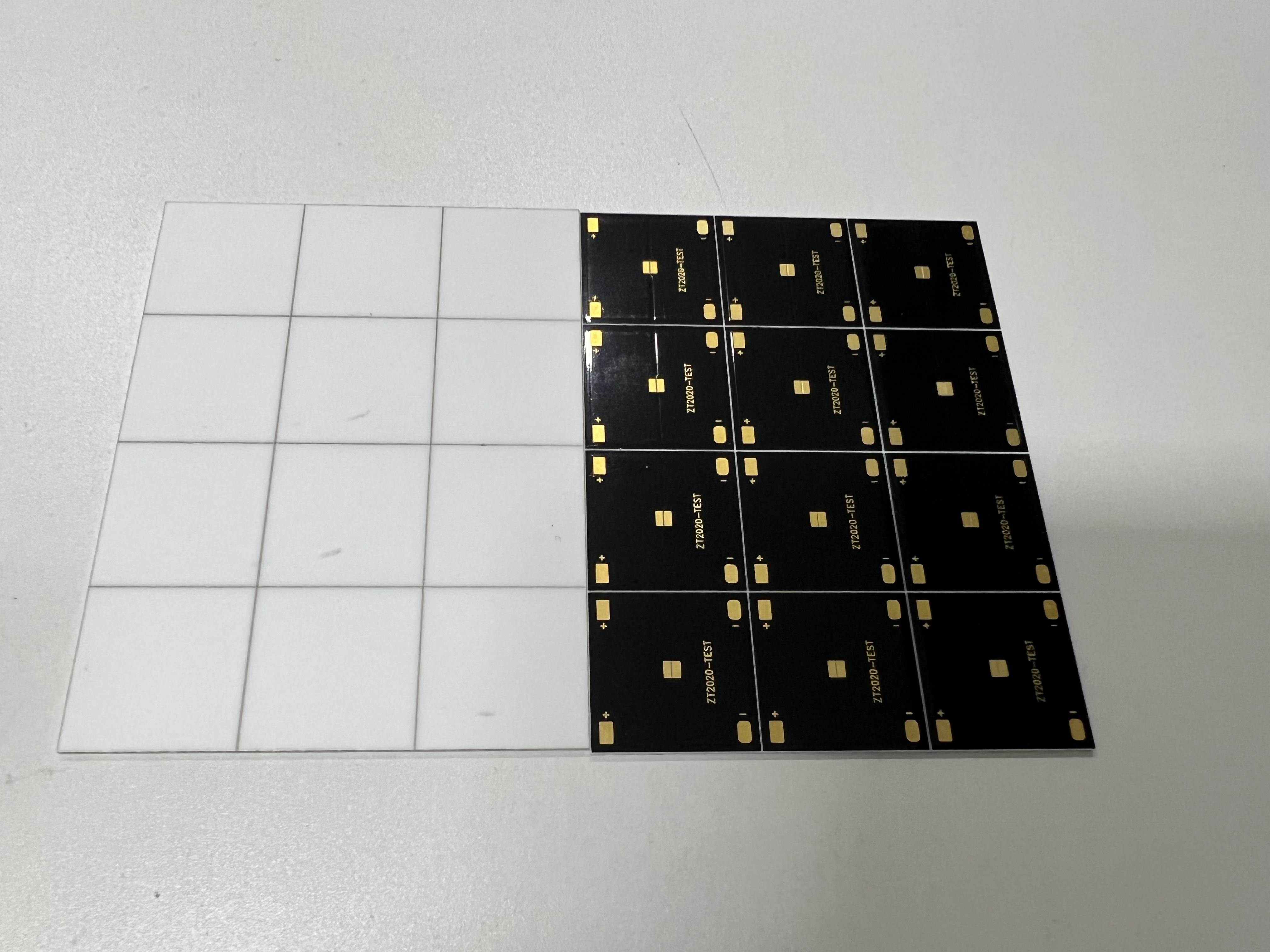

Ceramic PCB vs Traditional PCB Manufacturing Process Explained

You notice that the ceramic pcb manufacturing process utilizes advanced materials and techniques, setting it apart from traditional PCB methods that rely on standard substrates. Ceramic PCBs have gained popularity in high-power LED lighting and aerospace electronics due to their superior performance. LT CIRCUIT leads the industry in delivering reliable PCB solutions through expertise in the ceramic pcb manufacturing process. It’s important to identify which type best matches your project demands.

Key Takeaways

Ceramic PCBs offer superior thermal conductivity, making them ideal for high-power applications like LED lighting and aerospace electronics.

Choosing the right substrate material is crucial; options like aluminum nitride provide excellent heat management and dielectric strength.

Traditional PCBs are cost-effective and versatile, suitable for everyday electronics, but may not perform as well in extreme conditions compared to ceramic options.

Ceramic PCB Manufacturing Process

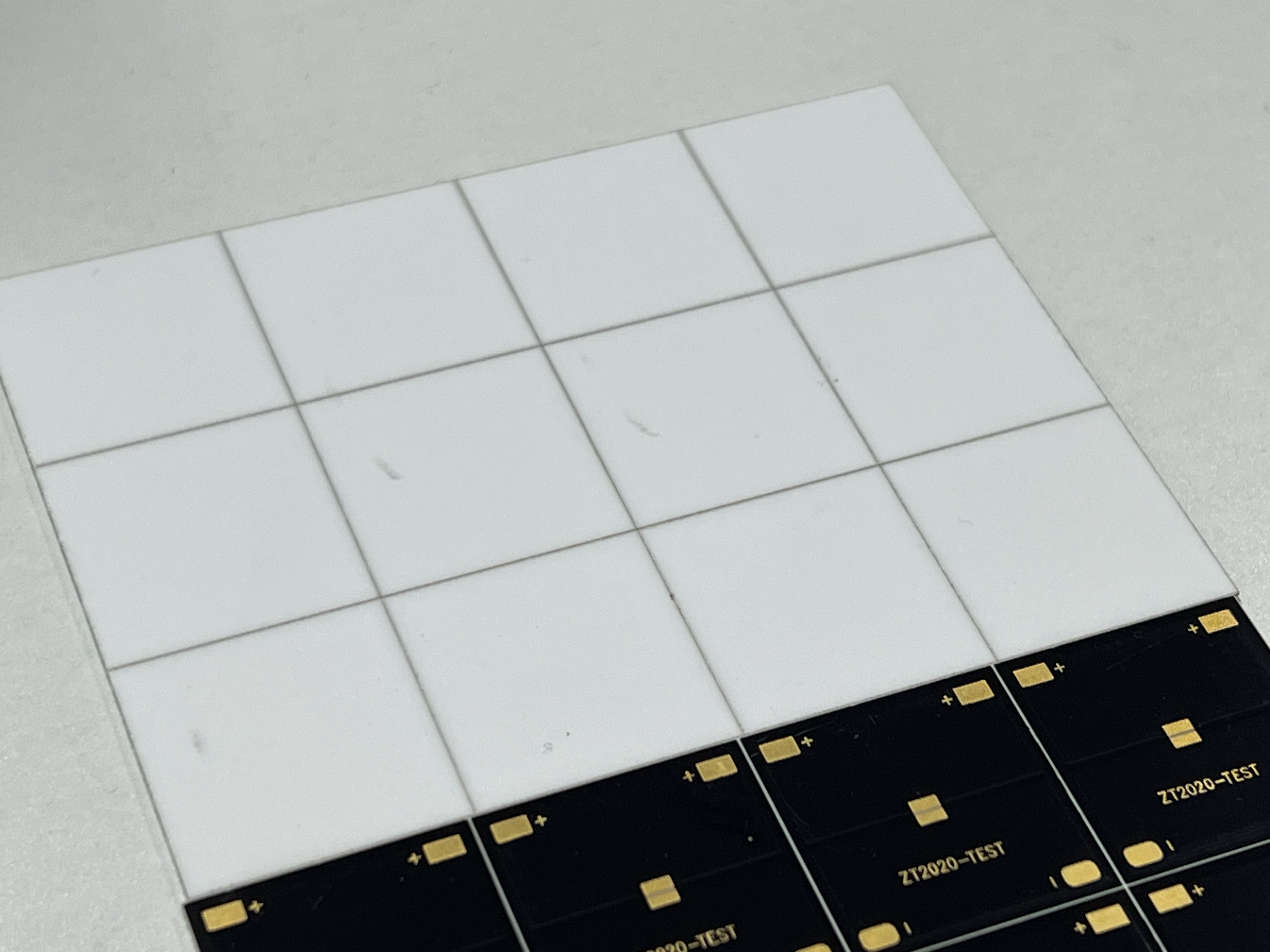

Substrate Materials

You start the ceramic pcb manufacturing process by selecting the right substrate. Ceramic circuit boards use materials with high thermal conductivity, which helps manage heat in demanding applications. You often see aluminum oxide, aluminum nitride, beryllium oxide, and silicon nitride as popular choices. Each material offers unique benefits for dielectric strength and heat dissipation. The table below shows the thermal conductivity of common substrates:

Substrate Material | Thermal Conductivity (W/mK) |

|---|---|

Aluminum Oxide (Al2O3) | 24-29 |

Aluminum Nitride (AlN) | 170-220 |

Beryllium Oxide (BeO) | ~9 times that of Al2O3 |

Silicon Nitride (SiN) | 85-90 |

You select a substrate based on the specific needs of your ceramic circuit boards, such as high dielectric performance or superior heat resistance.

Process Steps

The ceramic pcb manufacturing process involves several advanced steps. You begin with raw material preparation, followed by ceramic slurry printing. After drying and pre-curing, you move to high-temperature sintering, which bonds the ceramic circuit boards and enhances dielectric properties. LT CIRCUIT uses precise temperature control during sintering to prevent defects and ensure reliability.

You then apply surface metallization, which creates conductive paths on the ceramic pcb. Advanced techniques like laser drilling and laser patterning allow you to form precise vias and circuit traces. Laser drilling produces cleaner holes, improving electrical performance and durability. You use thick film or thin film deposition to add conductive layers, which boosts the dielectric strength and reliability of ceramic circuit boards.

You finish the ceramic pcb manufacturing process with soldering, component mounting, testing, and shaping. Each step ensures your ceramic circuit boards meet strict quality standards. LT CIRCUIT’s expertise in these processes guarantees high-performance ceramic pcb solutions for your most challenging projects.

Traditional PCB Manufacturing

Materials Used

When you work with traditional pcbs, you often choose from a range of materials based on your project’s needs. The most common material is FR4, which gives you excellent electrical insulation and strong mechanical support. You may also use CEM-1 or CEM-3 for moderate performance, or polyimide and PTFE (Teflon) when you need flexibility or chemical resistance. Some traditional pcbs use metal cores for better heat management.

Here’s a quick look at the properties of these materials:

Material | Electrical Properties | Mechanical Properties |

|---|---|---|

FR4 | Excellent electrical insulation | High mechanical strength |

CEM-1 | Moderate electrical insulation | Moderate mechanical strength |

CEM-3 | Good electrical insulation | Good mechanical strength |

Polyimide | High thermal stability | Flexible |

PTFE (Teflon) | Excellent chemical resistance | Low friction, flexible |

Metal Core PCB | Good thermal conductivity | High mechanical strength |

You select the right material for your traditional pcb by considering the electrical, thermal, and mechanical demands of your application.

Process Overview

The manufacturing process for traditional pcbs follows a series of well-defined steps. You start by preparing the laminate, which usually has a copper layer on both sides. Next, you apply a photosensitive film and expose it to UV light to create the circuit pattern. After developing the image, you etch away unwanted copper, leaving only the desired traces.

You then drill holes for component leads and vias. After drilling, you add a solder mask to protect the copper traces and apply a silkscreen layer for labeling. The final steps include electrical testing and assembly, where you mount and solder components onto the board.

Tip: Each step in the traditional pcb process affects the final quality and reliability of your board. Careful control during manufacturing ensures your traditional pcbs meet industry standards.

Traditional pcbs remain popular because they balance cost, performance, and versatility for many electronic products.

Comparison

Thermal Conductivity

You need to consider thermal conductivity when you compare ceramic circuit boards and traditional PCBs. Thermal conductivity measures how well a material moves heat away from hot spots. This property is critical in high-power electronics, where overheating can cause failure.

Here is a table that shows the difference in thermal conductivity between common PCB materials:

Material Type | Thermal Conductivity (W/mK) |

|---|---|

Ceramic (Aluminum Nitride) | Up to 180 |

Ceramic (Aluminum Oxide) | 20-30 |

Traditional PCB (FR4) | 0.3 |

You see that ceramic circuit boards offer much higher thermal conductivity than traditional PCBs. For example, aluminum nitride ceramics can reach up to 180 W/mK, while FR4 only reaches about 0.3 W/mK. This means you can use ceramic PCBs in devices that generate a lot of heat, such as power modules and LED lighting. LT CIRCUIT uses advanced materials and strict quality control to ensure high reliability and excellent thermal conductivity in every product.

Electrical Performance

Electrical performance is another key factor in your comparison. You want your PCB to deliver strong signal integrity and low signal loss, especially in high-frequency applications. Ceramic PCBs have a low dielectric constant and low dielectric loss, which helps you maintain high signal quality.

PCB Type | Dielectric Constant | Dielectric Loss | Signal Integrity |

|---|---|---|---|

Ceramic PCBs | Low | Low | High |

Traditional FR4 | Higher (~4.5) | Higher | Lower |

You get better electrical performance from ceramic PCBs, which makes them ideal for RF, microwave, and high-speed digital circuits. LT CIRCUIT’s innovation in both ceramic and traditional PCB manufacturing ensures you receive products with high reliability and strong electrical performance.

Heat Resistance

You must also look at heat resistance when you choose a PCB. Ceramic PCBs can handle much higher temperatures than traditional PCBs. This makes them perfect for high-temperature performance in demanding environments.

Feature | Ceramic PCB | FR4 PCB |

|---|---|---|

Up to 350+°C | Up to 130-150°C |

You can use ceramic PCBs in applications that reach up to 350 degrees Celsius. Some ceramic circuit boards even operate safely from -40°C to 850°C. Traditional PCBs, like FR4, work best below 150°C. LT CIRCUIT’s ceramic PCBs maintain reliability and high reliability even in extreme heat, which is essential for aerospace, automotive, and industrial uses.

Mechanical Strength

Mechanical strength affects how well your PCB stands up to stress, bending, and vibration. Ceramic PCBs give you high rigidity and superior tensile strength. Traditional PCBs, such as FR4, offer good strength but are less robust than ceramics.

Property | Ceramic PCBs | Traditional PCBs (FR4) |

|---|---|---|

Flexural Strength | High mechanical strength and rigidity | Lower mechanical strength |

Tensile Strength | Superior strength and stiffness | Varies, generally less robust |

Thermal Conductivity | High thermal conductivity | Lower thermal conductivity |

High-Temperature Operation | Suitable for high temperatures | Limited high-temperature performance |

You benefit from the high mechanical strength of ceramic PCBs in harsh environments. These boards resist cracking and warping, even under rapid temperature changes. LT CIRCUIT tests every ceramic PCB for mechanical shock and thermal cycling, so you can trust their reliability in critical applications.

Note: Ceramic PCBs also provide excellent corrosion resistance and chemical stability. You can use them in corrosive or humid environments without worrying about moisture absorption or chemical damage. LT CIRCUIT’s advanced manufacturing methods further improve corrosion resistance and reduce chemical waste, supporting both product longevity and environmental responsibility.

When you compare ceramic and traditional PCB manufacturing, you see clear advantages in thermal conductivity, electrical performance, heat resistance, and mechanical strength for ceramic circuit boards. LT CIRCUIT’s commitment to innovation and quality ensures you receive high reliability and superior performance, no matter which PCB type you choose.

Cost Comparison

Material Costs

When you compare the material costs for different types of circuit boards, you see a clear difference. Ceramic substrates use advanced materials like alumina and aluminum nitride. These materials have a higher cost than the fiberglass used in traditional FR-4 boards. The table below shows the average material cost per square meter in 2023:

Type of PCB | Cost Range (per square meter) |

|---|---|

Ceramic Substrates | $538.20 - $2152.78 |

Traditional FR-4 | $139.35 - $538.20 |

You also notice a difference when you look at the cost per square foot:

Material Type | Cost Range (per square foot) |

|---|---|

FR-4 | $1.00 - $8.00 |

Ceramic | $5.00 - $50.00 |

Ceramic materials cost more because they offer better heat resistance and durability. You pay more for these benefits, especially in high-performance applications.

Production Costs

Production costs for ceramic boards are much higher than for traditional options. You need specialized equipment and skilled labor to handle ceramic materials. Processes like high-temperature sintering and vacuum metal deposition add to the cost. Ceramic PCBs can cost five to ten times more to produce than FR-4 boards.

You may face some challenges when you try to scale up ceramic PCB production:

Complex fabrication steps

Longer lead times

Scalability issues that require advanced technology

When you do a cost comparison, you see that ceramic boards are more expensive, but they deliver unique advantages for demanding environments.

Applications

Ceramic PCB Uses

You find ceramic PCBs in many advanced industries. These boards work well where you need strong heat management and high reliability. The table below shows where you often use ceramic PCBs and what makes them special:

Application Area | Performance Advantages |

|---|---|

Reliability under high-temperature conditions due to superior thermal properties. | |

Medical Devices | Precision, miniaturization, and reliability are crucial for diagnostic equipment. |

Aerospace and Defense | Ability to perform in extreme environments for radar systems and avionics. |

Telecommunications | Essential for high-frequency communication devices, especially with 5G technology. |

LED Lighting | Superior heat management for automotive headlights and industrial lighting. |

You choose ceramic PCBs because they offer unmatched thermal conductivity. These boards handle heat better than most other materials. You also get high-frequency performance with low signal loss, which is important for 5G and radar systems. Ceramic PCBs resist moisture, corrosion, and chemicals, so you can use them in harsh environments. Their design supports miniaturization, letting you fit more circuits into smaller spaces.

Tip: If you need a board that works in extreme heat or high-frequency settings, ceramic PCBs give you a clear advantage.

Traditional PCB Uses

You see traditional PCBs in many everyday products. These boards support a wide range of electronics because they balance cost and performance. You find them in:

Consumer electronics like smartphones, computers, and televisions.

Industrial control systems and automation equipment.

Home appliances such as washing machines and microwaves.

Automotive dashboards and entertainment systems.

Communication devices, including routers and modems.

You pick traditional PCBs when you want a reliable, cost-effective solution for general electronics. These boards work well in most environments and support many types of components. You can use them for both simple and complex circuits, making them a popular choice in the electronics industry.

Choosing the Right PCB

Decision Factors

When you select the best circuit board for your project, you need to look at several important factors. Start by defining your design goals and the main functions your board must perform. Next, think about the environment where your board will work. Will it face high temperatures, strong vibrations, or harsh chemicals? These details help you decide if you need a ceramic or traditional board.

Here is a table to help you compare key decision factors:

Factor | Description |

|---|---|

Thermal Conductivity | Needed for heat management; ceramics like AlN and BeO work well for high-power uses. |

Electrical Insulation | Ceramics provide strong insulation and high dielectric strength. |

Coefficient of Thermal Expansion (CTE) | Matching CTE with components prevents stress and damage. |

Mechanical Strength & Toughness | Ceramics are rigid; some types offer better toughness or flexibility. |

Cost Considerations | Alumina is affordable; AlN and BeO cost more for special uses. |

Manufacturing Compatibility | Some ceramics allow complex designs; others limit the number of layers. |

You should also create a requirement document before you start. This document keeps your project on track and helps you avoid mistakes or delays.

Tip: Always check if your board needs to meet special certifications or standards for your industry.

LT CIRCUIT Solutions

LT CIRCUIT gives you many ways to customize your board for different industries. For example, you can choose boards that handle high temperatures and strong vibrations for automotive uses. In aerospace, you get boards built for extreme conditions and extra protection. Power electronics benefit from heavy copper layers, which improve heat management and strength.

You can also count on LT CIRCUIT for thorough testing and quality checks, such as:

Flying probe testing

AOI (Automated Optical Inspection)

Solderability and leakage tests

X-ray and microsection analysis

Functional and burn-in testing

These services make sure your pcb meets strict standards and works well in real-world conditions. LT CIRCUIT helps you find the right solution, whether you need a ceramic or traditional board.

You see clear differences in manufacturing between ceramic and traditional PCBs. Ceramic boards use thick-film and thin-film methods for precision and durability. The table below highlights key aspects:

Aspect | Ceramic PCB | Traditional PCB |

|---|---|---|

Heat Resistance | High | Moderate |

Design Precision | Excellent | Good |

When you choose a pcb, consider these tips:

Match board type to circuit complexity and environment.

Select flexible designs for compact devices.

Balance performance needs with your budget.

LT CIRCUIT helps you find the best fit for your project.

FAQ

What makes ceramic PCBs different from traditional boards?

You get better heat management and higher reliability with ceramic PCBs. These boards use advanced materials that handle extreme temperatures and harsh environments.

Can you use ceramic PCBs in consumer electronics?

You usually find ceramic PCBs in high-performance or industrial devices. Most consumer electronics use traditional boards for cost and flexibility.

How do you choose the right PCB for your project?

You should look at your project’s heat, strength, and cost needs. LT CIRCUIT can help you select the best pcb for your application.

See Also

Understanding The Process Behind PCB Manufacturing Techniques

A Comprehensive Overview Of Multilayer Ceramic PCB Production

The Role Of Ceramic PCBs In Today's Industrial Applications