Ceramic multilayer PCB explained for beginners

Have you ever wondered why some electronics perform exceptionally well, even under tough conditions? A ceramic multilayer PCB is engineered with multiple layers of advanced ceramic materials, providing robust and reliable circuit performance. This type of ceramic multilayer PCB enables devices to withstand high temperatures and resist harsh chemicals, ensuring long-lasting operation. Many innovative companies incorporate ceramic multilayer PCB technology into their cutting-edge gadgets, as it maintains signal integrity and allows for more components to be integrated into compact spaces. The global market for ceramic multilayer PCB is rapidly expanding, as shown below:

Year | |

|---|---|

2024 | 1.59 billion |

2025 | 1.84 billion |

2034 | 5.75 billion |

Leading brands like LT CIRCUIT are at the forefront of this field, utilizing premium ceramic materials in their ceramic multilayer PCB products. This commitment ensures your electronics deliver superior performance and durability.

Key Takeaways

Ceramic multilayer PCBs are very strong and last long. They work well in places with harsh conditions.

These PCBs use special ceramic materials. These materials help control heat better than regular FR4 boards. They also make the boards tougher.

Picking a ceramic multilayer PCB can make your devices work better. You can fit more circuits into smaller spaces.

LT CIRCUIT lets you choose custom ceramic PCBs. This helps you get the right type for your own electronics.

Many industries use ceramic multilayer PCBs. They are used in cars, planes, and medical tools. This shows they are useful and work well.

What is a ceramic multilayer PCB?

Basic concept

A ceramic multilayer PCB is a special printed circuit board. It is made by stacking thin ceramic layers on top of each other. Each layer has small paths for electricity and spots for parts. When these layers are put together, the board becomes strong and small. This lets it handle more complex circuits than a board with just one layer.

Ceramic materials like alumina and aluminum nitride make up the base of these boards. These materials give the board strength and help it deal with heat. You will find ceramic PCBs in devices that work in tough places or need to handle lots of power. The ceramic layers protect the circuits inside from damage. They also help keep everything working well.

The main parts of a ceramic multilayer PCB are the ceramic substrates and the conductor materials. Here is a table that shows the usual materials in these boards:

Component Type | Materials Used |

|---|---|

Ceramic Substrates | Aluminum Nitride (AIN), Aluminum oxide (Al2O3), Beryllium oxide (BeO) |

Conductor Materials | Copper (Cu), Silver (Ag), Gold (Au), Platinum (Pt), Palladium (Pb) |

Ceramic PCBs use special materials that move heat away from important parts fast. This helps keep your electronics safe and working well.

Most ceramic multilayer PCBs have between 4 and 12 layers. Simple devices might use a 4-layer or 6-layer board. Advanced electronics can use 8, 10, or even 12 layers. More layers mean more connections and features in a smaller space.

How it differs from standard multilayer PCB

You might wonder how a ceramic multilayer PCB is different from a regular multilayer PCB. The biggest difference is the materials used. Standard multilayer PCBs use FR4, which is a kind of fiberglass. Ceramic PCBs use ceramic materials like alumina and aluminum nitride.

Here are some main differences:

Ceramic multilayer PCBs use materials with high thermal conductivity, like alumina and aluminum nitride. These materials help the board handle heat much better than FR4.

Standard multilayer PCBs use FR4, which does not move heat as well as ceramic.

Ceramic PCBs have better shape stability and are stronger. They keep their shape and work well even when it is hot or in tough places.

You can trust ceramic circuit boards to work well, even where regular boards might stop working.

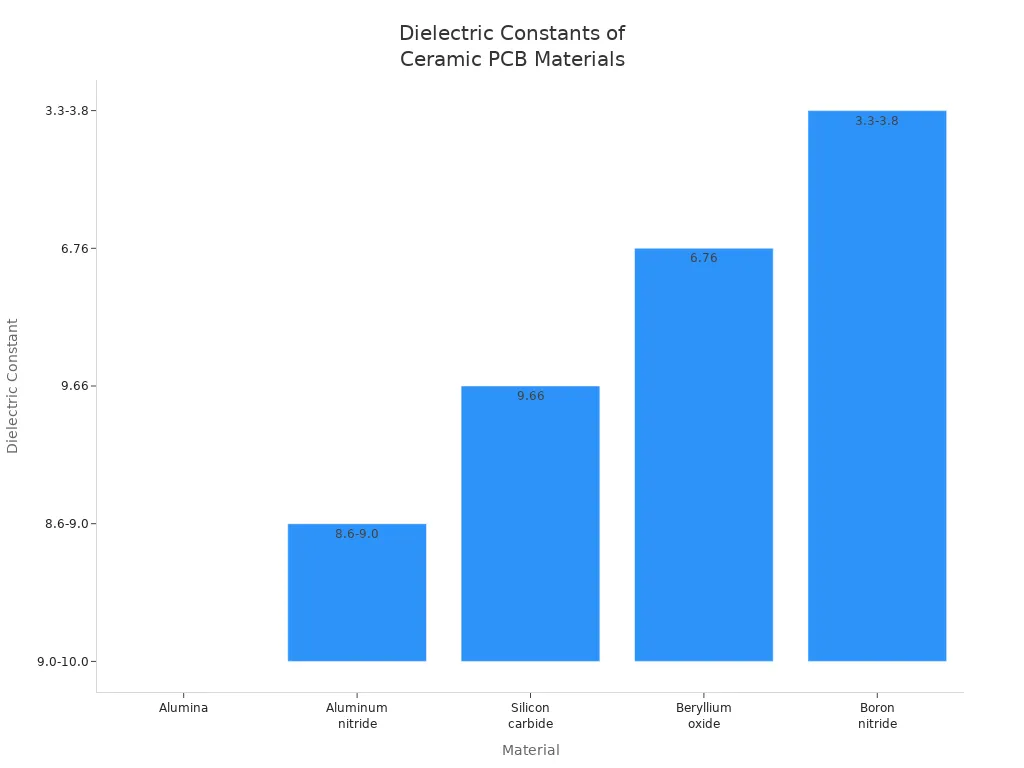

Ceramic multilayer PCBs also have different electrical properties. Look at this table to see how ceramic materials compare to FR4:

Material | Thermal Conductivity | Dielectric Constant |

|---|---|---|

Alumina | ~20x FR4 | 9.0 to 10.0 |

Aluminum nitride | ~100x FR4 | 8.6 to 9.0 |

Silicon carbide | ~100x FR4 | ~9.66 |

Beryllium oxide | >100x FR4 | ~6.76 |

Boron nitride | >100x FR4 | 3.3 to 3.8 |

You can also see the dielectric constants of these materials in this chart:

When you pick a multilayer ceramic PCB, you get a board that handles heat better, lasts longer, and works well in hard situations. These features make ceramic PCBs a great choice for advanced electronics and industries that need high performance.

How ceramic multilayer PCB works

Structure and stack-up

A ceramic multilayer PCB has a smart design. It helps electronics work better. The board is made of many layers stacked together. Each layer does something important. The ceramic layers make the board strong. They also help move heat away from parts that get hot. This is called high thermal conductivity. Alumina and aluminum nitride are used in these layers. These materials keep the board strong and cool.

You can see thin metal lines on the ceramic layers. These lines carry signals and power to different places. Most of the time, copper is used for these lines. Sometimes, silver or gold is used for even better results. Vias are tiny holes filled with metal. They connect the layers and let electricity move up and down. Tungsten is often used in these vias. Dielectric layers go between the metal lines. They stop electricity from going where it should not. Power and ground planes are also in the stack-up. These planes keep the voltage steady and help reduce noise.

Tip: If you design the stack-up well, your circuits stay safe from outside noise. It also helps the board work well in fast electronics.

Here is a simple list of what you find in a typical stack-up for a ceramic multilayer PCB:

Thin metal lines for signals and power

Vias that connect the layers

Dielectric layers for insulation

Power and ground planes for steady voltage

A good stack-up design helps stop problems from outside signals. It also makes the board work faster and more reliably. You can trust ceramic circuit boards to keep electronics safe and strong.

Signal and power flow

Signals and power move through a ceramic multilayer PCB in a special way. The metal lines on each layer act like tiny roads. They carry signals from one part of the board to another. When a signal needs to move between layers, it uses a via. The via acts like an elevator. It lets the signal travel up or down through the board.

Power moves through the power planes. These planes make sure every part of the board gets the right energy. The ground planes give a safe path for electricity to return. This setup keeps the board stable and helps stop errors.

How you arrange the layers changes how well signals move. If you put the power and ground planes close to the signal layers, you get less noise and better performance. This is important for fast electronics. A good stack-up also helps the board handle more complex circuits without losing speed or reliability.

You can see how the stack-up helps with signal integrity:

It lowers the chance of outside noise hurting your signals.

It helps with electromagnetic compatibility, which is important for fast devices.

It lets you route fast signals with less loss.

A ceramic multilayer PCB uses its special structure to keep signals clear and power steady. This makes it a great choice for devices that need to work in tough places or handle lots of power. You get a printed circuit board that is strong, reliable, and ready for advanced electronics.

Advantages of multilayer ceramic PCB

Thermal performance

You want your electronics to stay cool and work well. This is important when things get hot. A ceramic multilayer PCB helps with this. The ceramic materials in these boards move heat away fast. This keeps important parts from getting too hot. Your devices can work longer without overheating.

Here is a table that shows why ceramic PCB is good for heat:

Advantage | Description |

|---|---|

High Thermal Conductivity | Moves heat away quickly, keeping things cool. |

Thermal Shock Resistance | Handles fast temperature changes without breaking. |

Extended Temperature Range | Works in hot places where other boards might stop. |

Ceramic PCB spreads heat out evenly. This stops hotspots that can hurt your parts. You do not need as much extra cooling. This saves space and energy. Many industries use ceramic circuit boards in cars and airplanes. These boards can handle quick temperature changes and keep working.

Good heat control is important as parts get smaller and hotter.

Moving heat away from strong parts means you do not need big fans.

Even temperature keeps your board safe and working well.

Ceramic multilayer boards keep their insulation even when hot. FR4 boards cannot do this as well. Ceramic PCB gives you safety and stability in tough places.

Durability and reliability

You want your multilayer PCB to last a long time. This is true even in hard places. Ceramic PCB is very strong and tough. The ceramic layers make the board hard to break. In factories, multilayer ceramic PCB can last for many years.

Ceramic multilayer boards do not get damaged by water or big temperature changes. They do not bend or crack easily. The layers stay together, even if the board shakes or bends. This means your electronics keep working, even when things get rough.

Evidence Type | Description |

|---|---|

Fracture Mechanism | Ceramic can break under big stress, but smart design helps stop this. |

Stress Distribution | Engineers use tests to spread stress safely in the layers. |

Geometric Parameters | The shape and stack of layers help the board handle stress. |

Ceramic PCB is known for being reliable. You can trust these boards where failure is not okay. The strong design and careful building give you peace of mind. Your devices stay safe, steady, and ready for anything.

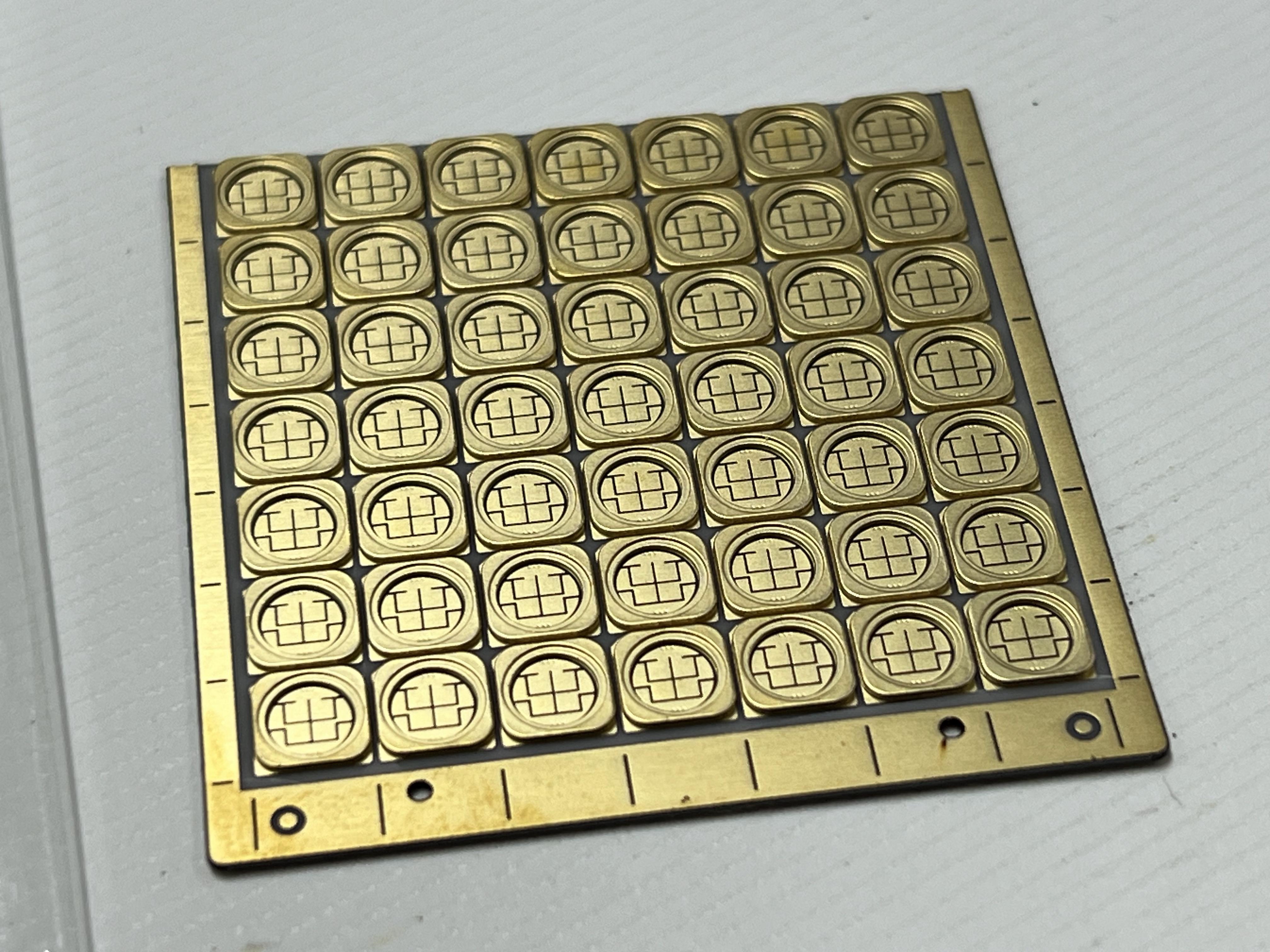

Multilayer ceramic PCB manufacturing with LT CIRCUIT

LT CIRCUIT is a leader in making advanced ceramic PCB. You can count on them for reliable multilayer PCB for your electronics. They have many types of ceramic circuit boards. They use the newest technology and the best materials. They always try to improve and make customers happy. That is why many people pick them for multilayer ceramic PCB.

Materials used

LT CIRCUIT uses only top ceramic materials for their multilayer PCB. Each material helps your printed circuit board in a special way. The table below lists the most used materials and what they do:

Material | Thermal Conductivity (W/m·K) | Dielectric Constant (Dk @ 10GHz) | Maximum Operating Temp (°C) | Cost (Relative) | Best Applications |

|---|---|---|---|---|---|

Alumina (Al₂O₃) | 20–30 | 9.8–10.0 | 1,600 | Low | General high-temperature, LED, power electronics |

Aluminum Nitride | 180–220 | 8.0–8.5 | 2,200 | High | High-power devices, thermal management critical |

Zirconia (ZrO₂) | 2–3 | 25–30 | 2,700 | Very High | Extreme mechanical stress (aerospace, defense) |

These ceramic materials give your PCB good heat control and strength. Your multilayer PCB works well in hard places and keeps your electronics safe.

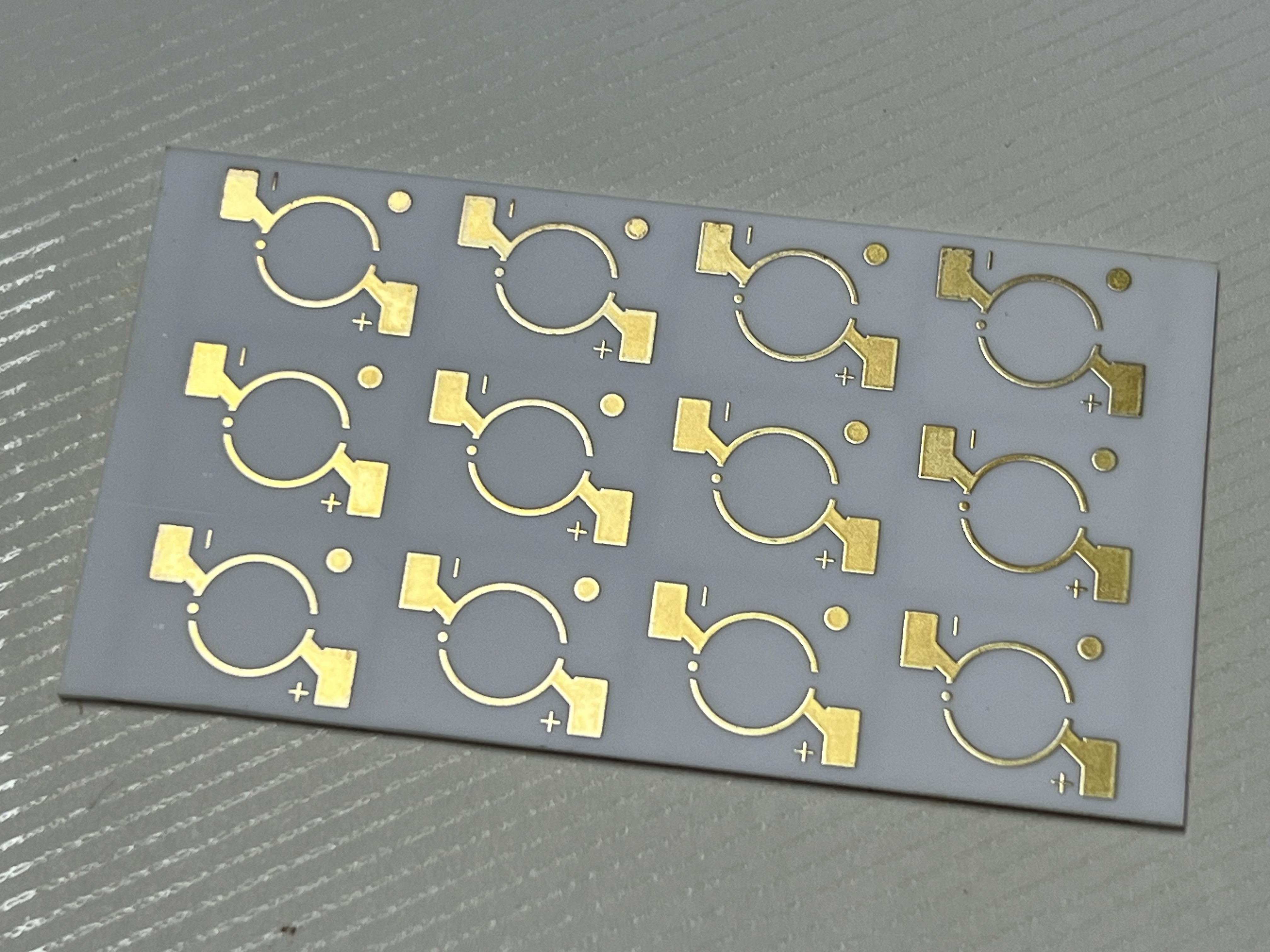

Manufacturing steps

LT CIRCUIT uses a careful process to make every ceramic multilayer PCB. Each step helps make the board strong and dependable:

You choose the right ceramic material, like alumina or aluminum nitride.

Workers mix ceramic powders with binders and liquids to make a paste.

They use tape casting to make thin, flat ceramic sheets called green sheets.

Each sheet is cleaned and treated so the layers will stick together.

Circuit patterns are printed on the sheets with screen printing.

The sheets are stacked and pressed to form the multilayer board.

Vias are made by drilling or punching holes for electrical paths.

The via walls get a metal coating using special methods.

The stack is heated at high temperatures to join the layers and finish the circuits.

LT CIRCUIT checks quality at every step. They use visual checks, machines to look for problems, and tests to make sure everything works. These checks help make sure your ceramic PCB has no defects and is ready for tough jobs.

You get a ceramic multilayer PCB that is strong and works well. LT CIRCUIT’s focus on quality and new ideas means your multilayer PCB will be top-notch.

Applications of ceramic multilayer PCB

Electronics and industries

Ceramic multilayer PCB is used in many big industries. These boards help devices work better and last longer. Ceramic PCB is special because it can handle heat and stress. You will find ceramic PCB where other boards might break.

Some industries and devices that use ceramic PCB are:

Heavy industrial equipment

Aerospace systems

LED lighting products

Semiconductor coolers

High power semiconductor modules

Power control circuits

Electronic heaters

Intelligent power components

Power mixing circuits

High frequency switching power supplies

Automotive electronics

Solid state relays

Military electronics

Communication devices

Medical devices

High-frequency electronics

Ceramic PCB is great for high-frequency and power electronics. It is also used in medical and aerospace equipment. These boards have many layers to fit more circuits in a small space. The ceramic moves heat away fast, so the board stays cool even when working hard.

Car makers pick ceramic multilayer PCB for many reasons. The table below shows why these boards are good for cars and electric vehicles:

Benefit | Description |

|---|---|

High Durability | Ceramic multilayer PCB lasts a long time, even in tough conditions. |

Reliability Under Stress | These boards keep working under heat and vibration. |

Superior Thermal Management | Ceramic PCB moves heat away fast, which is important for power systems. |

Vibration Resistance | Ceramic circuit boards resist shaking and keep circuits safe. |

Why choose LT CIRCUIT

You want your multilayer PCB to be strong and right for your needs. LT CIRCUIT gives you many choices for your ceramic PCB. You can pick how many layers, the size, and even the color. LT CIRCUIT offers high thermal conductivity, so your board stays cool. You can use these boards in devices that work in very hot or cold places.

Here is a table with some features you can pick with LT CIRCUIT:

Feature | Details |

|---|---|

Layers | 1 to 8 layers for complex designs |

Thermal Conductivity | Up to 170 W/mK for great heat control |

Solder Mask Color | Sleek black finish |

Standard PCB Size | 22mm x 19mm, good for small devices |

Operating Temperature Range | -50°C to 150°C, works in extreme conditions |

You get more than just choices. People like LT CIRCUIT because they answer fast and deliver on time. The company checks every detail and meets your needs. LT CIRCUIT cares about quality and making customers happy. When you pick LT CIRCUIT, you know your multilayer ceramic PCB will work well and last.

Tip: If you need a ceramic PCB for a special job, LT CIRCUIT can make it just for you. You get a board that fits your needs.

Ceramic PCB from LT CIRCUIT gives you the strong and steady performance you want for your electronics.

Ceramic multilayer PCB vs. other PCB types

Key differences

When you look at ceramic multilayer PCB and other types, you notice some big differences. Ceramic PCB is special because it uses ceramic materials, not fiberglass or metal. These materials help the board handle heat and stress much better.

Ceramic PCB uses a thermal conductive dielectric material as a thermal bridge.

This material moves heat away from important parts to a metal plate.

FR4 boards need extra heat sinks, which can cause hotspots.

You can see how different PCB types work in this table:

PCB Type | Thermal Conductivity | Application Suitability |

|---|---|---|

Ceramic PCBs | High | |

FR4 PCBs | Low | Not good for high heat jobs |

Ceramic PCB, like aluminum nitride and aluminum oxide, moves heat very well. FR4 PCB does not move heat well, so it is not good for hot jobs. Metal core PCB handles heat better than FR4, but ceramic PCB gives even more control.

Ceramic PCB also lets heat move up and down and spreads it out. This helps in hot spots, like laser diodes and power transistors. Aluminum PCB works in tough places, like power electronics and cars, but it can be thicker and cost more.

When to choose ceramic multilayer PCB

Pick a multilayer ceramic PCB if your device needs to handle lots of heat or work in hard places. Ceramic PCB is best for high-power and high-frequency electronics. Your devices will last longer and work better.

Here are some industries and uses where ceramic multilayer PCB is best:

Industry | Applications |

|---|---|

Automotive | Engine control units, Transmission control modules, Brake control systems, Exhaust gas sensors |

Aerospace | Satellite communication systems, Radar and guidance systems, Missile control systems, Avionics |

Medical | Implantable devices, Surgical instruments, Diagnostic equipment, Medical imaging systems |

RF and Microwave | Wireless communication systems, Radar and satellite systems, High-frequency test equipment |

Ceramic PCB is also good when you need many layers in a small space. The ceramic layers keep your circuits safe from heat and stress. You can trust your multilayer PCB to work well, even in tough conditions.

When you think about cost, remember that the type of ceramic, board size, metal thickness, and number of layers all matter. More complex designs and special finishes can make the price go up. If you need a strong, reliable, and heat-resistant board, ceramic PCB is the best choice.

Tip: If your project needs to work in harsh places and must be very reliable, ceramic multilayer PCB is the smart pick.

You now know that ceramic multilayer PCB lets you fit in more parts. It also helps your devices stay cool. Ceramic PCB is used in things like computers, solar panels, and wireless chargers. These boards are strong and last a long time. Ceramic stops copper from getting damaged. If you want a PCB that works for years, LT CIRCUIT has good multilayer ceramic options. You can find out more about why ceramic substrate, metalization, and testing make ceramic PCB a smart pick for new electronics.

Ceramic PCB is light, powerful, and tough.

Ceramic gives better heat control, insulation, and strength.

See how ceramic substrate is made.

Find out about metalization and making circuit patterns.

Learn how ceramic PCB is checked and tested.

FAQ

What makes ceramic multilayer PCBs different from other printed circuit boards?

Ceramic multilayer PCBs get rid of heat better than most boards. They are stronger because they use ceramic materials. These boards help your devices work well in hard places. They also keep signals clear, which is better than regular boards.

Why is integrity important in ceramic multilayer PCBs?

Integrity means your signals stay clear and your device works right. You want your electronics to run without mistakes. Ceramic multilayer PCBs protect circuits and keep integrity, even if it gets hot or cold fast.

How does low coefficient of thermal expansion help my device?

A low coefficient of thermal expansion means the board does not change shape much. This happens even when it gets hot or cold. Your connections stay safe, and your device lasts longer.

Where do you use ceramic multilayer PCBs?

Ceramic multilayer PCBs are used in cars, medical tools, and communication gear. These boards work well where there is a lot of heat or shaking. People trust them because they are strong and keep signals safe.

Can ceramic multilayer PCBs improve heat dissipation?

Yes, ceramic multilayer PCBs move heat away from parts very fast. This helps your device work better and stops it from getting too hot. It keeps your electronics safe and helps them last longer.

See Also

A Comprehensive Overview Of Multilayer Ceramic PCB Production

An In-Depth Look At The Creation Of Multilayer PCBs

Understanding The Differences Between PCB Types: Single, Double, Multilayer

Exploring Multilayer PCBs And Their Role In Modern Technology

Challenges And Processes In Manufacturing Multilayer Circuit Boards