Cost Optimization Strategies for Flex Rigid PCB Manufacturing Without Sacrificing Quality

Balancing cost optimization and quality in flex rigid PCB manufacturing is a daily challenge. Industry trends reveal that selecting the right materials, efficiently utilizing panels, and adopting new machines can reduce costs by up to 30%. LT CIRCUIT leads the way with innovative, high-quality PCB solutions that help you optimize costs while maintaining strength in a competitive market.

Key Takeaways

Make your PCB design simple by using less layers, basic shapes, and usual materials. This helps save money but keeps good quality.

Pick cheaper materials like FR-4 and adjust copper thickness. This helps you get good performance and a fair price.

Use machines, group boards together, and work well with suppliers. This makes production faster, cuts waste, and saves money.

Design

Stack-Up Simplification

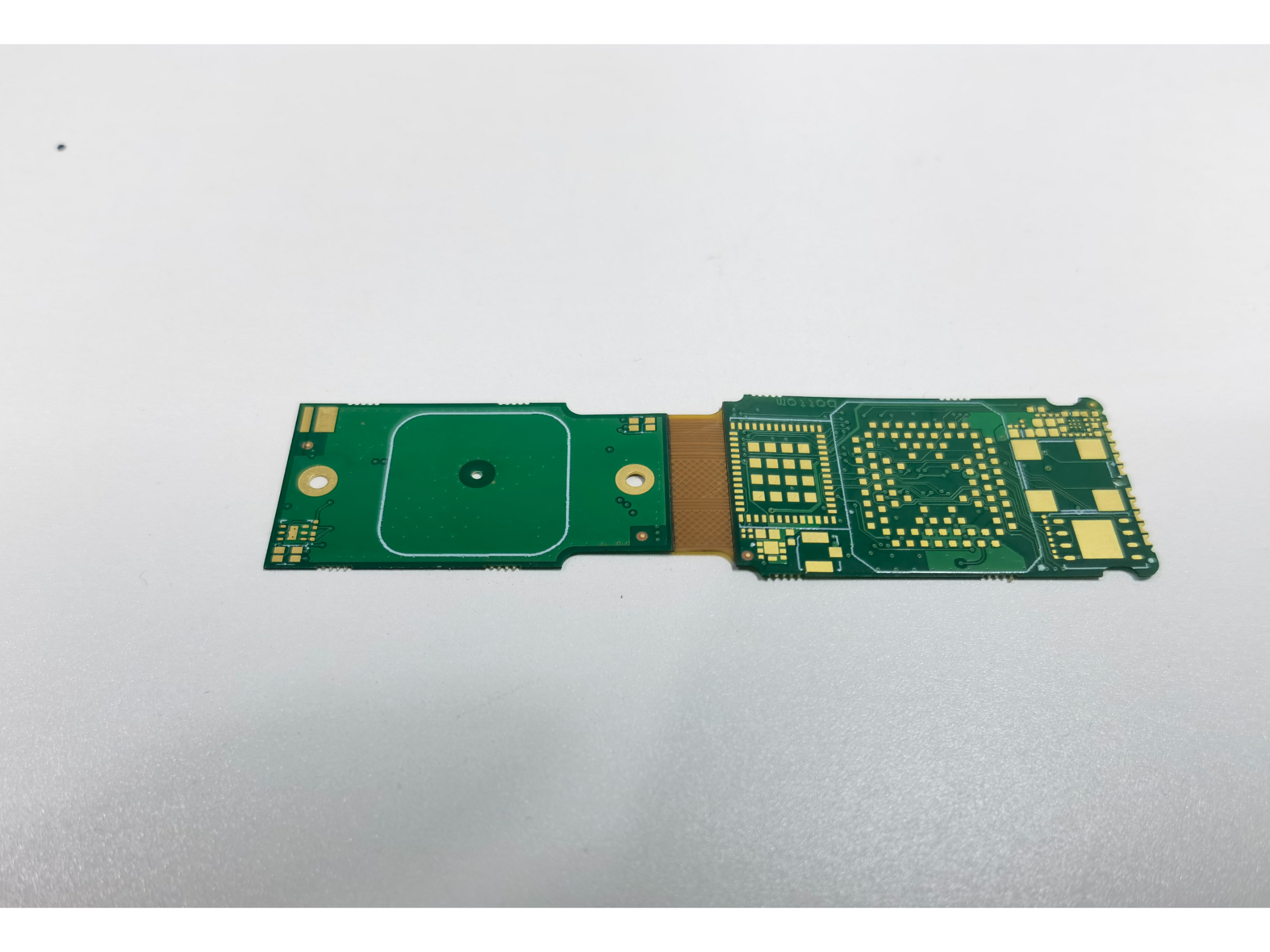

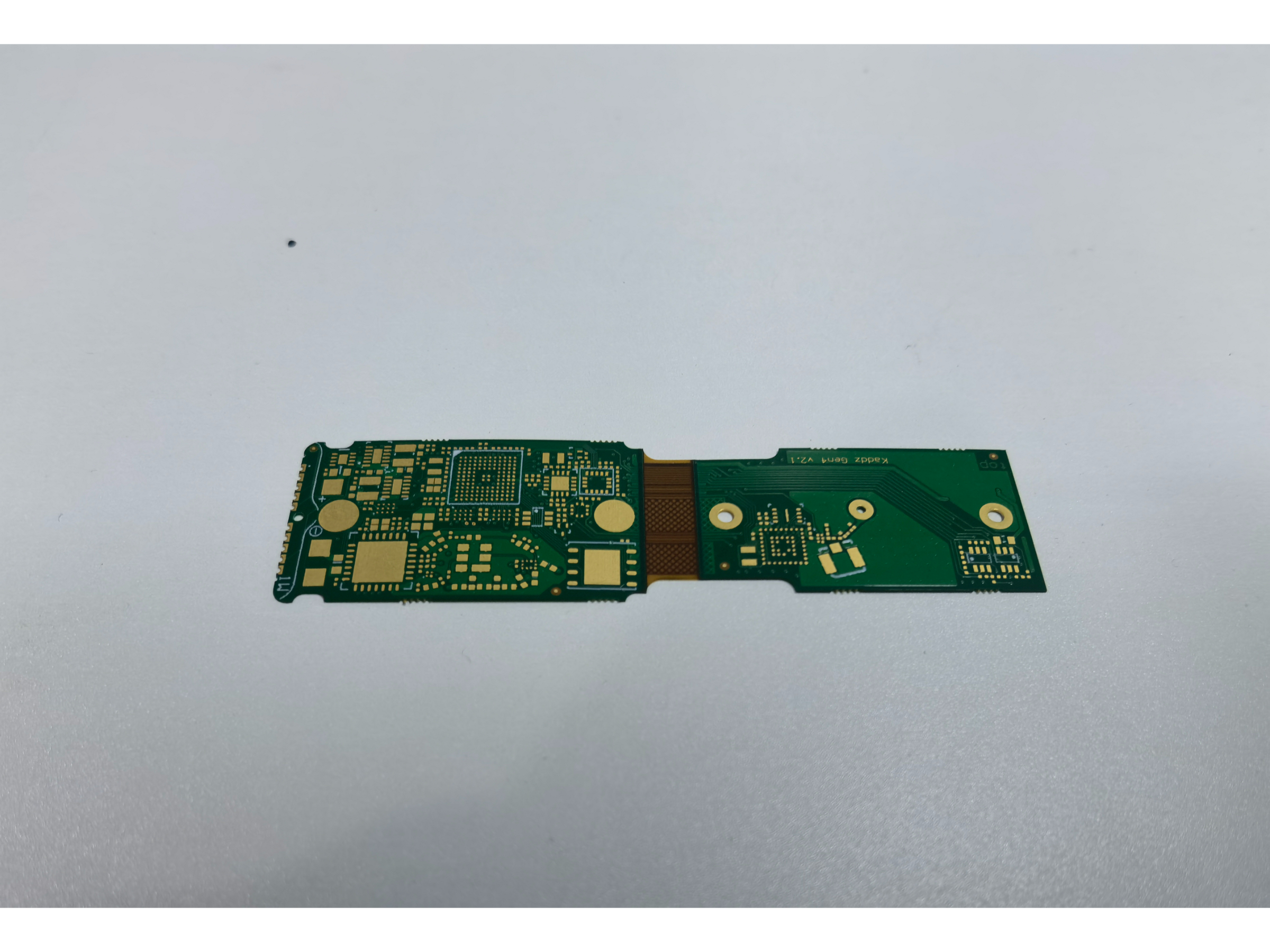

You can save money by making your PCB stack-up simple. Using fewer layers means you spend less on materials and lamination. Only use the layers you really need. This keeps things from getting too complicated. LT CIRCUIT’s team likes to use regular rectangle shapes and normal via sizes. These choices make building the PCB easier and quicker.

Tip: Talk to your manufacturer early. This helps you pick the best stack-up for cost and performance.

DFM Principles

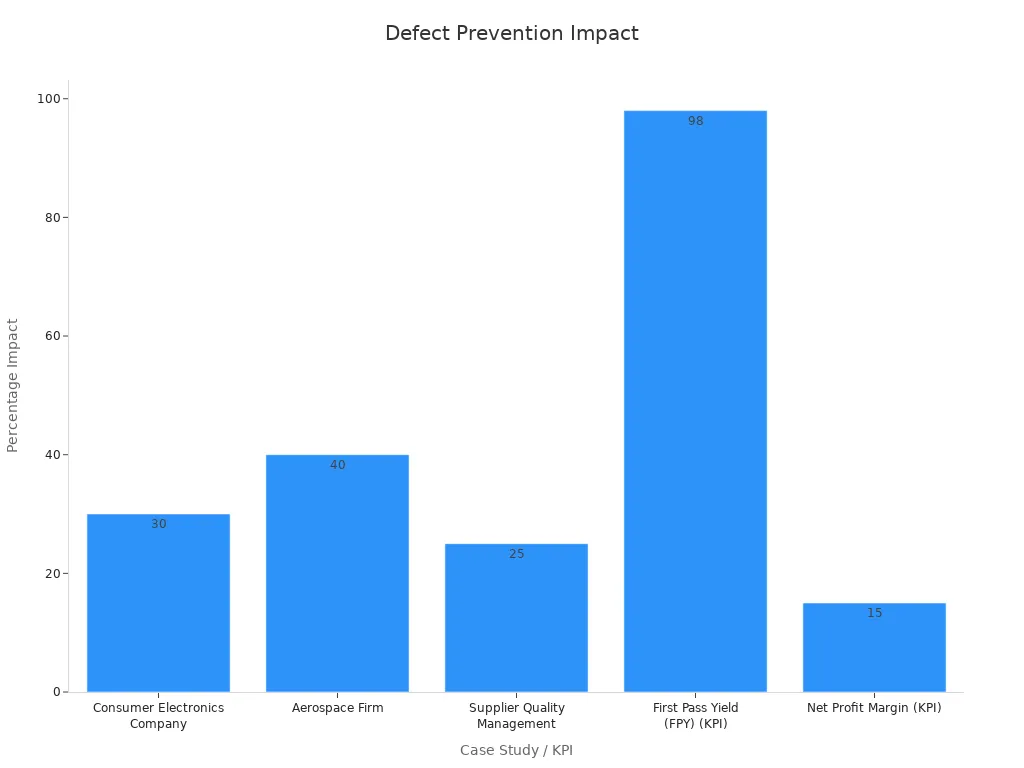

Design for Manufacturability, or DFM, makes PCBs easier to build and test. When you use DFM, you avoid making things too complex. You can make the bend radius and flex areas smaller. You also make trace width and spacing better, which helps more PCBs turn out right. Companies that use DFM have fewer mistakes and finish faster. One electronics company had 30% fewer defects and made PCBs 20% faster by using DFM. LT CIRCUIT uses special DFM tools to help you get these results too.

Minimize Layers

Having fewer layers costs less. Each layer you add needs more material and time. Always check if your design can work with less layers and still do its job. The table below shows how your choices change the cost:

Design Factor | Cost Impact | Strategy |

|---|---|---|

Number of PCB layers | More layers increase cost | Minimize layers |

Via count and size | Small, many vias raise cost | Use standard sizes, reduce via count |

PCB shape | Odd shapes cost more | Use standard shapes |

If you use these ideas, you can save money and keep good quality. LT CIRCUIT helps make sure your design fits your needs and your budget.

Materials

Cost-Effective Choices

You can spend less on your PCB by picking smart materials. FR-4 is a good choice for most projects. It works well and does not cost too much. Use regular copper thickness, like 1 oz or 2 oz, unless you need more power. Pick HASL for the surface finish. It costs less than ENIG or gold plating. Choose green solder mask and white silkscreen to save money. These are standard colors and do not add extra cost. When you pick materials that fit your project, you do not pay for things you do not need.

Tip: Use the same materials for different designs. This helps you buy more at once and get better deals from suppliers.

Alternative Substrates

You can save more by using other substrates sometimes. Polyimide is good for flexible PCBs and is cheaper than some high-end materials. Polyester is another choice for simple jobs. It is stable and keeps out water, but costs less than polyimide. For rigid parts, you can use CEM-1 or CEM-3 instead of FR-4 if you do not need high heat resistance. The table below shows how these substrates compare:

Application | Recommended Substrate | Cost per Unit Area | Max Temp Rating | Typical Use Case |

|---|---|---|---|---|

Automotive ECU | FR-4 (Tg 170°C) | ~$18.50/m² | 170°C | High-reliability, high-temp use |

Home IoT Devices | CEM-3 | ~$12.80/m² | 130°C | Cost-sensitive consumer electronics |

LED Controllers | CEM-1 | ~$9.20/m² | 110°C | Non-critical, budget applications |

If you use CEM substrates for the right jobs, you can cut material costs by up to 30%.

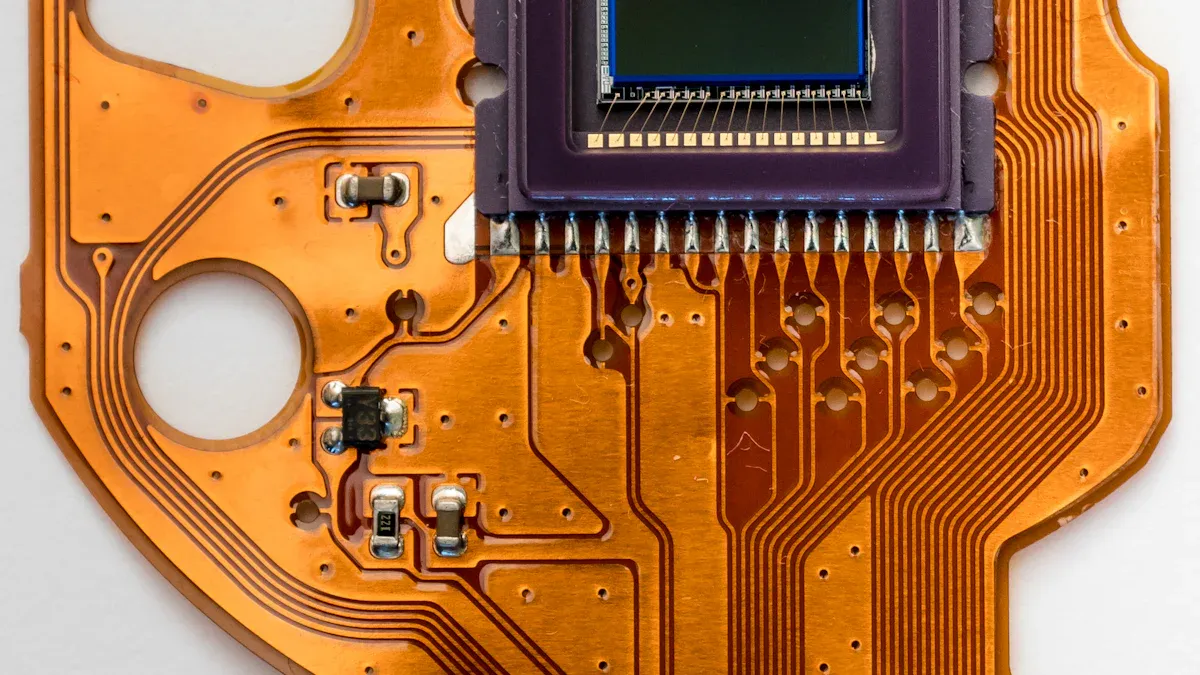

Optimize Copper Weight

Copper thickness changes cost and how your PCB works. Thinner copper, like 1 oz, is fine for most circuits and saves money. Only use thick copper if you need to carry more current. Flex rigid PCBs let you pick copper weight for each part. This helps you balance cost and what your PCB needs to do. By picking the right copper for each section, you do not waste money on extra material.

Process

Automation

Using automation helps factories work faster and save money. Machines can do jobs like soldering, drilling, and checking boards. They do these jobs quickly and do not make many mistakes. Automated Optical Inspection, or AOI, looks for problems very fast. It can check over 10,000 parts every hour. This means workers do not have to check as many boards by hand. Manual inspection time goes down by about 70%. In-Circuit Testing and X-ray inspection also help find hidden problems fast. When factories use machines for these jobs, they pay less for workers. They can also make boards quicker. Many factories say they spend 10-15% less on labor. They also send out orders faster. Automation makes each step better and helps save money.

Panelization

Panelization means putting many PCB designs on one big panel. This helps use materials better and makes less waste. More boards fit in each batch, so each board costs less. Using standard panel sizes makes it easier to move and work with panels. Good panel layouts leave less empty space and help make more boards at once. LT CIRCUIT uses special software to plan the best panel layouts. This helps make more boards and waste less material. It also keeps the factory running well and saves money.

Yield Improvement

Making more good boards and fewer bad ones is called yield improvement. You can watch some numbers to see how well you are doing:

Metric | Quantitative Impact | Explanation |

|---|---|---|

Yield Rate | More working boards, less waste | |

Cost Per Unit Reduction | 15%-20% decrease | Lower cost for each board |

Production Efficiency | 30% improvement | Faster output, shorter cycle times |

When you get more good boards, you do not have to fix or throw away as many. You also use the same materials and time to make more boards. This helps you spend less and still make high-quality products.

Cost Optimization with LT CIRCUIT

Supplier Partnerships

When you work with LT CIRCUIT’s suppliers, you get many benefits. These strong partnerships help you pay less and get your boards faster. You also get your deliveries on time. LT CIRCUIT uses computer models to find the best prices for you. They use these tools to talk with suppliers and get good deals. You get updates about costs and delivery times. This helps you plan your projects better.

You can see what is happening and make smart choices.

You spend less on extra parts and can change designs quickly.

You get help finding the best places to buy, which saves money.

Case studies show that companies working with suppliers save a lot of money each year. They do this by lowering product costs and working closely with their suppliers. You can get these savings and work better with LT CIRCUIT.

Volume Discounts

Buying more boards at once helps you save money. LT CIRCUIT gives you discounts when you order in big amounts. When you buy in bulk, each board costs less. This is because setup and material costs are shared over more boards. It is cheaper than buying just a few at a time.

Studies show that suppliers make their work better when you order more. They learn and improve, which lowers your costs even more. You also build a good relationship with suppliers. This helps you get better prices and faster service.

Order Quantity | Cost per Unit | Savings (%) |

|---|---|---|

5 units | $3.02 | — |

20 units | $1.01 | 66% |

Tip: Try to plan your orders so you can buy in bulk. This helps you save money and stay ahead of others.

Custom Solutions

LT CIRCUIT makes special PCBs just for you. You can work with their engineers to pick the right size, number of layers, and materials. If you use normal sizes and simple shapes, your boards are easier and cheaper to make. You also save by using common parts instead of special ones.

LT CIRCUIT uses smart tools and fast building methods. These help you finish your project up to 30% faster. You can also get your products ready for sale more quickly and spend less money.

Strategy | Description | Impact on Cost Optimization |

|---|---|---|

Makes building easier and lowers mistakes | Saves money on fixing errors | |

Speeds up how fast you can test ideas | Cuts down on time and costs | |

Checks quality better | Lowers the cost of fixing problems | |

Uses materials well and lowers each board’s cost | Saves a lot of money |

You can also work with LT CIRCUIT to find more ways to save. Their team uses special tools and new factory methods to make sure you get great boards for less money. This way, you save money but still get high quality.

Quality Control

Efficient Testing

Good testing keeps flex rigid PCBs working well and saves money. LT CIRCUIT uses special tools and follows strict IPC rules. These rules cover things like soldering, plating, and how boards handle heat. You can watch some key numbers to check quality:

First Pass Yield (FPY) shows how many boards pass the first test.

Defect Rate tells you how many boards have problems.

Cycle Time is how long it takes to test each board.

Throughput counts how many boards you finish in a certain time.

Overall Equipment Efficiency (OEE) checks if machines work well.

Rework and Repair Rate tracks how many boards need fixing.

Watching these numbers helps you find problems early. This lets you fix things fast and save money.

In-Process Checks

It is important to check quality during every step, not just at the end. LT CIRCUIT uses sensors and computers to watch for problems as they happen. This means you can fix mistakes right away. It keeps defect rates low and stops waste. The table below shows how checking during the process helps save money and keep quality high:

KPI | Description and Role in In-Process Checks |

|---|---|

Defect rates | Finding problems early lowers waste and fixing costs. |

First-pass yield | High numbers mean fewer problems and less waste. |

Scrap and rework rates | Lower numbers show strong checks during the process. |

Customer complaint rates | Fewer complaints mean better products and happier customers. |

Using automation and AI helps you get good data. It also lets your team focus on more important jobs.

Early Defect Prevention

Stopping problems before they start saves time and money. LT CIRCUIT does this with regular machine care, training workers, and checking suppliers. Companies that stop defects early see big changes:

For example, one car company had 20% less downtime and 50% fewer defects. An electronics company had 30% fewer defects by using quality circles. These steps help you get more good boards, spend less on repairs, and make more money. Stopping defects early is smart for saving money and doing well in the long run.

You can save money by using smart design and picking the right materials. Using machines and working with suppliers also helps lower costs. Good quality checks with AI and IoT sensors catch problems early. Following industry rules keeps defects and costs down. LT CIRCUIT gives you strong, high-quality flex rigid PCB solutions. This helps you stay ahead and work better than others.

FAQ

What is the main way to lower flex rigid PCB costs?

You can make your design simple. Use regular materials that are easy to get. Buy lots of boards at one time. These steps help you spend less money. You still get good quality.

How does LT CIRCUIT ensure high quality at lower costs?

LT CIRCUIT uses smart testing and machines to check boards. They work with trusted suppliers to get good deals. You get strong PCBs with fewer problems and better prices.

Can you customize flex rigid PCBs for special projects?

Yes, you can. LT CIRCUIT engineers help you pick size, layers, and materials. Custom boards match what your project needs and fit your budget.

See Also

Top Strategies To Reduce Expenses In Custom PCB Manufacturing

Comprehensive Overview Of Flexible PCB Production Techniques

Major Benefits Of Rigid-Flex PCBs In Compact Electronics

Industrial Rigid PCB Production: Materials, Methods, And Quality

Step-By-Step Guide To Manufacturing Multilayer Rigid-Flex Boards