The application and advantages of Copper-based PCB thermoelectric separation process

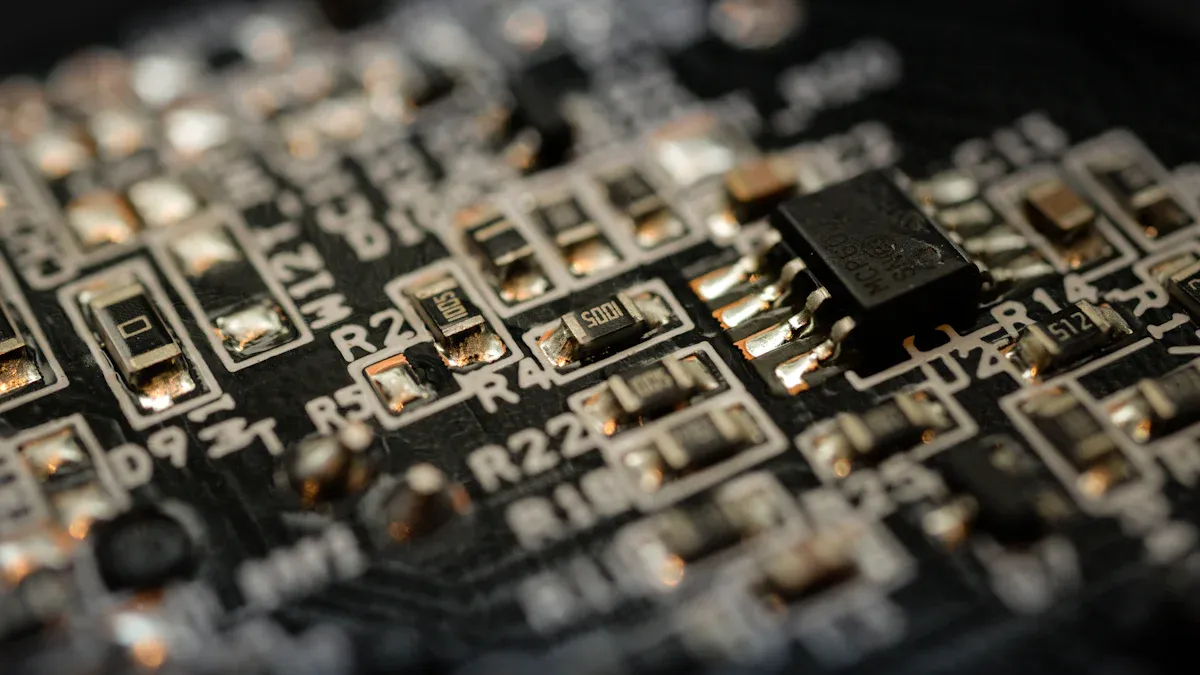

The copper-based PCB process uses heat and electricity to separate copper. This method helps recover materials while keeping reusable parts safe. It is important in industries needing good heat control and reliability, like electronics making and recycling.

Key Takeaways

Copper-based PCB thermoelectric separation helps recycle electronics better and greener.

It speeds up production, saves time, and makes products higher quality.

LT CIRCUIT creates special PCB designs that handle heat well, making them reliable for strong power and factory use.

Applications of Copper-based PCB Thermoelectric Separation Process

Electronics Recycling

The copper-based PCB process is key in recycling electronics. It recovers copper and other useful materials from old PCBs. Heat and electricity separate these materials without harming reusable parts. This makes recycling better by cutting waste and reusing items. Many recycling centers use this method to save resources and meet eco-friendly rules.

Manufacturing and Production

In factories, this process improves how materials are handled. It separates copper from PCBs to make better products. Industries like electronics and telecom need this for precise work. Using this method reduces wasted materials and boosts product quality. It also speeds up production, helping modern factories work faster.

High-Power and Industrial Uses

This process is great for high-power and heavy-duty machines. It helps with heat control and keeps devices working well. Separating copper improves heat flow, which is vital for tough conditions. Big machines, power systems, and industrial tools last longer with this method. It keeps them stable and running for a long time.

Advantages of Copper-based PCB Thermoelectric Separation Process

Efficiency in material separation

This process separates copper and materials from PCBs with precision. It uses heat and electricity to remove copper safely. Valuable materials are recovered, reducing waste and saving resources. Industries using advanced electronics benefit by improving product quality and reliability.

Environmental benefits and sustainability

This method helps protect the environment by recycling materials. Recovering copper reduces the need for mining raw resources. It cuts down on electronic waste that harms nature. Recycling PCBs this way supports green technology and lowers carbon footprints. It also meets eco-friendly rules for waste management.

Cost-effectiveness for businesses

Businesses save money by using this process. It reduces waste and improves production efficiency. For example, recovery time dropped from 124 hours to 14 minutes. Exergy efficiency reached 61.38%, showing great results. The table below shows key data:

Metric | Value |

|---|---|

Total Cost Rate | |

SOFC Stack Contribution | 65.11 % |

Inverter Contribution | 11.9 % |

Exergy Efficiency | 61.38 % |

Optimization Time Reduced | From 124 h to 14 min |

These numbers prove this process saves costs and boosts productivity.

Technological innovation and advancements

This process is a big step in technology. It combines heat control with smart material recovery. It improves product performance, especially for precise industries. It also helps manage heat in powerful devices. Using this technology keeps businesses competitive in a fast-changing market.

Why LT CIRCUIT is Best for Copper-based PCB Solutions

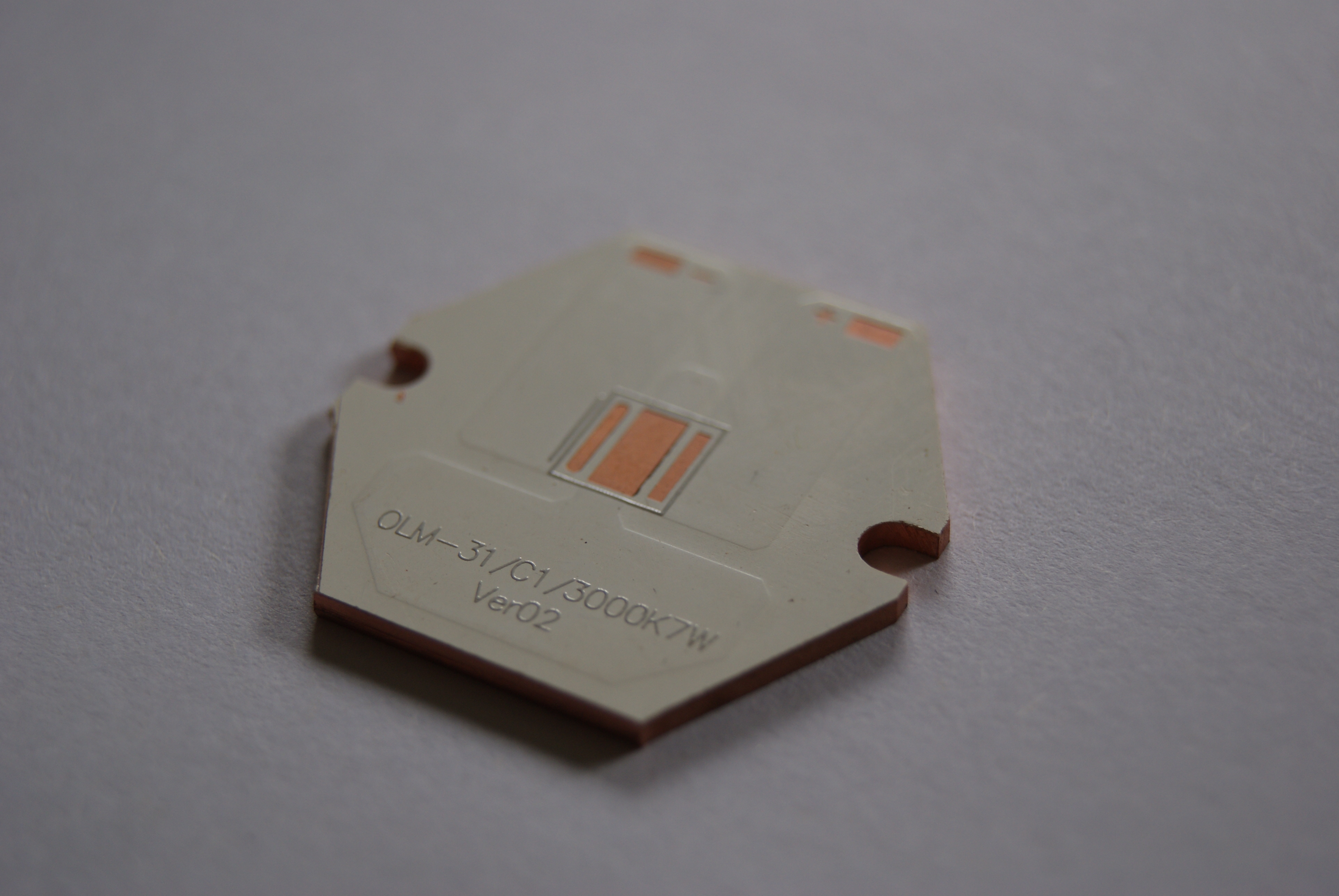

Great at Handling Heat

PCBs must manage heat well for powerful devices. LT CIRCUIT uses copper-based designs to handle heat better. These PCBs cool down fast, keeping devices stable. They work well with rigid designs and advanced processes. LT CIRCUIT's focus on heat control protects important parts. This makes their PCBs perfect for cars and big machines.

Works Well in Tough Conditions

High-power systems need reliable PCBs. LT CIRCUIT's copper-based PCBs work great even in harsh places. Their strong designs make them last longer and avoid problems. Industries like telecom and aerospace trust these PCBs for important tasks. LT CIRCUIT ensures your projects run smoothly and stay reliable.

Custom Designs and Smart Manufacturing

LT CIRCUIT makes PCBs that fit your needs exactly. Their advanced methods allow for detailed and complex designs. For example:

A car electronics company needed a PCB for their infotainment system. It had to handle fast signals and heat well. LT CIRCUIT made perfect PCBs, helping the product sell better than expected.

This focus on custom designs gives you the right PCB for any job. Their smart manufacturing makes them a top choice for creative solutions.

Comparison with alternative methods

Mechanical separation techniques

Mechanical methods use shredding, grinding, and sieving to separate materials. These are common in recycling to break PCBs into small parts. While simple, they often lack accuracy. Some copper may remain, or PCB layers might get damaged.

The thermoelectric process works better for separating materials. It uses heat and electricity to recover copper without damage. Studies show it uses 35% less energy than mechanical methods. This makes it a smarter choice for saving energy and cutting costs.

Chemical-based separation methods

Chemical methods use acids and solvents to dissolve PCB materials. They can separate copper well but may harm the environment. Chemicals can release harmful waste, polluting air and water.

The thermoelectric process avoids these problems by using heat, not chemicals. It keeps PCB layers safe and reduces pollution risks. For eco-friendly industries, this is a cleaner and safer option.

Emerging hybrid processes

Hybrid methods mix mechanical, chemical, and thermoelectric techniques for better results. They use advanced tools like machine learning and simulations to improve control. For example, hybrid systems make separation more efficient and products purer.

The table below shows hybrid process benefits:

Evidence Description | Key Benefits |

|---|---|

Combining hybrid models with older methods | Better separation and purer products |

Using machine learning for design and efficiency | Smarter predictions and better control |

Real-time simulations for system analysis | Quick checks and fixes for processes like gas or water separation |

Hybrid methods are the future of material separation. They combine the best parts of different techniques while fixing their flaws. For industries needing advanced solutions, hybrids offer great performance and flexibility.

The copper-based PCB process is useful in recycling and factories. It helps recover materials, saves money, and protects nature. This method manages heat well, keeping powerful devices working smoothly. LT CIRCUIT creates smart designs that handle heat and last long. They are a reliable choice for advanced PCB needs.

FAQ

What is a thermoelectric separation substrate?

It is a special material used to separate PCB layers. This helps remove copper and other parts easily and quickly.

How does thermoelectric separation improve flexible PCB recycling?

It uses heat and electricity to safely recover copper. This keeps the PCB layers safe and makes recycling easier and greener.

Why is thermoelectric separation better for thermal management systems?

It improves heat flow by separating layers carefully. This helps devices work better in high-power and heat-control systems.

See Also

Utilizing Horizontal Copper Sinking Technology in PCB Manufacturing

Comprehensive Guide to Heavy Copper Multilayer PCB Production

Investigating Thermal and Electrical Performance of Aluminum PCBs

Impact of Vertical Continuous Electroplating on Copper Thickness Uniformity