Top Trends Shaping Ceramic PCB Prototype Technology in 2025

Miniaturization in ceramic pcb prototype technology leads to smaller, more efficient devices.

High thermal conductivity enables ceramic pcb prototype to improve device reliability.

Integration with IoT and flexible ceramic pcb prototype expands design options.

Eco-friendly manufacturing shapes the future of ceramic printed circuit boards.

Understanding these trends helps you drive innovation and stay ahead in electronics manufacturing. LT CIRCUIT delivers the latest innovations in ceramic pcb prototype, ensuring your prototyping and technology goals align with industry advancements.

Key Takeaways

Miniaturization in ceramic PCB technology leads to smaller, more efficient devices, allowing for advanced electronics in compact spaces.

High thermal conductivity of ceramic materials enhances device reliability, making them ideal for high-power applications.

Integration with IoT and flexible designs expands possibilities for innovative product development in various industries.

Ceramic PCB Prototype Trends

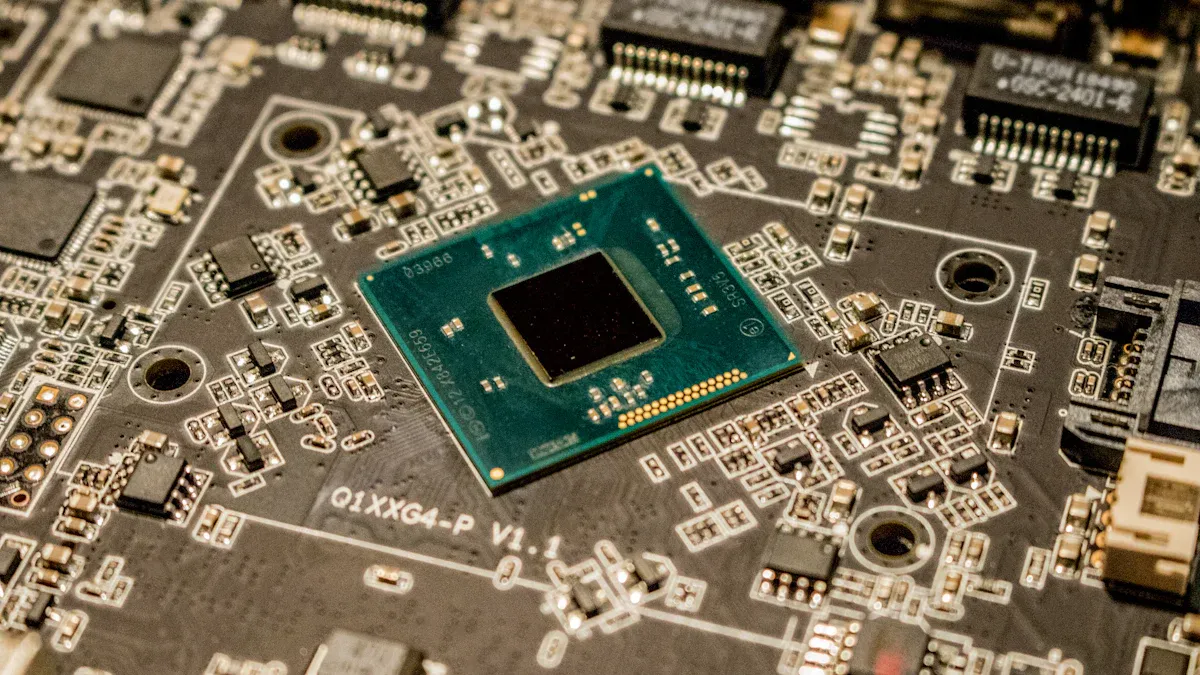

You see rapid changes in the world of ceramic pcb prototypes. These trends shape how you design, manufacture, and use printed circuit boards. Companies like LT CIRCUIT lead the way by bringing new technology and innovation to the market. Let’s explore the most important trends that will define ceramic pcb development in 2025.

Miniaturization & HDI

Miniaturization trends drive the need for smaller, more powerful devices. You want your electronics to do more in less space. High-density interconnect (HDI) technology helps you achieve this goal. HDI allows you to pack more connections into a smaller area, which is essential for modern devices.

Here are the key drivers behind miniaturization and HDI in ceramic pcb prototypes:

Driver | Description |

|---|---|

Ultra-Precision Manufacturing | Upgraded production lines with UV laser drilling and advanced LDI systems for smaller trace sizes. |

AI-Driven Production Ecosystem | Integration of AI tools for design review and defect detection, enhancing manufacturing efficiency. |

Next-Gen Material Partnerships | Collaborations with material suppliers for innovative substrates, improving thermal and signal performance. |

You benefit from several advancements in HDI technology:

Miniaturization techniques improve pcb performance while reducing size.

Advanced vias, such as microvias, enable greater routing density.

Embedding components within layers saves space and boosts performance.

Innovations in materials support high-frequency performance in smaller packages.

Enhanced soldering methodologies address the challenges of miniature components.

Rigid-flex pcbs combine the strengths of rigid and flexible technologies for durable, space-saving designs.

LT CIRCUIT uses these trends to deliver ceramic pcb prototypes that meet your needs for compact, high-performance electronics. You can rely on their expertise to keep your products at the forefront of technology.

Advanced Materials

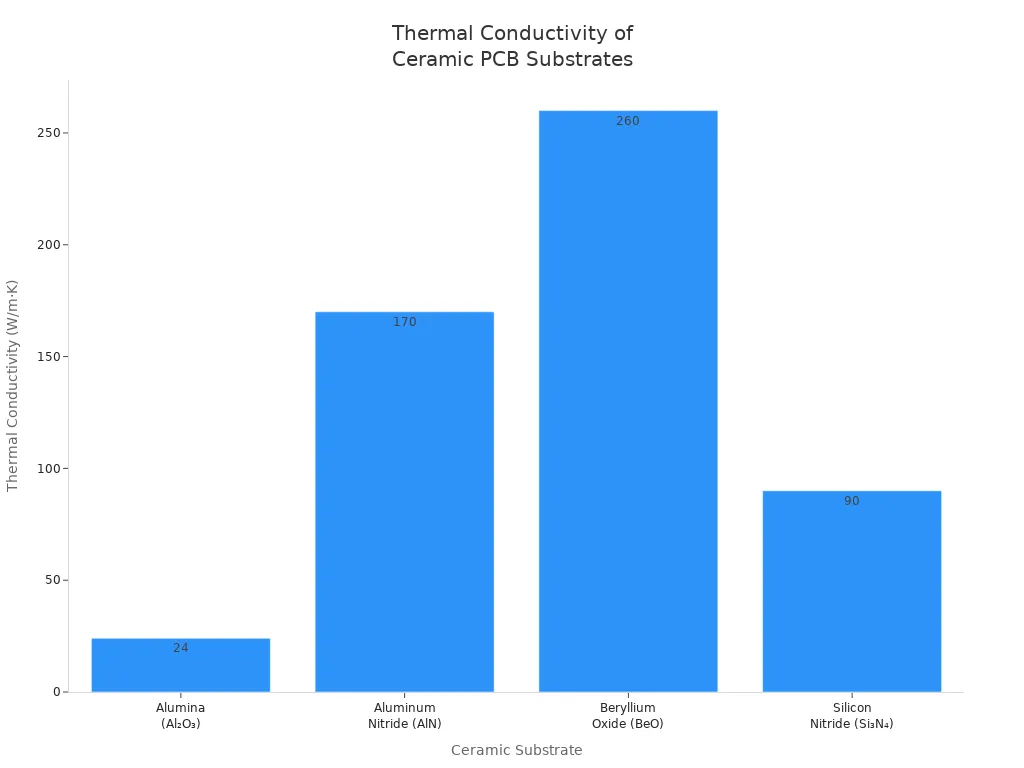

The choice of materials in ceramic pcb manufacturing has a big impact on performance. You see advanced materials in ceramic pcb prototypes, such as aluminum oxide, aluminum nitride, and beryllium oxide. These ceramics offer much higher thermal conductivity than traditional metal-clad pcbs. They also provide excellent electrical insulation and low dielectric constants, which are important for high-frequency performance and power applications.

Here’s a comparison of common ceramic pcb substrates:

Ceramic PCB Substrate | Thermal Conductivity (W/m·K) | Dielectric Constant (1MHz) | Typical Uses | Key Strengths |

|---|---|---|---|---|

Alumina (Al₂O₃) | ≥ 24 W/m·K | 9 – 10 | LED modules, general power boards | Affordable, good all‑rounder |

Aluminum Nitride (AlN) | ≥ 170 W/m·K | ≈ 8.5 – 9 | High‑power inverters, RF & microwave | Very high heat transfer, CTE matched to Si |

Beryllium Oxide (BeO) | ≈ 260 – 285 W/m·K | ≈ 6.5 – 7 | Laser drivers, aerospace & defense | Highest conductivity; requires strict safety controls |

Silicon Nitride (Si₃N₄) | ≈ 90 W/m·K | 7.8 | EV power modules, harsh‑environment electronics | Tough, excellent thermal‑shock resistance |

You also see new manufacturing techniques for ceramics, such as Direct Bonded Copper (DBC) and Direct Plated Copper (DPC). DBC gives you strong adhesion and excellent heat dissipation, which is perfect for power modules. DPC supports finer line widths, making it ideal for high-frequency performance in advanced circuits. Thick film ceramic pcb methods offer a cost-effective solution for sensors and hybrid microelectronics.

Material innovation affects both cost and reliability. For example, aluminum nitride provides high thermal conductivity and mechanical strength, making it suitable for high-power devices and 5G base stations. Silicon nitride offers very high mechanical strength and is used in automotive electronics and high-speed data transmission. You can choose the right material based on your application needs.

LT CIRCUIT stays ahead by using advanced materials in ceramic pcb prototypes. Their commitment to quality ensures your products deliver reliable performance in demanding environments.

3D Printing & Direct Printing

3D printing and direct printing represent some of the most exciting emerging trends in ceramic pcb technology. These methods let you create complex geometries and multilayer boards that were not possible before. You can now design, print, and test a new pcb in a single day, which speeds up your innovation cycle.

Recent breakthroughs include:

New fabrication strategies for standing ceramic circuit boards (S-CCBs) achieve high resolution and aspect ratio.

Sacrificial-coating-assisted micro-3D printing combines with electric-field-driven techniques for precise results.

Ceramic circuits now reach resolutions of 7 μm and aspect ratios of 2.3, surpassing older methods.

You benefit from these improvements in several ways:

Benefit | Description |

|---|---|

Rapid Iterations | Changes to the design can be implemented and printed within hours. |

Complex Geometries | Enables non-planar multilayer boards that can wrap around curves. |

Reduced Production Time | Printing multiple layers in a single process cuts down on assembly steps. |

You can achieve mass customization without the need for expensive molds.

Rapid prototyping lets you optimize power consumption and validate components quickly.

The cost-effectiveness of 3D printing supports unique applications, such as patient-specific medical devices.

LT CIRCUIT adopts these new technologies to help you stay ahead of the competition. Their focus on innovation ensures you have access to the latest trends in ceramic pcb manufacturing.

Tip: By following these trends in ceramic pcb prototypes, you position your projects for success in a fast-changing electronics industry.

Ceramic PCB Assembly & Automation

Smart Manufacturing

You see smart manufacturing changing the way ceramic pcb assembly works. This approach uses technology to improve every step of the process. You follow standard operating procedures to keep each ceramic pcb assembly consistent. Cross-training employees gives your team flexibility and reduces downtime. Regular quality audits help you catch problems early and fix them fast.

Strategy | Description | Outcome |

|---|---|---|

Set guidelines for ceramic pcb production. | Consistent quality in ceramics batches. | |

Cross-Training Employees | Train staff in multiple ceramic pcb tasks. | Flexible workforce and less downtime. |

Regular Quality Audits | Check ceramic pcb quality often. | Find issues early and fix them fast. |

You also use advanced testing methods in ceramic pcb assembly. Automated optical inspection finds defects quickly. X-ray testing checks internal connections. Functional testing makes sure each pcb works as expected. These steps ensure your ceramic pcb assembly meets high standards.

AI Integration

AI now plays a big role in ceramic pcb assembly. You use AI to review designs and spot errors before production starts. AI-driven systems monitor the assembly line and adjust settings in real time. This reduces mistakes and improves the quality of each pcb. You rely on AI to predict when machines need maintenance, which helps you avoid unexpected downtime.

AI also helps you analyze data from ceramic pcb assembly. You can find patterns and make better decisions for future projects. This leads to faster production and higher quality in every pcb you build.

LT CIRCUIT’s Advanced Assembly

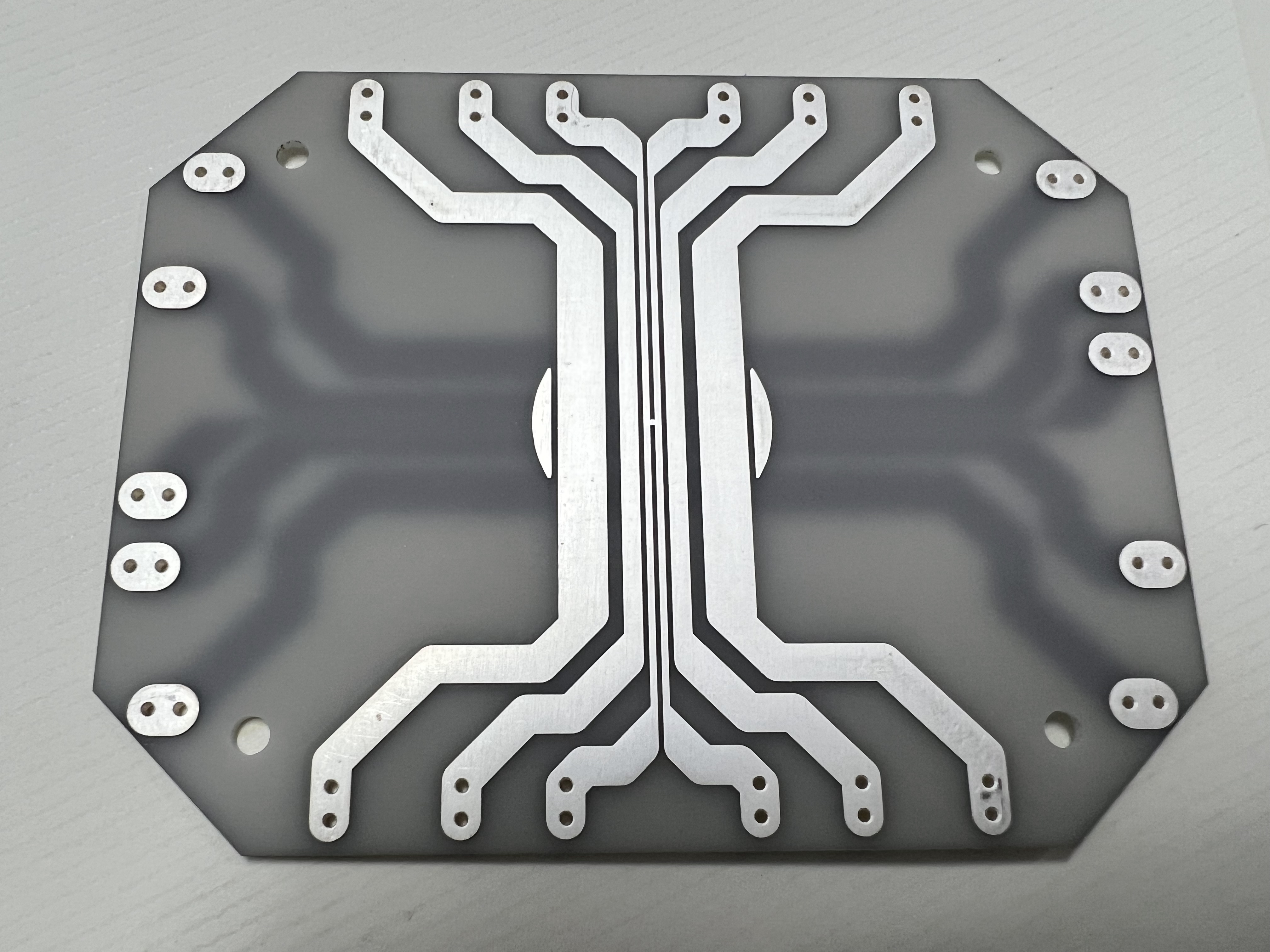

LT CIRCUIT leads the way in ceramic pcb assembly by using advanced technologies. You benefit from direct bonding copper, which bonds copper foils to ceramic substrates at high temperatures. This method gives your pcb strong connections and supports high copper thicknesses. Direct plating copper uses magnetron sputtering for precise circuits and effective plating of through-holes and vias. Active metal brazing forms a strong bond between ceramic and copper, giving your ceramic pcb assembly high mechanical strength and thermal conductivity.

You also see automation in ceramic pcb assembly with pick and place robots, automated dispensing systems, CNC routing, soldering reflow ovens, and robotic arms. These tools make ceramic pcb assembly faster and more accurate. They reduce labor costs and material waste, giving you a better return on investment. LT CIRCUIT’s commitment to quality and innovation ensures your ceramic pcb assembly meets the demands of modern electronics.

Tip: Embracing these technologies in ceramic pcb assembly helps you achieve reliable, high-performance pcb products for every application.

Advanced Ceramic PCB Materials

Aluminum Nitride (AlN)

You want your pcb to handle heat and power without failure. Aluminum nitride (AlN) stands out as a top choice for ceramic pcb materials. AlN offers outstanding thermal conductivity, reaching up to 170 W/mK. This means your pcb can move heat away from sensitive components quickly. AlN also supports miniaturization by allowing compact designs and high-density layouts. You get excellent dielectric properties, high operating temperatures above 350°C, and a low thermal expansion coefficient. These features make AlN ideal for high-power applications like LEDs and RF modules. AlN also provides hermetically sealed packages and minimal outgassing, which helps your pcb last longer.

Advantage | Description |

|---|---|

More than five times that of alumina (Al₂O₃) | |

Uniform Heat Spreading | Reduces hotspots on the pcb |

Excellent Thermal Shock Resistance | Handles rapid temperature changes |

Compatible with High Power Devices | Perfect for LEDs and RF modules |

Thermal Management

You need your pcb to stay cool, even in demanding environments. Ceramic materials like AlN and alumina have much higher thermal conductivity than standard FR-4. This helps your pcb dissipate heat from high-power components. You see miniaturization trends pushing for more power in smaller spaces, so thermal management becomes critical. Ceramic pcb substrates support intricate designs and high-density interconnections, which improve heat dissipation. Your pcb can now handle harsh conditions in automotive and aerospace sectors without extra cooling systems.

Reliability & Lifespan

You expect your pcb to deliver superior reliability in every application. Ceramic pcb materials maintain excellent electrical insulation, even at high temperatures. Dielectric strengths often exceed 10 kV/mm, which prevents breakdown in high-voltage uses. Your pcb benefits from efficient heat dissipation, resistance to temperature swings, and moisture protection. These qualities ensure your pcb lasts longer and performs better. LT CIRCUIT uses only high-quality ceramic materials, so you get miniaturization, reliability, and long-term performance in every pcb.

Tip: Choosing advanced ceramic materials for your pcb boosts miniaturization, reliability, and efficiency in every project.

Flexible & Stretchable Ceramic PCB

Design Innovations

You see new design innovations changing how you use pcb technology. Engineers now create flexible ceramic pcb and rigid-flex ceramic pcb structures that bend and twist without breaking. These designs use thin ceramic layers and advanced bonding techniques. You can shape a pcb to fit inside curved devices or wrap it around tight spaces. Rigid-flex ceramic pcb combines the strength of rigid boards with the flexibility of thin circuits. This approach lets you design smaller, lighter, and more reliable electronics. You also get better thermal management and improved signal integrity.

Applications in 5G & IoT

You find flexible ceramic pcb and rigid-flex ceramic pcb essential for 5G and IoT devices. These technologies need compact, high-performance pcb solutions. You can use a flexible ceramic pcb in wearable sensors, smart medical devices, and compact communication modules. Rigid-flex ceramic pcb works well in antennas, automotive electronics, and high-power applications. You get better durability and performance in harsh environments. The ability to bend and stretch a pcb opens new possibilities for device design.

Tip: When you use flexible ceramic pcb in 5G and IoT, you improve device reliability and enable new product shapes.

LT CIRCUIT’s Solutions

LT CIRCUIT leads the way in flexible ceramic pcb and rigid-flex ceramic pcb technology. You benefit from their advanced manufacturing processes and strict quality control. LT CIRCUIT offers custom pcb solutions for unique shapes and demanding environments. Their expertise helps you achieve high-density layouts and robust connections. You can trust LT CIRCUIT to deliver pcb products that meet the needs of modern electronics.

Sustainability in Ceramic PCB

Green Manufacturing

You see green manufacturing changing how you produce pcb. Companies now focus on eco-friendly manufacturing to reduce waste and energy use. You can follow practices that help protect the environment and improve sustainability. The table below shows some leading methods in ceramic pcb production:

Practice | Description |

|---|---|

Eco-friendly PCB materials | Use biodegradable options like cellulose or paper. |

Lead-Free Solder Materials | Replace lead to lower health and environmental risks. |

Recyclable Materials | Choose copper and aluminum that you can reuse. |

Modular PCB architecture | Design for easy part replacement and less waste. |

Green manufacturing | Use additive processes to minimize material waste. |

Optimized chemical usage | Improve chemical steps for safer disposal. |

PCB recycling programs | Support responsible recycling and disposal. |

Tip: You can help the planet by choosing pcb suppliers who use eco-friendly manufacturing and recycling programs.

Eco-Friendly Materials

You want your pcb to use eco-friendly materials for better sustainability impact. Many manufacturers now select recyclable substrates and renewable resources. You see bamboo and bio-resins used to lower environmental harm. Ceramic pcb made from natural, non-toxic materials also supports eco-friendly goals. These choices offer several benefits:

Sustainable sourcing ensures you use recyclable and renewable alternatives.

Recyclable substrates make it easier to recover materials at the end of the pcb’s life.

Bamboo and bio-resins reduce the carbon footprint.

Ceramic pcb lasts longer, so you create less electronic waste.

Energy-efficient ceramic pcb needs less cooling, saving power.

Non-toxicity keeps the environment safer.

Reduced waste means fewer pcb replacements.

Industry Standards

You follow strict industry standards to improve sustainability in pcb manufacturing. These rules help you use eco-friendly materials and safe processes. The table below highlights important standards:

Regulation / Standard | Scope & Focus | Impact on PCB Manufacturing |

|---|---|---|

RoHS | Limits hazardous substances | Promotes lead-free solder and safer laminates |

REACH | Controls chemical use | Ensures safer coatings and finishes |

WEEE | Requires e-waste recycling | Encourages recyclable design and disposal |

IPC Standards | Sets material and performance requirements | Supports eco-friendly base materials |

ISO 14001 | Environmental management | Helps factories reduce waste and energy use |

Note: You can meet global sustainability goals by following these standards and choosing eco-friendly materials for your pcb projects.

Future of the Ceramic PCB Market

5G & Market Growth

You see the global ceramic pcb market expanding quickly as new technologies emerge. The future of the ceramic pcb market looks bright, especially with the rollout of 5G networks. You notice several important trends driving this growth:

The ceramic pcb market is projected to grow from $1.59 billion in 2024 to $1.84 billion in 2025.

Advancements in technology and the expansion of 5G infrastructure fuel this increase.

The compound annual growth rate for ceramic pcb is estimated at 13.5%.

The global 5G pcb market could reach $420 billion by 2025, with a CAGR of 22-28%, much higher than the average pcb market.

You can expect more demand for high-performance pcb as 5G and advanced electronics become standard.

Industry Drivers

You see several key drivers shaping the trends in ceramic pcb technology. The table below highlights what pushes the industry forward:

Driver | Description |

|---|---|

Demand for High-Performance Devices | You need reliable pcb for advanced electronics in many industries. |

Trend Towards Miniaturization | Smaller devices require efficient thermal management in pcb. |

Automotive Shift to EVs and ADAS | Electric vehicles and driver assistance systems need robust pcb solutions. |

These drivers ensure that you stay focused on innovation and quality in every pcb project.

LT CIRCUIT’s Market Leadership

You benefit from LT CIRCUIT’s leadership in the pcb industry. The company sets high standards for quality and adapts quickly to new trends. You get advanced technology, strong customer support, and competitive pricing. LT CIRCUIT earns recognition for expertise in HDI pcb and gains trust from major electronics makers. You can rely on their commitment to innovation as you plan for the future.

Stay alert to new trends and partner with leaders like LT CIRCUIT to keep your pcb projects ahead in a fast-changing market.

You see the future of pcb shaped by innovation, adaptability, and sustainability. The table below highlights why ceramic pcb stands out:

Feature | Benefit |

|---|---|

Superior Thermal Management | Keeps pcb cool and reliable |

Mechanical Durability | Ensures pcb lasts in tough settings |

Frequency Stability | Maintains pcb performance |

You should choose pcb solutions that support sustainability and high performance.

LT CIRCUIT offers advanced pcb options for every need.

Ongoing advancements in pcb technology will drive sustainability and open new possibilities.

FAQ

What makes ceramic pcb different from standard pcb?

You get better thermal management and higher reliability with ceramic pcb. Ceramic pcb handles heat and power better than standard pcb. You see improved performance in demanding applications.

How does LT CIRCUIT ensure quality in ceramic pcb production?

You benefit from strict quality checks at every step. LT CIRCUIT uses advanced testing for each pcb. You receive pcb that meets high industry standards for reliability and performance.

Can you use ceramic pcb for flexible and 5G devices?

You can use ceramic pcb in flexible electronics and 5G devices. Ceramic pcb supports miniaturization and high-frequency needs. You get strong, reliable pcb for modern technology.

See Also

Investigating How Ceramic PCBs Are Used Across Industries

Examining Al₂O₃ Ceramic PCBs and Their Industrial Uses

The Superior Heat Dissipation Properties of Ceramic PCBs

A Comprehensive Guide to Manufacturing Multilayer Ceramic PCBs

Utilizing Aluminum Nitride Ceramic PCBs in Various Industries