Ceramic Substrate PCB Trends Shaping Electronics Right Now

Ceramic substrate pcb is widely used in modern electronics, playing a crucial role across various industries. Automotive, telecom, and industrial systems all depend on ceramic substrate pcb for their advanced electronic needs. The table below highlights the main applications of ceramic substrate pcb:

Application | Impact |

|---|---|

Automotive | Ceramic substrate pcb is a major driver due to the demand for advanced electronic systems in vehicles, especially electric and autonomous vehicles. |

Telecommunications | The growth of ceramic substrate pcb is fueled by 5G technology, which requires high-frequency components to ensure efficient operation. |

Consumer Electronics | The adoption of ceramic substrate pcb is driven by miniaturization and the need for high-performance devices like smartphones and laptops. |

Aerospace & Defense | Ceramic substrate pcb is essential for components that must withstand extreme conditions, such as those used in satellites and radar systems. |

Industrial | Advanced electronics in manufacturing and medical devices rely on ceramic substrate pcb, especially with the rise of automation and IoT. |

Ceramic substrate pcb stands out for its high thermal conductivity, excellent electrical insulation, and strong mechanical strength. When you need reliability, conductivity, and performance in harsh environments, ceramic substrate pcb delivers. Staying informed about ceramic substrate pcb trends helps you design better, more durable electronics.

Key Takeaways

Ceramic substrate PCBs excel in high-performance applications, making them ideal for industries like automotive, telecommunications, and aerospace.

These PCBs offer superior thermal conductivity and electrical insulation, ensuring reliability in extreme conditions and high-frequency environments.

Investing in ceramic substrate PCBs enhances the longevity and performance of electronic devices, especially in demanding applications like medical and industrial systems.

Applications of Ceramic Substrate PCBs

Ceramic substrate pcbs have become essential in modern electronics because they offer unmatched thermal management and reliability. You will find these pcbs in fields that demand high performance and durability, especially where traditional materials fall short. The main applications of ceramic substrate pcbs include electric vehicles, medical devices, aerospace, rail transit, and power transmission networks. These areas require solutions that can handle extreme temperatures, high power, and harsh environments.

Power Electronics and Inverters

When you work with power systems, you need pcbs that can manage heat and maintain stability under stress. Ceramic pcbs excel in power electronics and inverters because they have a high melting point and excellent thermal stability. This means you can use them in environments where temperatures soar, and they will still perform reliably. Their low coefficient of thermal expansion keeps the structure intact even when temperatures change rapidly.

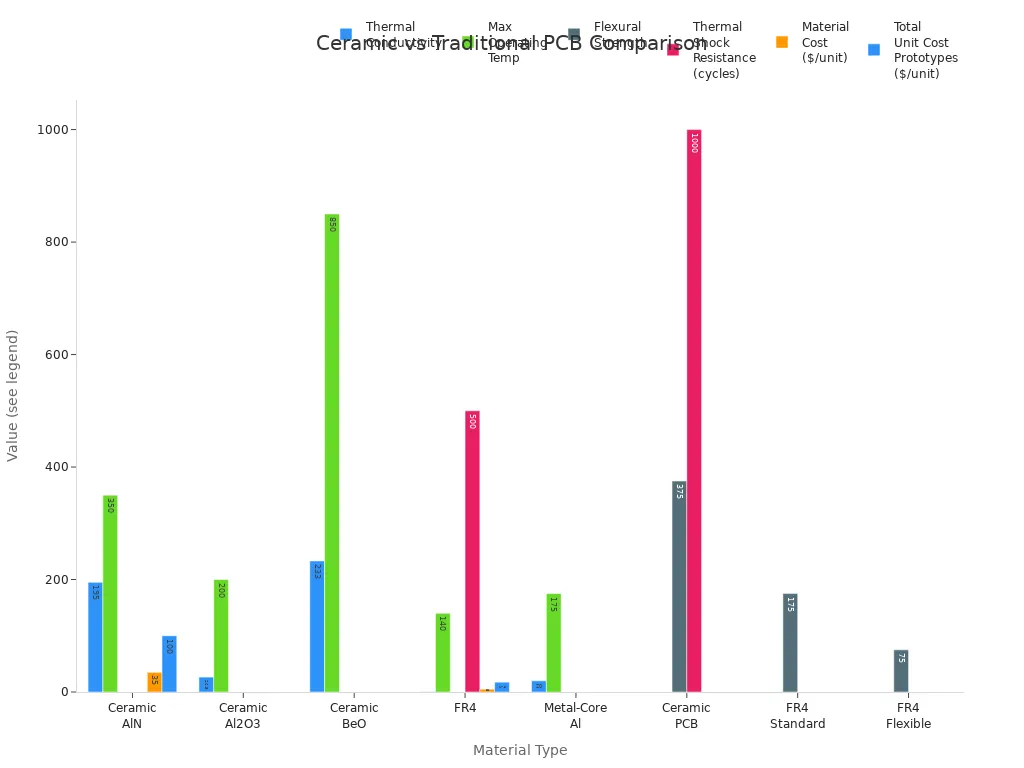

Here is a comparison of common pcb materials used in power applications:

Material | Thermal Conductivity (W/mK) | Max Operating Temp | Use Case Example |

|---|---|---|---|

Ceramic (Aluminum Nitride, AlN) | 170–220 | 350°C+ | EV powertrain inverters, 5G base station amplifiers |

Ceramic (Aluminum Oxide, Al2O3) | 24–29 | 200°C | Industrial LED lighting, medical device sensors |

Ceramic (Beryllium Oxide, BeO) | 216–250 | 850°C | Aerospace radar systems, nuclear sensors |

Traditional FR4 | 0.3 | 130–150°C | Smartphones, laptops, home appliances |

Traditional Metal-Core (Al) | 10–30 | 150–200°C | Automotive infotainment, low-power LEDs |

You can see that ceramic substrate pcbs, especially those made from aluminum nitride or beryllium oxide, outperform traditional pcb materials in thermal conductivity and temperature resistance. This makes them the top choice for power systems that need to dissipate heat quickly and operate safely at high temperatures.

Ceramic pcbs also provide better dielectric properties and lower signal loss, which is crucial for high-frequency power electronics. Although the cost of ceramic substrate pcbs is higher than traditional options, their superior performance and reliability in demanding applications justify the investment.

LED Lighting Solutions

In LED lighting, you need pcbs that can handle intense heat and keep the system running efficiently. Ceramic substrate pcbs offer high thermal conductivity, which allows LEDs to stay cool and last longer. This is especially important in industrial and automotive lighting, where reliability and performance matter most.

The table below shows how ceramic substrate pcbs compare to traditional FR4 substrates in LED applications:

Performance Metric | Ceramic Substrates | Traditional FR4 Substrates |

|---|---|---|

High-Temperature Resistance | Excellent, withstands high temperatures | Poor, degrades at high temperatures |

Heat Dissipation | High thermal conductivity | Low thermal conductivity |

Electrical Insulation | Superior, prevents short circuits | Moderate, can lead to failures |

Mechanical Strength | High, resistant to physical stresses | Low, less durable in harsh conditions |

Lifespan | Prolonged, reduces thermal stress | Limited, prone to degradation |

You will notice that ceramic pcbs extend the lifespan of LEDs by reducing thermal stress and preventing electrical failures. Their mechanical strength also ensures that lighting systems remain reliable even in tough environments.

Automotive Electronics

Automotive electronics demand pcbs that can survive extreme conditions and deliver consistent performance. Ceramic substrate pcbs meet these needs because they resist moisture, handle high temperatures, and maintain circuit stability. In electric vehicles and advanced driver-assistance systems, you need pcbs that will not fail under pressure.

Ceramic pcbs have low moisture absorption rates, close to 0%.

They maintain stability and performance even when exposed to extreme temperatures.

Alumina-based ceramic pcbs offer thermal conductivity of about 20-30 W/m·K, while aluminum nitride can reach up to 170 W/m·K.

Ceramic substrate pcbs can handle temperatures up to 850–1000°C, far beyond the limits of FR4 pcbs, which start degrading above 130–150°C.

You can rely on ceramic substrate pcbs for automotive electronics because they withstand high temperatures and pressures. Their high thermal conductivity and low coefficient of thermal expansion make them ideal for high power density circuits, which are common in modern vehicles.

Tip: When you design power systems or automotive electronics, choosing ceramic substrate pcbs can help you achieve better reliability and performance, even if the initial cost is higher.

Ceramic pcbs outperform traditional pcbs in versatility and reduced complexity, which is crucial for high-density circuit designs. Their ability to dissipate heat efficiently and remain stable under thermal stress ensures that your electronics will last longer and perform better in critical applications.

Ceramic Substrate PCBs in RF and High-Frequency Devices

Ceramic pcbs have become the top choice for high-frequency and high-speed electronics. You need these pcbs when you want to keep signal integrity and reduce signal loss in demanding environments. Ceramic pcbs offer excellent electrical insulation, with dielectric strengths from 10 kV/mm to over 20 kV/mm. Their low dielectric constants and low dielectric loss help you minimize signal distortion, which is critical for high-frequency performance.

Telecommunications Systems

You will find ceramic pcbs in high-frequency RF circuits, antennas, and microwave devices. These pcbs help you maintain stable signal transmission, even at frequencies above 10 GHz. The table below shows why ceramic pcbs are ideal for telecommunications:

Feature | Description |

|---|---|

Low Dielectric Loss | Maintains signal integrity in high-frequency applications. |

Excellent Thermal Conductivity | Dissipates heat efficiently, supporting high-frequency systems. |

High Electrical Insulation | Reduces interference and keeps circuits stable. |

To get the best performance, you should:

Keep signal paths short and direct to reduce signal loss.

Maintain consistent impedance to prevent signal bounce-backs.

Radar and Microwave Circuits

Radar and microwave circuits demand pcbs that can process signals in the gigahertz range. Ceramic pcbs give you stable signal transmission, which is essential for accurate detection and measurement. These pcbs keep temperature rise under control, often within 12℃, while traditional solutions can exceed 30℃. You can rely on ceramic pcbs for precise detection, even in snowy or harsh conditions, thanks to their ±0.05 dielectric constant stability.

Note: Ceramic pcbs deliver improved high-frequency performance and help you achieve reliable results in advanced radar and microwave systems.

Ceramic PCBs in Medical Devices

Medical Imaging Equipment

You see ceramic pcbs used in medical imaging equipment because they deliver high performance and reliability. These pcbs handle high voltages and rapid temperature changes during imaging scans. Ceramic pcbs offer excellent thermal management, which keeps sensitive components cool and stable. You can trust these pcbs to maintain signal clarity in devices like CT scanners and X-ray machines. Their electrical insulation prevents interference, so you get accurate images every time. When you need top-notch reliability and durability, ceramic pcbs stand out in the medical field.

Implantable and Diagnostic Devices

Ceramic pcbs play a key role in implantable and diagnostic devices. You need pcbs that can survive inside the human body and work without failure. Ceramic pcbs resist chemicals and radiation, so they stay strong after sterilization. They also last longer than organic pcbs, which can break down over time. You get stable performance even when temperatures change or moisture is present. The table below shows why ceramic pcbs are the best choice for these critical applications:

Advantage | Description |

|---|---|

Chemical and Radiation Resistance | Ceramic substrates can endure sterilization processes without degrading, making them suitable for harsh chemical environments. |

Longevity and Reliability | They have a long operational lifetime and low failure rates, unlike organic materials that degrade over time. |

Thermal, Chemical, and Dimensional Stability | They maintain stability across a wide temperature range and resist moisture absorption, ideal for implantable devices. |

You can rely on ceramic pcbs for medical devices because they combine thermal stability, high reliability, and consistent performance. These pcbs help you create safer, longer-lasting medical solutions.

Ceramic Substrate PCB Use in Harsh Environments

Industrial Sensors and Controls

You often face harsh conditions when designing industrial sensors and controls. Ceramic pcbs help you solve problems that standard pcb materials cannot handle. These pcbs work in extreme heat, high humidity, and strong vibrations. For example, oil rig sensors use ceramic pcbs to operate at 175°C and 95% humidity. These sensors last over five years, while standard pcbs fail in less than a year. In aerospace avionics, ceramic pcbs survive temperatures from -55°C to 125°C and high radiation. You can see how different applications benefit from ceramic pcbs in the table below:

Application | Conditions | Solution | Result |

|---|---|---|---|

Oil Rig Sensors | 175°C, 95% humidity, 50G shocks | PTFE substrate with 2oz rolled copper, ENIG finish, parylene coating | Operated reliably for 5+ years, vs. 6–12 months for standard FR4 boards. |

Aerospace Avionics | -55°C to 125°C, 10k rads radiation, 30G shocks | Ceramic-filled laminate, redundant traces, hard gold plating, coating | Zero failures in 10+ years of orbit, meeting NASA’s reliability standards. |

Industrial Furnace Controllers | 500°C furnace, ambient 150°C | Aluminum core pcb, high-Tg FR4, thick copper, thermal vias | Lifespan extended from 2 to 7 years, reducing maintenance costs by 60%. |

You can also use high temperature co-fired ceramics in spacecraft and satellites. These ceramic pcbs withstand rapid thermal cycling and keep your sensors working even in gas turbines at 1250°C. This level of reliability and performance is unmatched by traditional pcb materials.

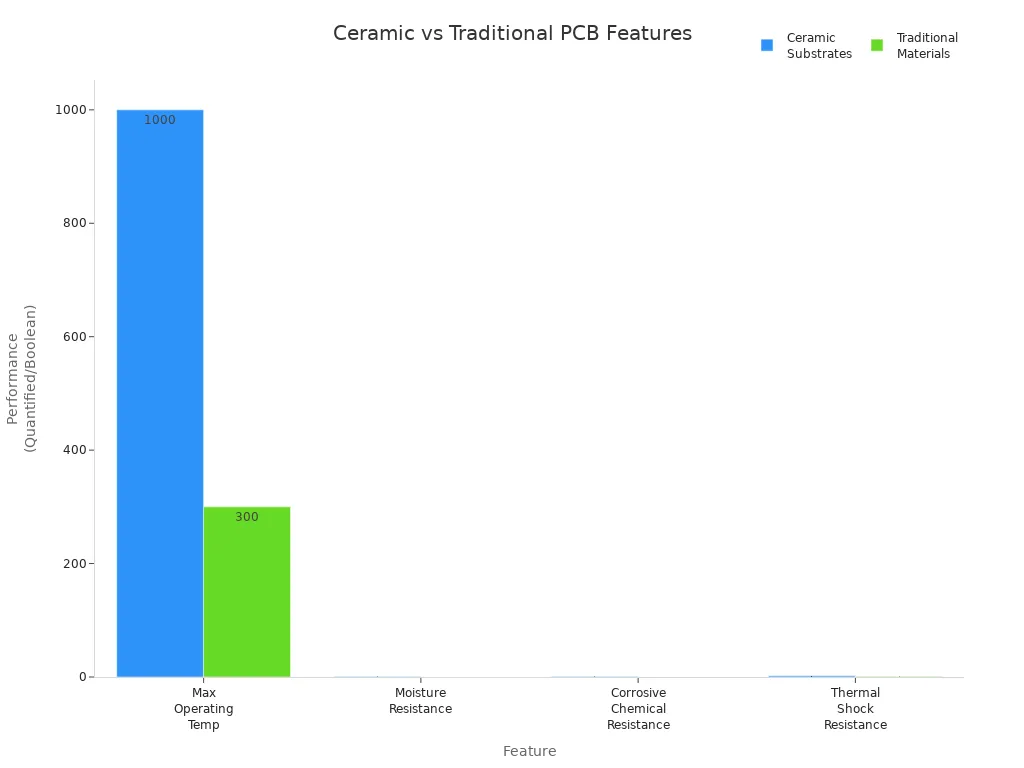

Aerospace and Defense

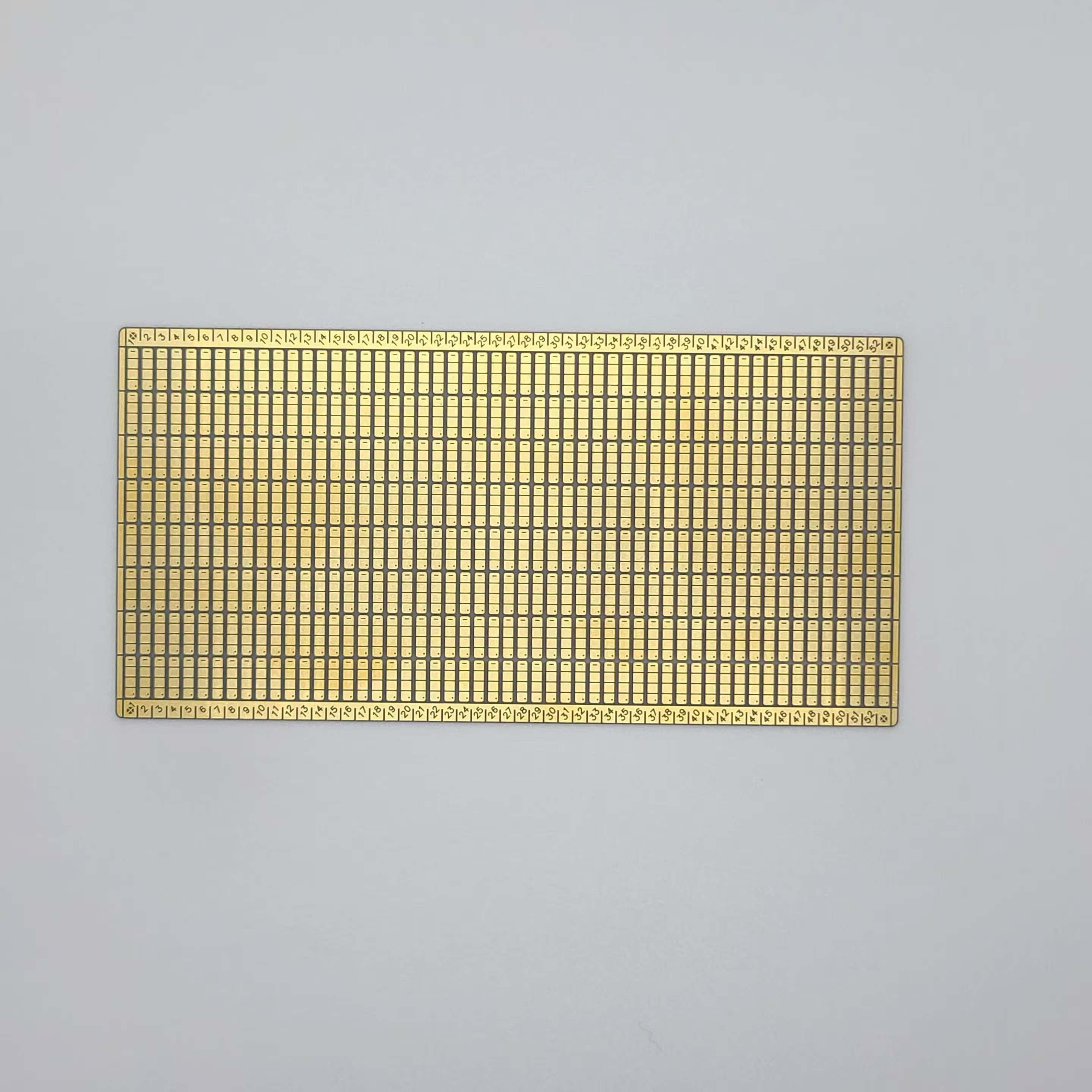

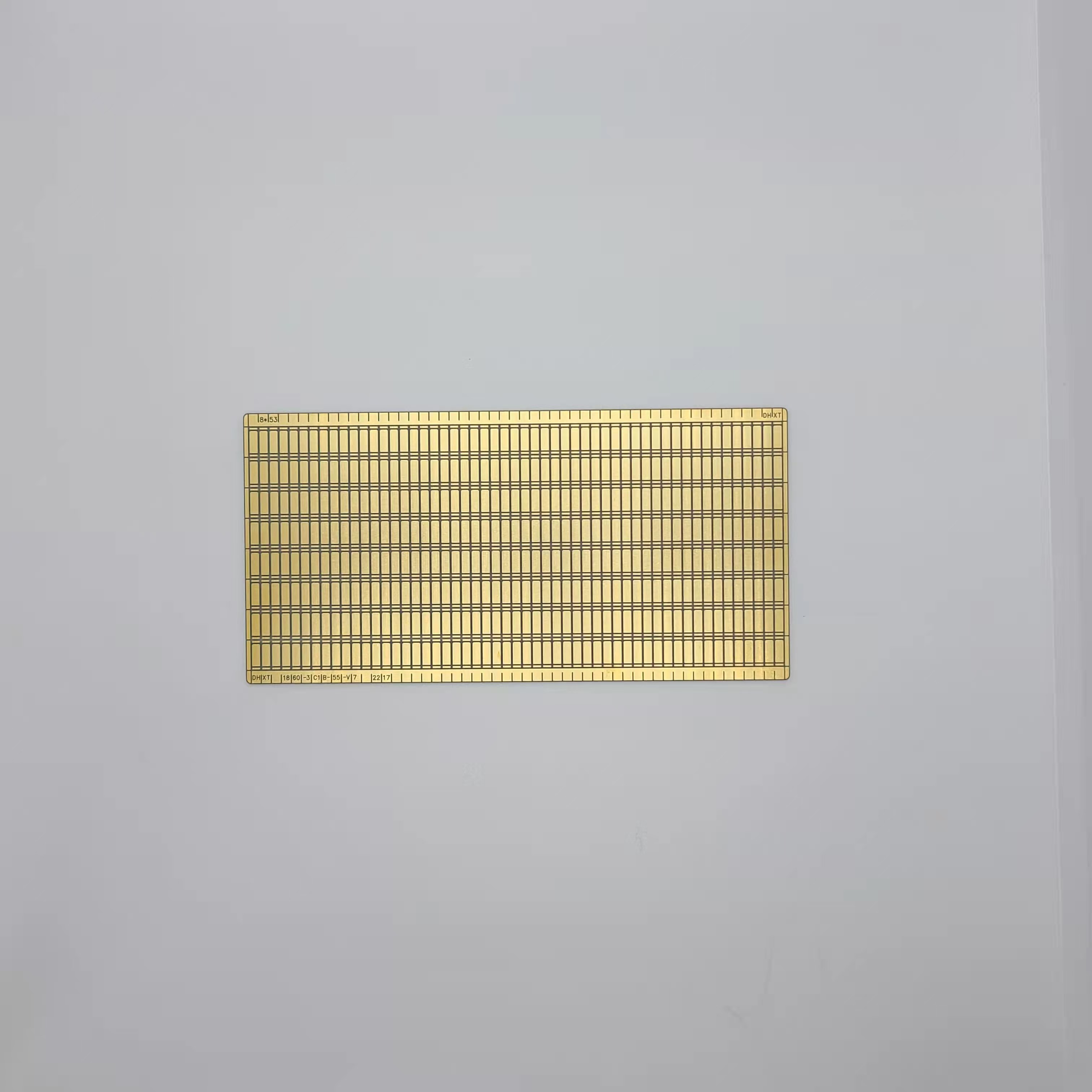

You need ceramic pcbs in aerospace and defence because they deliver exceptional reliability and performance under extreme conditions. These pcbs resist moisture, corrosive chemicals, and thermal shock. You can compare ceramic substrates to traditional materials in the chart below:

Ceramic pcbs operate at temperatures above 1000°C, while standard pcbs fail below 300°C. You get high mechanical strength, which supports flight-critical electronics. Missile guidance and avionics systems rely on ceramic pcbs for shock and vibration resistance. In military aircraft, you find these pcbs in engine controls and navigation systems.

Ceramic-reinforced laminates give you high thermal conductivity, so your electronics dissipate heat quickly. This is crucial for aerospace and defence, where rapid temperature changes and mechanical stress are common.

You can trust ceramic pcbs for mission-critical reliability. For example, Lockheed Martin’s radar systems in the F-35 jet use silicon carbide ceramic pcbs and achieve 99.9% operational reliability. These pcbs last over 500,000 hours, far longer than FR-4 boards. When you need the highest level of performance and reliability, ceramic pcbs are your best choice.

Trends in Ceramic Substrate PCB Technology

Miniaturization and Advanced Packaging

You see a strong push for miniaturization in ceramic pcbs as electronics become smaller and more powerful. This trend shapes the way you design and manufacture pcb solutions. Ceramic pcbs now support fine line widths and multi-layered structures, which allow you to fit more components into less space. You can use advanced packaging methods like chip-on-board and multi-chip modules with ceramic pcbs to boost integration and efficiency. These improvements help you create compact devices with high reliability.

The demand for miniaturization in ceramic pcbs grows as you work on smartphones, wearables, and IoT devices.

You benefit from high-density interconnects and advanced packaging, which drive the market to $3.5 billion in 2024.

You choose materials like aluminum oxide and aluminum nitride for their high thermal conductivity and electrical insulation in compact designs.

New standing-CCB technology lets you achieve high-resolution and high aspect-ratio designs, supporting high-density integration.

Electric Vehicles and 5G Adoption

You notice that electric vehicles and 5G networks increase the need for ceramic pcbs. These fields require high-frequency, high-performance components, and ceramic pcbs deliver the electrical conductivity and minimal signal loss you need. As you design for 5G, you rely on ceramic pcbs for their ability to handle complex circuit patterns and advanced metallization. The market for ceramic pcbs in automotive and telecom sectors is set to reach up to $4 billion by 2033.

Year | Key Sectors | |

|---|---|---|

2024 | 1.5 - 2 | Automotive, Telecom |

2033 | 3 - 4 | Automotive, Telecom |

You face challenges like thermal stress and cost, but you can overcome them with better manufacturing and industry standards. As you adopt ceramic pcbs, you help shape the future of electronics with reliable, high-performance technology.

You see ceramic pcbs shaping the future of electronics. The table below highlights key application areas and trends:

Application Area | Significance |

|---|---|

Aerospace, Military | Extreme temperature and radiation resistance |

LEDs, Automotive | Enhanced heat dissipation and reliability |

Telecommunications | Superior electrical properties |

Power Modules, Medical | Efficient thermal management and stability |

Ceramic pcbs deliver unmatched thermal conductivity and electrical insulation.

You benefit from miniaturization, green development, and intelligent manufacturing.

Choose ceramic pcbs for your next pcb project to ensure reliability and performance.

The momentum in advanced pcb technology makes ceramic pcbs essential for modern pcbs.

You find ceramic pcbs in high-frequency, high-power, and high-temperature pcb environments.

Ceramic pcbs support efficient heat dissipation in critical pcb applications.

You rely on ceramic pcbs for medical, automotive, and aerospace pcb solutions.

The demand for ceramic pcbs grows as electronics advance and pcb requirements increase.

Ceramic pcbs outperform traditional pcb materials in stability and durability.

You secure long-term success in electronics by adopting ceramic pcbs for your pcb designs.

FAQ

What makes ceramic pcbs better than traditional pcb materials?

You get higher thermal conductivity and better electrical insulation with ceramic pcbs. These pcbs handle heat and stress better than standard pcb materials, making your pcb designs more reliable.

Can you use ceramic pcbs in high-frequency pcb applications?

You can use ceramic pcbs for high-frequency pcb circuits. These pcbs reduce signal loss and maintain signal integrity. Your pcb projects benefit from stable performance in demanding environments.

Are ceramic pcbs suitable for harsh environments and automotive pcb systems?

You can trust ceramic pcbs in harsh environments. These pcbs resist moisture, chemicals, and extreme temperatures. Your automotive pcb systems last longer and perform better with ceramic pcbs.

See Also

Investigating How Ceramic PCBs Are Used in Today's Industries

Understanding the Role of Al₂O₃ Ceramic PCBs in Industries

The Superior Heat Dissipation Properties of Ceramic PCBs

Diverse Uses of Multilayer PCBs in Various Industries

A Comprehensive Overview of Multilayer Ceramic PCB Production