How to Choose the Right LED PCB Aluminum Lamp Plate for Your Lighting Project

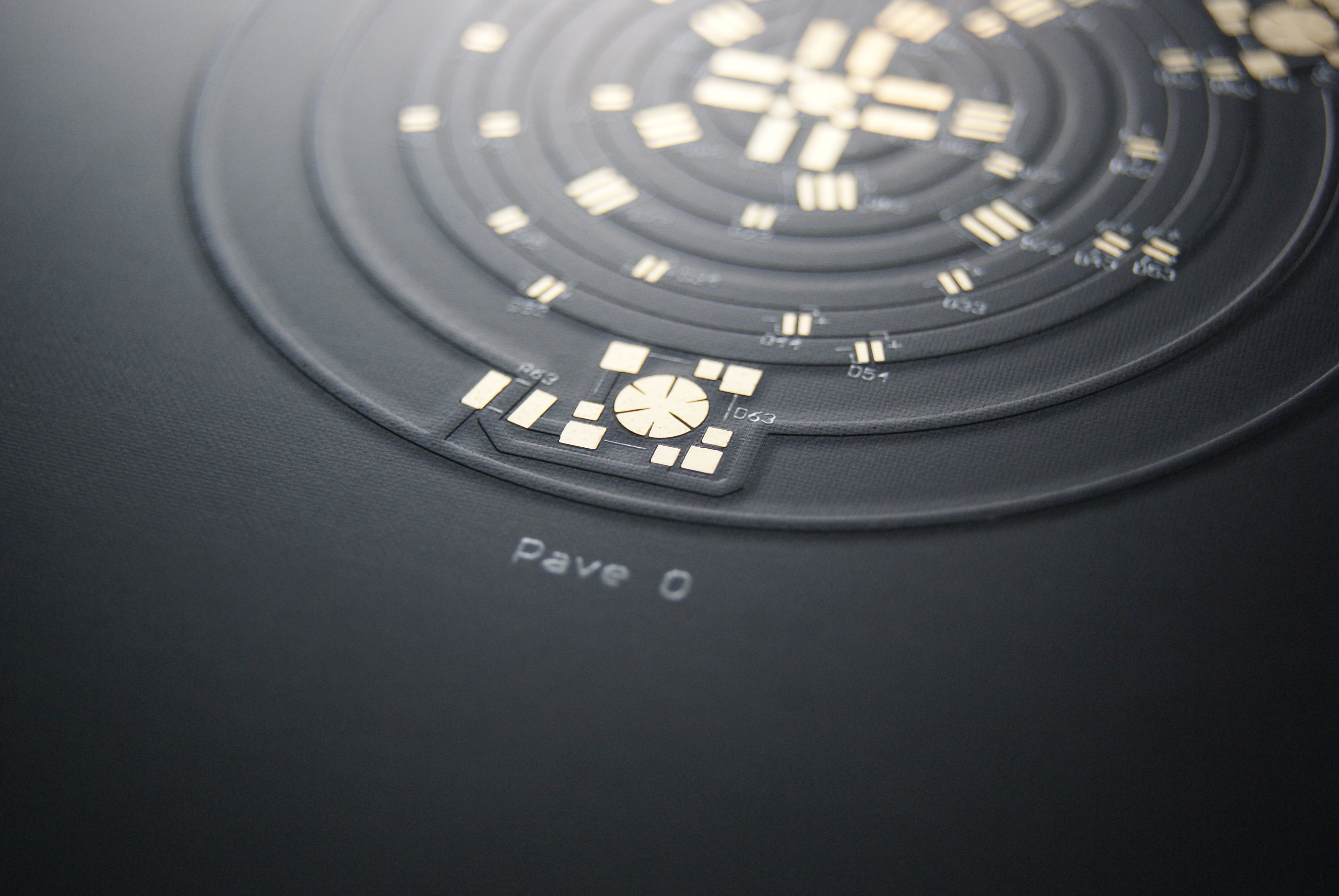

You want your lighting project to shine, right? Choosing the right led pcb aluminum lamp plate ensures you achieve top LED performance, enhanced safety, and excellent value for your investment. When selecting a led pcb aluminum lamp plate, prioritize features such as superior thermal management, robust durability, reliable mechanical support, and seamless integration with control systems. Your LED setup deserves the dependable performance that a quality led pcb aluminum lamp plate can deliver.

Key Takeaways

Choose a lamp plate with excellent thermal management to extend LED life and improve performance.

Select the right size and assembly method for your lamp plate to ensure optimal brightness and energy efficiency.

Work with a trusted supplier like LT CIRCUIT for high-quality, customizable LED PCB solutions that meet your project needs.

Project Needs for LED Lighting

Application and Size

You want your lighting project to work perfectly, so start by thinking about where you will use your led setup. Are you planning to light up a cozy living room, a busy office, or maybe an outdoor garden? Each space has different led lighting needs. For example, homes and offices often use led bulbs, tube lights, or panel lights. Outdoor areas need led streetlights or floodlights that can handle weather changes.

Here’s a quick look at common applications for led PCB aluminum lamp plates:

Sector | Application Description |

|---|---|

Residential & Commercial | Used in energy-saving led bulbs, tube lights, and panel lights for homes, offices, and retail spaces. |

Outdoor Lighting | Employed in streetlights, floodlights, and landscape lighting due to high brightness and weather resistance. |

Specialty Lighting | Includes applications like plant growth lamps, aquarium lights, and medical examination lamps. |

Industrial | Powers indicator lights and displays in factory machinery and automation systems. |

Telecommunications | Utilized in base stations and network equipment for status signaling. |

Robotics | Supports collision-avoidance systems and sensor arrays in industrial robots. |

Pick the right size for your lamp plate. If you choose a plate that’s too small, you might not get enough brightness. If it’s too large, you could waste energy and money.

Power and Environment

Think about how much power your led system needs. High-power led projects need lamp plates that can handle more heat and deliver steady performance. If you install led lights in a hot or humid place, you need a lamp plate with good heat dissipation and moisture resistance. This helps your lights last longer and keeps their performance strong.

Don’t forget about diffusers. They spread the light evenly and reduce glare. You also need to consider how you’ll install your lamp plate. Some plates snap into fixtures, while others need screws or brackets. Choose a method that fits your space and makes maintenance easy.

By matching your lamp plate to your project’s size, power, and environment, you boost performance and support sustainability. You set yourself up for a lighting solution that works well and lasts.

Choosing the Right LED PCB Aluminum Lamp Plate

Heat Dissipation and Material

When you pick a led pcb aluminum lamp plate, you want your lights to stay bright and last a long time. Heat is the enemy of led performance. If your lamp plate cannot handle heat, your leds will fade or fail early. That is why you need to look at thermal conductivity. This tells you how well the plate moves heat away from the leds.

You will see different materials like aluminum, alumina, and aluminum nitride. Each one has its own level of thermal conductivity. Aluminum is common and works well for most projects. If you need even better heat control, you might choose alumina or aluminum nitride. These materials help with optimal thermal management, especially in high-power or high-temperature setups.

Here is something interesting. UFO LED Aluminum PCBs can keep over 90% of their brightness even after running for 50,000 hours at temperatures above 60°C. That means if you choose a lamp plate with strong thermal conductivity, you get a longer-lasting and more reliable lighting system.

You want your led pcb aluminum lamp plate to deliver top performance and efficiency. Good heat dissipation means your leds stay cool, shine brighter, and use less energy. Always check the material and thermal conductivity before you decide.

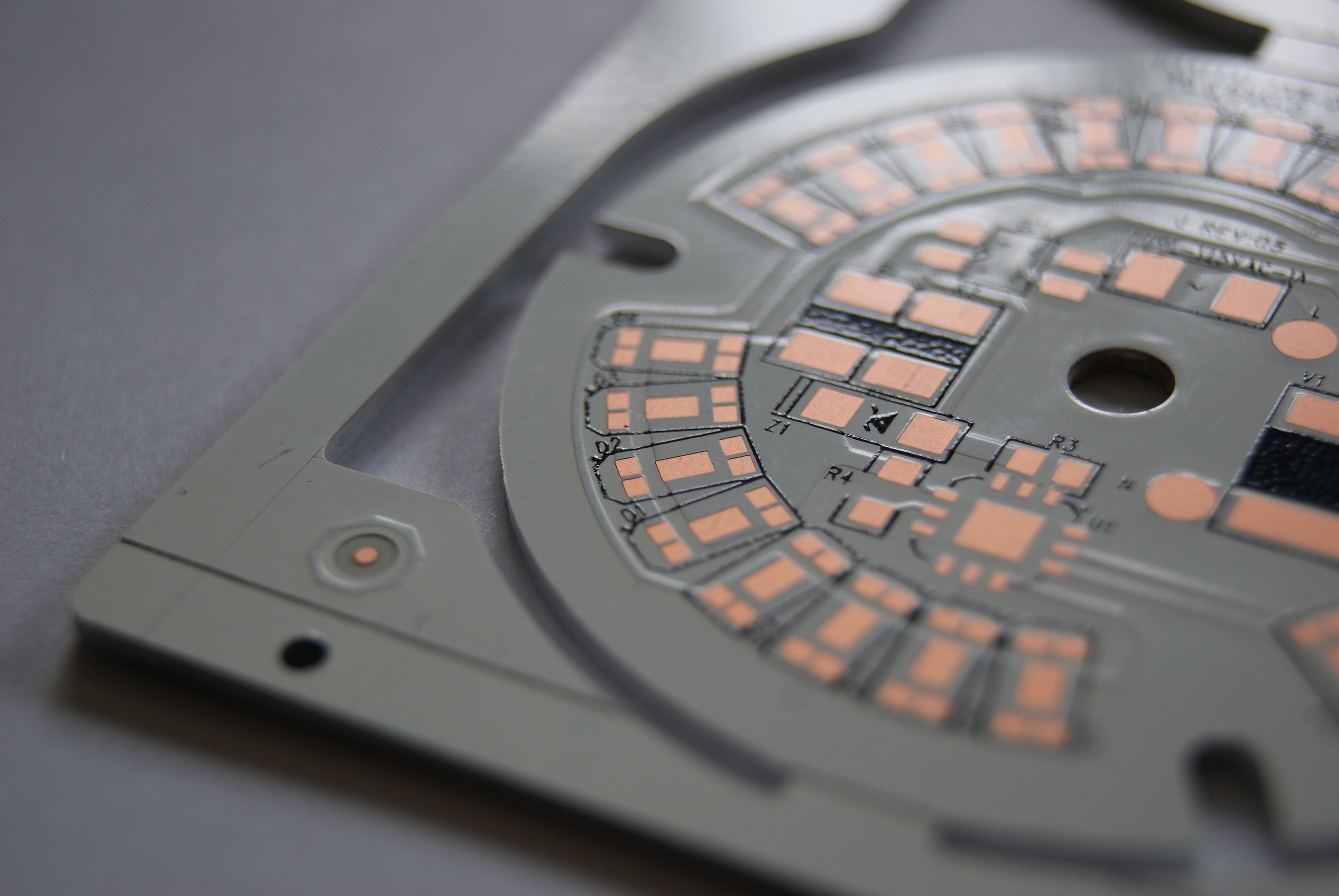

Electrical Specs and Layers

You also need to think about the electrical side of your led pcb aluminum lamp plate. The number of layers in the board can change how well your leds work. A single-layer board is simple and works for basic lights. If you want more features or higher power, you might need a multi-layer board. More layers can help with better current flow and stronger performance.

Look at the voltage and current ratings. Make sure your lamp plate matches your led power needs. If you use the wrong specs, your leds might flicker or burn out. You want steady, safe, and efficient lighting.

LT CIRCUIT gives you lots of options here. You can pick the number of layers, the thickness, and even the type of aluminum led printed circuit board you need. This way, you get a lamp plate that fits your project perfectly and boosts your lighting efficiency.

Safety and Certifications

Safety should always come first. When you choose a led pcb aluminum lamp plate, check for certifications like UL, CE, or RoHS. These show that the lamp plate meets strict safety and environmental rules. Certified plates protect you from electrical hazards and make sure your leds run safely.

You also want to know that your lamp plate can handle tough conditions. Look for features like moisture resistance and strong insulation. This keeps your leds safe in damp or dusty places.

LT CIRCUIT takes safety seriously. They test every lamp plate and follow global standards. You get peace of mind knowing your lighting project uses safe, high-quality parts.

Tip: Always ask your supplier for test reports or certificates. This helps you avoid problems and keeps your lighting project running smoothly.

Choosing the right led pcb aluminum lamp plate is not just about picking any board. You need to look at thermal conductivity, electrical specs, and safety. When you focus on these points, you get better performance, longer life, and a lighting system you can trust.

Comparing Suppliers Like LT CIRCUIT

Quality and Customization

When you look for a led pcb manufacturer, you want more than just a basic product. You want a partner who cares about quality and can customize solutions for your project. Not all suppliers offer the same level of care. Some focus on speed, but you need someone who pays attention to every detail in led pcb production.

A reliable led pcb manufacturer uses strict quality control at every step. Here’s a quick look at the most effective quality checks:

Quality Control Measure | Description |

|---|---|

AOI Testing | Automated Optical Inspection for each board, ensuring defects are caught early. |

First Article Inspection | Inspection of the first article before the SMD process to verify quality. |

IQC | Incoming Quality Control to assess materials before production. |

IPQC | In-Process Quality Control to monitor production quality. |

OQC | Outgoing Quality Control to ensure finished products meet standards. |

Spot Inspection | Random checks to ensure ongoing quality throughout production. |

LT CIRCUIT stands out as a led pcb manufacturer because they use high-quality pcb materials and advanced thermal management techniques. You get lamp plates that handle heat well and last longer. They also offer custom options, so your led pcb production matches your exact needs.

Support and References

You want a supplier who supports you from start to finish. Good after-sales service makes a big difference. LT CIRCUIT helps you with prototyping, answers your questions, and gives you advice on thermal design. Their team works with you to solve problems fast.

When you choose a led pcb manufacturer, check their track record. LT CIRCUIT shares real-world case studies and references, so you can see how their products perform. Here are some examples of what you might find:

Simulation-based FMEA methods to test reliability of led boards.

Numerical simulations combined with fatigue models to predict system failures.

Comprehensive reliability analysis that includes uncertainties in model parameters.

These references show that LT CIRCUIT takes led pcb production seriously. You get confidence knowing your project uses proven, reliable solutions.

Tip: Always ask for references or case studies before you decide on a supplier. This helps you see their real results and gives you peace of mind.

You want your lighting project to shine, so keep these steps in mind:

Pick a lamp plate with strong thermal management for longer LED life.

Match the assembly method to your needs.

Choose a trusted supplier like LT CIRCUIT for reliable performance.

Ready to light up your space? Follow these tips for success!

FAQ

What is the main benefit of using an LED PCB aluminum lamp plate?

You get better heat dissipation, which helps your LEDs last longer and shine brighter. Your lighting project stays safe and efficient.

How do I know which size lamp plate to pick?

Check your fixture’s dimensions and your LED layout. You want a plate that fits snugly and supports your desired brightness.

Can I customize my LED PCB aluminum lamp plate with LT CIRCUIT?

Absolutely! You can choose the size, thickness, and layer count. LT CIRCUIT helps you design a lamp plate that matches your project needs.

See Also

Choosing Between Aluminum, FR4, And Flexible LED PCBs

Creating Efficient PCBs Tailored For LED Use Cases

Understanding LED PCBs And Their Impact On Lighting Today

When To Opt For Aluminum Base PCBs Over FR4

Boosting LED And Power Electronics With Aluminum-Backed PCBs