Critical Design Considerations When Specifying Immersion Gold PCBs for Your Electronics Project

When selecting immersion gold PCBs, it is essential to consider several critical design considerations. You need to evaluate the surface finish, gold thickness, solderability, signal integrity, cost, reliability, and the expertise of the manufacturer. Gold plating provides low contact resistance, which helps reduce signal loss and enhances data transmission. It also prevents corrosion, ensuring your boards perform reliably in demanding environments such as automotive or aerospace applications. A multi-layer FR-4 board with an immersion gold finish can support complex circuits and withstand rigorous electrical testing, guaranteeing optimal performance.

Key Takeaways

ENIG surface finish gives a flat and smooth surface. This helps you put small parts on the board easily. It also protects your PCB from rust. This makes solder joints strong and keeps electrical connections working well.

The right gold thickness keeps your board safe from rust. It also makes solder joints strong. You should work with a skilled manufacturer. They check the gold layers carefully. This helps stop common problems.

ENIG finish works well for fast signals and boards that last long. It is a smart choice even if it costs more at first. This is true when you use expert manufacturers like LT CIRCUIT. They make sure you get good quality and custom solutions.

Surface Finish Choice

Why ENIG Matters

Picking a surface finish for your PCB is very important. ENIG stands out because it gives a flat and smooth surface. This finish has a nickel layer that is between 2.5 and 6.3 micrometers thick. On top of the nickel, there is a thin gold layer. The nickel stops copper from spreading and keeps the board safe from rust. The gold layer, which is 0.05 to 0.2 micrometers thick, protects the nickel from air and helps with soldering.

ENIG’s flat surface is good for small parts and packed designs. ENIG helps you get strong soldering and good electrical connections.

HASL can be bumpy, but ENIG is much smoother and keeps signals clear. Some finishes like ASIG might lose less signal in some tests, but ENIG is easier to find and people trust it more.

Benefits for Modern Electronics

ENIG is used in many fields, like planes and medical tools. Its flat surface lets you put tiny parts on the board easily. ENIG also works with lead-free solder, so it is safe for the environment.

ENIG gives you:

Great protection from rust

Good performance in tough places

Works well with new ways to build boards

Companies like LT CIRCUIT check their boards carefully with special tests. They use X-ray and solder tests to make sure every board is good. ENIG has been trusted since the 1990s. That is why it is a top pick for new electronics. When you think about important design choices, ENIG gives you the strong and steady results you need.

Gold Thickness & Uniformity

Performance Impact

Gold thickness is very important for how your PCB works. The right thickness helps stop rust and keeps solder joints strong. A thin gold layer, between 0.05 and 0.2 micrometers, covers the nickel. This layer keeps air away from the nickel and stops it from rusting. It also makes the surface flat. Flat surfaces are needed for fine-pitch and BGA components. If the gold is too thin, nickel can come up after heating. This can cause rust and make soldering harder. You need a gold layer that is thick enough to stop this.

A gold layer that is even everywhere helps solder stick better. It also stops problems like black pad. It keeps your board looking nice and makes checking it easier.

Here is a simple table about gold thickness and how it helps:

Parameter | ENIG Gold Thickness (µm) | Performance Impact |

|---|---|---|

Gold Layer Thickness | 0.05 - 0.2 | Flat surface for fine-pitch and BGA components |

Surface Flatness | 0.05 - 0.1 | Better solder joint reliability |

Solderability | Excellent | Strong, reliable solder joints |

Corrosion Resistance | High | Protects nickel, boosts durability |

Wear Resistance | Moderate | Good for most uses, less for heavy contact areas |

Industry Standards

You should always check if your PCB meets the rules for gold thickness. The IPC-4552 standard tells you how thick the gold and nickel should be. The gold layer should be between 0.025 and 0.05 micrometers. The nickel layer should be 3 to 6 micrometers. Makers use X-ray fluorescence to check the layers after plating. They also watch the pH and temperature of the bath to keep the gold layer even and smooth.

Electroless nickel needs 6-8% phosphorus for the best mix of rust protection and soldering.

Special plating controllers help keep the chemicals steady, so the finish is always the same.

New gold chemicals make the surface even smoother and less likely to rust.

If you follow these rules, your immersion gold PCB will last longer and work better in your project.

Solderability & Assembly

Fine-Pitch Components

Fine-pitch components need a flat and smooth PCB surface. ENIG gives this kind of surface. The gold layer sits on a nickel-phosphorus base. This makes the board hard and tough. It also keeps the board safe from rust and ready to use.

Fine-pitch parts are in phones, computers, and medical tools. These parts have tiny spaces between pins. A flat surface helps stop solder bridges. Solder bridges can cause short circuits. ENIG’s thin finish stops extra solder from building up. This helps you place and solder small parts without mistakes.

ENIG works with new ways to make electronics. It is good for lead-free and RoHS-safe processes. You can use it for both surface-mount and wire-bond parts.

Feature | ENIG | |

|---|---|---|

Surface Flatness | Uneven | Very flat |

Fine-Pitch Suitability | Risk of bridging | Excellent, prevents bridging |

Shelf Life | Moderate | Long |

Reliable Soldering

You want every solder joint to be strong and last long. ENIG helps by giving a smooth and even surface. The nickel layer is kept between 3 to 6 microns thick. This stops bad reactions that can make joints weak. The gold layer is 0.05 to 0.10 microns thick. It helps electricity flow and stops rust.

Makers use special tools like X-ray fluorescence to check layer thickness. They also look at the boards to find any problems. These steps help stop weak joints or “black pad” rust.

Tests show ENIG boards stay strong after heat. Shear tests and wire bonding checks prove solder joints stay tough and free from defects. You can trust ENIG for important projects, even after many soldering cycles.

Signal Integrity

High-Frequency Needs

You want your PCB to send signals fast and clear. Immersion gold finishes like ENIG protect against rust and keep signals strong. Gold finishes help your signals stay clean at high frequencies over 10 GHz. This is important for new things like 5G and UHDI boards. Gold also keeps your board safe from the environment. This helps your product last longer.

But the nickel layer in ENIG does not conduct as well as silver. This can make you lose more signal at very high frequencies. For example, at 28 GHz, using immersion silver instead of ENIG can lower signal loss by 15%. You might also see a small impedance mismatch at via transitions with ENIG. This can change how signals move through your board. Still, ENIG gives good EMI shielding on ground planes and vias. This helps block signals you do not want.

Tip: If your project needs the best at very high frequencies, ask your PCB maker about the right finish.

Impedance Control

Impedance control keeps signals steady as they move on the PCB. You need this for fast circuits. Even small changes can cause signal loss or distortion. With immersion gold PCBs, you can check impedance by measuring resistance, inductance, and capacitance. Special tools send signals through the board and measure changes. These tests make sure your board keeps the right impedance. This helps your signals stay strong and clear.

Impedance control helps:

Lower signal loss

Stop distortion

Make performance better

If you work with a skilled manufacturer, you get careful testing and steady results. This means your fast designs will work right every time.

Cost & Value

Budget Considerations

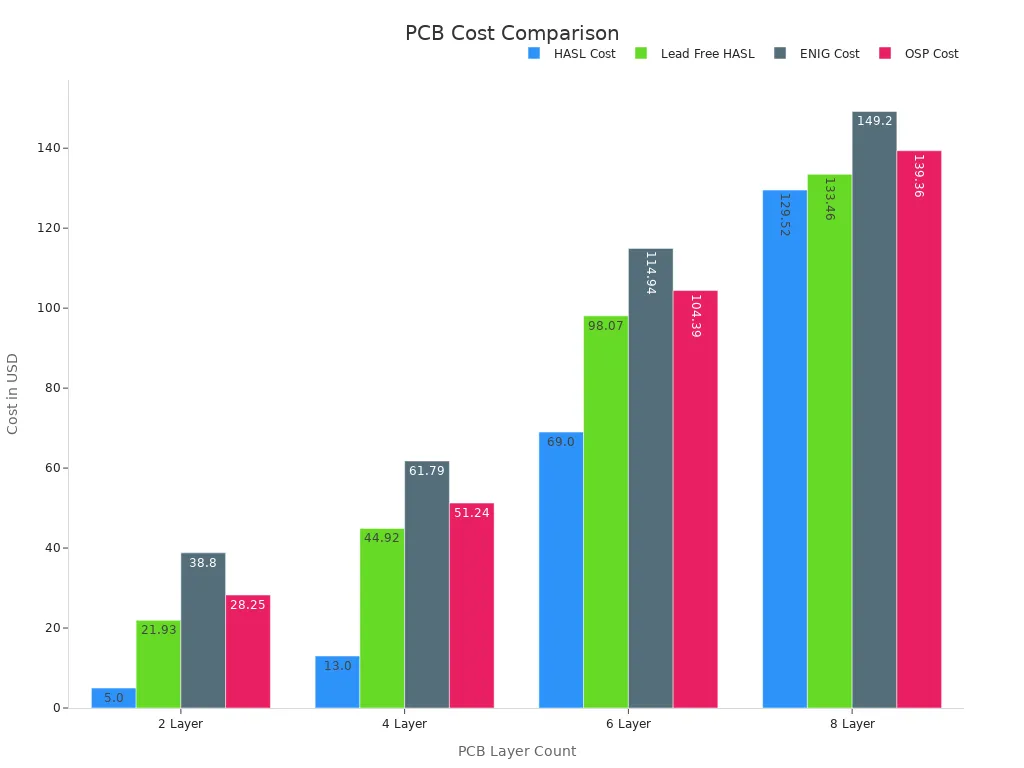

You should think about your budget before picking ENIG PCBs. The price changes based on board size and how many layers you need. It also depends on how many boards you order and what materials you pick. The surface finish you choose matters too. If you only need a few boards, setup and tooling fees can make them cost more. Some companies have lower setup fees for small orders. This helps if you want to build a quick project.

ENIG costs more than other finishes. This is because it needs special steps and equipment to make. ENIG gives you a flat and strong surface. It also lasts a long time, over 12 months. OSP is cheaper but only lasts about 6 months. ENIG costs more, but it makes soldering easier and the board more reliable. This is important for hard jobs.

Here is a table that shows how ENIG costs compare to other finishes:

PCB Layer Count | HASL Cost (USD) | Lead Free HASL Cost (USD) | ENIG Cost (USD) | OSP Cost (USD) |

|---|---|---|---|---|

2 Layer | 5.00 | 21.93 | 38.80 | 28.25 |

4 Layer | 13.00 | 44.92 | 61.79 | 51.24 |

6 Layer | 69.00 | 98.07 | 114.94 | 104.39 |

8 Layer | 129.52 | 133.46 | 149.20 | 139.36 |

ENIG costs more at first, but you save money later. You get fewer problems and do not need to fix as much.

Application Fit

ENIG is good for many new electronics projects. It gives a flat surface, which is great for SMT. ENIG also stops rust, so it works well in cars and planes. You can trust ENIG for fast data and strong signals. This makes it a good pick for telecom jobs.

Medical tools like pacemakers and monitors

Plane parts that face tough weather

Routers and servers that need fast data

Car systems that must last a long time

Projects that need lead-free, green boards

ENIG is best when you need your board to be flat and last a long time. If your project needs these things, ENIG is a good investment.

Reliability & Durability

Corrosion Resistance

You want your PCBs to work well in hard places. Immersion gold finishes like ENIG help stop rust and chemical harm. The gold layer acts like a shield. It keeps air and water away from the nickel and copper under it. Scientists use special tests to see how well gold stops rust. These tests include atomic force microscopy and electrochemical impedance spectroscopy. They show that tiny holes or defects in the gold can cause problems. If there are fewer holes, your board will last longer.

If the gold is smoother and thicker, it protects your PCB better from rust.

Researchers found that some chemicals can stick to the gold. These chemicals make the gold even stronger while you store the board. But you must clean off these chemicals before using the board. How the gold is put on and how thick it is are both important. Boards with thicker and smoother gold have less rust and work better for a long time.

Method/Parameter | Description/Details |

|---|---|

Gold deposit thickness | 75 to 190 nm |

Key corrosion factors | Porosity, galvanic cell formation, substrate dissolution, pore size increase |

Importance of porosity | Directly related to corrosion resistance and life expectancy |

Electrochemical tests | Rapid, reliable, and quantitative for checking corrosion resistance |

Shelf Life

You want your PCBs to stay good, even if you store them for months. ENIG finishes let you keep boards for over a year without losing quality. This is helpful for projects that need more time for building or shipping.

Other finishes, like immersion tin or silver, do not last as long. Immersion tin works best if you use it in 30 days and only lasts up to six months. Immersion silver can last up to a year but needs careful storage so it does not tarnish. ENIG is better because it does not tarnish and keeps its solderability for a long time.

Surface Finish | Shelf Life Duration | Notes on Durability and Handling |

|---|---|---|

ENIG (Immersion Gold) | Long shelf life, high reliability | |

Immersion Tin | 3-6 months (best within 30 days) | Short shelf life, needs careful handling |

Immersion Silver | 9-12 months | Medium shelf life, sensitive to tarnishing |

ENIG lets you store your boards longer. You can trust they will work when you need them.

Manufacturer Expertise: LT CIRCUIT

Advanced Capabilities

You need a skilled manufacturer for immersion gold PCBs. LT CIRCUIT uses new technology to make high-quality ENIG boards. Their process makes the surface very smooth. The PCB electrodes have an average roughness of about 21 nm. This careful control helps your boards work well in sensitive jobs. LT CIRCUIT checks every detail with atomic force microscopy and electrochemical tests. They clean the boards with special steps, like low-temperature SC-1 cleaning and oxygen plasma treatment. These cleaning steps help give you results you can trust every time.

LT CIRCUIT follows strict rules, like IPC-6012, IPC-4552, and IPC Class 3. You can trust their quality because they use automated inspections like AOI and AXI. Their process capability index (Cpk) is always above 1.33. This shows their process is steady and has few defects. The table below shows some of their quality numbers:

Quality Metric | Measured Value / Range | What It Means for You |

|---|---|---|

Water contact angle | Less than 10° | Excellent surface activation and preparation |

Nickel content in film | Below 5 weight percent | High-purity gold finish |

Sheet resistance | 3.1 ± 0.6 Ω/sq | Uniform conductivity |

Resistance stability | 3.1 to 6.2 Ω/sq over 7 months | Long-term reliability |

Process capability (Cpk) | Above 1.33 | Consistent, low-defect manufacturing |

IPC Compliance | IPC-6012, IPC-4552, Class 3 | Meets top industry standards |

Custom Solutions

Sometimes you need more than basic options for your project. LT CIRCUIT gives you many custom choices to fit your needs. You can pick different surface finishes, like ENIG, HASL, or immersion silver. They offer many solder mask colors and can put parts inside the board for small designs. Their testing includes flying probe and E-tests. This helps make sure your boards meet all your needs.

LT CIRCUIT has helped many industries do well. For example, an aerospace company got a 99.8% first-pass yield rate. A medical device company launched products 40% faster. These results show LT CIRCUIT matches your design needs with their skills. Talking clearly with their team helps make sure your Critical Design Considerations are met from start to finish.

When you work with LT CIRCUIT, you get a partner who knows what you need and gives you strong, high-quality PCBs every time.

Critical Design Considerations Summary

Key Takeaways

You want your electronics project to do well. To make this happen, you must think about some important things when picking immersion gold PCBs. Here are the main ideas you should remember:

Surface Finish Choice: ENIG gives a flat and smooth surface. This helps with tiny parts and keeps your board safe from rust. You get better soldering and strong electrical links.

Gold Thickness & Uniformity: The right gold thickness keeps your board safe from rust. It also makes solder joints strong. If the gold is too thin or thick, problems can happen. You should work with a maker who checks the gold layer carefully.

Solderability & Assembly: ENIG makes it easier to put and solder small parts. You get fewer solder bridges and stronger joints. This means your boards work better and last longer.

Signal Integrity: A good ENIG finish keeps signals clear, even at high speeds. You need to control impedance to keep your circuits working well.

Cost & Value: ENIG costs more at first, but you save money later. You get fewer problems and do not need to fix as much. This makes ENIG a smart pick for projects that need to be strong and last.

Reliability & Durability: ENIG protects your board from rust and harm. Your PCBs last longer, even in tough places. You can store them for over a year and they will still work well.

Manufacturer Expertise: You need a partner who knows these important things. LT CIRCUIT uses new technology and strict checks. They also offer custom choices. They follow industry rules and use special tools. This means you get boards you can trust every time.

Tip: When you work with LT CIRCUIT, you get more than just a PCB. You get a team that helps you fix problems, improve your design, and make products that last.

You should know that experts use special checks to make sure the gold layer is right. They look at things like the r/D ratio of nickel and palladium nodules. A higher r/D ratio means less rust and longer board life. Special RAIG electrolytes help make the gold layer better. Advanced tests help find and fix problems before you get your boards.

Each step, from surface finish to the maker’s skills, is important for your project. When you pay attention to these things, you get better boards that last longer and have fewer problems. LT CIRCUIT is a trusted partner because they use good technology, have lots of experience, and care about your needs.

You need to think about Critical Design Considerations when picking immersion gold PCBs. These choices change how well your board works, how long it lasts, and how much it costs. Reports say ENIG stops rust and is easy to solder, but it must be handled by experts. It is smart to work with skilled companies like LT CIRCUIT and use a checklist to make sure you do not miss anything important.

FAQ

What is the main benefit of using ENIG for my PCB project?

ENIG gives you a flat surface. You get strong solder joints and better protection from rust. Your board lasts longer and works better.

How does LT CIRCUIT ensure the quality of immersion gold PCBs?

You get strict quality checks. LT CIRCUIT uses advanced tests like AOI and X-ray. They follow IPC standards for every board.

Can I use ENIG PCBs for high-frequency applications?

Yes, you can. ENIG works well for high-speed signals. You get stable performance for 5G, servers, and advanced electronics.

See Also

Why Immersion Gold Outperforms Other PCB Surface Finishes

Expert Guide To Immersion Tin Methods In PCB Design

Understanding OSP Finish Advantages And Challenges In PCB Production

Key Strategies For Designing Heavy Copper PCBs With High Current

Comprehensive Production Techniques For Heavy Copper Multilayer PCBs