Why Ceramic PCBs Excel in Heat Dissipation

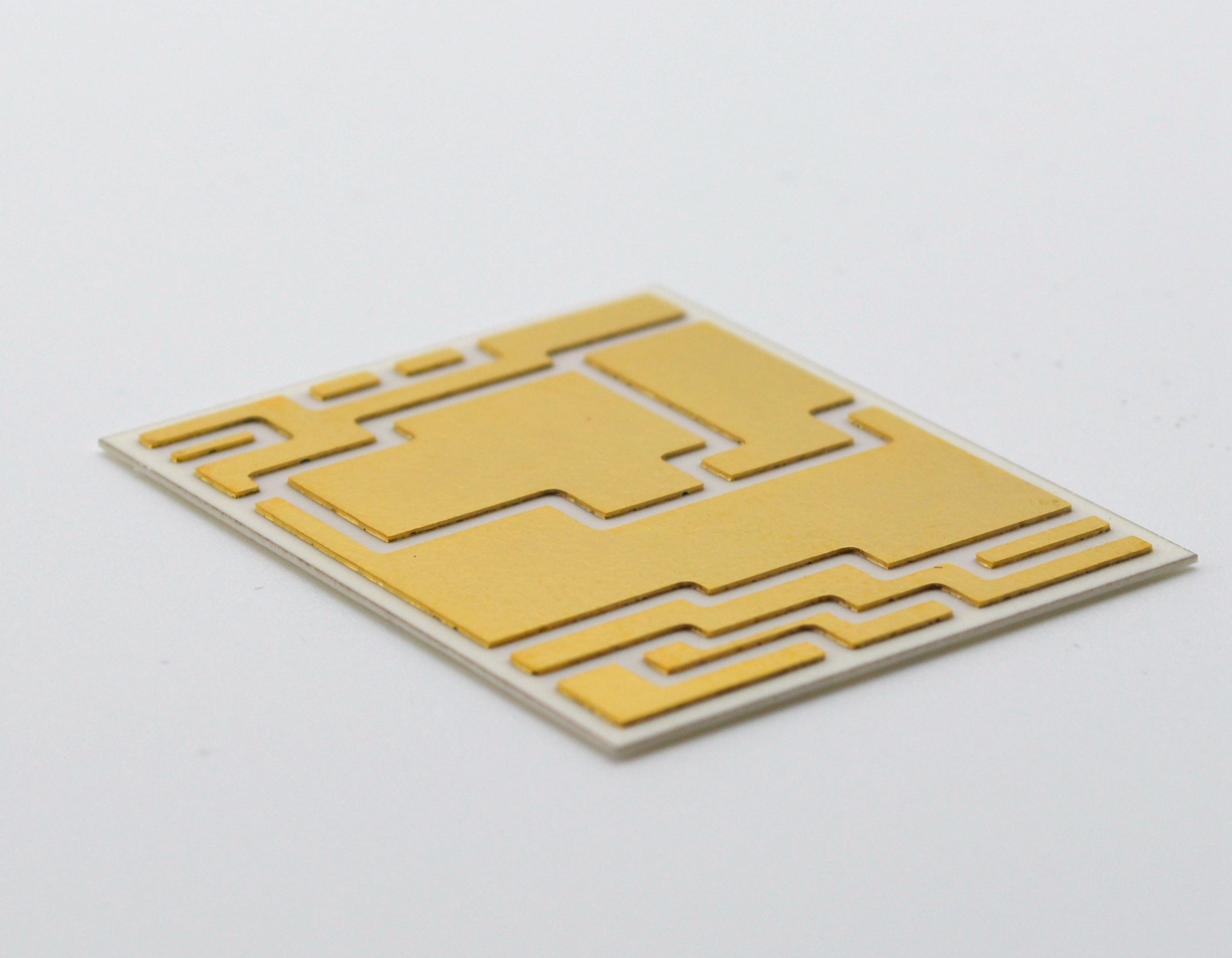

You need good heat control for powerful devices. Ceramic PCBs are great at removing heat because of their special materials. They move heat well and stay strong in high temperatures. These features make ceramic PCBs important for devices that work in tough conditions.

Key Takeaways

Ceramic PCBs are great at getting rid of heat fast.

They stay strong and stable even in very hot or cold places.

LT CIRCUIT makes ceramic PCBs that last long and work well.

Key Advantages of Ceramic PCBs in Heat Dissipation

Superior Thermal Conductivity

Ceramic PCBs are great at handling heat. They use materials like aluminum oxide and aluminum nitride. These materials move heat away from parts quickly. This stops overheating and keeps devices working well, even with high power.

Here’s a simple comparison of how well these materials handle heat:

Material | Thermal Conductivity (W/m·K) | Uses |

|---|---|---|

Aluminum Oxide | Medium-to-high power devices | |

Aluminum Nitride | 170-200 | High-power devices, RF circuits, power amplifiers |

Beryllium Oxide | 270-300 | Aerospace, military, radar systems |

Silicon Carbide | 120-270 | Power electronics, car sensors, industrial machines |

As shown, materials like aluminum nitride and beryllium oxide handle heat much better than regular PCB materials. This makes ceramic PCBs perfect for devices that get very hot, like power amplifiers or industrial machines.

High-Temperature Stability

Ceramic PCBs work well even in very high heat. Regular PCBs can bend or break, but ceramic ones stay strong. This means devices with ceramic PCBs work reliably in hot places, like deserts or factories.

For instance, aluminum nitride and silicon carbide can handle much higher temperatures than FR4 PCBs. This makes ceramic PCBs essential for things like airplanes and cars, where temperatures change a lot. You can count on ceramic PCBs to work well, no matter the heat.

Mechanical Strength and Durability

Ceramic PCBs are not just heatproof; they’re also very strong. They can handle stress, shaking, and long use without breaking. This makes them a good choice for tough jobs.

Tests show ceramic PCBs stay strong in harsh conditions. Here’s a summary of the test results:

Test Condition | Details |

|---|---|

Temperature Range | |

Duration | Hundreds to thousands of hours |

Humidity Control | Controlled humidity levels |

Electrical Performance | Changes in resistance, capacitance, and impedance |

Mechanical Properties | Changes in strength and adhesion |

Microstructural Analysis | Tools like SEM and XRD used for study |

These tests prove ceramic PCBs can handle heat and moisture for a long time. They don’t lose their strength or electrical abilities. This makes them a lasting choice for industries like aerospace, cars, and high-power electronics.

Why LT CIRCUIT Leads in Ceramic PCB Innovation

Advanced Manufacturing Techniques

LT CIRCUIT uses modern methods to make ceramic PCBs. They use tools like laser drills and screen printers for precise designs. These methods make sure the PCBs work well and last long. Automated machines help keep production steady and reduce mistakes. With advanced tools, LT CIRCUIT makes products that fit today’s industry needs.

Commitment to Quality and Precision

LT CIRCUIT focuses on making high-quality PCBs you can trust. Each PCB is tested carefully to meet strict rules. Special tools check for any problems to ensure accuracy. They also follow global quality standards, so you know their products are reliable. This care makes their PCBs work well, even in tough conditions.

Tailored Solutions for Diverse Applications

LT CIRCUIT knows every project needs something different. They offer custom options to match your needs. Whether for powerful electronics or airplanes, they can help. You can pick materials, designs, and finishes to fit your project. This flexibility makes LT CIRCUIT a top choice for many industries.

Ceramic PCBs vs. Traditional PCB Materials

Ceramic PCBs vs. FR4

Ceramic PCBs are much better at handling heat than FR4 boards. FR4 struggles with high temperatures, while ceramic PCBs stay strong. The table below shows the main differences:

Feature | Ceramic PCBs | FR4 Boards |

|---|---|---|

Works great in extreme heat | Struggles in high heat | |

Thermal Conductivity | Excellent at moving heat | Only okay at moving heat |

Mechanical Strength | Very strong and durable | Weaker and less durable |

Insulation Performance | Great for high-voltage use | Decent but less reliable |

Aging Resistance | Slows down wear and tear | Ages faster |

Ceramic PCBs can handle heat levels from 20 to 200 W/mK. FR4 boards only manage 0.3 to 1.5 W/mK. This makes ceramic PCBs perfect for things like power amplifiers or LED lights. FR4 boards are better for low-power devices that don’t get too hot.

Ceramic PCBs also stay strong in tough conditions. FR4 boards might bend or break in high heat. This makes ceramic PCBs a better pick for industries like aerospace and cars, where strength matters.

Ceramic PCBs vs. Metal Core PCBs

Metal core PCBs (MCPCBs) are another option for heat control. But ceramic PCBs still perform better in many ways. MCPCBs use metal layers, like aluminum or copper, to move heat. Ceramic PCBs use their natural materials, which work better for both heat and insulation.

Here’s a quick comparison:

Thermal Conductivity: MCPCBs handle 1 to 10 W/mK, less than ceramic PCBs’ 20 to 200 W/mK.

Electrical Insulation: Ceramic PCBs insulate well, great for high-voltage use. MCPCBs need extra layers for insulation, making them harder to design.

Durability: Ceramic PCBs last longer and resist stress better than MCPCBs.

If you need both heat control and electrical safety, ceramic PCBs are the best choice. MCPCBs are fine for medium heat but not for high-power or high-voltage needs.

Unique Benefits of Ceramic Materials

Ceramic materials have special features that make them great for PCBs. Each type has its own strengths:

Aluminum Nitride (AlN): Best for high-frequency RF uses. It handles heat well and keeps signals clear in powerful devices.

Alumina (Al₂O₃): A budget-friendly choice for LED lights. It balances good heat control with low cost.

Silicon Nitride (Si₃N₄): Very strong and works in shaky or hot places. It helps parts last longer in cars and factories.

These materials make ceramic PCBs great at handling heat, staying strong, and keeping electrical performance steady. Whether for planes, cars, or powerful electronics, ceramic PCBs are a smart and reliable choice.

Applications of Ceramic PCBs in Modern Industries

High-Power Electronics

High-power electronics are used in factories and energy systems. These devices create a lot of heat, which can harm parts. Ceramic PCBs are great here because they remove heat well. They quickly move heat away, keeping devices safe and working.

For example, power amplifiers and inverters use ceramic PCBs to stay stable. They work well under heavy use and high heat. Their strength and heat resistance make them perfect for tough jobs.

LED Lighting Solutions

LED lights are used in homes and on streets. They create heat that can shorten their life. Ceramic PCBs are better than regular materials for handling this heat.

Using ceramic PCBs in LED lights makes them brighter and last longer. Materials like aluminum nitride keep LEDs cool and steady. From big floodlights to small bulbs, ceramic PCBs improve performance and durability.

Aerospace and Automotive Applications

Planes and cars need parts that handle tough conditions. Ceramic PCBs are great for these industries because they resist heat and stay strong.

For example, in planes or electric cars, ceramic PCBs work well despite heat and shaking. They are key for safety systems like radars, engines, and batteries.

Tip: For tough environments, ceramic PCBs are the most reliable choice.

Ceramic PCBs are great for controlling heat in tough places. They move heat well, stay strong, and work reliably. LT CIRCUIT makes high-quality ceramic PCBs to fit your needs. These boards are important for industries needing good heat control. Using ceramic PCBs improves device performance and helps them last longer in hot conditions.

FAQ

Why are ceramic PCBs good at removing heat?

Ceramic PCBs use materials like aluminum nitride. These materials move heat quickly. This keeps parts cool and helps devices work well.

Can ceramic PCBs survive tough conditions?

Yes, ceramic PCBs handle heat, moisture, and stress easily. They work great in hard places like factories, cars, and airplanes.

Are ceramic PCBs good for LED lights?

Yes! Ceramic PCBs help LEDs last longer and shine brighter. They control heat well, making them perfect for streetlights and big lamps.

Tip: Pick ceramic PCBs for strong heat control and long-lasting use.

See Also

Investigating How Ceramic PCBs Are Used in Today's Industries

Understanding the Role of Al₂O₃ Ceramic PCBs in Industry

Utilizing Aluminum Nitride Ceramic PCBs Across Various Industries

Comprehensive Guide to Heavy Copper Multilayer PCB Production