Top Trends in Ceramic PCB Application for Advanced Devices

In 2025, you’ll see a rapid transformation in ceramic pcb application as advanced devices require greater power and reliability. The global market for ceramic pcb application is expanding quickly, fueled by the demand for superior thermal management and high-performance electronics.

Market value for ceramic pcb application is projected to rise from USD 1.2 billion in 2023 to USD 2.3 billion by 2032.

The sector is expected to maintain a steady 8.0% CAGR, with industries such as aerospace, telecommunications, and consumer electronics driving growth.

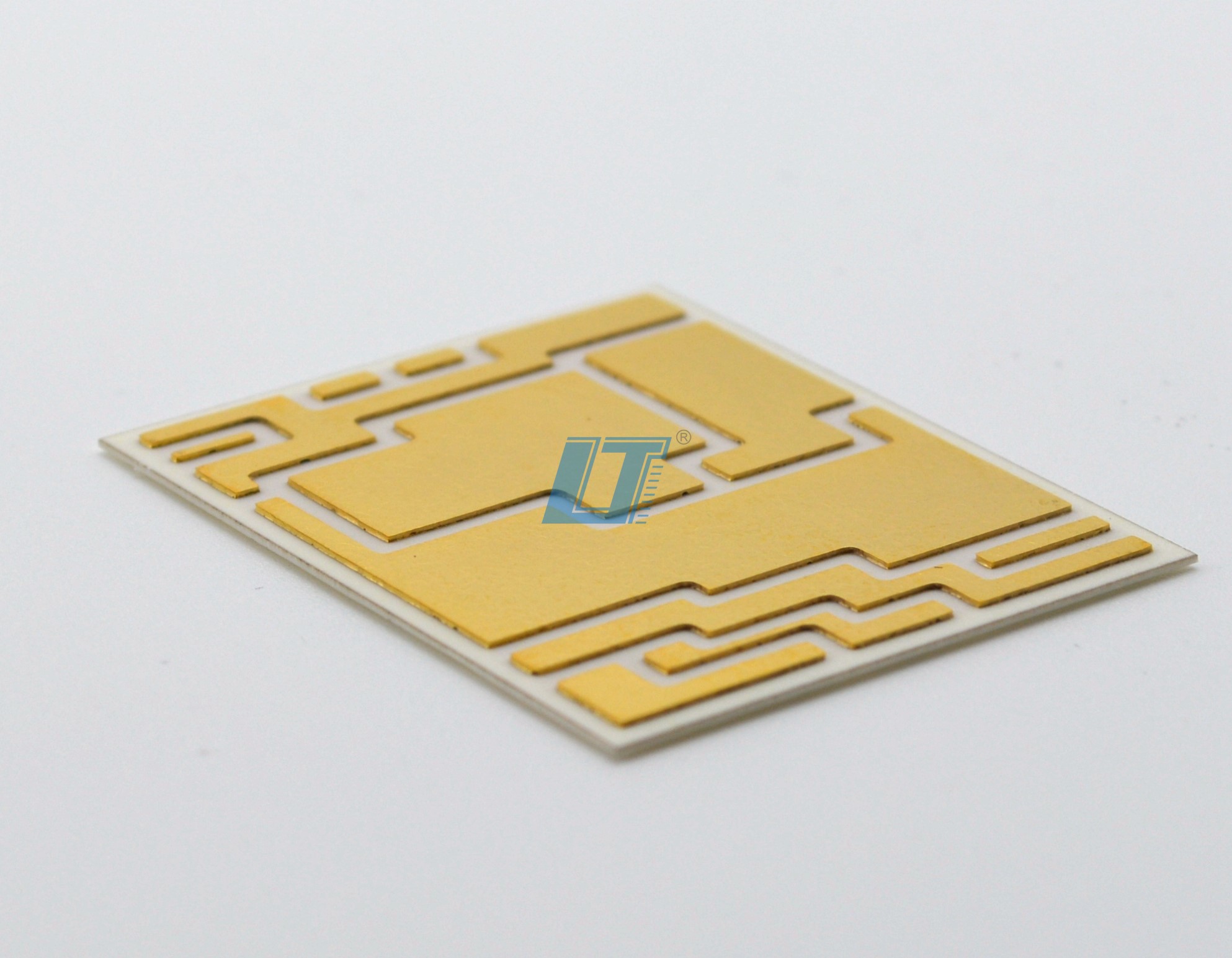

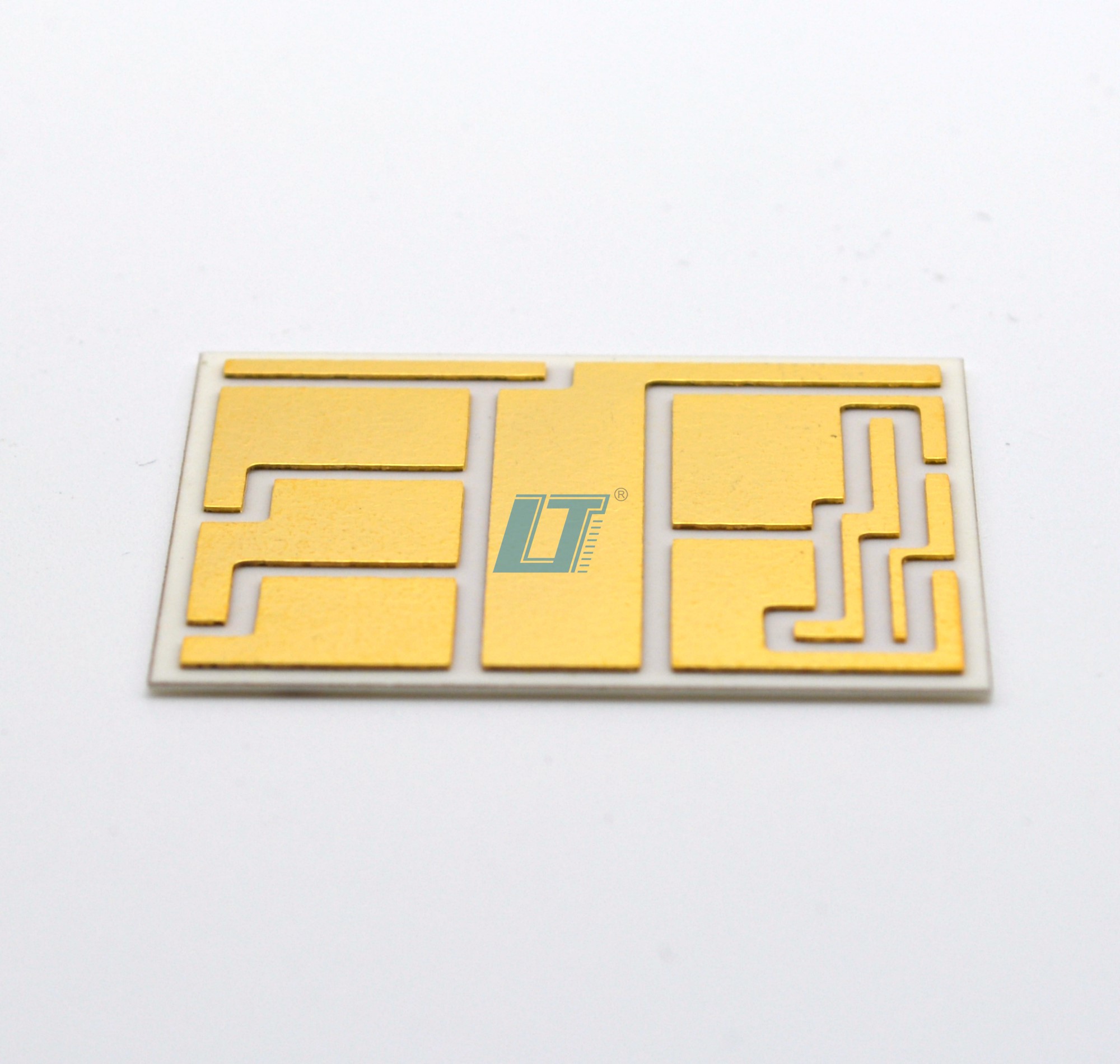

Brands like LT CIRCUIT are setting new benchmarks for innovation and quality in ceramic pcb application, shaping the future of technology with every breakthrough.

Key Takeaways

Ceramic PCBs are essential for advanced devices, offering superior thermal management and reliability, especially in high-power applications.

Miniaturization allows for smaller, more efficient devices, making ceramic PCBs ideal for wearables and IoT sensors.

Ceramic PCBs excel in harsh environments, providing durability and stability for industries like aerospace, automotive, and medical devices.

The rise of IoT and 5G technology increases the demand for ceramic PCBs, which handle high-frequency signals with minimal loss.

LT CIRCUIT leads innovation in ceramic PCB technology, ensuring high quality and sustainability in their manufacturing processes.

Ceramic PCB Application Trends

Ceramic pcb application continues to evolve as you look for better performance in advanced devices. In 2025, several trends stand out. These trends shape how you design, build, and use electronics in many industries. LT CIRCUIT leads the way by using advanced manufacturing techniques and strict quality standards. You can see how these trends impact everything from smartphones to electric vehicles.

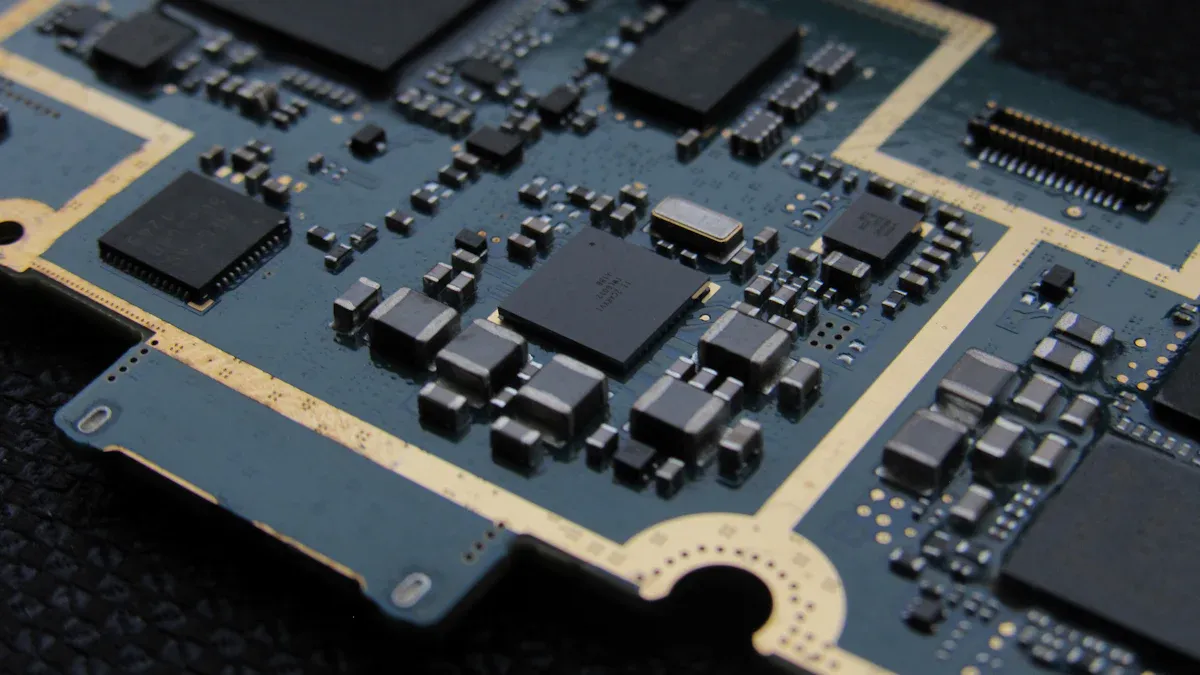

Miniaturization

You see a strong push toward smaller and more powerful devices. Miniaturization in ceramic pcb application lets you fit more features into less space. This trend is important for wearables, medical devices, and IoT sensors. You can now use chip resistors and capacitors in tiny packages, such as the 0201 size. This allows you to add more functions without making devices bigger.

However, miniaturization brings challenges. You must manage heat from tightly packed components. You also need to keep signals clear and avoid interference. LT CIRCUIT addresses these issues by using laser direct structuring and micro-via technology. Their engineers plan each layer and use advanced materials like Low-Temperature Co-fired Ceramics (LTCC). This helps you achieve high density and reliability in your ceramic pcb application.

Miniaturization drives innovation in SMD technology. You can now create fitness trackers and implantable medical devices that are smaller and more efficient than ever before.

High-Power Applications

High-power applications demand circuit boards that can handle large amounts of heat and current. Ceramic pcb application excels in these situations. You find ceramic PCBs in electric vehicles, power supplies, and industrial inverters. These boards offer excellent thermal management and electrical insulation.

Here is a table showing how ceramic pcb application supports high-power applications in different industries:

Application Area | Key Features | Example Use Case |

|---|---|---|

Aerospace and Avionics | Thermal stability, reliability in extreme temperatures | Used in satellite power management systems to dissipate heat from power amplifiers operating at 50 W. |

Automotive Electronics | High thermal conductivity, low CTE, reliable under high temperatures | In EV charging stations, can handle currents up to 200 A with minimal temperature rise. |

Industrial and Power Electronics | Excellent thermal management, electrical insulation for high-voltage systems | Supports power transistors in solar inverters operating at 600 V, maintaining junction temperatures below 175°C. |

You benefit from ceramic pcb application in high-power applications because ceramic substrates keep sensitive components cool. This extends the life of your devices. You also get stable performance even when temperatures change quickly. LT CIRCUIT uses vacuum reflow soldering and automated inspection to ensure every board meets strict standards. Their focus on high-power applications means you get reliable products for demanding jobs.

In aerospace, you use ceramic pcb application for satellite modules that need to survive extreme heat and cold.

In automotive, you rely on these boards for electric vehicle systems that must handle high currents.

In industrial settings, you use ceramic pcb application in inverters and power supplies where heat management is critical.

Ceramic pcb application in high-power applications gives you a clear advantage over traditional boards. You get better heat dissipation, longer device life, and more reliable operation.

IoT and 5G Integration

The rise of IoT and 5G technology changes how you connect devices. Ceramic pcb application plays a key role here. You need boards that can handle high-frequency signals with little loss. Ceramic PCBs have a low dielectric constant and low dielectric loss. This makes them perfect for 5G antennas and IoT modules.

You also want your devices to last longer and work reliably. Ceramic pcb application provides thermal stability and electrical insulation. This is important for sensors and communication devices that run all day, every day.

"Ceramic circuit boards (CCBs) have been extensively utilized in 5G communications, aerospace, and artificial intelligence due to their excellent thermal conductivity and electrical performance. The proposed technique free from traditional lithography, etching, and plating processes opens up a promising strategy of implementing both high-density integration and large current-carrying capacity."

LT CIRCUIT supports IoT and 5G integration by offering advanced ceramic pcb application solutions. Their engineers design boards that keep signals clear and devices cool. You can trust their products for your next smart device or communication system.

Harsh Environment Reliability

You often need electronics that work in tough conditions. Ceramic pcb application stands out for its ability to handle extreme heat, chemicals, and moisture. This makes it ideal for automotive, aerospace, and industrial uses.

Ceramic PCBs have high dielectric strength and excellent thermal conductivity. You can use them in power electronics and automotive systems where heat dissipation and stability matter most. LT CIRCUIT ensures each board meets ISO 9001 and IPC standards. Their careful design and testing give you confidence in every product.

You see ceramic pcb application in high-power applications where reliability is non-negotiable. Whether you build satellites, electric vehicles, or factory automation systems, you need boards that last. LT CIRCUIT delivers this reliability through advanced engineering and strict quality control.

Note: When you choose ceramic pcb application for harsh environments, you get better performance and longer device life compared to traditional boards.

Industry Adoption in 2025

Automotive and Electric Vehicles

You see the automotive industry leading the way in ceramic PCB adoption. Electric vehicles need advanced electronics that can handle high power and heat. Ceramic PCBs give you superior thermal management, reliability under harsh conditions, and support for advanced electronics like ADAS and infotainment systems.

Driver | Explanation |

|---|---|

Superior Thermal Management | Essential for handling heat in advanced electronics, especially in electric vehicles. |

Reliability Under Harsh Conditions | Critical for automotive applications that face extreme environments and operational stresses. |

Integration of Advanced Electronics | Necessary for modern features like ADAS and infotainment, which require high-performance substrates. |

A major automotive supplier switched to aluminum nitride ceramic PCBs for 77 GHz radar modules. This change gave you a 30% longer detection range and reduced system failures by 85% during high-temperature testing. You also get more compact designs and better reliability. LT CIRCUIT supports automotive innovation by delivering high-quality ceramic PCBs for electric vehicles and smart systems.

L&T Semiconductor Technologies (LTSCT) partnered with C-DAC to boost semiconductor capabilities for automotive, industrial, and energy applications.

LTSCT also works with IIT Gandhinagar to develop secure ICs and SoCs for national automotive projects.

Aerospace and Defense

You rely on ceramic PCBs in aerospace and defense for their high thermal stability and low weight. These boards work well in radar, avionics, and missile guidance systems. They resist extreme temperatures and environmental factors, making them perfect for critical defense systems.

Ceramic PCBs use high thermal conductivity materials to dissipate heat.

Advanced substrates resist thermal degradation, ensuring performance in extreme conditions.

You meet strict standards like IPC-6012, ISO 9001, MIL-PRF-31032, and AS9100 for quality and reliability.

The EPA, FAA, and DoD set regulations for hazardous substances and testing protocols in military and defense electronics.

LT CIRCUIT’s expertise helps you meet these requirements, supporting aerospace and defense projects with reliable ceramic PCB solutions.

Medical Devices

You depend on ceramic PCBs in medical devices for their thermal management, reliability, and electrical insulation. These boards help prevent overheating and ensure signal integrity in sensitive equipment.

Advantage | Description |

|---|---|

Thermal Management | High thermal conductivity and efficient heat dissipation prevent overheating in medical devices. |

Reliability and Durability | High mechanical strength and chemical resistance ensure durability in various medical environments. |

Electrical Insulation | Excellent dielectric properties prevent current leakage, ensuring signal integrity in devices. |

Biocompatibility | Certain ceramics are biocompatible, suitable for direct contact with biological systems. |

Miniaturization and Flexibility | Enables smaller designs and complex functionalities in medical devices. |

You find ceramic PCBs in medical imaging equipment, patient monitoring systems, implantable devices, and diagnostic instruments. LT CIRCUIT delivers solutions that meet strict medical standards, helping you create safer and more reliable medical devices.

Industrial Automation

You use ceramic PCBs in industrial automation for their heat dissipation, electrical insulation, and durability. These properties keep your power amplifiers, motor controllers, and LEDs running smoothly, even in harsh environments.

Property | Benefit | Application Areas |

|---|---|---|

Prevents overheating, increasing lifespan of components | Power amplifiers, motor controllers, LEDs | |

Enhanced Electrical Insulation | Minimizes signal interference, ensuring better performance | RF communication, high-voltage supplies |

Durability in Harsh Conditions | Reliable operation in extreme environments | Aerospace, automotive, medical electronics |

LT CIRCUIT’s ceramic PCBs help you achieve stable operation and long-lasting performance in your automation systems.

Telecommunications and 5G

You see rapid growth in 5g telecommunications, driven by urbanization and the need for high-frequency, durable PCBs. Ceramic PCBs offer superior thermal and electrical performance, making them ideal for 5G base stations and IoT infrastructure.

5G technology needs low-loss materials and advanced manufacturing to support high data rates.

OEMs now increase ceramic PCB procurement for telecommunications equipment.

The integration of industrial IoT also drives demand for advanced PCB materials.

LT CIRCUIT provides ceramic PCB solutions that support the expansion of 5g telecommunications, helping you build faster and more reliable networks.

Ceramic Multilayer PCB Innovation

Advanced Materials

You see rapid progress in ceramic multilayer pcb technology because of new materials. These materials give you better heat management, electrical insulation, and durability. You can choose from options like aluminum oxide and silicon nitride. Each material offers unique benefits for high-performance applications.

Material Type | Dielectric Constant | Thermal Conductivity (W/mK) | Applications |

|---|---|---|---|

Aluminum Oxide (Al₂O₃) | 9-10 | 30-35 | Power electronics, automotive |

Silicon Nitride (Si₃N₄) | 5-7 | 140-180 | High-power and high-temperature systems |

You also work with HTCC and LTCC. These advanced ceramic pcbs use high-temperature or low-temperature co-fired ceramics. You get strong, reliable boards for power and advanced electronics. Ceramic multilayer pcb stands out for high-performance applications in automotive, aerospace, and telecommunications. You benefit from superior heat dissipation and long-lasting performance.

LT CIRCUIT Technology Leadership

LT CIRCUIT leads the way in ceramic multilayer pcb innovation. You rely on their advanced engineering and strict quality control. Their team uses the latest materials and processes to create power solutions for high-performance applications. LT CIRCUIT’s focus on advanced design helps you meet the demands of modern devices.

You see their commitment to sustainability in every step. LT CIRCUIT uses eco-friendly materials and efficient manufacturing. Their sustainability focus means you get products that support both performance and environmental goals. You trust LT CIRCUIT for advanced ceramic multilayer pcb solutions that deliver power, reliability, and sustainability.

Case Studies

You can look at real-world examples to see the impact of ceramic multilayer pcb. In one case, an automotive company needed a power pcb for electric vehicle inverters. LT CIRCUIT provided a ceramic multilayer pcb with silicon nitride. This board handled high power and kept temperatures low, even in tough driving conditions.

Another example comes from telecommunications. A client needed advanced ceramic multilayer pcb for 5G base stations. LT CIRCUIT delivered a solution that managed power and heat, supporting high-performance applications with zero signal loss. These cases show how you can use ceramic multilayer pcb for advanced, high-power, and sustainable designs.

Tip: Choose ceramic multilayer pcb for your next project if you want advanced performance, power management, and sustainability.

Drivers of Adoption

Performance and Reliability

You demand high performance and reliability from your electronics, especially in high-power applications and data centers. Ceramic PCB technology gives you excellent thermal conductivity, high-frequency performance, and resistance to extreme conditions. These features make ceramic PCBs ideal for high-speed electronics, high-density PCBs, and high-speed communication devices. You can see how these metrics support advanced devices in the table below:

Metric | Description |

|---|---|

Thermal Conductivity | Excellent thermal management, essential for high-performance devices. |

High-Frequency Performance | Handles high-frequency signals, crucial for advanced electronics. |

Extreme Condition Resistance | Withstands harsh environments, ideal for automotive and aerospace applications. |

LT CIRCUIT ensures every PCB meets strict quality standards, so your devices run reliably in demanding applications.

Cost and Scalability

You consider cost and scalability when choosing PCBs for your electronics. Ceramic PCBs often cost more than traditional options due to material and manufacturing complexity. However, you gain value in high-power applications and data centers where performance matters most. The table below compares key factors:

Factor | Ceramic PCBs | Traditional PCBs |

|---|---|---|

Material Costs | Higher due to advanced materials and processes. | Lower for most commercial applications. |

Manufacturing Complexity | Specialized techniques required. | Mature, scalable, and cost-effective. |

Scalability | Fewer vendors, but technology is advancing. | Widely available for high-volume production. |

LT CIRCUIT invests in advanced manufacturing to help you scale your electronics projects efficiently.

Sustainability

You want your electronics to support sustainability goals. Ceramic PCBs use natural, non-toxic materials and offer long lifespans. They require less cooling, which lowers energy use in data centers and high-power applications. The table below highlights the sustainability benefits:

Sustainability Benefit | Description |

|---|---|

Eco-Friendliness | Made from recyclable, non-toxic materials. |

Energy Efficiency | Excellent thermal management reduces cooling needs. |

Longer Lifespan | Durable, reducing electronic waste. |

Non-Toxic Materials | Safer for the environment. |

LT CIRCUIT focuses on eco-friendly processes, helping you meet environmental targets in your electronics applications.

Standards and Compliance

You must meet strict standards in regulated industries like medical, automotive, and data centers. Ceramic PCBs undergo rigorous testing, including visual inspection, dielectric strength, thermal cycling, and environmental testing. You also need to comply with:

IEC 60601 and UL 94 for safety and material compliance.

LT CIRCUIT delivers PCBs that pass all required tests, giving you confidence in your electronics for high-speed, high-power applications and data-driven devices.

You see ceramic PCB technology shaping the future of advanced devices in many ways:

The market grows quickly as high-performance electronics, automotive, and aerospace drive demand.

Manufacturers invest in multilayer ceramic PCBs for better thermal conductivity and signal transmission.

5G and IoT devices increase the need for high-frequency ceramic PCBs.

Automotive and aerospace sectors rely on ceramic PCBs for heat resistance and reliability.

Ceramic PCBs give you better thermal management, insulation, and durability than traditional boards. LT CIRCUIT leads with innovation and quality. Watch for new breakthroughs in ceramic PCB technology as you build the next generation of smart devices.

FAQ

What makes ceramic PCBs ideal for high-power devices?

You get excellent thermal management and electrical insulation from ceramic PCBs. These features help your high-power devices run cooler and last longer. You can trust ceramic PCBs for stable performance in demanding environments.

How do ceramic PCBs support telecommunication advancements?

You use ceramic PCBs in telecommunication because they handle high-frequency signals with low loss. These boards help your devices achieve faster data transmission and better signal clarity. You see them in 5G base stations and advanced network hardware.

Are ceramic PCBs suitable for harsh environments?

You choose ceramic PCBs for harsh environments because they resist heat, moisture, and chemicals. These boards keep your devices reliable in aerospace, automotive, and industrial settings. You benefit from their durability and long service life.

What industries use ceramic PCBs in telecommunications equipment?

You find ceramic PCBs in telecommunications equipment for their high reliability and signal integrity. Companies use them in routers, switches, and wireless infrastructure. These boards help your networks stay fast and dependable.

Can you customize ceramic PCBs for specific applications?

You can customize ceramic PCBs to fit your needs. Manufacturers offer different materials, sizes, and layouts. You get solutions tailored for medical, automotive, or industrial uses.

See Also

Investigating How Ceramic PCBs Are Used in Today's Industries

Examining Al₂O₃ Ceramic PCBs and Their Industrial Uses

The Superior Heat Dissipation Properties of Ceramic PCBs

Utilizing Aluminum Nitride Ceramic PCBs in Various Industries