Comparing Bulk HDI PCB Prices and Quality for Wholesale Buyers

If you’re looking at wholesale hdi pcb options, you know price and quality go hand in hand. Here’s what you should keep in mind:

More pcb layers, bigger boards, and tighter tolerances raise costs.

Skipping tests or using cheap materials can lead to failures.

Quality should never lose out to price.

Key Takeaways

Price and quality are closely linked in HDI PCB orders. Always prioritize quality to avoid failures.

Bulk orders can lead to significant savings. Ask suppliers about volume discounts to maximize your budget.

Choose the right materials and finishes for your PCBs. This balance ensures performance without overspending.

HDI PCB Pricing Basics

Price Drivers

When you start comparing price quotes for electronic pcb boards, you’ll notice several factors that shape the final pricing. Let’s break down what really drives the price for bulk HDI pcb orders.

Factor | Description |

|---|---|

Materials and Components | High-quality materials and components increase costs but improve performance and reliability. |

Manufacturing Complexity | More layers, smaller track sizes, and advanced surface finishes lead to higher manufacturing costs. |

Order Quantity | Volume discounts reduce the price per unit as the order quantity increases. |

Lead Time | Shorter lead times generally increase costs due to premium services required. |

Global Market Influences | Demand fluctuations and material costs influenced by geopolitical factors affect pricing. |

Technological Innovations | Advanced manufacturing techniques for HDI and flexible PCBs can lead to higher prices. |

You might wonder how design complexity affects the price. If you choose electronic pcb boards with more layers and vias, you’ll see the price go up. Larger printed circuit board sizes also add to the cost. Specialized materials and advanced via technology, like blind and buried vias, require extra manufacturing steps. These steps mean more drilling and lamination, which increases the price. Microvias and other advanced features can push costs even higher.

If you order a larger quantity, you can usually get discounts. Suppliers often lower the price per unit for bulk orders. This is one way you can save on electronic pcb boards when buying in volume. Lead time also matters. If you need your boards fast, expect to pay a premium price for expedited service.

Industry price trends can shift quickly. Global market influences, like material shortages or changes in demand, can affect pricing. You should keep an eye on these trends to make sure you’re getting a fair price.

Tip: Always ask your supplier about volume discounts and current industry price trends before placing a bulk order.

Material and Finish Impact

The materials and finishes you choose for your electronic pcb boards play a huge role in the final price. Some materials offer better performance but come with a higher cost. For example, advanced manufacturing processes, such as heavy copper plating or microvias, can add $2-$10 per square foot to your cost because they need specialized equipment.

Surface finishes also affect pricing. Here’s a quick look at how different finishes impact the price and quality of your pcb:

Surface Finish | Cost Implication | Description |

|---|---|---|

HASL | Low | Cost-effective, good solderability, uneven surface. |

ENIG | High | Excellent planarity and solderability, ideal for precision packages. |

OSP | Moderate | Eco-friendly, low-cost, but short shelf life. |

If you need high reliability for your electronic pcb boards, you might pick ENIG or even ENEPIG, but these finishes cost more. For wider pitch components, lead-free HASL is a budget-friendly choice. Finer pitch designs benefit from ENIG, though the gold thickness in this finish can raise the price.

Designers must balance performance and price. The choice of materials and finishes should match your needs and budget. If you want to optimize cost, talk to your supplier about which options fit your application and industry price trends.

Note: The right material and finish can help you get the best value for your electronic pcb boards without sacrificing quality.

Quality in Wholesale HDI PCB

When you buy HDI PCBs in bulk, you want every board to work perfectly. You need to know that each board meets strict standards and passes tough tests. Let’s look at how you can make sure your electronic pcb boards deliver the quality your business expects.

Manufacturing Standards

You can’t talk about quality without mentioning industry standards. These standards guide how manufacturers design and build HDI pcb. They help you get consistent results, even when you order thousands of boards at once.

Here’s a quick look at the main standards that shape the quality of HDI pcb:

Standard | Description |

|---|---|

Design Guide for High Density Interconnects (HDI) and Microvias. | |

IPC-2226 | Detailed standards and guidance for HDI pcb design. |

IPC/JPCA-4104 | Specification for HDI and Microvia Materials, ensuring the right materials for your boards. |

IPC-6012 | Qualification and Performance Specification for Rigid Printed Boards. |

You want your supplier to follow these standards. When they do, you get electronic pcb boards that meet your technical needs and last longer in the field.

Manufacturers use advanced processes to keep quality high. Here are some of the steps you’ll find in a top-tier factory:

Process/Technology | Description |

|---|---|

Creates precise holes for high-density connections. | |

Plasma Treatment | Prepares surfaces for better adhesion and quality. |

Chemical Cleaning | Removes dirt and oils, so your pcb starts clean. |

Copper Plating | Fills vias and ensures strong electrical connections. |

Electroplating Hole Filling | Makes sure every via is completely filled for reliability. |

Polishing | Gives the board a smooth finish and prepares it for inspection. |

Automated Optical Inspection (AOI) | Spots defects early in the process, so you get fewer surprises. |

X-ray Inspection | Checks inside the board to make sure all layers line up. |

Comprehensive Testing | Confirms that each pcb meets the demands of high-speed and high-frequency applications. |

Tip: Ask your supplier about their manufacturing steps. If they use these advanced processes, you can expect stable quality in every shipment.

Testing and Assurance

You want to feel confident that every pcb in your order works as it should. That’s where testing comes in. Reliable suppliers use several methods to check for defects and make sure your boards meet your requirements.

Here are some of the most common testing methods for HDI pcb:

Testing Method | Description |

|---|---|

Measures voltages, currents, and resistances to check the integrity of the pcb and its components. | |

Automated Testing Systems (ATS) | Quickly finds short circuits and misplaced parts, making sure every board is built right. |

X-Ray Inspection | Looks inside the board to spot hidden defects you can’t see from the outside. |

Boundary Scan Testing | Checks connections without touching the board, great for hard-to-reach spots. |

You should always ask your supplier about their testing process. The best suppliers test every batch, not just a few samples. This way, you know your electronic pcb boards will perform well in your products.

Note: Consistent testing means fewer failures in the field and less hassle for you down the road.

When you focus on manufacturing standards and thorough testing, you get the quality you need for your business. You save time, reduce returns, and build trust with your customers.

Bulk Pricing Factors

Order Volume

When you place bulk orders for pcb, you unlock better pricing. Suppliers often reward you with lower price per unit as your order size grows. This happens because bulk pcb manufacturing lets factories run longer production cycles without stopping to reset machines. You save money, and the supplier saves time. If you need pcb prototypes, you might see a higher price per board since small runs do not offer the same efficiency. As your order volume increases, the cost per pcb drops. This is a smart way to manage your budget and get more value from each dollar you spend.

Tip: Always ask your supplier about price breaks for larger quantities. You might be surprised at how much you can save by increasing your order size just a little.

Lead Time

Lead time plays a big role in pcb pricing. If you need your boards fast, you will likely pay a premium price. Shorter production times or rush orders usually come with extra charges. On the other hand, if you can stick to standard lead times, you can keep your cost lower. Sometimes, lead times get longer because of limited component supplies. This can disrupt production schedules and force you to look for creative solutions. Planning ahead helps you avoid these issues and keeps your pricing stable. When you manage your schedule well, you control both the price and the quality of your pcb.

PCB Mass Production Insights

Economies of Scale

When you order pcb mass production, you unlock big advantages. The more boards you produce, the lower your mass production cost per unit. You save money because factories run longer cycles and use materials more efficiently. You also get your pcb faster, which helps you launch products quickly. Consistent quality becomes easier to achieve since standardized testing checks every batch. Here’s what you gain from economies of scale in pcb mass production:

Cost-effective production lowers your mass production cost as output increases.

Faster production cycles help you reach the market sooner.

Standardized testing ensures quality across all pcb batches.

If you plan for high-volume orders, you can negotiate better prices. You also reduce waste and avoid delays. This strategy makes pcb mass production a smart choice for growing your business.

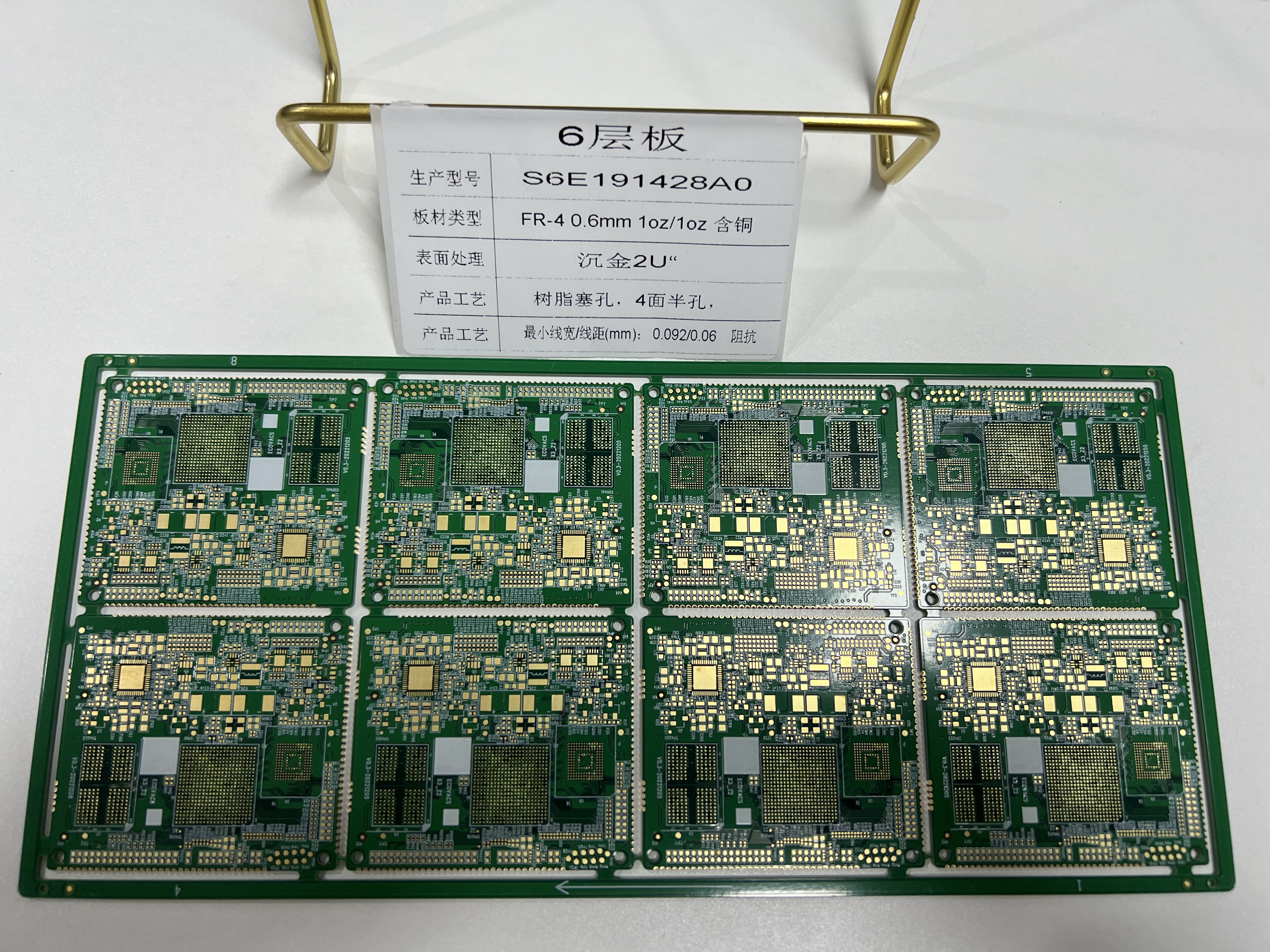

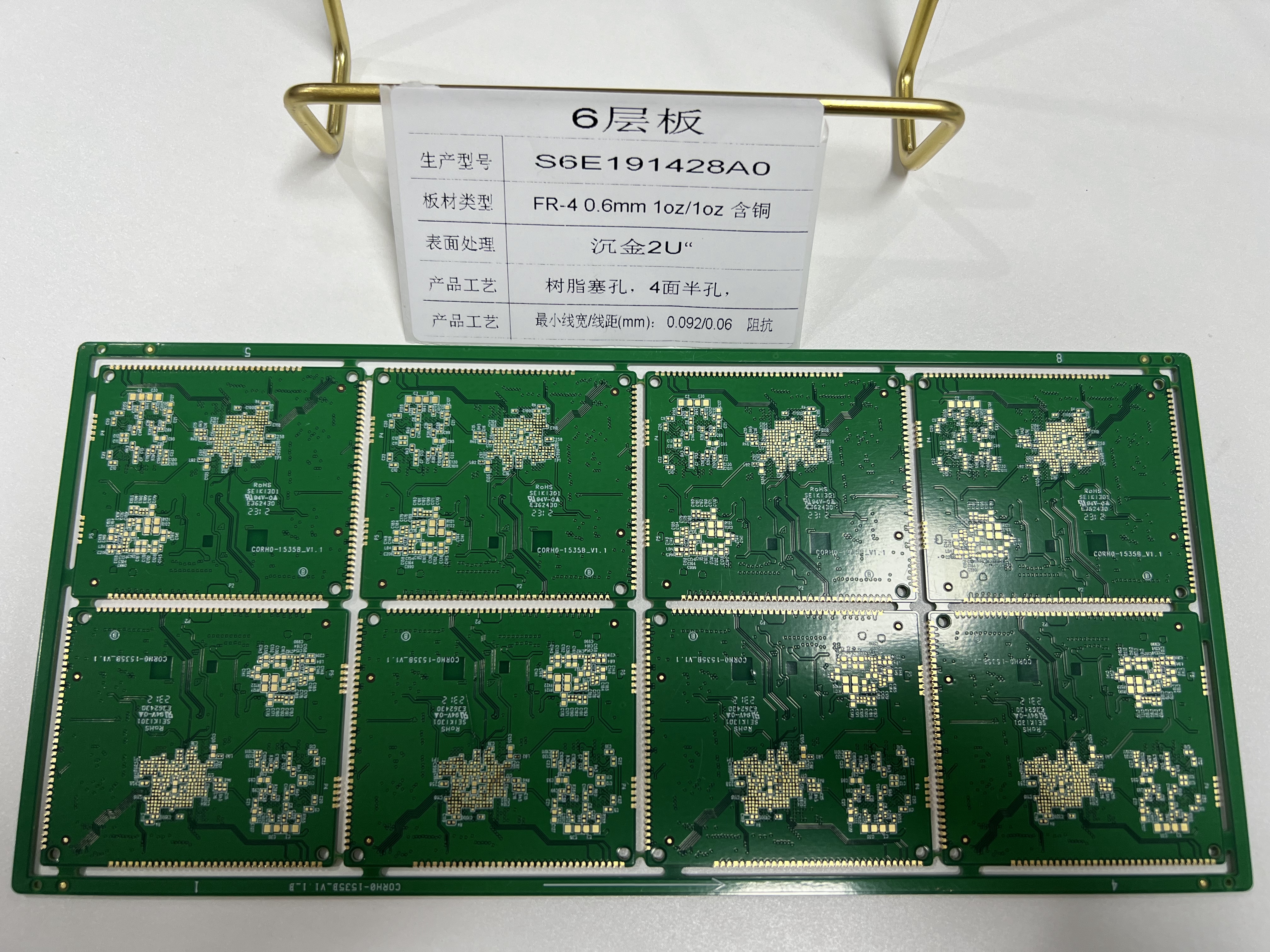

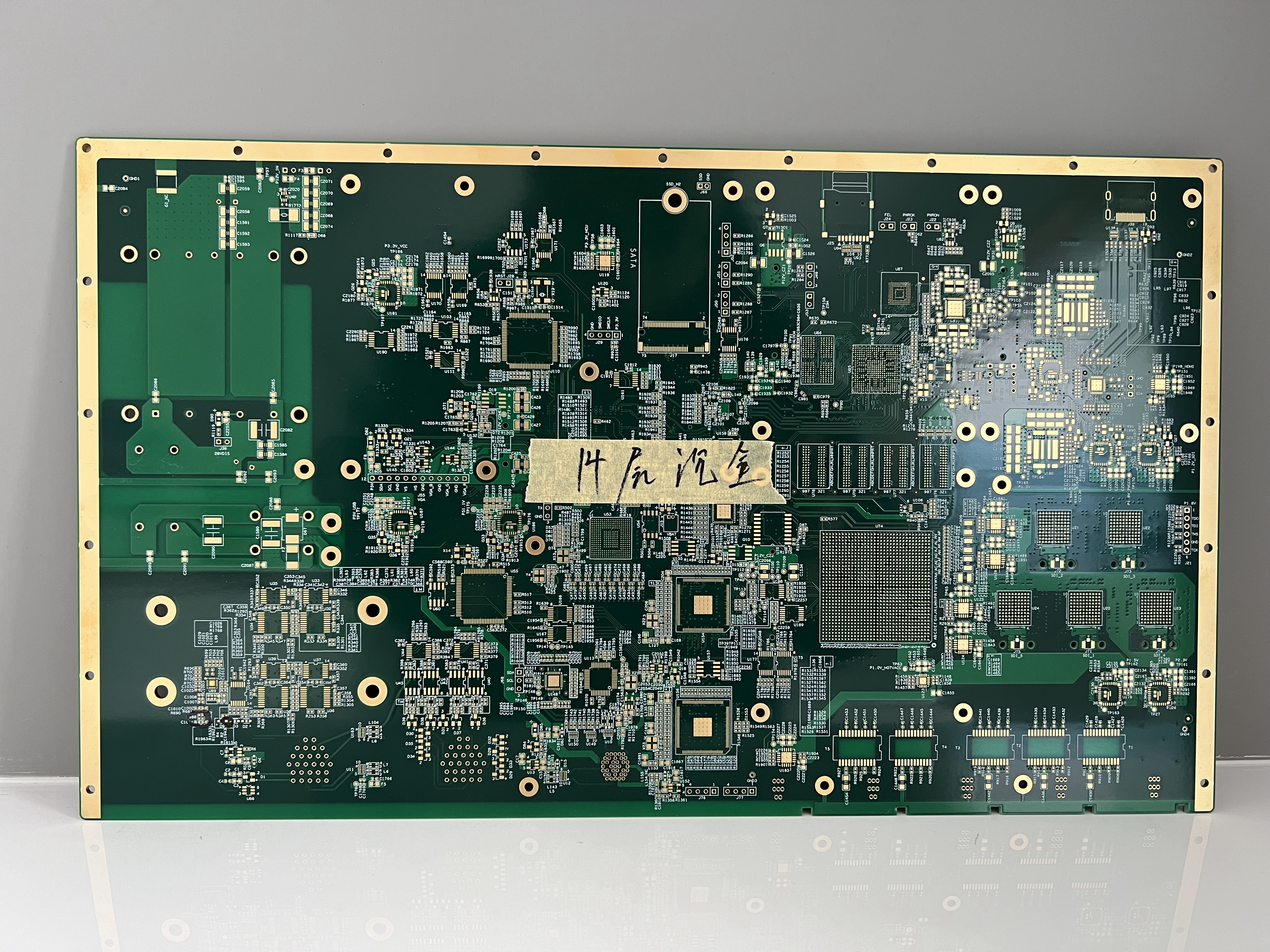

LT CIRCUIT’s Production Capabilities

LT CIRCUIT stands out when it comes to pcb mass production. You get advanced manufacturing processes that cut mass production cost and boost quality. Real-time defect detection means fewer mistakes and less rework. Modular designs let you scale from small runs to high-volume orders with ease. Take a look at how LT CIRCUIT’s technology compares:

Factor | Quick Turn HDI Impact | Traditional PCB Impact |

|---|---|---|

Material Waste | 30% waste due to larger board sizes | |

Rework Costs | 60% lower with real-time detection | High rework due to post-production |

Scalability | Modular, supports 10–100,000+ units | Limited for complex designs |

You also benefit from LT CIRCUIT’s impressive production specs:

Specification | Details |

|---|---|

Thickness | 0.4-3.2mm |

Layer Count | 4 to 20 layers |

Minimum Hole Size | 0.15mm |

Material | FR4 IT180 |

Testing Protocols | 100% E Testing |

With LT CIRCUIT, you get reliable pcb mass production, lower mass production cost, and consistent quality for every pcb. You can trust their expertise for your next high-volume orders.

Comparing Wholesale HDI PCB Suppliers

Supplier Selection

When you start looking for a wholesale hdi pcb partner, you want to make sure you pick a supplier who can handle your needs for pcb mass production. Selecting the right manufacturer means checking more than just price. You need to look at certifications, capacity, engineering support, and payment terms. Here’s a quick table to help you compare suppliers:

Criteria | Details |

|---|---|

Certifications | |

Capacity & Turnaround | Volume capability (e.g., 200,000 m²/month), Prototyping + large-scale production, Express shipping options |

Engineering Support | DFM reviews, Stack-up and impedance simulation, Gerber & ODB++ compatibility |

Certifications like ISO9001 and UL show that a supplier follows strict quality standards. These certifications help reduce defects and build trust in your electronic pcb boards. You also want a supplier with strong engineering support. This makes sure your pcb designs work well in mass production.

Don’t forget to check payment options and order terms. Some suppliers offer flexible payment plans or no minimum order, while others have specific requirements. Comparing these details helps you make the best choice for your wholesale hdi pcb needs.

LT CIRCUIT Advantages

Selecting the right manufacturer can feel overwhelming, but LT CIRCUIT makes it simple. You get a team focused on innovation, quality, and customer satisfaction. LT CIRCUIT holds top certifications, so you know your pcb mass production meets global standards. Their advanced engineering support helps you optimize your electronic pcb boards for every project.

You benefit from fast turnaround and scalable capacity. LT CIRCUIT can handle everything from prototypes to large-scale pcb mass production. Their customer support team answers your questions quickly and helps you solve problems before they grow. When you choose LT CIRCUIT, you get a reliable partner for every wholesale hdi pcb order.

Tip: Selecting the right manufacturer with strong certifications and support ensures your pcb mass production runs smoothly and your products perform as expected.

Pricing Trends and Strategies

Market Trends

You see big changes in the HDI pcb market every year. The demand for pcb mass production keeps rising because new technologies need better boards. Take a look at the market growth:

Year | CAGR (%) | |

|---|---|---|

2024 | 16.45 | N/A |

2025 | 18.12 | 10.1 |

2029 | 27.04 | 10.5 |

You notice several trends driving this growth:

Implementation of 5G technology

Rise in IoT devices

Advancements in automotive electronics

Growth in wearable devices

Technological advancements in pcb design

These trends push suppliers to improve pcb mass production and offer better pricing. You want to watch these changes because they affect the price you pay and the quality you get.

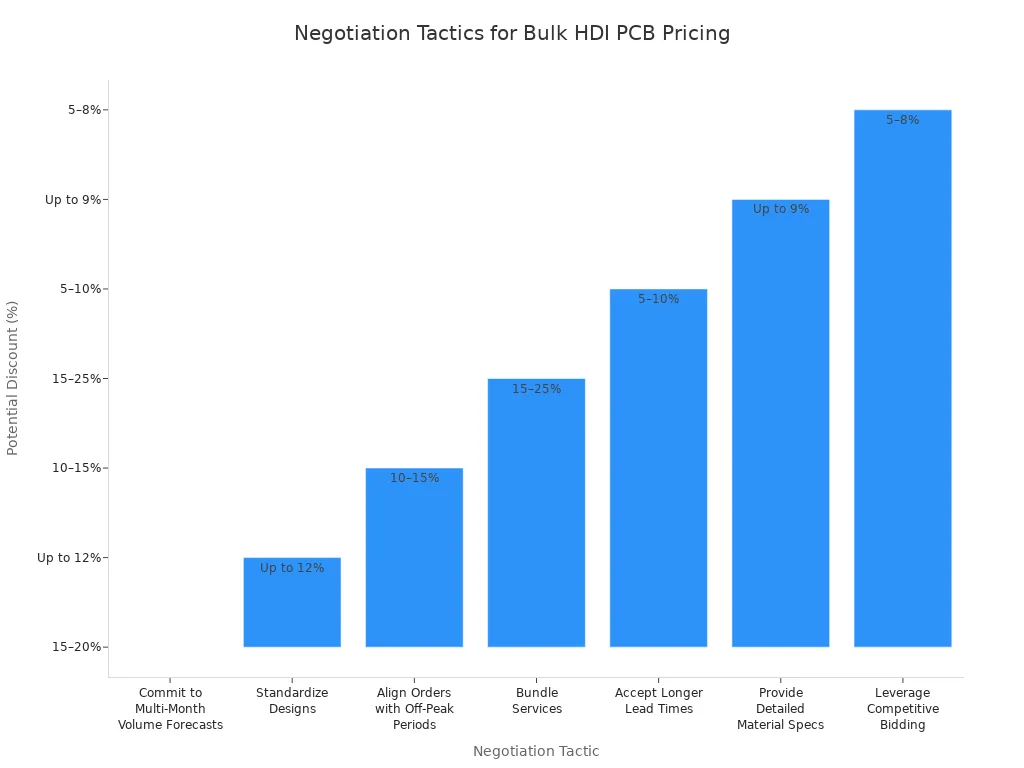

Cost Optimization

You can lower your pcb mass production cost without losing quality. Try these strategies:

Optimize panel design by mirroring and arraying to reduce waste.

Simplify pcb designs by reducing layers and using larger traces.

Choose standard materials to keep cost down.

Consolidate orders to get volume discounts.

Negotiation tactics help you secure better price and pricing terms. Here’s a quick look at what works best:

Tactic | Description | Potential Discount |

|---|---|---|

Commit to Multi-Month Volume Forecasts | Provide a 3–6 month forecast with guaranteed minimum volumes to ensure steady capacity utilization. | 15–20% |

Standardize Designs | Reduce setup complexity by using common features across products. | Up to 12% |

Align Orders with Off-Peak Periods | Schedule orders during slow periods to fill idle capacity. | 10–15% |

Bundle Services | Combine PCB fabrication with assembly services to reduce logistics costs. | 15–25% |

Accept Longer Lead Times | Agree to longer lead times to allow batching and cost optimization. | 5–10% |

Provide Detailed Material Specifications | Offer detailed specs for critical materials while allowing flexibility for non-critical ones. | Up to 9% |

Leverage Competitive Bidding | Use quotes from other suppliers to motivate better terms without damaging relationships. | 5–8% |

Tip: You get the best price when you combine smart design choices with strong negotiation. Always ask about volume discounts and flexible lead times during pcb mass production.

You want the best price and quality for every pcb order. Here’s what matters most:

Compare suppliers for price, pcb reliability, and customer ratings.

High-volume pcb orders lower cost per unit.

LT CIRCUIT’s turnkey solutions cut cost, streamline pcb production, and eliminate hidden price surprises.

Benefit | How LT CIRCUIT Helps |

|---|---|

Lower cost | |

Fast pcb delivery | Quick turnaround for every order |

Consistent quality | Strict controls for every pcb batch |

Reach out to LT CIRCUIT for tailored pcb solutions that fit your price and cost goals.

FAQ

What is the minimum order quantity for bulk HDI PCBs?

You can start with as few as 5-10 pieces. For the best price, order larger quantities. LT CIRCUIT offers flexible options for wholesale buyers.

How does LT CIRCUIT ensure consistent quality in mass production?

LT CIRCUIT uses strict testing, advanced inspection, and certified processes. Every batch gets checked for defects. You always receive reliable boards.

Can I get custom HDI PCB designs for my project?

Yes! You can request custom layouts, materials, and finishes. LT CIRCUIT’s engineers help you create the perfect board for your needs.

See Also

Save Project Costs in 2025 with Quick Turn HDI PCBs

Essential Design Factors for Reliable HDI PCB Manufacturing

Explore Cutting-Edge Techniques for HDI PCB Prototyping