How to Choose a Reliable 3 Step HDI PCB Manufacturer for Your Needs

When selecting a 3 step hdi pcb manufacturer, reliability should be your top priority. A 3 step hdi pcb manufacturer with proven experience and technical expertise ensures higher reliability in every project. Certifications from a 3 step hdi pcb manufacturer demonstrate adherence to strict quality standards, further reinforcing reliability. Utilizing advanced technology, a 3 step hdi pcb manufacturer can support reliability even in the most complex designs. Additionally, strong customer support from your 3 step hdi pcb manufacturer enhances reliability throughout the entire production process.

Skilled teams at a 3 step hdi pcb manufacturer increase reliability by identifying potential issues early.

Reliability is further strengthened when the 3 step hdi pcb manufacturer’s capabilities align with your project requirements.

Clear communication and ongoing monitoring from your 3 step hdi pcb manufacturer boost reliability and help ensure on-time delivery.

Key Takeaways

Prioritize reliability by checking a manufacturer's certifications and quality standards. Look for ISO, IPC, and UL certifications to ensure adherence to strict quality rules.

Evaluate technical expertise in microvia and fine trace production. This expertise is crucial for high-density interconnect designs and ensures high performance.

Review customer feedback and industry reputation. Positive testimonials and case studies can guide you to manufacturers who deliver quality and reliability.

Key Qualities of a Reliable 3 Step HDI PCB Manufacturer

Certifications and Quality Standards

When you choose a 3 step hdi pcb manufacturer, you should check their certifications and quality standards first. These certifications show that the manufacturer follows strict rules for quality and safety. You can use the table below to see the most common certifications held by reliable pcb manufacturers:

Certification Type | Description |

|---|---|

ISO Certifications | Ensures adherence to quality management systems and environmentally sustainable practices. |

Guarantees compliance with strict guidelines for high-quality printed circuit boards. | |

UL Certification | Ensures adherence to electrical safety and fire hazard standards, crucial for various applications. |

Manufacturers that follow IPC standards produce high-quality pcbs with consistent results. You get high-reliability pcb products because these standards reduce errors and lower failure rates. When a manufacturer uses ISO 9001 and IPC standards, you can expect high-quality output and superior product quality. These certifications also show a commitment to quality assurance and environmentally friendly practices.

Tip: Always ask your 3 step hdi pcb manufacturer for proof of their certifications. This step helps you confirm their dedication to quality and certifications.

Technical Expertise in Microvia and Fine Trace

You need a reliable pcb manufacturer with strong technical skills in microvia and fine trace production. These skills are important for making high-density interconnect board designs. The process for microvia drilling and fine trace production is complex. Manufacturers must use advanced techniques to create traces as narrow as 2 to 5 mils.

Microvia and fine trace production require precise control and careful planning.

Signal integrity issues can happen because of the close spacing of traces and high layer counts.

High-frequency signals increase the risk of crosstalk and impedance mismatches.

A 3 step hdi pcb manufacturer with expertise in high-density interconnects can solve these challenges. You get high quality circuit boards that perform well in demanding applications. Technical expertise also means the manufacturer can handle circuit board manufacturing for modern devices with multiple layers and fine features.

Experience and Reputation

Experience and industry reputation matter when you select a reliable pcb manufacturer. You should look for companies with a long history of producing high-quality output and high-reliability pcb products. The table below shows common indicators of a strong reputation among 3 step hdi pcb manufacturers:

Indicator | Description |

|---|---|

Quality Control (QC) | Strict QC guidelines to detect defects early in the production process. |

Customer Feedback | Reviews and testimonials from previous clients, especially from established companies. |

Manufacturing Processes | Consistent and accurate processes that influence the final quality of the product. |

You can read customer feedback and reviews to learn about the manufacturer’s reliability. Positive reviews from clients in similar industries show that the manufacturer delivers superior product quality. Transparency about past work and willingness to share testimonials are signs of a reliable pcb manufacturer.

Note: You should ask about the types of tests performed, such as flying probe tests. These tests check electrical continuity and verify the integrity of pcb traces.

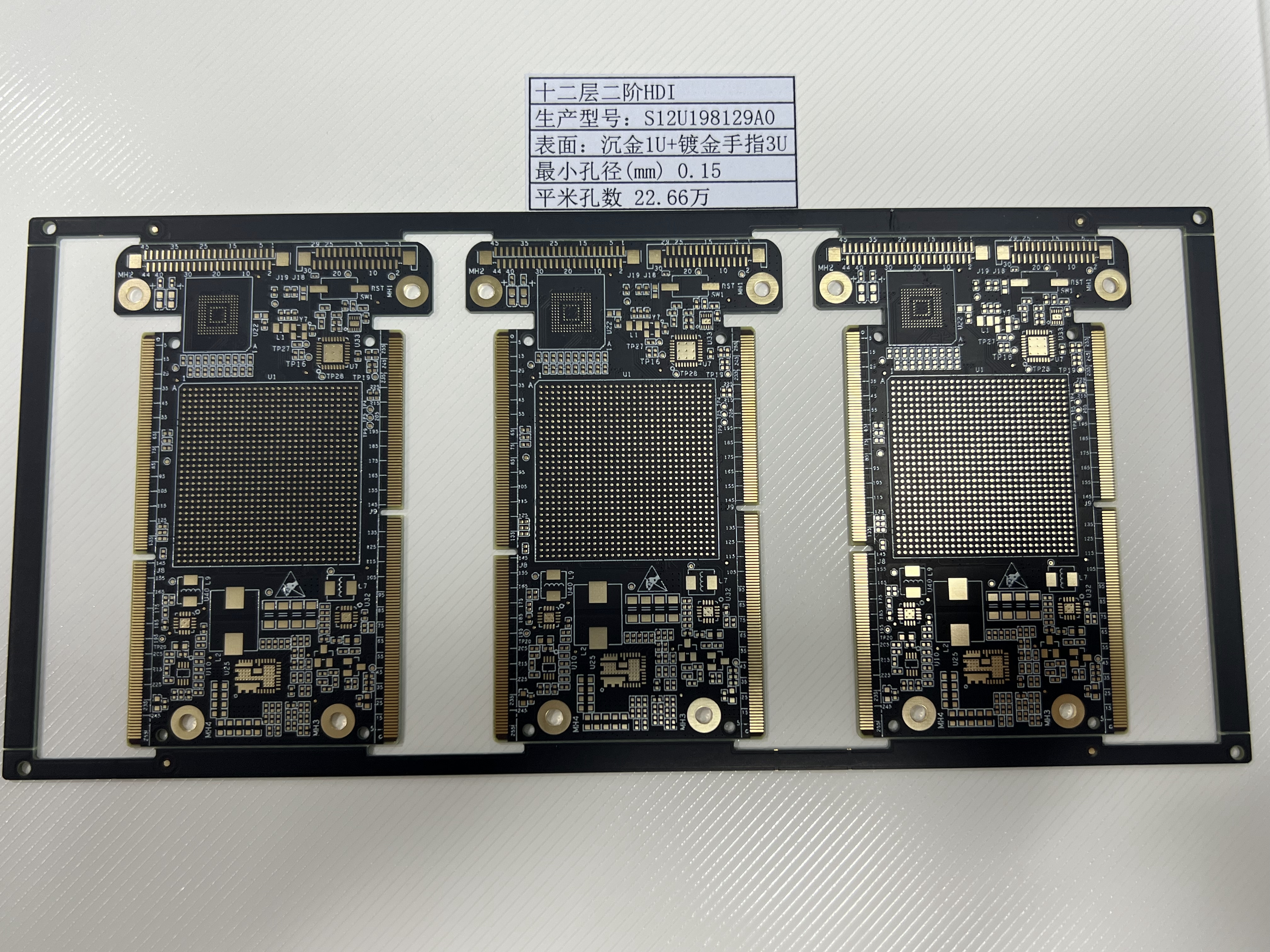

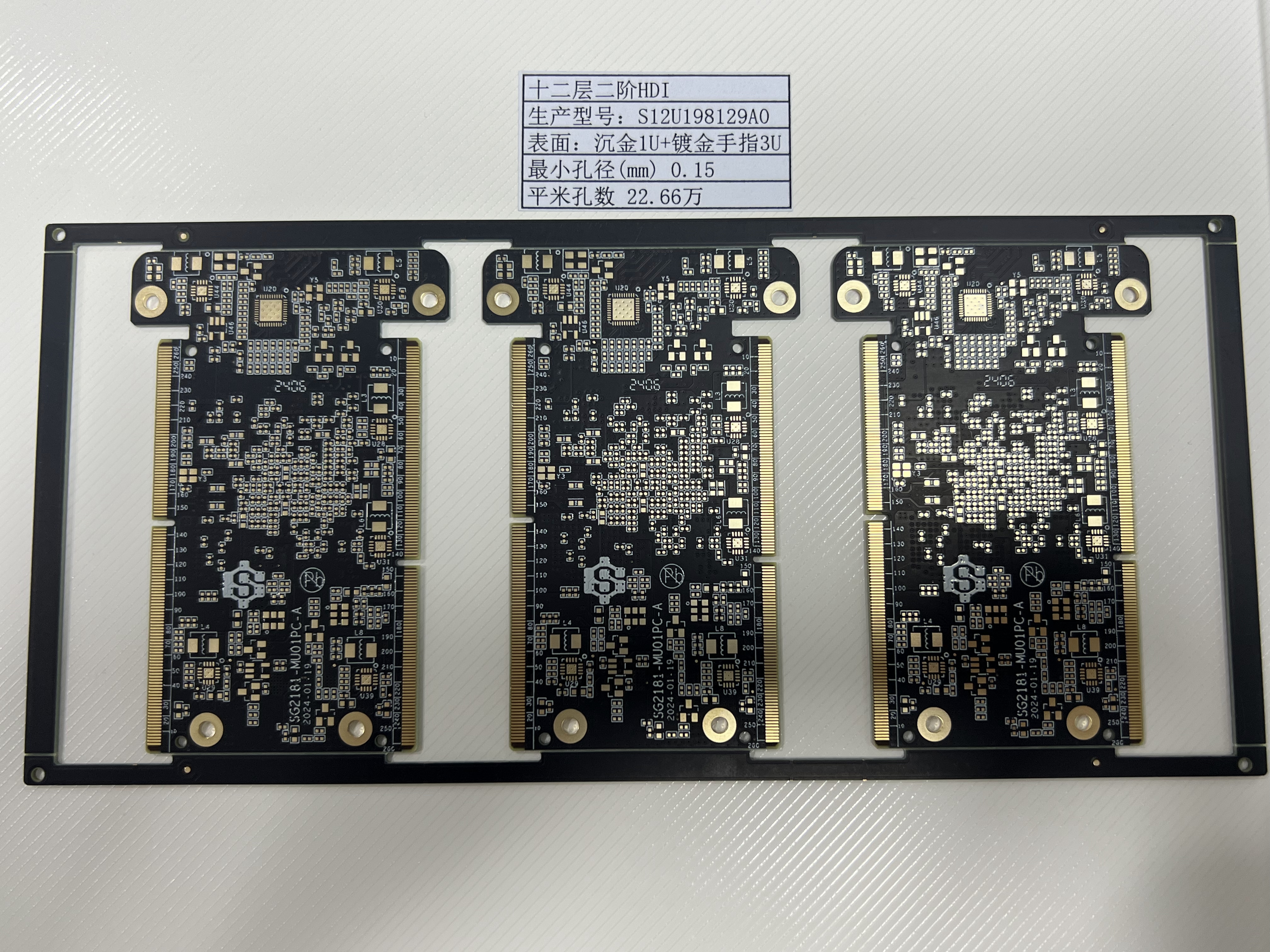

LT CIRCUIT’s Advanced Capabilities

LT CIRCUIT stands out as one of the best pcb manufacturers in the industry. You benefit from their advanced capabilities in 3 step hdi pcb manufacturing. LT CIRCUIT uses cutting-edge materials and technologies to produce high-quality pcbs for many applications. Their expertise covers high-density interconnects, multilayer boards, and custom finishes.

Customers praise LT CIRCUIT for its high quality and customer satisfaction. Engineers and buyers report reliable service and strong HDI skills. LT CIRCUIT’s commitment to quality assurance and superior product quality makes it a trusted choice for circuit board manufacturing. You can rely on LT CIRCUIT for high-quality output and high-reliability pcb solutions.

“To ensure high-quality production, attention must be paid to process capabilities and quality control plans of the PCB factory.”

When you choose LT CIRCUIT, you get a reliable pcb manufacturer with proven experience and industry reputation. Their advanced capabilities help you achieve the best results for your high-density interconnect board projects.

How to Choose a PCB Manufacturer Step by Step

Assessing Quality Control and Testing

You need to focus on quality control and testing when you choose a pcb manufacturer. These steps help you avoid costly mistakes and ensure your printed circuit boards meet your requirements. The best pcb manufacturer uses advanced inspection and testing methods to guarantee reliability.

Automated Optical Inspection (AOI) detects defects like misalignment and open circuits.

X-ray inspection checks buried vias and internal connections.

Electrical testing, including flying probe and bed-of-nails, confirms all connections work as intended.

In-circuit testing (ICT) finds open circuits or wrong components in high-volume runs.

Burn-in testing stresses the board to ensure long-term reliability.

Functional testing verifies the prototype circuit board works in real-world conditions.

You should ask for documentation of these tests. The best pcb manufacturer will share reports and communicate any defects found during production. This feedback helps you correct design issues and improve future quickturn projects.

Tip: Always review the manufacturer’s certifications, such as ISO 9001 and IPC standards. These show a commitment to quality and process control.

Reviewing Customer Feedback and Case Studies

Reputation and client feedback play a big role when you choose a pcb manufacturer. You can learn a lot from customer reviews and case studies. The best pcb manufacturer will have positive feedback from clients in your industry. Look for details about turnaround, quickturn services, and production and lead times.

Read testimonials that mention quickturn process and support.

Check for case studies that show how the manufacturer solved complex design challenges.

Ask for references from customers who ordered prototype circuit board runs.

You should look for manufacturers who document their quality control and testing procedures. This transparency builds trust and helps you avoid surprises during the quickturn process.

Comparing Customization and Support

Customization and support are key factors to consider when you evaluate manufacturing capabilities. The best pcb manufacturer offers flexible options for printed circuit boards, including different sizes, thicknesses, and layer counts. You can request special features like blind and buried vias or heavy copper for your prototype circuit board.

Choose a manufacturer who tailors solutions for both prototypes and mass production.

Ask about turnaround for custom orders and quickturn projects.

Make sure the support team can answer technical questions and guide you through the quickturn process.

A reliable pcb prototype manufacturer provides unmatched expertise and a customer-centric approach. You get help from engineers who understand HDI PCB design and manufacturing capabilities. This support improves your experience and ensures your quickturn project meets your needs.

LT CIRCUIT as a Reliable PCB Prototype Manufacturer

LT CIRCUIT stands out as a reliable pcb prototype manufacturer. You benefit from their advanced manufacturing capabilities and quickturn services. LT CIRCUIT offers a wide range of customization options for printed circuit boards, including various sizes, thicknesses, and layer configurations. You can order prototype circuit board runs with features like blind and buried vias, heavy copper, and special finishes.

LT CIRCUIT’s support team guides you through every step of the quickturn process. You get fast turnaround and clear communication about production and lead times. Their engineers help you optimize your design for manufacturability and reliability. LT CIRCUIT documents all quality control and testing procedures, giving you confidence in your quickturn project.

Note: LT CIRCUIT’s reputation for quickturn and customer satisfaction makes them the best pcb manufacturer for prototype circuit board and HDI projects.

Avoiding Common Pitfalls

You can avoid common pitfalls by following a checklist when you choose a pcb manufacturer. The best pcb manufacturer will help you address these issues early in the quickturn process.

Pitfall | Explanation |

|---|---|

Small Vias | HDI boards use microvias, blind vias, and buried vias. Misalignment can cause circuit failure. |

Difficult Inspection | HDI PCBs need high-resolution inspections to catch defects. |

Improper Material Selection | Not all materials suit HDI designs. Wrong choices affect performance and reliability. |

Improper Vias Design | Vias must follow specific diameter-to-depth ratios. Mistakes can lead to cracks and faults. |

Improper Thermal Management | Dense designs need careful thermal management. Thin traces can cause overheating. |

You should conduct Design for Manufacturability (DFM) checks early. Define the board’s layer stack-up and via types. Use simulation tools to spot design challenges. Select materials that meet your performance needs. Engage with the manufacturer to understand their manufacturing capabilities and avoid issues with turnaround and quickturn projects.

Tip: Clear communication and early DFM checks help you avoid delays and ensure your quickturn project succeeds.

You can select the right 3 step HDI PCB manufacturer by following these steps:

Review technical expertise.

Confirm material quality.

Evaluate customer service and communication.

Research industry reputation and references.

Consider environmental responsibility.

Compare cost-effectiveness.

A thorough evaluation helps you avoid project failure. You should look for durability testing, electrical validation, and environmental testing. You need a partner who meets these standards. Your partner must show strong technical skills and use high-quality materials. You want a partner with a good reputation and clear communication. Your partner should offer responsive support and sustainable practices. You need a partner who can handle both small and large orders. Your partner must provide cost-effective solutions without lowering quality. You should choose LT CIRCUIT as your partner for reliable results. LT CIRCUIT is the partner that matches your needs and helps you succeed. You can trust LT CIRCUIT as your partner for every HDI PCB project. Your partner should always focus on your goals and deliver the best outcomes.

FAQ

What certifications should you check when choosing a 3 step HDI PCB manufacturer?

You should look for ISO 9001, IPC standards, and UL certification. These show the manufacturer meets strict quality and safety rules.

How does LT CIRCUIT support your custom HDI PCB projects?

LT CIRCUIT offers flexible customization, fast turnaround, and expert guidance. You get help with design, material selection, and testing for reliable results.

Why is technical expertise important for HDI PCB manufacturing?

Technical expertise helps you avoid design errors and ensures high performance. Skilled engineers solve challenges with microvias, fine traces, and multilayer boards.

See Also

Selecting A Reliable PCB Manufacturer For Your Company Needs

Essential Design Factors For Dependable HDI PCB Production

Explore Innovative Techniques For HDI PCB Prototyping Now

The Design And Production Process Of HDI Any Layer PCBs

Advantages Of LDI Exposure Machines In HDI PCB Circuit Production