What is a Copper Base PCB and Why is it Ideal for Industrial Applications

A copper base PCB gives you strong heat dissipation and high electrical performance. You find these boards essential in automotive, LED lighting, and industrial automation.

Sector | Application Description |

|---|---|

Automotive | Key component in power electronics for motors, inverters, and battery management systems. |

LED Lighting | High-power LED systems benefit from effective heat transfer to prevent overheating. |

Industrial Automation | Heavy machinery and industrial equipment utilize enhanced thermal management capabilities. |

LT CIRCUIT stands out as a copper base PCB exporter, delivering advanced solutions with proven reliability.

Key Takeaways

Copper base PCBs excel in heat dissipation, making them ideal for high-power applications in industries like automotive and LED lighting.

These boards offer superior mechanical strength and reliability, ensuring they withstand harsh conditions and last longer in demanding environments.

Customization options for copper base PCBs allow you to tailor thickness and surface finishes to meet specific project needs, enhancing performance and efficiency.

What is Copper Base PCB

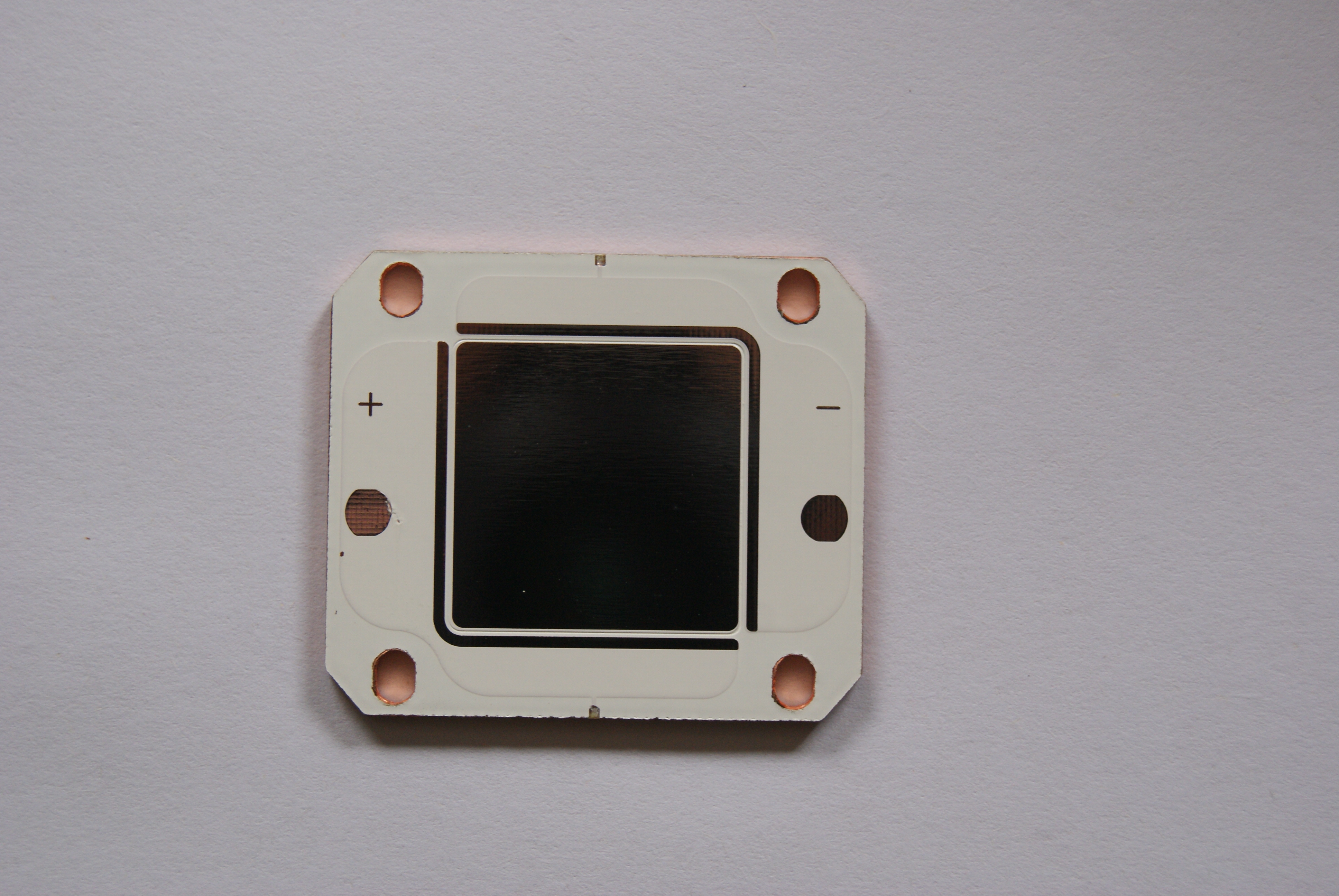

Copper based pcb stands out as a specialized type of copper printed circuit boards designed for demanding industrial environments. You see these boards built with a solid copper substrate, which gives them unique properties compared to standard PCBs. The copper layer acts as the foundation, supporting the other materials and layers that make up the board. This structure allows copper based pcb to handle higher power and heat loads, making them ideal for applications where reliability and performance matter most.

Key Features

When you look at copper based pcb, you notice several features that set them apart from other types of copper printed circuit boards. The table below highlights the main differences:

Feature | Copper Based PCB | Other PCBs (e.g., FR-4) |

|---|---|---|

Base Material | Solid copper layer | Fiberglass or other insulating materials |

Thermal Conductivity | Lower thermal conductivity | |

Electrical Performance | Improved due to lower resistance | Standard performance |

Mechanical Strength | Superior rigidity and durability | Varies, generally lower |

Customization | Customizable thickness | Limited customization |

Applications | General applications |

You benefit from these features in several ways:

High thermal conductivity lets copper based pcb transfer heat quickly, protecting sensitive components.

Improved electrical performance means lower resistance and better efficiency for your circuits.

Enhanced mechanical strength gives you a board that resists bending and warping, even in tough conditions.

Customizable thickness allows you to choose the right board for your specific needs.

Compatibility with surface mount technology (SMT) makes assembly easier and more reliable.

Copper based pcb also uses advanced materials in its layer structure. You find copper layers forming the conductive pathways, while the core substrate often consists of fiberglass-reinforced epoxy resin (FR-4) for strength. For high-frequency or high-temperature applications, manufacturers may use ceramic-filled PTFE composites or polyimide. This combination of materials ensures that copper printed circuit boards deliver both durability and performance.

Tip: Copper based pcb offers thermal conductivity up to 386 W/mºC, much higher than standard PCB materials, which usually range from 0.3 to 0.6 W/mºC. This means your board can handle large temperature changes without losing efficiency.

Why Industries Choose Copper Base PCB

You see industries selecting copper based pcb for several important reasons. These boards excel in environments where heat, power, and reliability are critical. The following table summarizes the main advantages:

Advantage | Description |

|---|---|

Copper based pcb dissipates heat efficiently, reducing the need for extra cooling systems. | |

Enhanced Electrical Conductivity | Thick copper layers provide low-resistance paths, improving efficiency in high current applications. |

Improved Mechanical Strength | The copper core adds structural integrity, making the board resistant to bending and warping. |

Longer Lifespan and Reliability | Reduced thermal stress and mechanical strength lead to fewer replacements and maintenance needs. |

Corrosion Resistance | Copper's natural resistance to corrosion enhances durability in harsh environments. |

You rely on copper based pcb in industrial automation, automotive electronics, and LED lighting because these boards keep your systems running smoothly. Efficient heat dissipation and reduced thermal resistance help maintain temperature uniformity, which is vital for high-power devices. You also benefit from higher power handling, which allows your equipment to operate at peak performance without overheating.

Copper printed circuit boards offer long-term durability. When you choose materials with a high glass transition temperature and a low coefficient of thermal expansion, you get a board that withstands environmental stress. Quality controls during manufacturing further ensure that copper based pcb meets your reliability standards.

Efficient heat dissipation protects your components.

Reduced thermal resistance keeps your system stable.

Temperature uniformity prevents hot spots and failures.

Higher power handling supports demanding industrial tasks.

You find copper based pcb to be the preferred choice for critical applications because they combine strength, reliability, and performance. These boards help you reduce maintenance costs and extend the lifespan of your equipment, making them a smart investment for any industrial setting.

Copper Base PCB Manufacturing with LT CIRCUIT

Manufacturing Process

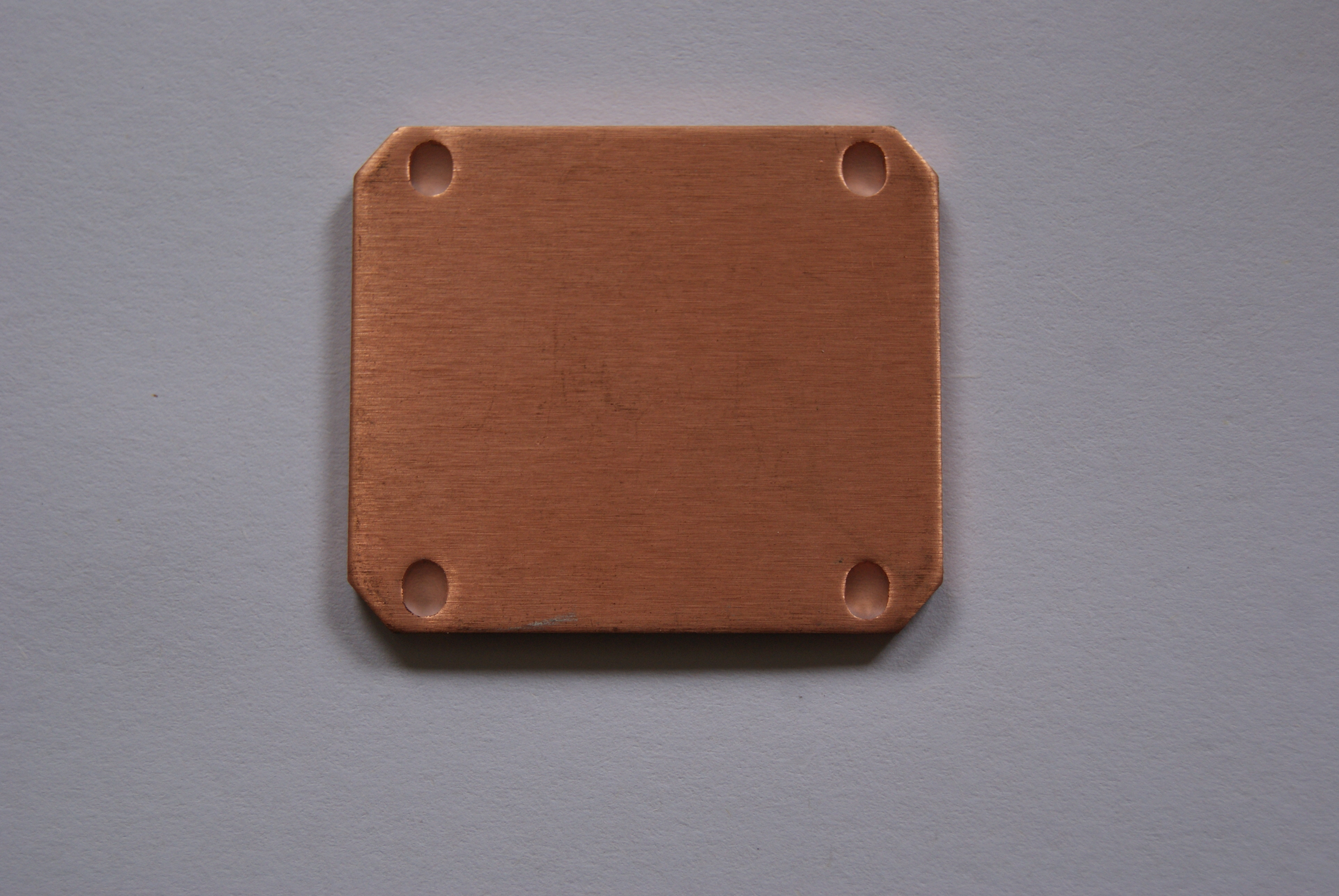

You experience a precise and reliable copper base pcb manufacturing process at LT CIRCUIT. The journey starts with preparing the copper substrate, which forms the foundation for your board. You see each step designed to ensure quality and durability:

Substrate Preparation

Copper Cladding

Photoresist Application and Exposure

Developing and Etching

Drilling

Plating

Solder Mask Application

Silkscreen Printing

Surface Finish Application

Electrical Testing

Final Inspection and Packaging

Each stage uses advanced equipment and strict controls. You benefit from a process that protects the copper substrate and delivers consistent results. LT CIRCUIT’s expertise means your boards meet high standards for industrial use.

Quality and Customization

You get more than just standard boards when you choose LT CIRCUIT. The company uses high-performance copper clad laminates and special resins to match your needs. The table below shows how these materials improve your board’s performance:

Material Type | Features |

|---|---|

High-performance copper clad laminates | Tight control over dielectric properties and thermal stability, ideal for demanding applications like 5G networks and automotive electronics. |

Special resins or flexible materials | Selected for unique applications, ensuring high standards for electrical conductivity, durability, and reliability. |

Consistent dielectric properties | Low signal loss, important for advanced applications in modern electronics. |

You can customize your copper substrate thickness, surface finish, and solder mask color. LT CIRCUIT offers flying probe tests and E-tests to guarantee reliability. You see a commitment to innovation and quality in every product.

Advantages for Industrial Use

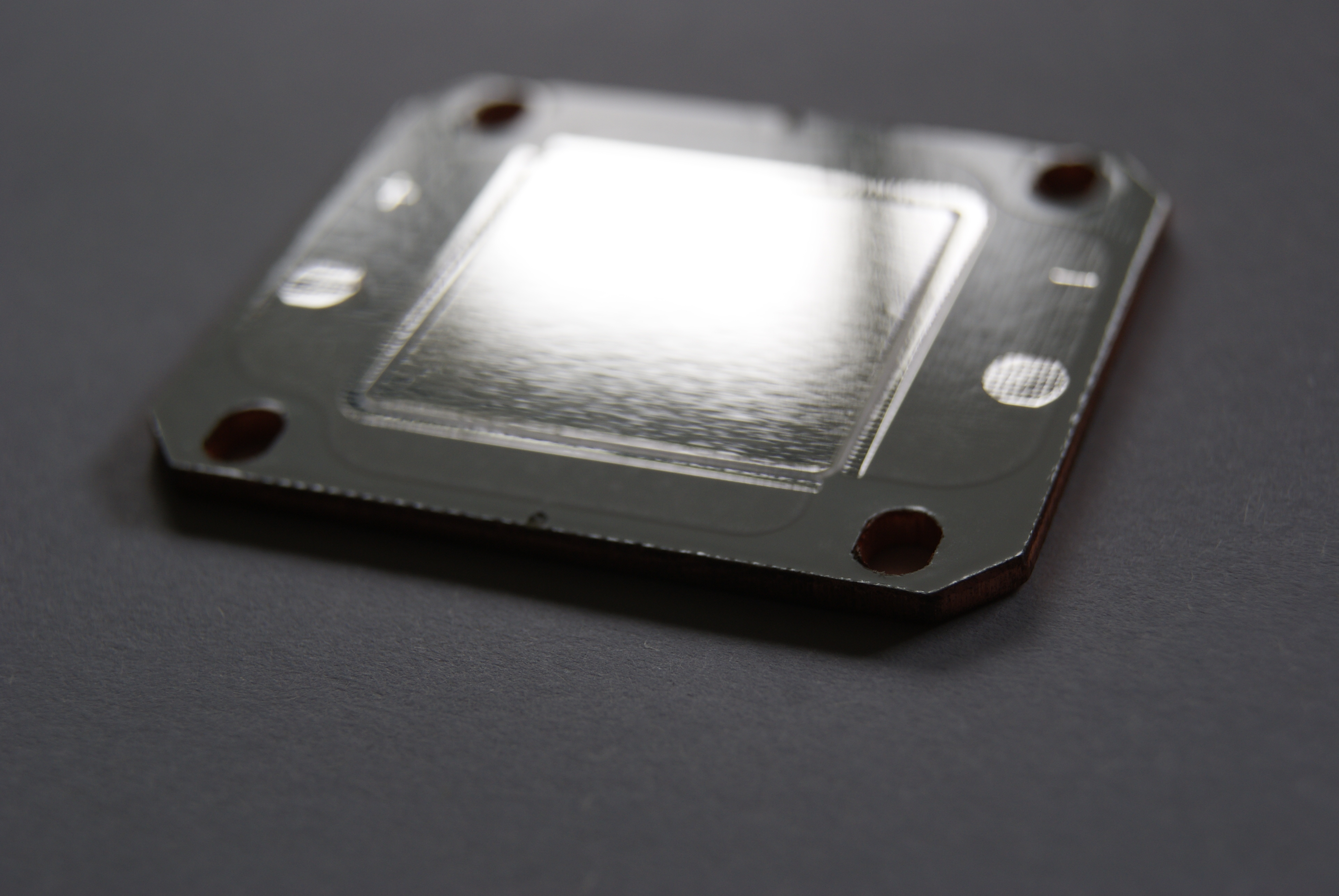

Thermal and Electrical Performance

You gain a clear advantage when you use copper base PCBs in industrial environments. These boards deliver outstanding heat dissipation performance, which is essential for keeping your equipment safe and reliable. Copper’s high thermal conductivity, measured at 398 W/mK, allows your board to move heat away from sensitive components quickly. This property helps you avoid overheating and keeps your systems running at peak performance.

Attribute | Description |

|---|---|

Thermal Conductivity | Copper has a thermal conductivity of 398 W/mK, facilitating efficient heat dissipation. |

Copper Thickness | Increased thickness enhances current-carrying capability and reduces heat generation. |

Busbars | Serve as high-power distribution pathways, reducing thermal and electrical burden on PCB traces. |

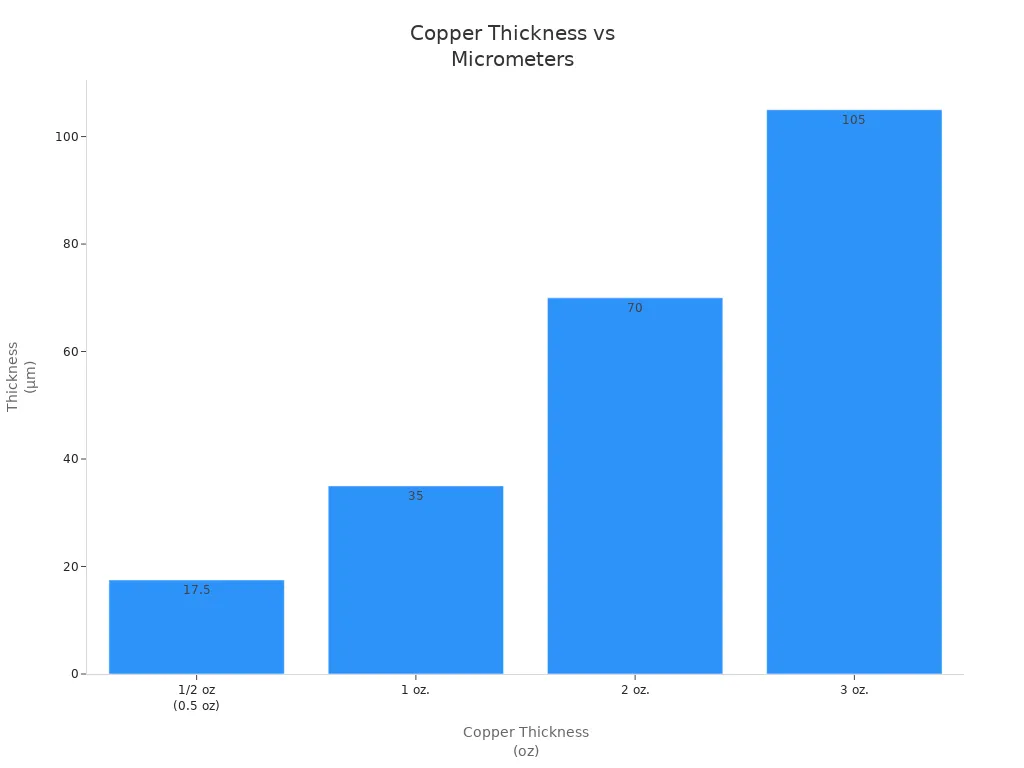

You see this level of heat management in action with power modules and high frequency pcb designs. These applications demand good heat dissipation and stable electrical performance. Copper base PCBs handle these requirements with ease. You can select different copper thicknesses to match your needs:

Copper Thickness | Equivalent in Micrometers (µm) |

|---|---|

1/2 oz (0.5 oz) | 17.5 µm |

1 oz. | 35 µm |

2 oz. | 70 µm |

3 oz. | 105 µm |

You benefit from this flexibility because you can design boards that are suitable for high power applications. Thicker copper layers support higher currents and reduce heat buildup. This means your power modules stay cool and operate efficiently, even under heavy loads.

Copper base PCBs also provide excellent electrical performance. You experience lower resistance and less signal loss, which is important for high-speed and high-frequency circuits. The low coefficient of thermal expansion ensures that your board maintains excellent dimensional stability, even when temperatures change rapidly. This stability protects your circuits from stress and extends the lifespan of your equipment.

Note: The global copper coin PCB market reached $3.7 billion in 2024 and is expected to grow to $6.9 billion by 2033. This growth shows how industries value heat dissipation performance and advanced thermal management.

You also see copper base PCBs used in electric vehicle charging stations and power electronics. Federal spending on EV charging infrastructure hit $7.5 billion in 2024, and each station relies on multiple high-power PCBs. Automotive manufacturers now invest heavily in electrification programs, using copper base PCBs to meet strict emission standards and improve performance.

Mechanical Strength and Reliability

You need your industrial equipment to last, even in harsh conditions. Copper base PCBs give you high mechanical strength, which means your boards can handle physical stress, vibration, and temperature changes without failing. This makes them a smart choice for automotive, aerospace, and heavy machinery applications.

PCB Substrate | Flexural Strength | Young's Modulus |

|---|---|---|

Copper Base | High | High |

FR-4 | Moderate | Moderate |

CEM-1 | Low | Low |

CEM-3 | Moderate | Moderate |

You see that copper base PCBs outperform other substrates like FR-4 and CEM-1 in both flexural strength and Young’s modulus. This means your board resists bending and warping, even when exposed to mechanical shock or pressure. The low coefficient of thermal expansion further improves reliability by reducing the risk of cracks or solder joint failures during temperature swings.

Reliability testing confirms these benefits. You can trust copper base PCBs to pass tough tests, such as:

Testing Method | Purpose |

|---|---|

Thermal Stress Testing | Evaluates mechanical stability under high temperatures, focusing on solder joints and vias. |

Damp Heat Test | Simulates high humidity and temperature effects, assessing moisture resistance and corrosion. |

Salt Spray Test | Tests corrosion resistance in salty environments, crucial for marine and automotive applications. |

Ionic Contamination Testing | Measures residual ionic contaminants that can lead to corrosion and electrochemical migration. |

You get peace of mind knowing your boards will perform reliably in demanding environments. The excellent dimensional stability of copper base PCBs means your circuits stay intact and your equipment keeps working, even after years of use.

Tip: Copper base PCBs are also environmentally friendly because copper is recyclable. This helps you support sustainability while enjoying top-level performance.

You find that copper base PCBs combine heat dissipation performance, high mechanical strength, and electrical reliability. These features make them the preferred solution for industries that demand the best in durability and efficiency.

Copper Base PCB Exporter and Applications

Industrial Applications

You rely on a copper base pcb exporter like LT CIRCUIT when your projects demand high reliability and advanced performance. LT CIRCUIT serves global clients in sectors such as automotive, aerospace, LED lighting, and industrial control. You see copper base PCBs used in heavy machinery, power electronics, and high-frequency communication systems. These boards support your needs in environments where heat, vibration, and electrical stress challenge ordinary PCBs.

Here are some notable industrial projects that use copper base PCBs:

Project | Details |

|---|---|

High-reliability PCBA for aerospace data recording systems operating in harsh environments. | |

Client Background | Leader in signal acquisition in harsh environments with 46 years of experience. |

Core Challenge | High precision requirements for embedding copper coins in PCB manufacturing. |

Solution | Developed a PTFE+FR4 hybrid laminate for embedding copper coins, ensuring stability and reliability. |

You also find high-precision boards in aerospace, where you need low quantity per model, frequent orders, and high-quality soldering for BGAs. LT CIRCUIT meets these needs with no minimum order quantity, fast response, and thorough inspection.

Real-World Benefits

When you choose a copper base pcb exporter, you gain several advantages for your industrial applications:

You achieve high current carrying capacity, which supports powerful devices.

You benefit from excellent thermal management, keeping your systems cool.

You enjoy improved mechanical strength, so your equipment lasts longer.

You can design complex circuits with fewer layers, saving space and cost.

You see an increased lifespan for your products, reducing downtime.

A copper base pcb exporter like LT CIRCUIT helps you meet strict industry standards. You receive boards that perform reliably in demanding environments. Your investment in quality PCBs leads to fewer failures and better results in every project.

Tip: Partnering with a trusted copper base pcb exporter ensures you get consistent quality and expert support for all your industrial control and automation needs.

You see copper base PCBs leading the way in electric vehicles, renewable energy, and automation. These boards offer unmatched heat management and reliability. LT CIRCUIT stands as your trusted partner for advanced PCB solutions. Choose LT CIRCUIT to support your next industrial project with proven quality and innovation.

FAQ

What makes copper base PCBs better for heat management?

You get excellent heat dissipation with copper base PCBs. The copper layer moves heat away from components quickly, which helps prevent overheating in your devices.

Can you customize copper base PCBs for special projects?

Yes, you can choose thickness, surface finish, and solder mask color. LT CIRCUIT offers custom solutions to fit your unique industrial requirements.

How do you know LT CIRCUIT delivers quality copper base PCBs?

LT CIRCUIT uses strict testing, advanced materials, and thorough inspections. You receive reliable boards that meet high industry standards every time.

See Also

Utilizing Horizontal Copper Sinking Technology in PCB Manufacturing

Key Considerations for Designing High-Current Heavy Copper PCBs

Using Panasonic Copper-Clad Laminates in PCB Production Processes

Diverse Uses of Multilayer PCBs in Various Industries

Investigating Ceramic PCB Uses in Contemporary Industrial Applications