Copper IMS PCB vs Aluminum IMS PCB Which Is Better for Your Application

When you need the right PCB for your project, LT CIRCUIT’s expertise demonstrates that copper ims pcb is the ideal solution where high thermal conductivity and superior electrical performance are essential, such as in automotive, LED, and power electronics applications. Aluminum IMS PCBs also provide a cost-effective, lightweight option for a variety of LED and computing device uses.

Key Takeaways

Copper IMS PCBs excel in high thermal conductivity, making them ideal for high-power applications like automotive and industrial electronics.

Aluminum IMS PCBs offer a lightweight and cost-effective solution, perfect for LED lighting and consumer electronics where budget and weight are key factors.

Choosing the right IMS PCB depends on your specific needs; consider factors like heat dissipation, weight, cost, and long-term reliability to make the best decision.

Material Types

When you choose a printed circuit board for your project, you often see the term insulated metal substrate. This type of board uses a metal base to improve heat management and mechanical strength. An insulated metal substrate pcb has three main layers: a metal base, a dielectric layer, and a copper circuit layer. The metal base, usually aluminum or copper, acts as a heat spreader. The dielectric layer sits between the metal and the copper circuit, allowing heat to move away from components while keeping the circuit electrically isolated. This design helps lower thermal resistance and boosts reliability.

Tip: IMS PCBs are popular in high-power and high-heat applications because they move heat away from sensitive parts, making your devices last longer.

LT CIRCUIT leads the way in using advanced materials and technology for insulated metal substrate pcb solutions. The company uses low-loss dielectrics for faster signals, strong laminates with special resin for better performance, and even 3D-printed electronics for complex designs. These innovations help you get the most out of your PCB, no matter the application.

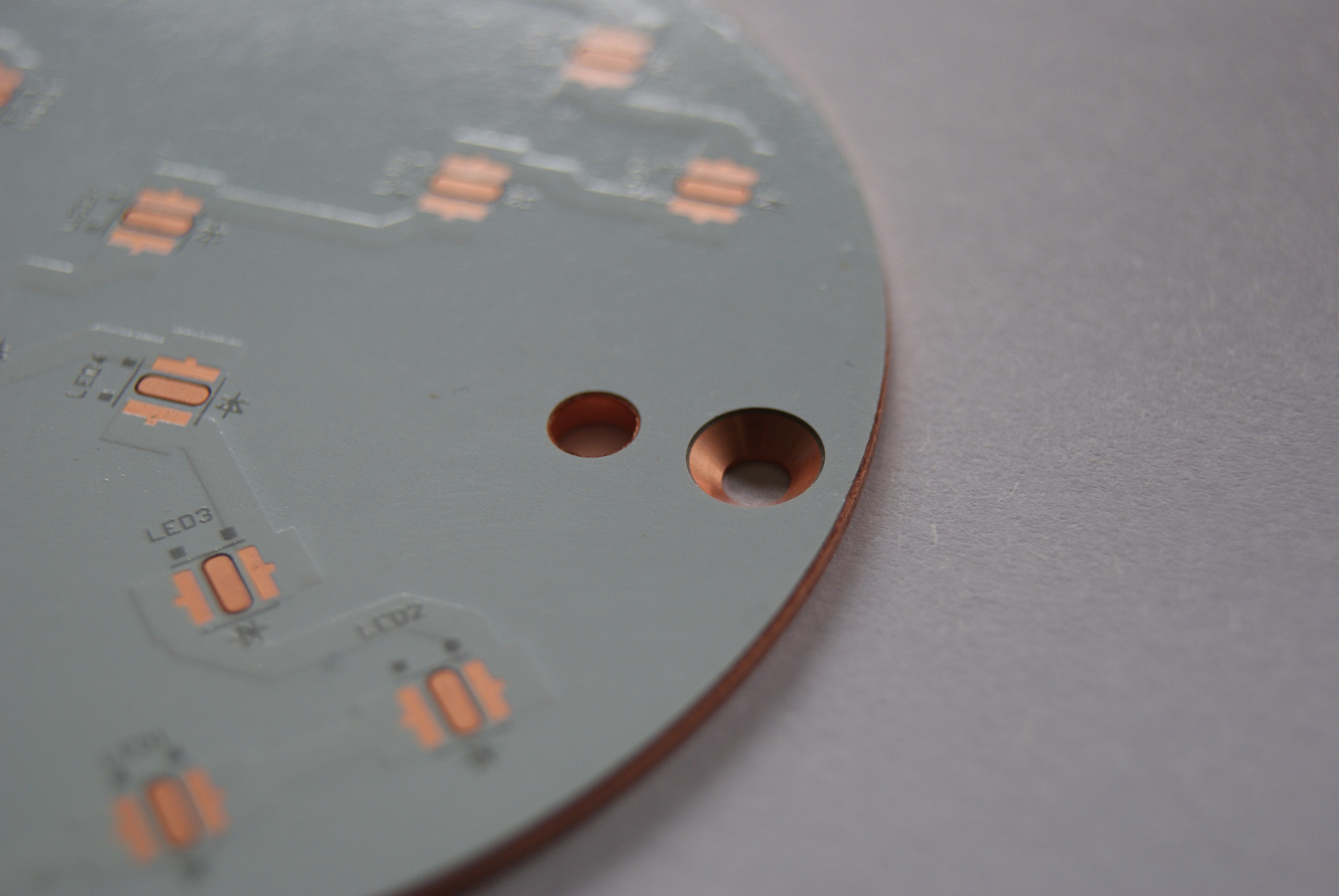

Copper IMS PCB

Copper ims pcb uses a copper base layer instead of aluminum. Copper offers higher thermal conductivity, which means it moves heat away from components more efficiently. This type of board works well in situations where you need to handle high current or where heat management is critical. You often see copper IMS PCBs in automotive electronics, power supplies, and other demanding environments.

Key Features:

Excellent thermal conductivity (385 to 401 W/mK)

High mechanical strength

Suitable for high-current and high-stress applications

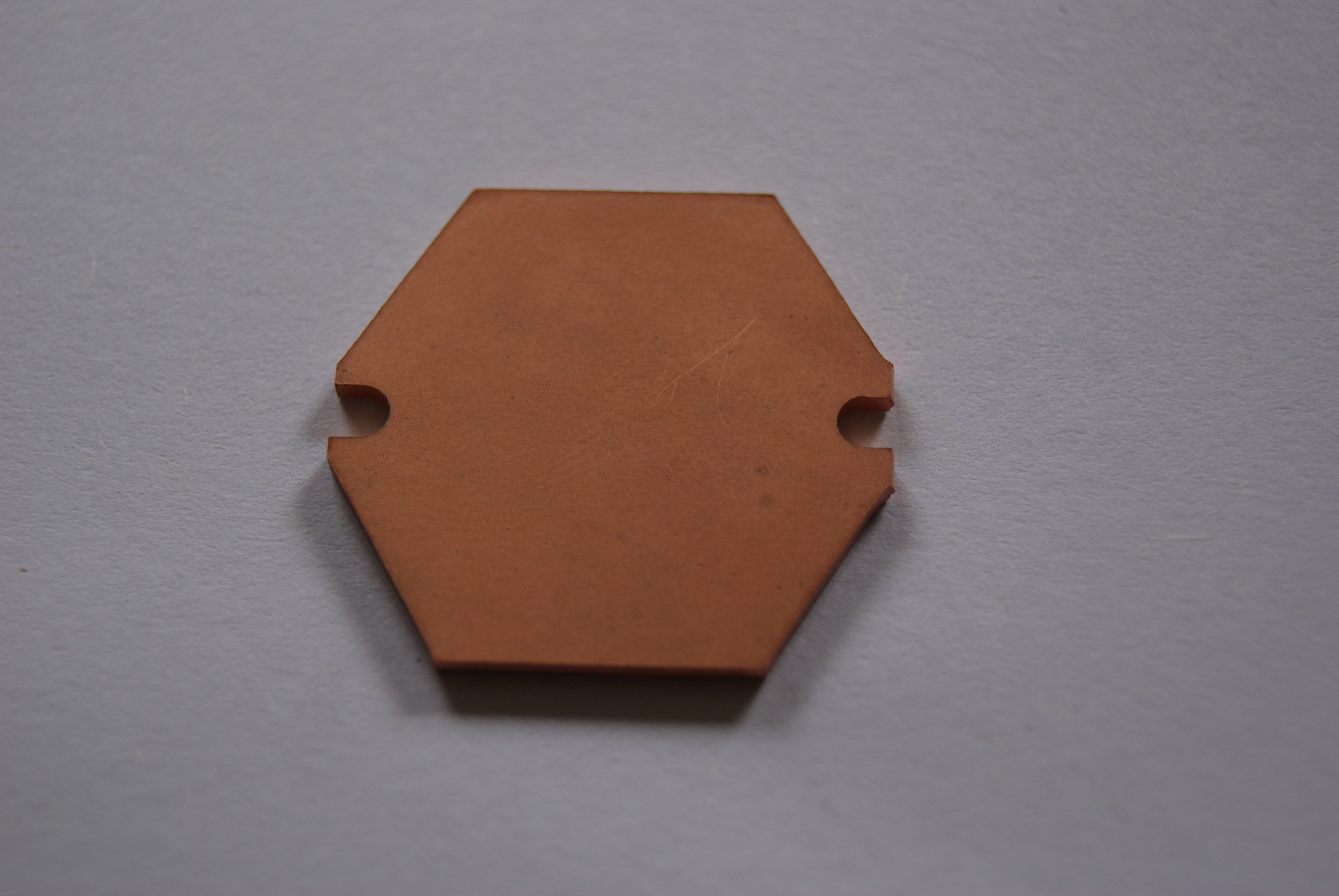

Aluminum IMS PCB

Aluminum IMS PCBs use an aluminum base layer. Aluminum is lighter and more cost-effective than copper. It still provides good thermal conductivity, making it a popular choice for LED lighting and power electronics. You benefit from a lighter board that is easier to handle and install.

Key Features:

Good thermal conductivity (160 to 220 W/mK)

Lightweight and cost-effective

Common in LED and computing devices

Here’s a quick comparison to help you see the differences:

Feature | Aluminum IMS PCBs | Copper IMS PCBs |

|---|---|---|

Material Composition | Thin layer of aluminum (0.5mm to 3mm) | Layer of copper (1 oz. to 10 oz.) |

Thermal Conductivity | 160 to 220 W/mK | 385 to 401 W/mK |

Mechanical Strength | Lower, not suitable for high stress | Higher, suitable for high current |

Weight | About 3 times lighter than copper | Heavier than aluminum |

Manufacturing Cost | Lower cost | More expensive |

Applications | LED lighting, power electronics | Power supplies, automotive electronics |

You can rely on LT CIRCUIT to deliver both types of IMS PCBs with top-quality materials and the latest innovations. This ensures your application gets the best balance of thermal conductivity, strength, and cost.

Thermal Performance

Copper IMS PCB Thermal

You get outstanding thermal performance when you choose a copper ims pcb. Copper has a much higher thermal conductivity than many other materials. This means it moves heat away from components quickly. In high power electronics, this feature helps prevent overheating and keeps your devices reliable. The copper base layer can reach thermal conductivity values close to 400 W/m·K. This level of heat dissipation is much better than standard FR4 boards, which often fall short in thermal management.

When you use copper IMS PCBs, you lower thermal resistance and improve the lifespan of your electronics.

Here’s a quick comparison to show how copper IMS PCBs stand out:

Material Type | Thermal Conductivity (W/m·K) | Performance in High-Power Applications |

|---|---|---|

FR4 | Lower than 400 | Falls short in thermal performance |

Copper IMS | Superior heat management and reliability |

You can see that copper IMS PCBs offer the best choice for demanding environments.

Aluminum IMS PCB Thermal

Aluminum IMS PCBs also provide strong thermal management. Aluminum has good thermal conductivity, usually ranging from 1 to 7 W/m·K. This allows for effective heat dissipation in many applications, especially in LED lighting and computing devices. You benefit from lower thermal resistance compared to traditional boards. While aluminum does not match copper’s thermal conductivity, it still gives you a reliable solution for moderate heat loads.

For many projects, aluminum IMS PCBs deliver a balance of cost, weight, and thermal performance.

If your application does not require the highest level of heat control, aluminum IMS PCBs can meet your needs while keeping your devices cool and efficient.

Electrical Conductivity

Copper IMS PCB Conductivity

You get excellent electrical conductivity when you use a copper ims pcb. Copper stands out as one of the best conductors of electricity. This property helps your circuits carry signals with very little loss. In high-frequency and high power applications, you want to keep resistive losses as low as possible. Copper’s high thermal conductivity also supports this by reducing heat buildup, which can affect signal quality.

High electrical conductivity in copper reduces resistive losses. This is important for signal integrity, especially at high frequencies.

The skin effect causes current to flow near the surface of copper traces at GHz frequencies. Smooth copper surfaces help minimize these losses.

Copper’s low thermal resistance means your board can handle more current without overheating.

You can trust copper IMS PCBs for applications where signal quality and efficiency matter most. These boards work well in advanced LED systems, automotive electronics, and power supplies.

Aluminum IMS PCB Conductivity

Aluminum IMS PCBs offer good electrical performance for many uses. Aluminum conducts electricity well, but not as well as copper. This difference becomes more noticeable in high-frequency circuits. If you need a board for moderate power or standard LED lighting, aluminum IMS PCBs can meet your needs.

Aluminum has lower conductivity than copper. This may affect performance in high-frequency applications.

You may see more resistive losses in aluminum, which can impact signal integrity.

Aluminum still provides solid thermal conductivity, helping manage heat in your devices.

You should choose aluminum IMS PCBs when you want a balance of cost, weight, and thermal performance. These boards work best in applications where extreme signal integrity is not the main concern.

Weight & Strength

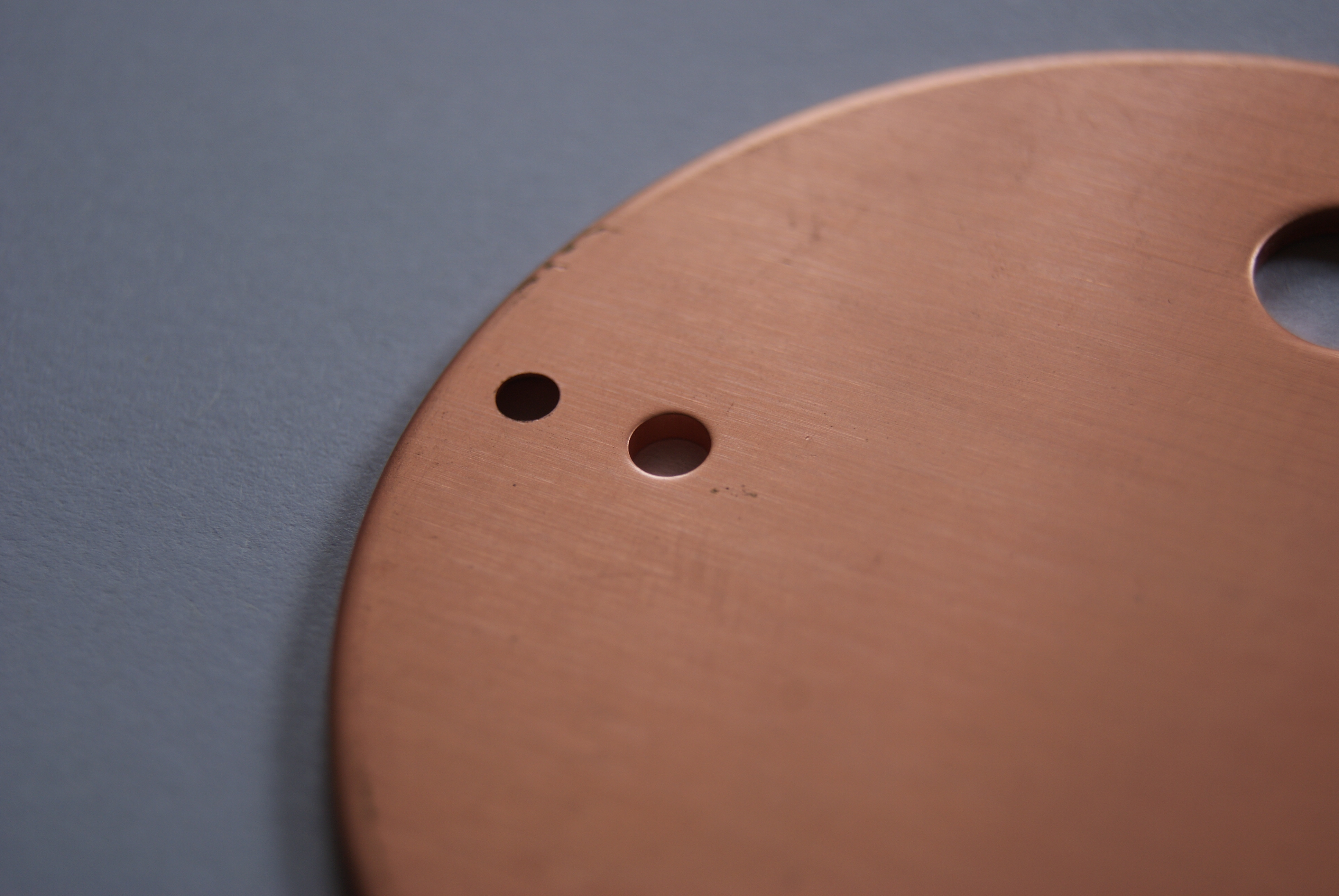

Weight Comparison

You need to consider weight when choosing between copper IMS PCB and aluminum IMS PCB. Aluminum is about three times lighter than copper. This difference becomes clear when you look at standard board sizes. If you want a lightweight device, aluminum IMS PCBs help you reduce the overall weight. This makes them a great choice for portable electronics or products where weight matters. Copper IMS PCB adds more mass, which can increase shipping costs and make handling harder. Lighter boards also make assembly easier and can improve the design of your final product.

Mechanical Strength

Mechanical strength plays a big role in how your PCB performs in tough environments. Copper IMS PCB offers higher mechanical strength than aluminum IMS PCB. You get better support for heavy components and more resistance to bending or breaking. This is important in high power applications where the board faces stress from heat dissipation and thermal management. Stronger boards also help lower thermal resistance, which keeps your circuits safe and reliable. If your project needs a board that can handle stress and last longer, copper IMS PCB gives you the durability you need.

Cost Factors

Copper IMS PCB Cost

When you select a copper IMS PCB, you invest in a premium solution. Copper costs more than aluminum, which directly affects your project budget. The price per square meter for copper IMS PCBs is typically 1.5 to 2 times higher than aluminum-based options. You can see the difference in the table below:

Type of IMS PCB | Cost per square inch | Cost Comparison to Aluminum |

|---|---|---|

Aluminum-Based IMS PCB | $0.20 | Baseline |

Copper-Based IMS PCB | 1.5x to 2x more | 1.5x to 2x more |

Copper IMS PCBs often appear in high power applications, such as automotive or industrial electronics. These projects require excellent thermal and electrical performance, which justifies the higher cost. However, you may notice that costs can rise quickly, especially for large-scale or LED projects. You can manage your budget by working with LT CIRCUIT to optimize your design and manufacturing process.

Note: Copper mining and recycling can impact the environment. The industry continues to seek eco-friendly practices to reduce its footprint.

Aluminum IMS PCB Cost

Aluminum IMS PCBs offer a cost-effective choice for many applications. You pay less per square meter compared to copper-based boards. This makes aluminum a popular option for LED lighting, computing devices, and consumer electronics. Lower material costs help you keep your project within budget, especially when you need many boards.

Aluminum IMS PCBs provide good thermal management at a lower price.

You benefit from a lighter board, which can reduce shipping and handling costs.

The recycling process for aluminum is less complex than copper, supporting sustainability goals.

You can rely on LT CIRCUIT to help you balance performance and cost, ensuring your application gets the right solution.

Application Fit

LT CIRCUIT gives you the flexibility to choose the right insulated metal substrate pcb for your industry. You can select from a wide range of solutions, each designed to meet specific performance needs. Whether you need high power handling, lightweight construction, or cost efficiency, LT CIRCUIT can customize your insulated metal substrate pcb to fit your requirements.

Copper IMS PCB Uses

You often see copper ims pcb in industries that demand the highest thermal and electrical performance. These boards work well in environments where heat, vibration, and reliability matter most. The copper-based ims pcb stands out in applications that require excellent heat dissipation and strong mechanical support.

Here is a table showing common uses and the performance requirements that drive the selection of copper IMS PCBs:

Application | Performance Requirement |

|---|---|

Automotive | Reduces overheating in LEDs/batteries – longer lifespan, lower maintenance |

Renewable Energy | Cuts heat loss in solar/wind systems – boosts efficiency, lowers costs |

Consumer Electronics | Prevents phone/tablet overheating – reliable performance, fewer repairs |

Medical Devices | Stable operation in critical tools – safer use, fewer replacements |

Aerospace/Defense | Withstands extreme temps/vibrations – reliable in harsh conditions |

Industrial Systems | Resists heat deformation – less downtime, higher productivity |

LED Lighting | Lowers temps in high-power lights – doubles lifespan, saves replacement costs |

You can rely on copper IMS PCBs for high power automotive modules, renewable energy converters, and advanced medical equipment. For example, LT CIRCUIT supplied oil rig sensors with a PTFE substrate and 2oz rolled copper. These sensors operated at 175°C and 95% humidity, lasting over five years in harsh downhole conditions. In aerospace avionics, LT CIRCUIT delivered ceramic-filled laminates with redundant traces and hard gold plating. These boards met NASA’s reliability standards and performed for over ten years in orbit.

Copper IMS PCBs also perform well in high-humidity or corrosive environments. You get boards that resist moisture and chemicals, ensuring reliable operation for up to 15 years. This makes them a strong choice for industrial and defense systems.

Aluminum IMS PCB Uses

Aluminum-based ims pcb offers you a lightweight and cost-effective solution for many industries. You benefit from good thermal management and efficient heat dissipation, especially in applications where weight and budget matter.

Here is a table showing where aluminum IMS PCBs excel and why industries prefer them:

Industry | Reasons for Preference |

|---|---|

LED Lighting | Superior thermal management, lightweight nature |

Automotive Electronics | Cost-effectiveness, high durability |

Medical Devices | Efficient heat dissipation |

Aerospace | Lightweight nature, superior thermal management |

Industrial Equipment | Cost-effectiveness, efficient heat dissipation |

You often find aluminum IMS PCBs in LED lighting, automotive controls, and industrial equipment. For instance, LT CIRCUIT helped an industrial high-bay lighting project dissipate 160W of heat using an aluminum-core PCB with a 2W/m·K thermal dielectric and integrated heat sink fins. This solution extended LED lifespan to over 60,000 hours, with less than 5% lumen loss after five years.

Aluminum IMS PCBs also suit automotive and aerospace applications where lightweight construction and moderate heat dissipation are key. You can use these boards in consumer power supplies and control modules, where cost efficiency and reliability are important.

Tip: LT CIRCUIT can tailor both copper and aluminum IMS PCBs to match your exact needs, from high power industrial drives to lightweight LED panels.

Decision Guide

Choosing the Right IMS PCB

Selecting the best IMS PCB for your project depends on your specific needs. You should look at factors like heat dissipation, weight, cost, and long-term reliability. Each material offers unique strengths. The table below gives you a quick comparison:

Material Type | Thermal Conductivity | Cost | Weight | Best Applications |

|---|---|---|---|---|

Aluminum | Lower | Lightweight | LED lighting, power supplies, automotive electronics | |

Copper | Up to 400 W/m·K | Higher | Heavier | Ultra-high-power applications (e.g., EV inverters) |

You should choose aluminum IMS PCBs if you want a lightweight and cost-effective solution. These boards work well in LED lighting and automotive electronics. Copper IMS PCBs suit you best when your project demands maximum heat dissipation and high reliability, such as in electric vehicle inverters or industrial power modules.

Tip: IMS PCBs act as built-in heat sinks. They pull heat away from important parts, which helps your devices last longer.

When you think about long-term reliability, remember these points:

IMS PCBs improve reliability by managing heat well.

Aluminum-based IMS is great for lower power needs, while copper-based IMS handles high-performance tasks.

The right material helps your board survive tough conditions and reduces maintenance.

Using finishes like ENIG or OSP protects against corrosion, making your board last longer.

Good mechanical design, such as screw supports and thicker bases, keeps your board safe from cracking.

You can talk with LT CIRCUIT to match your application with the right IMS PCB. This ensures your device runs efficiently and stays reliable for years.

You can use the table below to compare copper and aluminum IMS PCBs for your project:

Feature | Copper IMS PCBs | Aluminum IMS PCBs |

|---|---|---|

Conductivity | Superior | Moderate |

Strength | High | Lightweight |

Durability | Excellent | Good |

You should weigh your needs and consult LT CIRCUIT for expert, tailored PCB solutions.

FAQ

What is the main benefit of using a copper IMS PCB?

You get superior heat dissipation and electrical performance. Copper IMS PCBs work best for high-power or high-reliability applications.

Can you use aluminum IMS PCBs for high-power devices?

You can use aluminum IMS PCBs for moderate power. For extreme heat or current, copper IMS PCBs give you better results.

How do you choose between copper and aluminum IMS PCBs?

You should consider your budget, weight needs, and thermal requirements. Copper suits demanding tasks. Aluminum fits cost-sensitive or lightweight projects.

See Also

Utilizing Panasonic Copper-Clad Laminates in PCB Production Processes

Key Guidelines for Creating Heavy Copper PCBs for High Currents

Choosing Between Aluminum Base PCBs and FR4 for Designs

Implementing Horizontal Copper Sinking Techniques in PCB Manufacturing

Comprehensive Guide to Heavy Copper Multilayer PCB Production