | 150 – 180 |

Aluminum Oxide (Al₂O₃) | 18 – 36 |

Beryllium Oxide (BeO) | 184 – 300 |

Boron Nitride (BN) | 15 – 600 |

Silicon Carbide (SiC) | 70 – 210 |

You should look for pcb manufacturers who offer high-quality products with substrates like aluminum nitride or beryllium oxide. These materials provide superior thermal conductivity, which improves reliability and extends the life of your boards. In the pcb industry, manufacturers who focus on thermal management deliver better results for demanding applications.

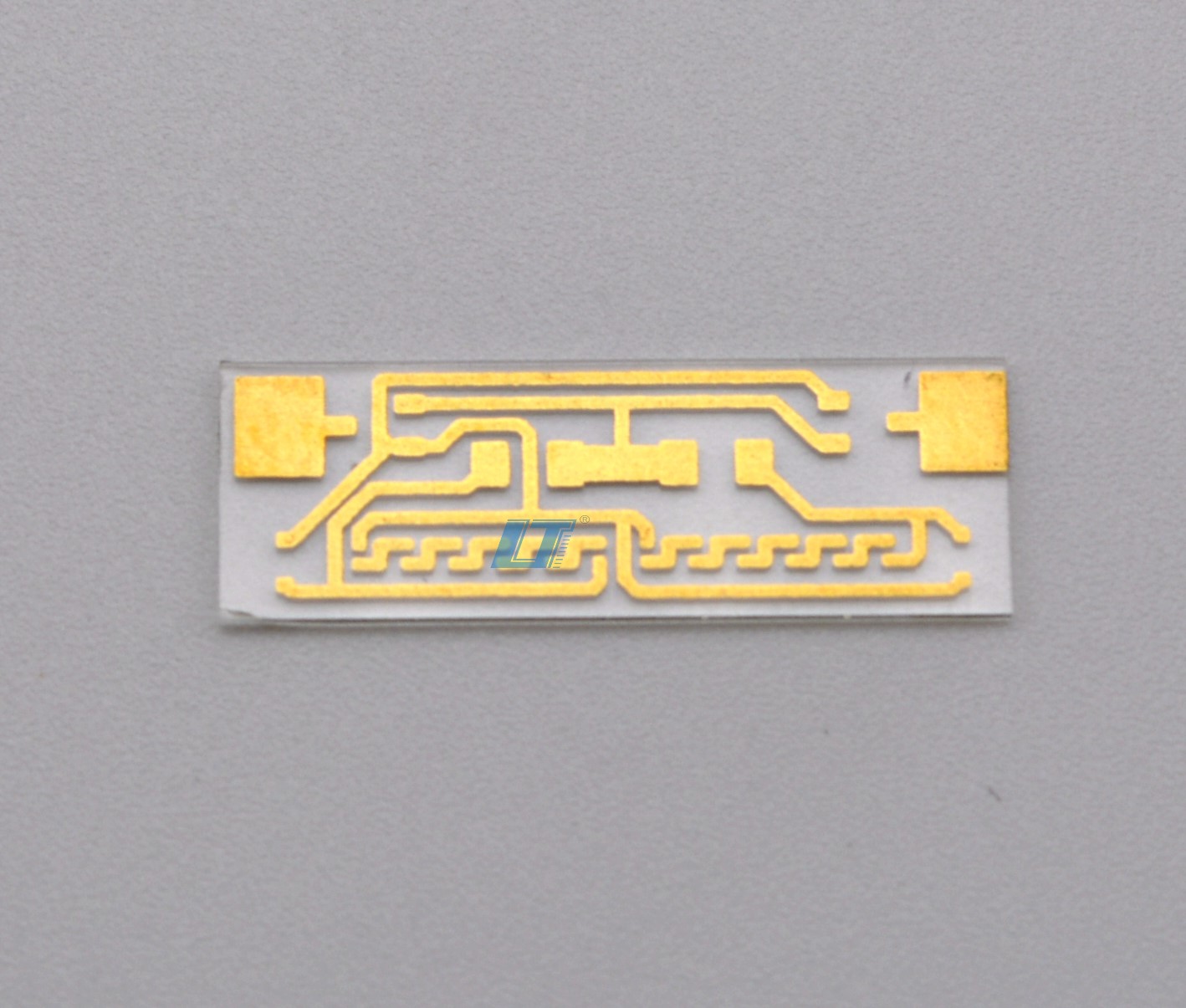

Electrical Performance

Electrical performance is another critical measure of quality for ceramic base PCB manufacturers. You need your boards to maintain strong insulation and low signal loss. Ceramic materials excel in this area, especially compared to standard FR4 boards. Here are the main electrical performance advantages you get from top pcb manufacturers:

Ceramic materials provide excellent electrical insulation.

Low dielectric loss and high breakdown voltage support high-frequency and high-voltage uses.

You benefit from better signal integrity and reduced distortion in advanced pcbs.

Ceramic PCBs handle high voltages without breakdown or leakage. This makes them ideal for power electronics and RF communication systems. When you choose pcb manufacturers who prioritize electrical performance, you get reliable boards for high-reliability sectors.

Reliability and Standards

Reliability sets the best pcb manufacturers apart. You want your boards to meet strict international standards. These standards ensure consistent quality and safety. Leading manufacturers in the pcb industry follow certifications that cover every stage of production. The table below lists important standards for ceramic base PCB manufacturers:

Standard | Description |

|---|---|

ISO 9001 | Structured quality management and traceability from raw ceramic to finished board. |

ISO 14001 | Environmental monitoring during firing and metallization. |

IATF 16949 | Automotive electronics production chain coverage. |

RoHS & REACH | Excludes hazardous substances, important for medical and consumer electronics. |

UL Certification | Flame resistance and dielectric strength for thermal and electrical stability. |

IPC-6012 | Performance and qualification for rigid PCBs, including ceramic materials. |

You should select pcb manufacturers who meet these standards. This ensures your boards deliver high reliability in every application. Manufacturers who invest in quality control and certification provide high-quality products that last longer and perform better.

Comparing Manufacturer Quality

LT CIRCUIT Quality Highlights

You want to know how LT CIRCUIT stands out among pcb manufacturers. LT CIRCUIT focuses on delivering high-quality products that meet strict standards in the pcb industry. You see this commitment in every step of their process. LT CIRCUIT uses advanced materials for ceramic pcb boards. These materials help your printed circuit boards handle heat and electrical stress. You get reliable performance in demanding environments.

LT CIRCUIT invests in strong quality control. You benefit from thorough inspections and testing. The company uses flying probe tests and E-tests to check every pcb. You can trust that each board meets your specifications. LT CIRCUIT follows international standards like ISO 9001 and IPC-6012. These standards ensure consistent quality and safety.

You also get customization options. LT CIRCUIT offers different solder mask colors and surface finishes. You can choose ENIG, HASL, or immersion silver. This flexibility helps you match your advanced pcbs to your project needs. LT CIRCUIT supports you with fast communication and design help. You get answers quickly and solutions that fit your requirements.

Tip: If you need high-quality products for critical applications, LT CIRCUIT gives you strong reliability and advanced technology.

Other Top Manufacturers

You may want to compare LT CIRCUIT with other leading ceramic base pcb manufacturers. Top pcb manufacturers like Kyocera Corporation, Murata Manufacturing, Rogers Corporation, NGK Spark Plug, and Maruwa also focus on quality. These manufacturers use advanced ceramic materials to improve thermal conductivity and electrical performance.

You see Kyocera and Murata lead in innovation. They develop new processes for ceramic pcb boards. Rogers Corporation uses precise manufacturing to deliver consistent quality. NGK Spark Plug and Maruwa create solutions for special applications. Each company invests in quality control and meets international standards.

Here is a table that shows how these manufacturers compare on key quality factors:

Manufacturer | Thermal Conductivity | Electrical Performance | Reliability Standards | Customization |

|---|---|---|---|---|

LT CIRCUIT | High | Excellent | ISO, IPC, UL | Strong |

Kyocera | High | Excellent | ISO, IPC, UL | Moderate |

Murata | High | Excellent | ISO, IPC, UL | Moderate |

Rogers Corporation | High | Excellent | ISO, IPC, UL | Moderate |

NGK Spark Plug | High | Excellent | ISO, IPC, UL | Moderate |

Maruwa | High | Excellent | ISO, IPC, UL | Moderate |

You notice that all these pcb manufacturers deliver high-quality products. LT CIRCUIT stands out for its customization and customer support. Other manufacturers focus on large-scale production and innovation. You should choose the manufacturer that matches your project needs. If you want advanced pcbs with strong support, LT CIRCUIT is a top choice. If you need mass production or special research, other manufacturers may fit your requirements.

Note: You should always check the manufacturer's certifications and testing methods. This helps you get reliable ceramic pcb boards for your application.

Cost of Ceramic PCBs

Price Ranges and Influencing Factors

You want to know how much ceramic PCBs cost before you start your project. The price can change based on the design and the manufacturer you choose. Most manufacturers in the PCB industry offer ceramic PCBs at different price points. You see standard, low-complexity designs priced between $10 and $50 per square inch. High-performance configurations can reach $50 to $500 or more per square inch. The table below shows typical price ranges:

Type of PCB | Price Range (per square inch) |

|---|---|

Standard, low-complexity designs | |

High-performance configurations | $50 to $500 or more |

Several factors influence the final cost of your ceramic PCB. You need to consider these when comparing manufacturers:

Type of ceramic material used

Board thickness and size

Metallization type and thickness

Circuit complexity

Production volume

Surface finishing and coatings

Type of ceramic PCB process

Tolerance and yield requirements

Post-processing needs

The type of ceramic material affects the price. Aluminum nitride costs more than aluminum oxide because it offers better thermal performance. Larger and thicker boards require more raw materials and longer manufacturing time. Complex circuits with fine lines and small spacing increase the cost. High-quality metallization, such as gold, adds to the expense. Surface finishes and coatings also play a role. If you order more boards, you often get a lower price per piece. Manufacturers with advanced technology can handle tight tolerances and special post-processing, but these features may raise the price.

Tip: You can lower your cost by choosing standard materials and simple designs. Ask your manufacturer about volume discounts for large orders.

Value for Money

You want to get the best value for your investment. Cost-effective manufacturing means you receive high-quality printed circuit boards at a reasonable price. When you compare manufacturers, look at both the price and the quality of service. Some manufacturers offer extra benefits that help you save money in the long run.

Manufacturers like PCBTok, Rush Flex PCB, and MCL PCB focus on cost-effective manufacturing for high-volume orders. They use design rule checks and design for manufacturability to optimize layouts and reduce waste. Skilled engineering staff ensures your advanced PCBs meet strict standards. The table below compares key features and cost-effectiveness:

Manufacturer | Key Features | Cost-Effectiveness |

|---|---|---|

PCBTok | Advanced DRC, Free DFM check, Strict Quality Assurance | High due to optimized processes and no minimum orders |

Rush Flex PCB | High-quality flex and rigid-flex PCBs | Competitive for large-volume orders |

MCL PCB | DRC, DFM, Skilled Staff, Quality Assurance | Reliable service, premium quality, higher costs |

You see PCBTok uses IPC Class 2/3 standards and tests every board for quality. Rush Flex PCB specializes in flex and rigid-flex PCBs for prototypes and large orders. MCL PCB has a dedicated quality control team that monitors every stage of production.

LT CIRCUIT stands out among PCB manufacturers for its balance of quality and cost. You get advanced ceramic PCBs with strong reliability and customization options. LT CIRCUIT uses high-grade materials and strict quality control, so you receive boards that last longer and perform better. The company offers flexible pricing for different order sizes, making it economical for both small and large projects. You benefit from fast communication and design support, which helps you avoid costly mistakes.

Note: When you compare cost-effective options, look beyond the initial price. Consider the manufacturer’s reputation, quality assurance, and support. LT CIRCUIT provides excellent value for money, especially if you need reliable ceramic PCBs for demanding applications.

You can use cost comparison to find the best deal. Ask manufacturers for detailed quotes and check what is included. Some offer free design checks or testing, which saves you money. Choose a manufacturer that matches your needs for quality, price, and service.

Manufacturer Capabilities

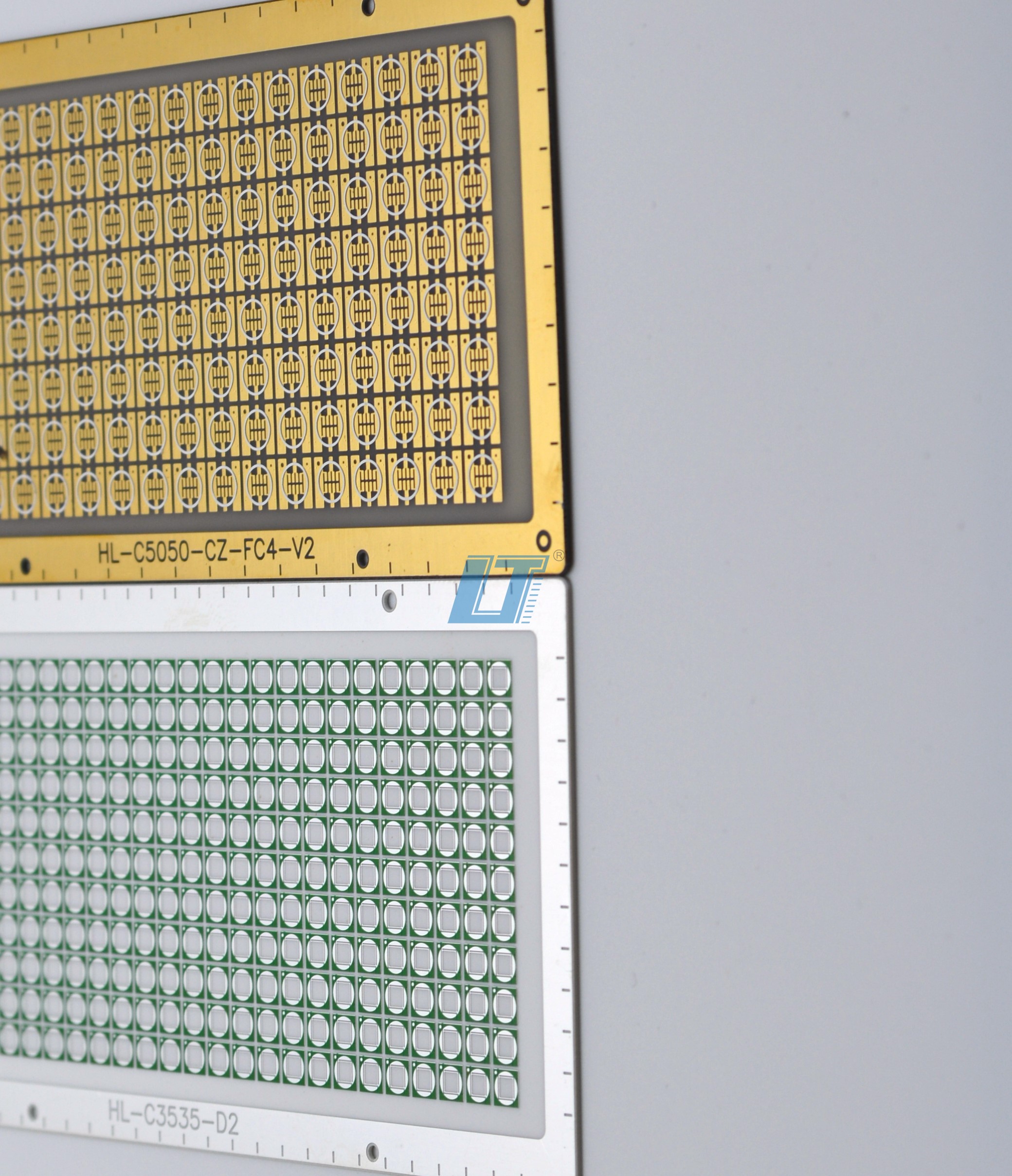

Customization and Technology

You want your ceramic base PCB to match your exact needs. Leading manufacturers give you many customization options. You can choose the board size, shape, and thickness. You select the type of ceramic substrate and metallization. Some companies let you pick surface finishes and solder mask colors. You also get to decide on testing methods, such as flying probe or E-test.

Manufacturers like Best Technology offer fully customized ceramic base PCBs. You can ask for special layouts or features for your application. LT CIRCUIT supports you with advanced design help and flexible solutions. You benefit from their experience in handling complex requirements.

Many top manufacturers invest in the latest production technologies. You see companies like BEST Technology focus on research and development. They build high-quality ceramic circuit boards using modern equipment. Almost half of key manufacturers now spend more on high-performance ceramic substrate production lines. The market shows a strong trend toward vertical integration and strategic alliances, especially in Asia-Pacific. These moves help manufacturers improve their capabilities and deliver better products.

Tip: When you need a unique solution, ask your manufacturer about their customization and technology options. Advanced capabilities mean you get a PCB that fits your project perfectly.

Production Capacity

You need a manufacturer with enough production capacity to meet your deadlines. Leading ceramic base PCB manufacturers run large-scale facilities. They use automated lines and strict quality control. You get consistent results, even for big orders.

LT CIRCUIT offers strong production capabilities. You can order small batches for prototypes or large volumes for mass production. The company adapts to your schedule and project size. Other top manufacturers also expand their capacity by investing in new equipment and better processes. This ensures you receive your boards on time and with reliable quality.

Note: Always check a manufacturer’s production capacity before placing your order. High capabilities mean you avoid delays and get the quality you expect.

Choosing the Right Ceramic Base PCB Manufacturer

Best for Quality

If you want the highest quality for your ceramic pcb, you should focus on manufacturers with strong capabilities and a proven track record. These manufacturers use high-quality base materials from trusted suppliers. They also have advanced machinery that can handle up to 32 copper layers and manage signal control. You get expert help with material selection and design improvement. Quick sample production lets you verify your design fast. Top manufacturers offer comprehensive assembly options, including surface mount and through-hole types. They test every board for durability and electrical performance. You can customize board thickness, copper weight, and solder mask to fit your needs. The best ceramic base pcb manufacturers also make ordering easy and deliver on time.

Key factors to look for:

Expert assistance in design and material selection

Use of high-quality materials

Customization options

Tip: Choose manufacturers who communicate well and support you through every step.

Best for Cost

If you need a cost-effective solution, look for manufacturers who optimize their processes and offer competitive price points. These manufacturers streamline their ordering process and use efficient production methods. You still get reliable quality, but at a lower cost. Some manufacturers focus on high-volume orders, which helps reduce the price per unit. They also provide quick sample runs so you can test your design without a big investment.

What to expect from cost-focused manufacturers:

Efficient manufacturing processes

Lower price for larger orders

Fast sample production

Reliable quality at a reasonable cost

Note: Always compare the total cost, including testing and delivery, not just the initial price.

Balanced Options

You may want a balance between quality and price. Some manufacturers, like Best Technology Co., Limited, are known for offering both. They provide high-quality ceramic pcb products and efficient service. You get advanced capabilities, strong quality control, and flexible customization. These manufacturers invest in technology and support, so you receive reliable boards without overspending. LT CIRCUIT also stands out for its balanced approach. You benefit from advanced manufacturing, excellent customer support, and a fair price.

Balanced manufacturers offer:

Reliable quality and advanced capabilities

Competitive pricing

Customization and design support

Timely delivery and clear communication

Choosing a balanced manufacturer helps you get the most value for your project.

You see top ceramic base pcb manufacturers excel in quality, price, and balanced value. If you need high performance, choose manufacturers with strict quality systems. For budget projects, focus on cost drivers like production volume and material choices. When you request a quote, share your pcb requirements, quantity, budget, timeline, and any special capabilities. Careful planning helps you avoid costly recalls and ensures reliable results. Contact LT CIRCUIT or other manufacturers to discuss your project and get expert support.

Recent case studies show that poor-quality PCBs can lead to expensive recalls and brand damage. Always match your technical needs with the right manufacturer.

Purpose | |

|---|---|

PCB requirements (layers, material type) | Ensure technical specifications are met |

Quantity needed | Get accurate pricing |

Target budget | Align with financial goals |

Expected production timeline | Set delivery expectations |

Special capabilities | Meet unique project needs |

FAQ

What makes ceramic base PCBs better than standard PCBs?

Ceramic base PCBs offer higher thermal conductivity and better electrical insulation. You get improved heat management and reliability. These features make them ideal for high-power and high-frequency applications.

How do you choose the right ceramic PCB manufacturer?

You should check the manufacturer’s certifications, quality control, and customization options. Look for strong customer support and proven experience. Ask for samples or references before placing your order.

Why does the price of ceramic PCBs vary so much?

Prices change based on material type, board size, complexity, and order volume. High-performance materials like aluminum nitride cost more. You can save by choosing standard designs or ordering in larger quantities.

What advantages does LT CIRCUIT offer for ceramic PCBs?

LT CIRCUIT gives you advanced materials, strict quality control, and flexible customization. You benefit from fast communication and expert design support. The company balances quality and cost, making it a strong choice for many projects.

See Also

The Superior Heat Dissipation Properties of Ceramic PCBs

Understanding How Ceramic PCBs Are Used Across Industries

A Comprehensive Overview of Multilayer Ceramic PCB Production