Critical Applications of Aluminum PCBs in the Automotive Industry

Aluminum PCBs are now very important in cars. New cars use a lot of electronics. These PCBs help move heat away fast. They are light and do not rust easily. Car makers get better safety, reliability, and efficiency. Aluminum PCBs help with power, lights, and control systems in cars today.

Key Takeaways

Aluminum PCBs help car electronics stay cool and strong. They move heat away fast. This helps parts last longer. It also helps them work better.

These PCBs are light and tough. They do not break easily from bumps or heat. This makes them good for power systems, lights, sensors, and control modules in cars.

Using aluminum PCBs makes cars lighter. This helps cars use less fuel. It also helps cars become safer, smarter, and better for the environment.

Aluminum PCBs Overview

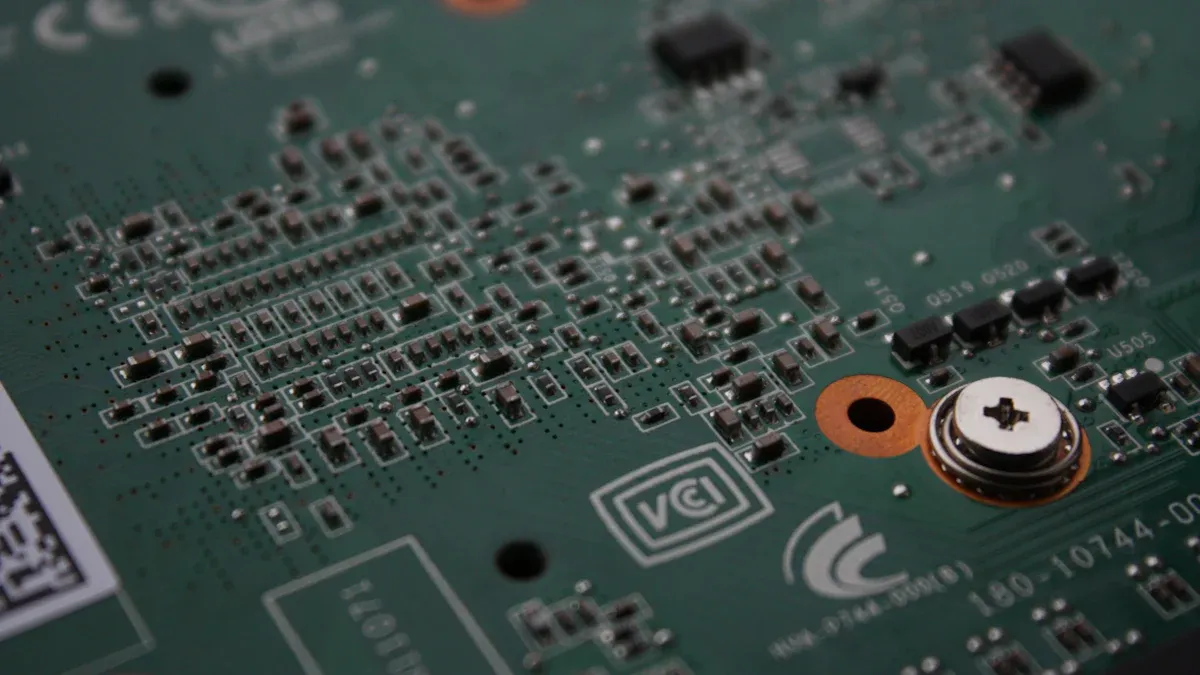

Structure and Materials

Aluminum PCBs are different from regular printed circuit boards. They have a special structure. These boards use a metal core. The core is usually aluminum, not fiberglass. The metal core helps heat move away fast. This protects important parts in car electronics. Most aluminum PCBs have three layers:

The metal base plate is made of aluminum. It gives the board strength and helps heat move away.

The dielectric layer sits between the metal base and the copper circuit. This layer lets heat pass through but stops electricity from crossing.

The copper circuit layer is on top. It makes the paths for electric signals.

This design helps aluminum PCBs manage heat well. They also stay strong and stable. The metal core blocks electromagnetic interference. This is very important in cars.

Key Properties

Aluminum PCBs have many good features for cars.

High thermal conductivity helps move heat away from power parts. This keeps systems cool.

Mechanical strength lets them handle shaking and bumps in cars.

Being lightweight helps lower the weight of car systems.

Cost-effectiveness means they last long and need fewer repairs.

Property | Description |

|---|---|

Thermal Conductivity | Moves heat away fast, keeps electronics safe in hot conditions. |

Mechanical Strength | Handles bumps and shakes, lasts longer in tough environments. |

Weight | Lighter than other printed circuit boards, helps cars stay efficient. |

Cost-Effectiveness | Saves money over time with fewer repairs and longer life. |

Aluminum PCBs use smart designs like thermal vias and careful part placement. These help balance heat and signal quality. More cars use aluminum PCBs now. They are chosen because they are strong and work well.

Importance in the Automotive Industry

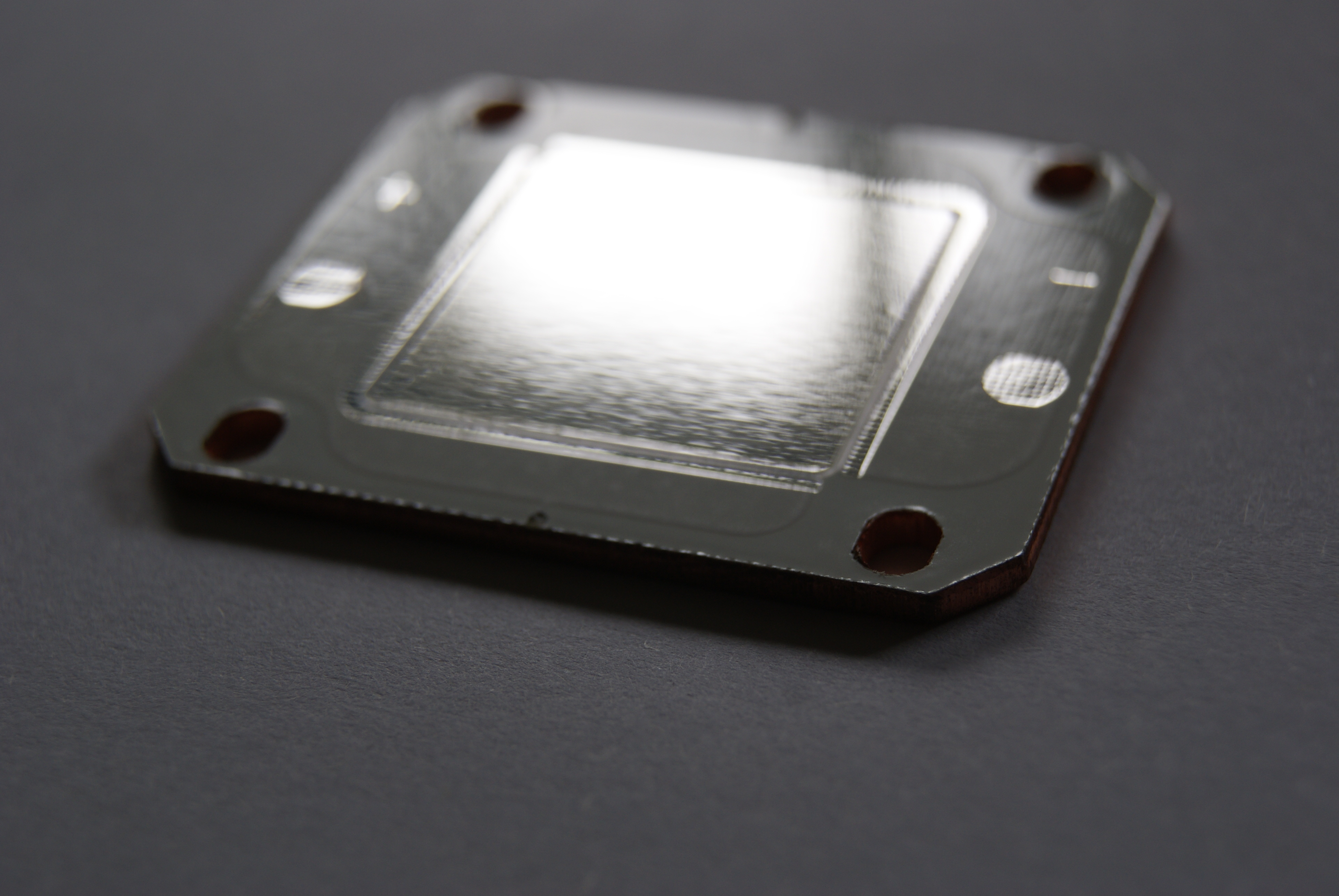

Heat Dissipation

Cars today use advanced electronics that make a lot of heat. Aluminum PCBs help control this heat, even in tough places. The metal core works like a strong heat sink. It moves heat away from important parts. This helps things like engine control units and LED headlights work well. Electric vehicle power modules also stay cool and safe.

Aluminum PCBs have special copper traces and thermal vias. They also use balanced dielectric layers to move heat better. These choices help keep parts cooler. Cooler parts last longer and work better. Systems can use more power without getting too hot. For example, LED headlights and battery management systems in electric cars stay at safe temperatures. This helps them last longer and work well.

Durability and Reliability

Car electronics face hard conditions like shaking, bumps, water, and big temperature changes. Aluminum PCBs are strong and can handle these problems. Their hard structure keeps them safe from damage. The aluminum base stops rust and keeps out water. This strength helps car systems work for a long time.

Aluminum PCBs also help slow down wear and tear on parts. They lower heat stress and stop materials from getting tired. This means important car parts last longer. LT CIRCUIT makes strong aluminum PCBs for cars. They help car makers build safe and reliable vehicles.

Applications in Automotive Components

Aluminum PCBs are very important in many car parts. Their special features make them a top pick for many uses. LT CIRCUIT makes great products for these needs. They help with new car technology.

Power Management

Power management is key in today’s cars. Aluminum PCBs help control and share energy in battery units, inverters, and converters. These boards can handle lots of electricity and heat. They keep battery packs and drive parts cool and safe. LT CIRCUIT makes strong aluminum PCBs for power systems. Their boards help car parts work well and last longer.

Lighting Systems

Car lights have changed with new LED technology. Aluminum PCBs are now used in headlights, taillights, and inside lights. They act as heat sinks and move heat away from LEDs fast. This keeps lights bright and working well, even when it’s tough. Some main benefits are:

Fast and even heat flow, which keeps LEDs from getting too hot.

Strong boards, so they don’t break from shaking or bumps.

Light weight, which helps make car parts lighter.

EMI shielding, which keeps signals clear and steady.

Boards stay the same shape, even when they get hot.

Aluminum PCBs also stick together well and can handle high heat when soldered. This makes them great for car lights. LT CIRCUIT makes custom boards for LED lights. Their boards help lights last long and work well.

Control Modules

Control modules help run many car systems. These include engine control units, transmission controllers, and body control modules. Aluminum PCBs help by moving heat away and staying strong. They protect important electronics from heat and shaking. This is very important for systems that control how the car moves, keeps people safe, and makes rides comfy. LT CIRCUIT makes aluminum PCBs for these control modules. Their boards work in both regular and electric cars.

Sensors and Safety

Sensors and safety systems need strong and steady electronics. Aluminum PCBs are used in airbag controllers, anti-lock brakes, and driver-assist features. Their strong boards can handle shaking and do not catch fire easily. They also help keep radar and camera modules cool. These are needed for new safety tech. LT CIRCUIT knows how to make good aluminum PCBs for sensors and safety. Their boards help make cars safer.

Note: LT CIRCUIT has many products and can make custom boards. Car makers can pick the best aluminum PCB for each job. Their focus on quality and new ideas helps car electronics and power systems get better.

Advanced Applications

Electric Vehicles

Aluminum PCBs are very important in new electric vehicles. These cars need strong electronics to handle power and heat. LT CIRCUIT makes aluminum PCBs that help with this. Their boards have metal cores and special copper layers. This helps heat move away from power parts. It keeps inverters, converters, and motor controllers cool and safe.

Metal core PCBs help heat move away fast. This is important for power electronics in electric vehicles.

Thicker copper in some places lets more electricity flow where needed.

These boards can take higher heat and support big power needs.

Good heat control stops overheating. This makes systems work better and last longer.

Aluminum bases help with changes in temperature. This makes the boards stronger.

LT CIRCUIT works with car makers to make special boards. Their smart designs help cars work better and last longer, even when driving is hard.

ADAS and Infotainment

Today’s cars use ADAS and infotainment for safety and fun. Aluminum PCBs help these systems by moving heat and power well. The need for double-sided aluminum PCBs is growing fast. This is because cars need strong electronics. Experts think this market will be about $4.3 billion by 2033. Most of this growth comes from cars.

ADAS and infotainment need PCBs that can handle lots of power. They must also work in tough places. LT CIRCUIT makes special aluminum PCBs for these needs. Their boards help data move well and keep electronics safe, even when it is hard. As more cars use new electronics, aluminum PCBs from LT CIRCUIT will stay important for safe and fun driving.

Benefits for the Automotive Industry

Weight Reduction

Aluminum PCBs help cars weigh less. Their metal core is thin and light. This is better than the heavy FR4 boards. In cars, every kilogram is important. Lighter cars use less energy to move. This helps cars go faster and handle better. Car makers pick aluminum PCBs for LED headlights and power modules. These parts need to be strong but not heavy.

The table below shows how aluminum PCBs and FR4 PCBs are different:

Feature | Aluminum PCBs | Traditional FR4 PCBs |

|---|---|---|

Thermal Conductivity | Low (0.3 W/mK) | |

Weight and Thickness | Lighter and thinner | Thicker and heavier |

Thermal Management | Efficient heat spreader | Needs extra heat sinks |

Durability and Lifespan | Durable in tough conditions | Less efficient under high heat |

Cost | Higher, but better performance | Lower, for general use |

Flexibility | Rigid | More flexible |

LT CIRCUIT uses these good points to help car makers. They help build lighter and smarter cars.

Fuel Efficiency

When cars are lighter, they use less fuel. The engine or motor does not have to work as hard. This saves gas in regular cars. It also helps batteries last longer in electric cars. Aluminum PCBs also help keep systems cool. Cooler systems work better and waste less energy. This makes car parts last longer.

LT CIRCUIT cares about quality and new ideas. Their aluminum PCBs help car makers meet tough fuel rules. By using smart designs and new materials, LT CIRCUIT helps make cars greener and more efficient.

Aluminum PCBs help make cars safer and better. They also help new ideas in car technology. LT CIRCUIT makes strong and trusted products for cars.

More people want advanced PCBs for electric cars, ADAS, and infotainment.

New technology and growth in different places will make even more cars use these PCBs soon.

FAQ

What makes aluminum PCBs better for automotive electronics?

Aluminum PCBs take heat away fast. They do not break in hard places. Car parts work well and last longer with these boards.

Where does LT CIRCUIT provide the most value in automotive PCBs?

LT CIRCUIT makes special aluminum PCBs for power, lights, and safety. Their boards help car makers build safe and smart cars.

Can aluminum PCBs help electric vehicles perform better?

Yes. Aluminum PCBs keep electric car parts cool. They handle lots of power and help batteries and motors work well and safely.

See Also

Industrial Uses of Aluminum Nitride Ceramic Circuit Boards

How Multilayer PCBs Are Utilized In Various Sectors

Modern Industry Benefits From Al₂O₃ Ceramic PCB Uses

Enhancing LED And Power Electronics With Aluminum-Backed PCBs

Key Quality Control Procedures For Heavy Copper PCB Assembly