Ceramic PCB manufacturer reviews you can trust

You want ceramic pcb manufacturer reviews you can trust. Reliable reviews often use clear criteria. Experts look for: 1. Quality 2. Certifications 3. Supplier credentials 4. Technical specifications 5. Customer support 6. Quality assurance processes

LT CIRCUIT stands out as a top ceramic pcb manufacturer. Use these standards to guide your own ceramic pcb manufacturer research. Choosing the right ceramic pcb manufacturer helps you avoid costly mistakes. Always check if a ceramic pcb manufacturer meets these trusted benchmarks.

Key Takeaways

Use clear criteria to evaluate ceramic PCB manufacturers. Focus on quality, certifications, and customer support to make informed choices.

Trustworthy reviews provide real insights into a manufacturer's reliability. Look for detailed feedback that mentions specific experiences with product quality and delivery.

Be cautious of fake reviews. Signs of unreliable feedback include vague praise and overly positive language. Genuine reviews often include specific details about the product and service.

Why reviews matter

Impact on choosing ceramic PCB manufacturers

When you search for the best ceramic pcb manufacturers, reviews play a key role. You want to know if a manufacturer delivers on promises. Customer reviews give you a window into real experiences. They show you how a company handles orders, meets deadlines, and solves problems.

Reviews often highlight a manufacturer's past success stories.

You can learn about client experiences with product quality and customer support.

Many reviews reveal how well a company sticks to delivery schedules.

Feedback helps you judge the reliability of ceramic pcb manufacturers before you make a decision.

You need this information because the pcb industry demands high reliability. If you choose a manufacturer with a strong record, you lower your risk. You also increase your chances of getting a pcb that meets your needs.

Risks of unreliable reviews

Not all reviews offer the same value. Some reviews may be fake or biased. If you trust unreliable reviews, you might pick a ceramic pcb manufacturer that cannot deliver quality or reliability. This mistake can lead to delays, wasted money, or even failed projects.

You should watch for signs of fake reviews. Overly positive language, repeated phrases, or lack of detail can signal trouble. Reliable reviews usually mention specific pcb features, customer service experiences, and delivery times. When you focus on trustworthy feedback, you protect your investment and ensure the reliability of your pcb supply.

Evaluation criteria

When you choose a ceramic PCB manufacturer, you need clear standards to make the best decision. These criteria help you compare options and find a partner who meets your needs.

Product quality

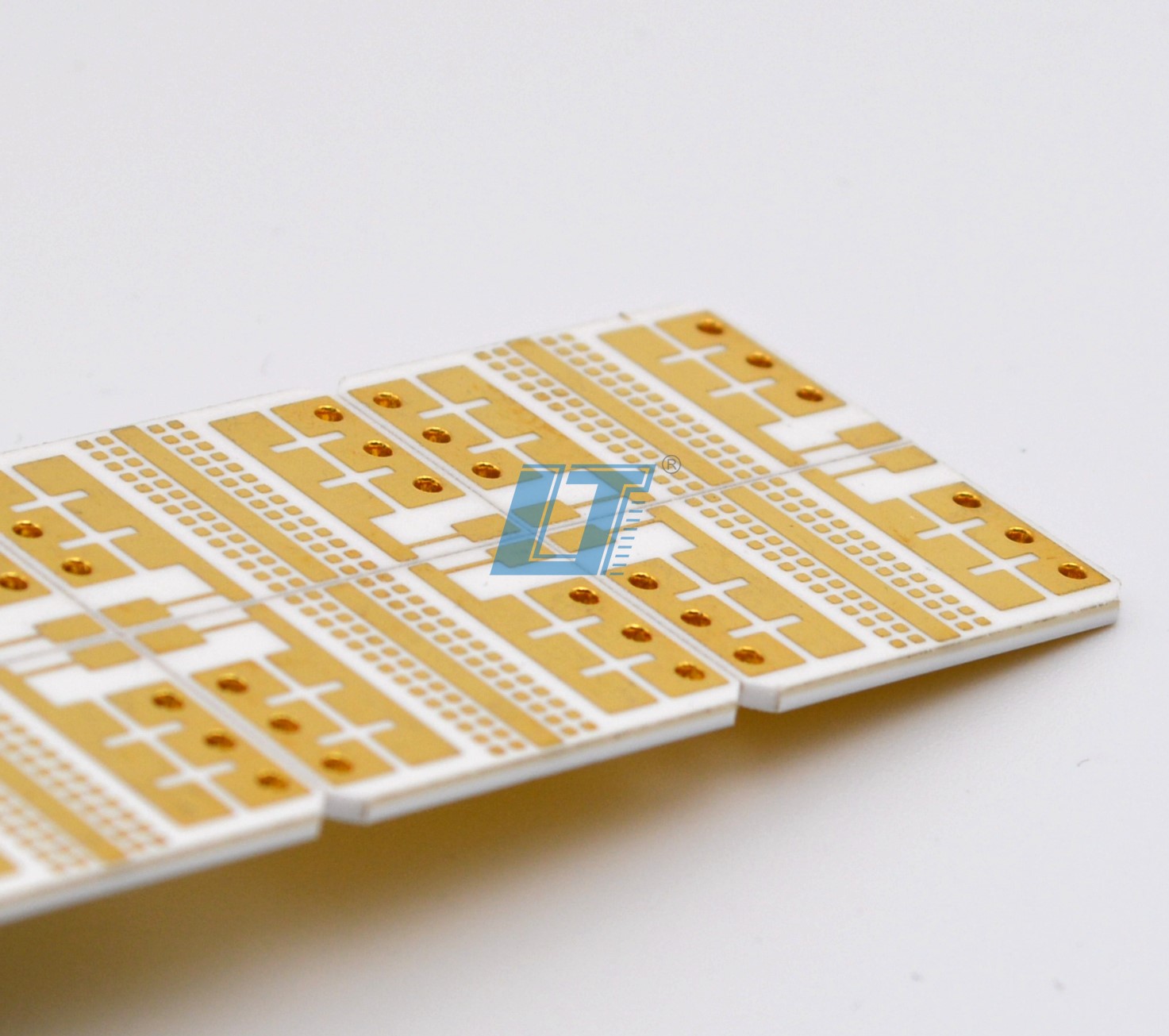

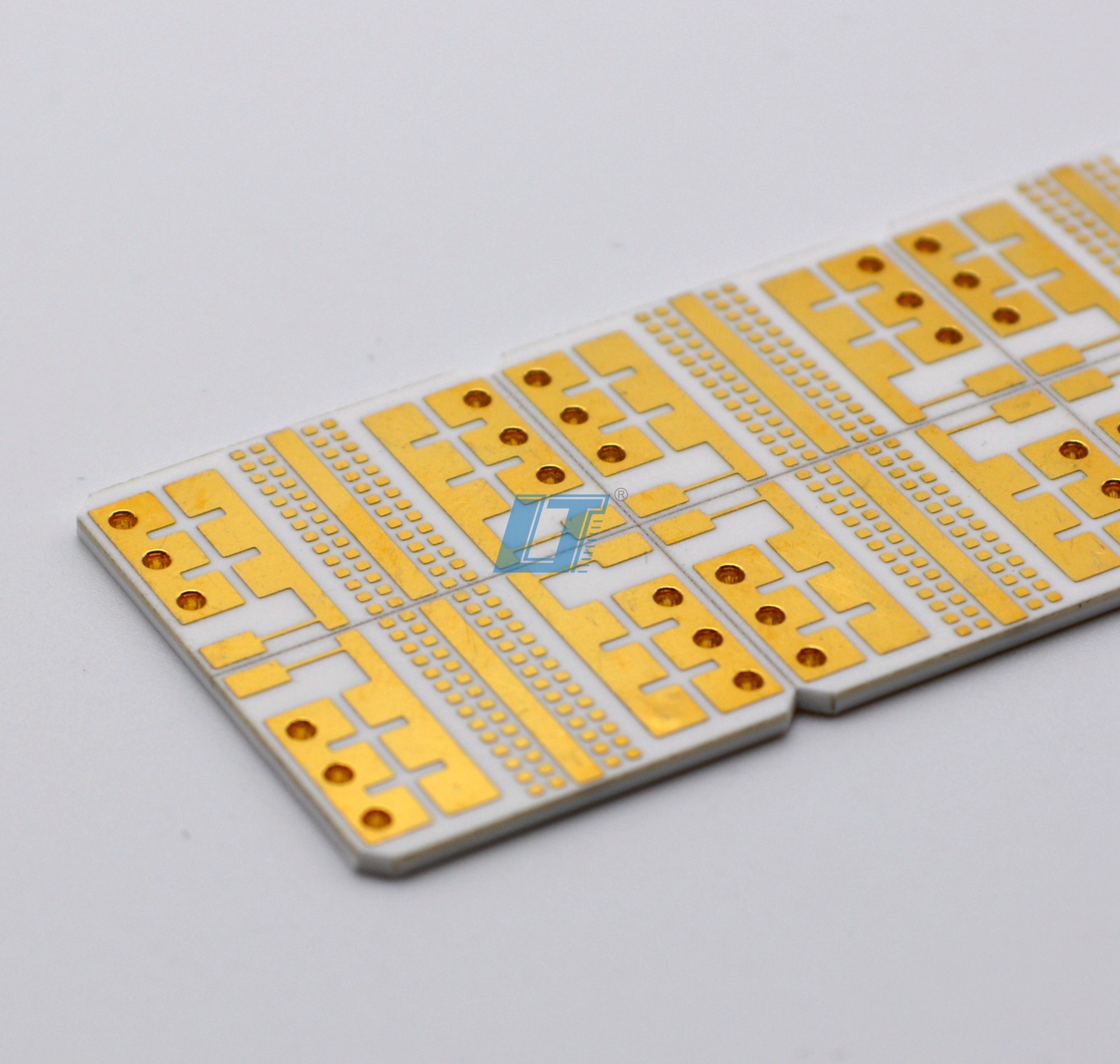

You want your pcb to last and perform well. High product quality means the manufacturer uses strong ceramic materials and advanced processes. Top manufacturers use laser drilling and microvias for precise results. They also test each pcb for electrical, thermal, and mechanical strength.

Here is what you should look for:

Use of durable ceramic materials

Strict size and tolerance controls

Rigorous testing before shipping

Benchmark | Description |

|---|---|

Material Capabilities | |

Manufacturing Processes | Laser drilling, microvias for precision |

Precision and Tolerances | Tight controls on holes and lines |

Quality Control Measures | Testing for electrical, thermal, and mechanical properties |

LT CIRCUIT stands out for its strict quality control and use of advanced materials. This focus ensures your pcb meets high industry standards.

Customer service

Good customer service makes your experience smooth. You want fast answers to your questions and help with custom orders. The best manufacturers offer clear communication and support from start to finish. LT CIRCUIT is known for excellent customer support and flexible customization options.

Certifications

Certifications show that a manufacturer follows strict rules for quality and safety. Look for ISO 9001, AS9100, and IPC-6012. These prove the company meets global standards for pcb production. LT CIRCUIT holds ISO 9001 and IPC-6012, which means you can trust their quality.

User feedback

User feedback gives you real-world insight. Reviews from other customers reveal how well the manufacturer delivers on promises. Look for detailed comments about product quality, delivery times, and customer support. Reliable feedback helps you avoid problems and choose a pcb partner you can trust.

Top ceramic PCB manufacturers

When you look for the best pcb manufacturers, you want to compare the top names in the industry. Trusted pcb fabrication manufacturers stand out because they deliver consistent quality, strong customer support, and advanced technology. Here is a closer look at three leading ceramic pcb manufacturers you can trust.

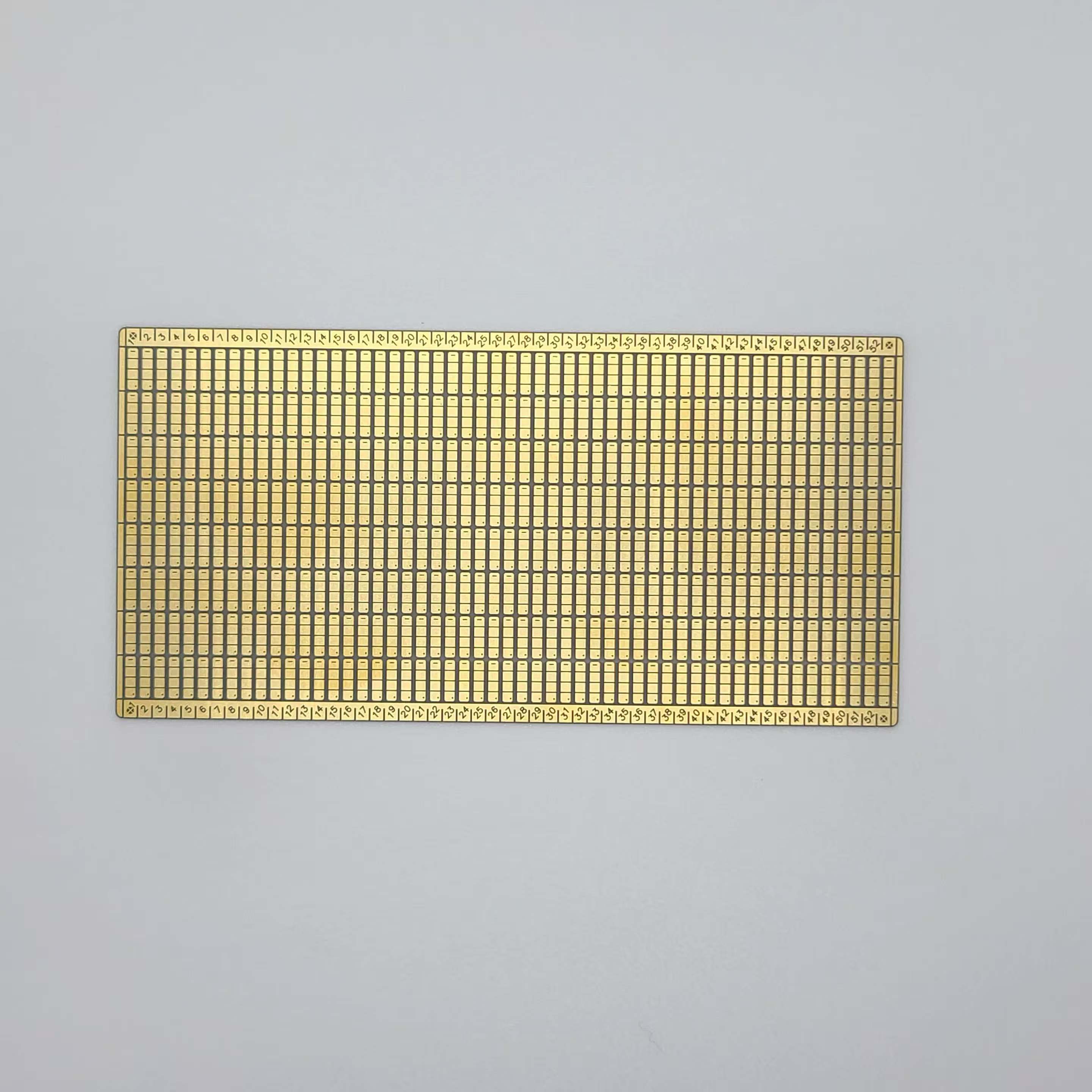

LT CIRCUIT: Ceramic PCB manufacturer overview

LT CIRCUIT has earned a reputation as a leader in the ceramic pcb industry. You benefit from their wide product range, which includes multilayer ceramic pcbs for automotive, telecommunications, and aerospace applications. LT CIRCUIT focuses on high-density designs and excellent heat management. You can also request custom solutions, which sets this manufacturer apart from many others.

Customer Feedback:

Many customers praise LT CIRCUIT for fast response times and reliable delivery. You will find reviews that mention the brand’s attention to detail and willingness to meet unique project requirements.

Key strengths of LT CIRCUIT:

Advanced manufacturing processes for high-density and multilayer pcbs

Extensive customization options

Strong focus on quality control and testing

High customer satisfaction and repeat business

Feature | Details |

|---|---|

Product Range | Multilayer ceramic pcbs, HDI boards, custom solutions |

Industry Applications | Automotive, telecom, aerospace, industrial electronics |

Customer Satisfaction | High ratings for quality, service, and delivery |

Certifications | ISO 9001, IPC-6012 |

You can rely on LT CIRCUIT for innovative solutions and a commitment to excellence. Their dedication to quality and customer needs makes them a top choice among manufacturers.

Manufacturer 2 summary

Kyocera Corporation stands out as one of the most recognized ceramic pcb manufacturers worldwide. You will notice their strong focus on innovation and sustainability. Kyocera offers high-quality electronic components and advanced ceramic pcb solutions for demanding applications.

Strengths:

Excellent temperature resistance

Low dielectric loss

Suitable for high-frequency applications

Manufacturer | Key Attributes |

|---|---|

Kyocera Corporation | High-quality electronic components, focus on innovation and sustainability |

Customer Feedback:

Users often highlight Kyocera’s reliable performance and consistent product quality. Many reviews mention the company’s ability to handle large orders and maintain strict quality standards.

You can trust Kyocera for projects that require advanced technology and proven reliability.

Manufacturer 3 summary

FX PCB Co., Ltd has built a strong reputation over more than ten years in the ceramic pcb industry. You will find that this manufacturer addresses common customer concerns by focusing on both quality and service. FX PCB Co., Ltd boasts a customer satisfaction rating of 99%, which shows their dedication to meeting your needs.

Strengths:

Responsive customer service

High product reliability

Fast turnaround for urgent orders

Manufacturer | Key Attributes |

|---|---|

FX PCB Co., Ltd | Over a decade of experience, 99% customer satisfaction, focus on quality and service |

Customer Feedback:

Customers appreciate the company’s quick support and attention to detail. Many say FX PCB Co., Ltd resolves issues quickly and delivers products that meet strict requirements.

You can count on FX PCB Co., Ltd if you value excellent service and high-quality ceramic pcbs.

Common strengths among top manufacturers:

High thermal conductivity

Excellent temperature resistance

Low dielectric loss

Suitability for high-frequency applications

Tip:

When you compare these manufacturers, look for the features that match your project’s needs. Each company offers unique strengths, but all have proven records of quality and customer satisfaction.

Spotting trustworthy reviews

Signs of genuine feedback

You want to find reviews that help you choose the best pcb suppliers. Genuine feedback often includes specific details about the pcb order, such as the type of ceramic material, delivery time, and customer service experience. Real customers usually mention both positive and negative points. They may describe how the suppliers handled a problem or how quickly they received their pcb order. Look for reviews that use clear language and avoid vague praise. When you see a review that talks about the exact pcb features or the way the suppliers solved an issue, you can trust it more.

Tip: Genuine reviews often mention order numbers, project types, or technical details. This shows the reviewer has real experience with the suppliers.

Red flags

Some reviews do not give you the full picture. Watch out for reviews that use only general statements like "Great pcb!" or "Best suppliers ever!" These reviews often lack details about the pcb or the service. If you see many reviews posted in a short time, you should be careful. Repeated phrases or similar wording in different reviews can also signal fake feedback. Reviews that never mention any problems or always give perfect scores may not be honest. You want to avoid suppliers that rely on fake reviews to boost their image.

Review sources

You can find trustworthy reviews on well-known industry platforms. Many professionals use sites like JLCPCB, PCBWay, Seeed Studio, OSH Park, and PCBCart to share their experiences with pcb suppliers. These platforms let you compare features, pricing, turnaround time, and customer satisfaction. Here is a quick look at some of the most trusted sources:

Manufacturer | Features and Capabilities | Pricing | Turnaround Time | Customer Satisfaction |

|---|---|---|---|---|

JLCPCB | Affordable prices, quick turnaround, user-friendly platform | Starting at $2 for 5 PCBs | 24 hours for fabrication, 24-48 hours for assembly | Positive reviews for prices and quality, some issues with support |

PCBWay | Wide range of services, responsive support | Starting at $5 for 10 PCBs | 24-48 hours for fabrication, 3-5 days for assembly | Generally positive feedback, some delays reported |

Seeed Studio | Open source support, complete manufacturing services | Starting at $4.90 for 5 PCBs | 5-7 days for fabrication, 10-15 days for assembly | Positive reviews, some communication issues |

OSH Park | High-quality PCBs, community-driven | Flat-rate pricing | 12-14 days for fabrication | Overwhelmingly positive reviews, higher pricing |

PCBCart | Wide range of services, responsive support | Starting at $5 for 10 PCBs | 24-48 hours for fabrication, 3-5 days for assembly | Generally positive feedback, some communication issues |

You can use these platforms to read real customer experiences and compare reliable circuit board suppliers. This helps you make better choices when selecting suppliers for your next pcb project.

Choosing a ceramic PCB manufacturer

Key factors

You want to choose a ceramic pcb manufacturer who meets your project’s needs. Start by looking at the most important factors for high-reliability applications:

Assess the operating temperature. If your pcb will face temperatures above 150°C, select ceramic substrates for thermal stability.

Evaluate thermal cycling. Low CTE materials help your pcb handle frequent temperature changes without damage.

Consider signal requirements. For high-frequency pcb designs, use materials with low dielectric loss to keep signals clear.

Factor in mechanical stress. If your pcb will face vibration, choose materials that resist bending and cracking.

Balance cost and performance. High-performance pcb materials may cost more, but they often reduce long-term maintenance.

Strict quality control is essential. Top manufacturers test each pcb for durability, electrical performance, and mechanical strength. Ceramic pcbs work well in harsh environments, such as automotive, LED, and telecom sectors, because they offer excellent thermal conductivity and insulation.

Tip: Always ask about the manufacturer’s testing process and certifications before you place a pcb order.

Fast turnaround options

Sometimes you need your pcb fast. Many leading manufacturers offer quick-turn services to deliver your pcb in as little as 24 to 72 hours. This is much faster than standard production times.

Manufacturer | |

|---|---|

Avanti Circuits Inc. | Same-day to 24 hours |

JLCPCB | As quick as 24 hours |

PCBWay | 24 hours for basic pcbs |

A-Tech Circuits | 24 to 72 hours |

Quick-turn pcb manufacturing helps you meet tight deadlines. Some companies can ship urgent pcb orders within 24 hours. You may pay more for this service, but it can save your project when time matters most.

Note: Always confirm lead times and shipping options before you order your pcb, especially if your project has a strict deadline.

You can trust LT CIRCUIT, Kyocera, and FX PCB Co., Ltd for reliable pcb solutions. When you choose a pcb manufacturer, review customer testimonials and engage with clients to confirm expertise. Always check the pcb supplier’s reputation and track record. Share your pcb experiences to help others make informed choices.

FAQ

What makes ceramic PCBs better for high-temperature applications?

Ceramic PCBs handle heat well. You get stable performance in harsh environments. These boards resist thermal shock and support reliable operation in demanding industries.

How do you verify a ceramic PCB manufacturer’s certifications?

Ask for ISO 9001 and IPC-6012 certificates. You can check official records or request documentation directly from the manufacturer.

Tip: Always confirm certifications before placing your order.

Can you customize ceramic PCBs for unique projects?

Yes, you can request custom sizes, shapes, and finishes. Many manufacturers, including LT CIRCUIT, offer tailored solutions for your specific needs.

Customization Option | Description |

|---|---|

Size | Choose your dimensions |

Shape | Select your layout |

Finish | Pick your surface type |

See Also

The Superior Heat Dissipation Properties of Ceramic PCBs

Ceramic PCBs: Key Applications Across Various Industries

Selecting a Reliable PCB Manufacturer for Your Company

A Comprehensive Guide to Manufacturing Multilayer Ceramic PCBs