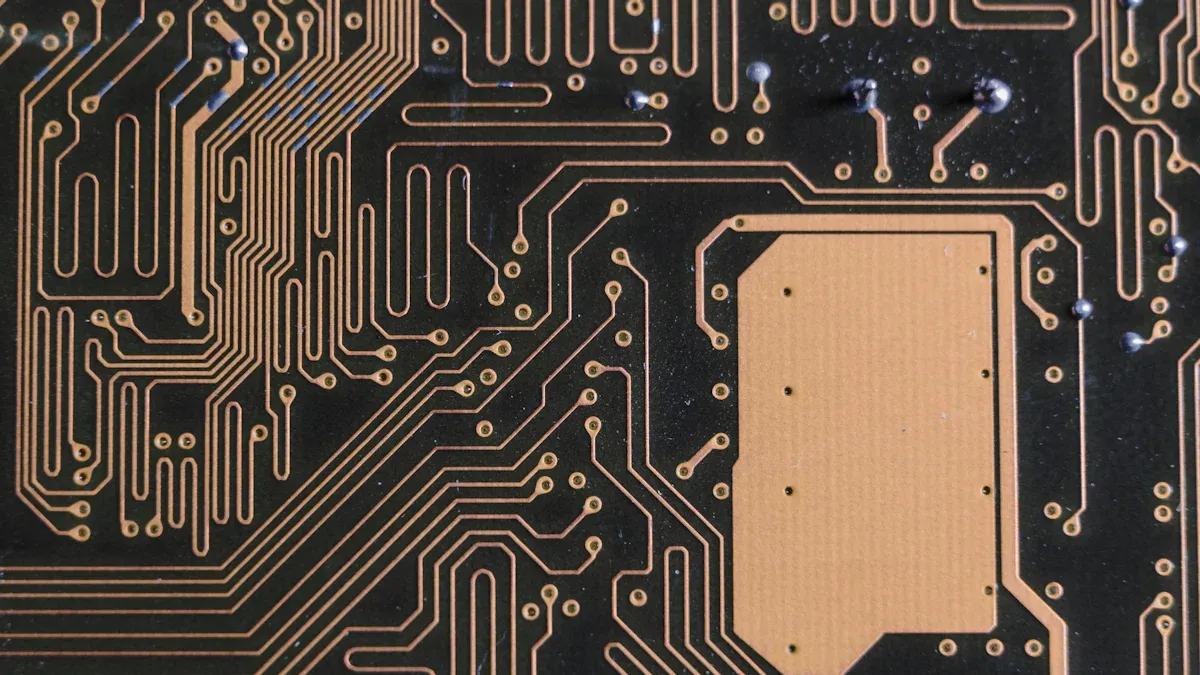

Choosing Between ENEPIG and ENIG for PCB Manufacturing

When making a PCB, the surface finish is very important. ENIG has a smooth gold-nickel layer. It is great for soldering and resists rust well. ENEPIG adds a palladium layer, which helps with wire bonding. It also lowers the chance of voids forming. Both finishes work well in different situations. ENEPIG is better for high-reliability uses, especially after many heat cycles. Research shows both ENEPIG and ENIG keep voids under 4%. This ensures good quality. Knowing these differences helps you choose cost and performance wisely.

Key Takeaways

ENEPIG is more reliable for advanced projects. Its palladium layer stops black pad problems and makes solder joints stronger.

ENIG costs less and works well for simple designs. It performs fine for basic electronics and is easier to make.

Think about your project's needs, like cost and performance, to pick the best surface finish for your PCB.

Understanding ENIG Surface Finish

What is ENIG?

ENIG stands for electroless nickel immersion gold. It is a common PCB surface finish. It uses two metal layers. Nickel is the bottom layer, and gold is on top. Nickel protects the copper underneath. Gold helps with soldering and stops rust. This finish creates a smooth, flat surface. It works well for PCBs with many small parts.

Advantages of ENIG

ENIG has many good features. It lasts a long time, even in storage. It handles high heat, so it works in tough conditions. ENIG also allows aluminum wire bonding. It makes strong solder joints. Below is a table showing its main benefits:

Properties | ENIG |

|---|---|

Yes | |

High Temperature Resistance | Yes |

Wire Bondable (When Aluminum Wire Is Used) | Yes |

Excellent for Assembly of Dense Topography PCBs | Yes |

Good Solder Joint Integrity | Yes |

These qualities make ENIG useful in electronics and telecom industries.

Limitations of ENIG

ENIG has some downsides too. One problem is the black pad issue. This happens when nickel rusts too much. It can make solder joints weak and breakable. This often happens if the nickel bath has too much phosphorus. Reheating the PCB many times can make it worse. Even though ENIG is strong, fixing these problems is important for reliable PCBs.

Exploring ENEPIG Surface Finish

What is ENEPIG?

ENEPIG stands for Electroless Nickel Electroless Palladium Immersion Gold. It is a special PCB surface finish. It improves on ENIG by adding a palladium layer. This layer sits between the nickel and gold. Palladium makes wire bonding easier and boosts reliability. ENEPIG is often called a better wirebonding version of ENIG. It costs less than full gold plating, making it popular for advanced PCBs. Here’s a quick look at its features:

Feature | Description |

|---|---|

Definition | ENEPIG is a wirebondable finish used in PCB manufacturing. |

Application | It provides a cheaper alternative to full gold plating for PCBs. |

Comparison | Like ENIG, but designed for better wire bonding. |

Advantages of ENEPIG

ENEPIG has many benefits that make it stand out. The palladium layer stops black pad defects, a problem with ENIG. It also improves soldering and wire bonding. Key advantages include:

ENEPIG works with aluminum wire bonding, unlike ENIG.

Palladium prevents black pad issues, making it more reliable.

It creates strong solder joints, even in tough conditions.

Palladium’s high melting point protects nickel during soldering.

Its hardness makes it durable and resistant to rust.

Using less gold lowers costs by up to 60% compared to ENIG.

These features make ENEPIG great for high-reliability uses, like in aerospace and telecom.

Limitations of ENEPIG

ENEPIG has some downsides too. Keeping the layers even can be tricky. This might affect soldering and wire bonding. The palladium layer needs careful application to work well. ENEPIG PCBs also need gentle handling to avoid damage. Other challenges include:

The multi-layer process is complex and may cause errors.

Starting costs are higher than simpler finishes like ENIG.

Chemicals used can harm the environment without proper care.

Fixing or changing ENEPIG PCBs is hard due to the layers.

Palladium can crack under stress because it is brittle.

Knowing these limits helps you decide if ENEPIG fits your needs.

ENEPIG vs. ENIG: A Simple Comparison

Material Composition and Structure

ENEPIG and ENIG are made differently, which affects how they work. ENIG has two layers: nickel and gold. Nickel protects copper and helps with soldering. Gold stops rust. ENEPIG adds a palladium layer between nickel and gold. This extra layer makes it stronger and avoids black pad problems.

Here’s a simple table showing their differences:

Feature | ENIG | ENEPIG |

|---|---|---|

Palladium Layer | None | Yes |

Rust Resistance | Okay | Better |

Solder Joint Strength | Weaker | Stronger |

Cost | Cheaper | More expensive |

Common Uses | Basic electronics | Advanced devices |

The palladium in ENEPIG also helps stop rust and makes solder joints stronger. ENEPIG is great for important projects needing strong materials.

Cost Factors

Cost is important when picking between ENIG and ENEPIG. ENIG costs less because it uses fewer materials and is simpler to make. ENEPIG costs more because of the palladium and extra steps in production.

Here are some cost facts:

ENEPIG avoids black pad issues, saving 8–12% on repairs.

Making ENEPIG needs 15–20% more money for equipment.

Even though ENEPIG costs more at first, it lasts longer and works better for advanced PCBs.

Soldering and Wire Bonding

Soldering and wire bonding work differently for ENIG and ENEPIG. ENIG can have weak solder joints because of issues between tin and gold. ENEPIG fixes this with its palladium layer.

Key points:

ENEPIG works with both aluminum and gold wires.

Palladium in ENEPIG stops nickel from rusting during soldering.

ENEPIG makes thinner layers, which helps soldering and avoids joint problems.

If your PCB needs strong soldering or many heat cycles, ENEPIG is better.

Strength and Rust Resistance

How long a PCB lasts depends on its strength and rust resistance. ENIG resists rust okay, but its nickel can rust in tough conditions. ENEPIG, with palladium, protects better against rust and wear.

Why ENEPIG is better:

It resists rust longer, making it more reliable.

Palladium shields nickel from damage.

It lasts longer, even in hard conditions.

For PCBs in rough environments, ENEPIG is a stronger choice than ENIG.

Uses in High-Tech PCBs

Choosing ENEPIG or ENIG is important for high-tech uses. ENIG can cause signal problems because of its nickel layer. ENEPIG avoids this with its palladium layer, giving better results.

Where ENEPIG works best:

High-frequency PCBs needing clear signals.

Aerospace and telecom, where reliability is key.

Medical devices needing steady performance.

For high-tech or reliable projects, ENEPIG is the smarter pick for better results.

Practical Tips for Picking the Best Surface Finish for Your PCB

Type of Use and Industry Needs

The right surface finish depends on how the PCB is used. For example, 5G PCBs need smooth surfaces to avoid signal problems. ENIG and ENEPIG are great for this because they are flat and strong. On the other hand, simpler electronics can use cheaper finishes like HASL.

Here are some tips to help you decide:

Follow the maker's rules for handling and using the PCB.

Test the finish to make sure it works well.

Keep tools clean and use protective covers to avoid dirt.

Make sure the finish meets rules like RoHS and IPC-610.

Matching the finish to your needs makes your PCB work better and last longer.

Budget and Cost Limits

Balancing cost and quality is key when picking a finish. ENIG costs less than ENEPIG, so it’s good for tight budgets. But ENEPIG saves money over time by lasting longer and avoiding problems. For instance, ENEPIG’s palladium layer stops black pad issues, cutting repair costs.

Think about these points:

Compare upfront costs with how long the PCB will last.

Complex finishes cost more to make.

Repairs from bad finishes can add to costs later.

Spending more on ENEPIG at first can save money for important projects.

Flatness and Smoothness

A smooth surface is very important for high-speed PCBs. It helps with soldering and keeps signals clear. ENIG and ENEPIG are known for being very flat, making them perfect for advanced uses.

Things to know:

ENIG has nickel and gold layers that make it smooth.

ENEPIG adds a palladium layer, making it even better for soldering.

Smooth finishes are a must for 5G and high-frequency PCBs.

Choosing a smooth finish ensures your PCB works well in tough jobs.

Wire Bonding and Touch Screens

If your PCB needs wire bonding or touch screens, ENEPIG is the best choice. Its palladium layer works with both aluminum and gold wires, unlike ENIG, which only works with aluminum. This makes ENEPIG more flexible for advanced uses.

For touch screens, ENEPIG’s smooth and strong surface works great. It resists wear and rust, so it’s good for devices used a lot.

When wire bonding or touch screens are needed, ENEPIG is the most reliable option.

Environmental Rules and Conditions

Rules like RoHS affect which surface finish you can use. Both ENIG and ENEPIG follow RoHS, so they are safe for many industries.

The environment also matters when choosing a finish:

ENEPIG handles humidity and harsh chemicals better, so it’s good for tough conditions.

ENIG works fine in normal conditions but might need extra protection in extreme places.

By thinking about the environment and rules, you can pick a finish that works well and follows the law.

Storage and Shelf Life

How long a PCB lasts depends on its finish and storage. ENIG and ENEPIG can last over a year if stored properly. Good handling and packaging keep them in good shape.

Surface Finish Type | Shelf Life Duration |

|---|---|

ENIG | 12+ months |

ENEPIG | 12+ months |

Tips to keep PCBs fresh:

Store them in cool, dry places to stop rust.

Use covers to keep them clean.

Handle them with clean tools to keep soldering easy.

Following these steps helps your PCBs stay ready for use and perform well during assembly.

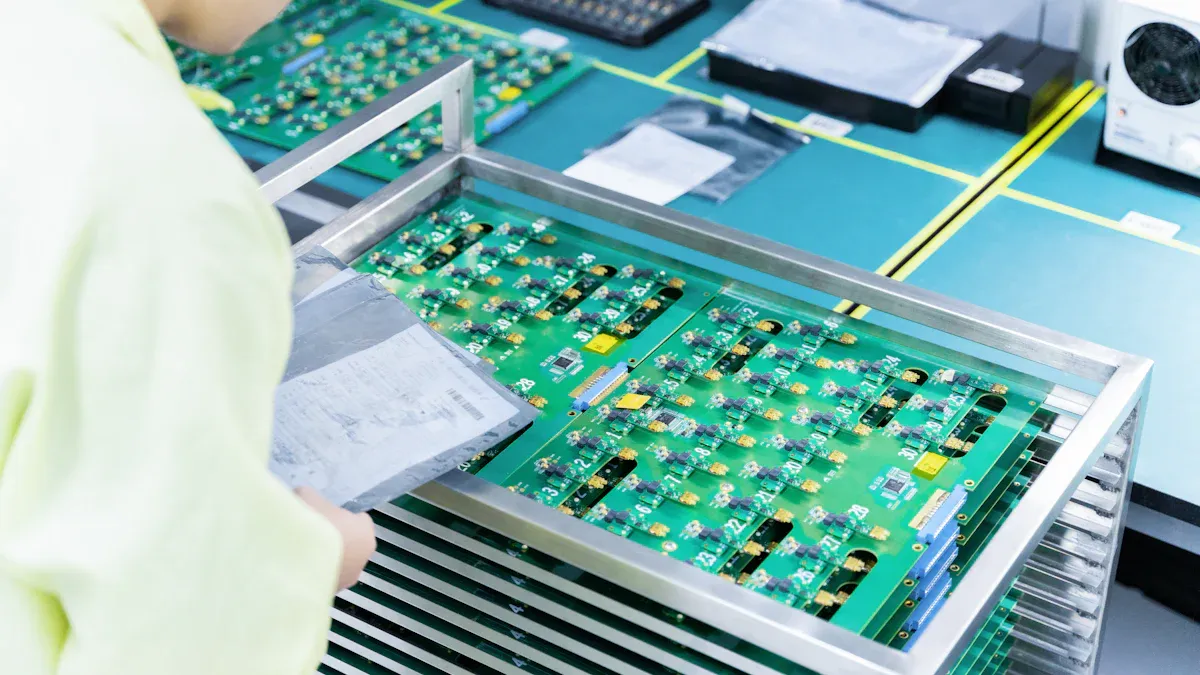

Why Pick LT CIRCUIT for Your PCB Surface Finish?

Skilled in ENEPIG and ENIG Finishes

LT CIRCUIT knows a lot about ENEPIG and ENIG finishes. These are used in fields like aerospace, medical, and telecom, where reliability matters. ENIG gives a smooth layer, great for lead-free soldering and small parts. ENEPIG adds a palladium layer, perfect for advanced tech and high-performance needs. Making ENIG involves nickel plating and gold coating for a top finish. ENEPIG adds palladium, improving soldering and wire bonding. LT CIRCUIT’s skills ensure accurate and dependable PCBs for tricky designs.

Focused on Quality and New Ideas

LT CIRCUIT values quality and new ideas in every step. They use modern methods to meet strict industry rules. ENIG’s nickel and gold layers fight rust and last long. ENEPIG’s design works better in tough conditions. LT CIRCUIT invests in research to make finishes even better. This ensures you get the best solutions for your needs.

Custom Solutions for Different Uses

LT CIRCUIT knows every project is different. They offer custom PCBs for high-frequency devices or tough equipment. ENEPIG is great for strong soldering and wire bonding. ENIG is good for budget-friendly projects. LT CIRCUIT adjusts its methods to make sure your PCB works well. Choosing LT CIRCUIT means getting a partner who cares about your needs and delivers with precision.

Picking ENEPIG or ENIG depends on what your PCB needs. ENEPIG is stronger and better for wire bonding. It’s great for projects needing high reliability. ENIG is cheaper and works well for simple designs. Think about your project’s needs and budget to decide. For advanced uses, ENEPIG usually lasts longer and works better.

FAQ

What makes ENIG and ENEPIG different?

ENIG has nickel and gold layers. ENEPIG adds a palladium layer. This extra layer helps with better soldering, stronger bonds, and lasting durability.

Which finish is best for reliable PCBs?

ENEPIG is the best choice for reliable PCBs. Its palladium layer stops rust and keeps solder joints strong, even in tough conditions.

Can ENIG and ENEPIG handle many heat cycles?

Yes, both can handle many heat cycles. But ENEPIG works better for projects needing high heat resistance and reliability.

See Also

Exploring ENEPIG's Importance in PCB Production Processes

Enhancing PCB Production Yield Through Online AOI Technology

Impact of LDI Technology on PCB Product Quality

Vacuum Two-Fluid Etching Machines in Precision PCB Manufacturing