Critical Factors to Consider When Choosing a Rigid-Flex PCBs Manufacturer

When you pick a rigid-flex PCB manufacturer, consider these critical factors: thorough quality checks, the proper certifications, advanced manufacturing capabilities, expertise in materials, and prompt communication. Poor manufacturing choices can cause up to 20% of electronics to fail. Selecting the right manufacturer also impacts how quickly your project is completed and the overall durability of your product.

Key Takeaways

Pick a manufacturer that checks quality well, has the right certificates, and has shown they can do the job. This helps make sure your rigid-flex PCBs work well and last long. - Choose a partner who uses good materials, follows the rules, and tests everything carefully. This helps stop problems and makes your product last longer. - Work with a manufacturer who gives clear prices, delivers fast, packs things safely, and answers your questions quickly. This helps your project stay on time and not cost too much.

Critical Factors Overview

Quality and Certifications

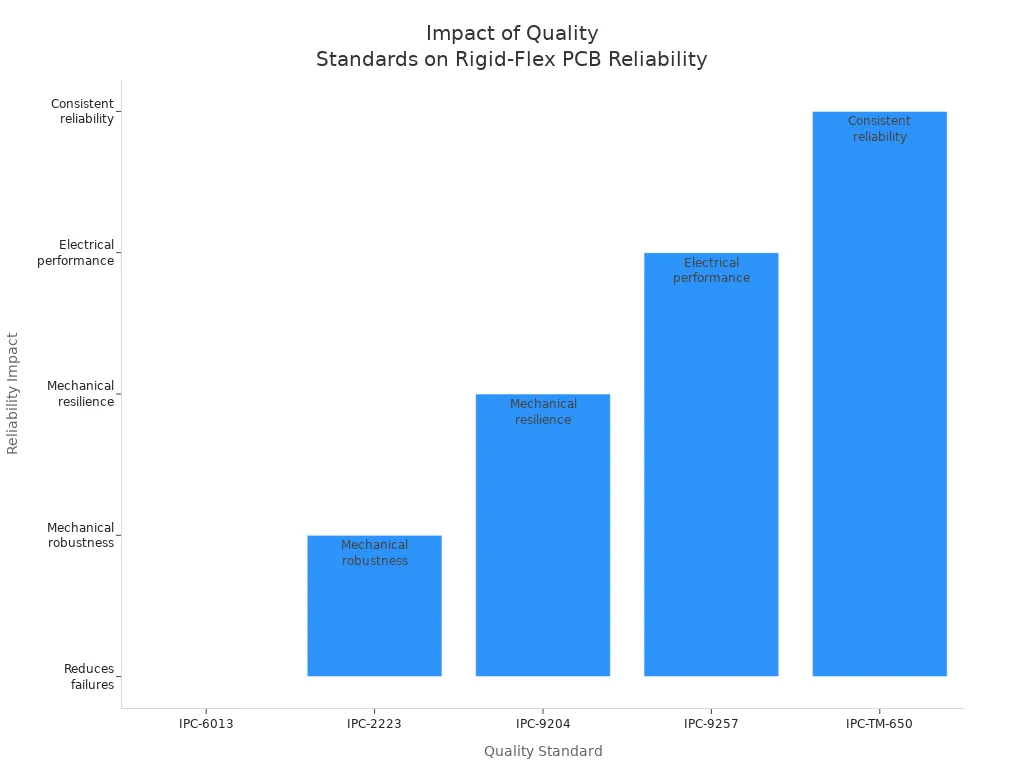

Start by checking quality and certifications. These are very important when picking a rigid-flex PCB manufacturer. Experts say certifications and standards help make products reliable and high-performing.

Tip: Always ask to see certifications before you begin.

Here are some common quality certifications and what they mean:

Standard | Purpose | Impact on Reliability |

|---|---|---|

Sets rules for how products should work | Helps stop failures from heat and bending | |

IPC-2223 | Rules for mounting and connections | Makes sure parts fit well and stay strong |

IPC-9204 | Checks flexibility and stretching | Shows the product can bend and stretch without breaking |

IPC-9257 | Tests electrical parts | Makes sure it works right before making many |

IPC-TM-650 | Gives ways to test products | Makes testing the same every time for better results |

Look for ISO 9001:2015, UL, AS9100 (for aerospace), and ISO 13485 (for medical devices). These show the company uses strict quality rules. They help lower mistakes and make products more alike.

Companies with these standards use special ways to check their work. They look for problems like heat damage, weak peeling, and wrong impedance. This helps your rigid-flex PCBs last longer and work better.

Experience and Reputation

Experience and reputation are very important for your project. You want a company that has made rigid-flex PCBs before. More years in business means they know how to fix hard problems and avoid mistakes. Good engineers can find issues early and give better ideas.

Experienced companies usually have fewer mistakes. They know how to follow world rules and solve tough problems in rigid-flex PCB work. This skill means better checks and fewer slowdowns.

When you check a company, look at their reputation. Here are some ways to do this:

Read what customers say in reviews and testimonials. These tell you if the company is reliable and makes good products.

Find case studies that show finished projects.

See how the company answers questions and fixes problems.

Ask about help after you buy and technical support.

Look at their past work to see if they have done projects like yours.

Note: A good reputation, with happy customers and expert praise, shows the company cares about quality and service.

A company with a good name will talk clearly and answer fast. This helps you avoid surprises and keeps your project moving. By looking at these important things, you help your project succeed.

Manufacturing Capabilities

Advanced Fabrication

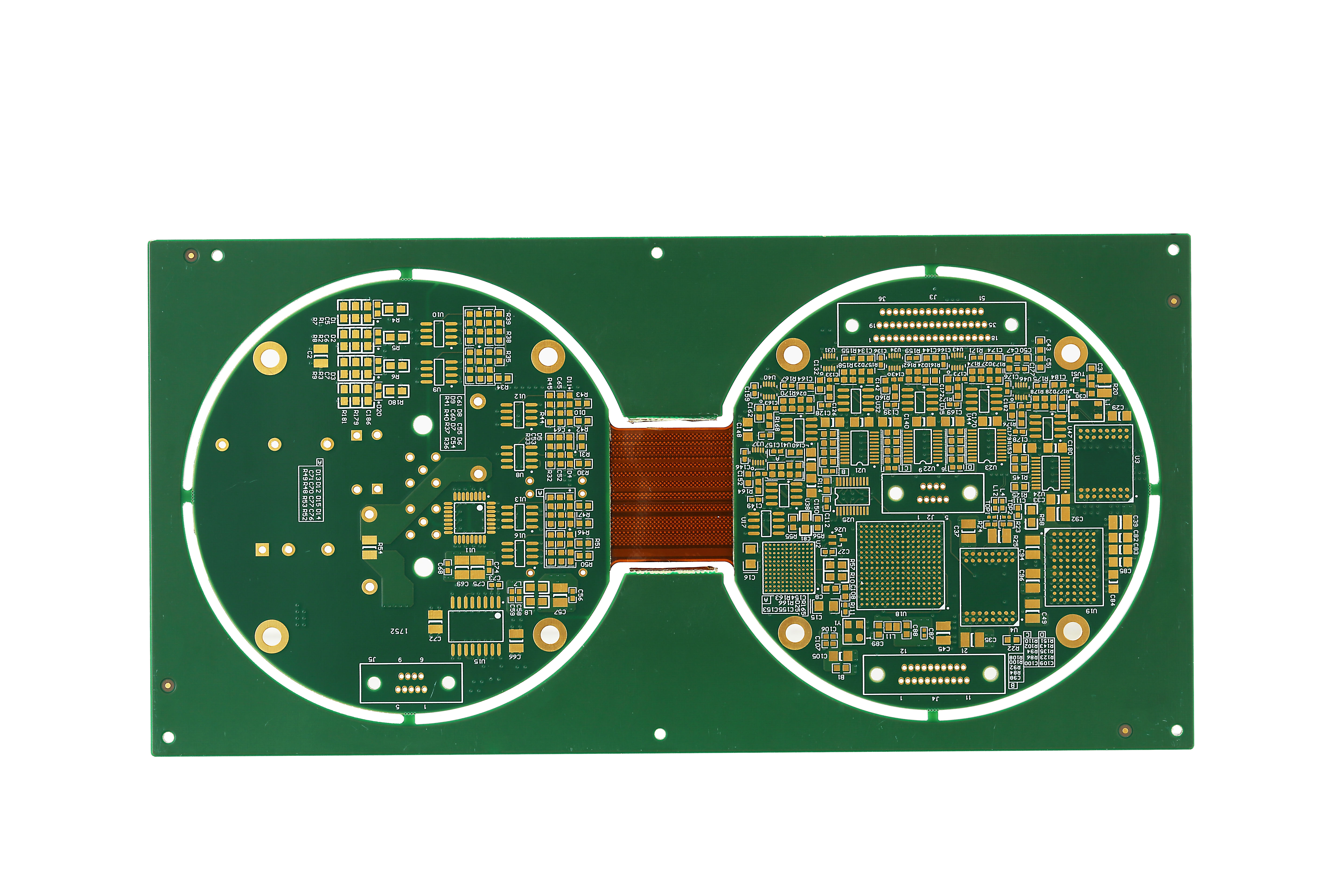

You need a manufacturer with advanced fabrication skills for high-quality rigid-flex PCBs. These skills mean using the right materials, cutting parts carefully, and making sure layers stick together well. The best manufacturers follow strict rules like IPC-6013 and IPC-2223. They use fiberglass-reinforced epoxy (FR4) for the hard parts. Polyimide is used for the flexible parts. Copper foils and special glue help make the boards strong and dependable.

Fabrication Aspect | Description |

|---|---|

Rigid Substrates | FR4 gives strength and insulation |

Flexible Substrates | Polyimide bends easily and handles heat |

17-35um thick, treated to help solder stick | |

Adhesive Materials | Epoxy or acrylic glue holds layers together |

Drilling and Plating | Careful drilling makes strong connections |

Surface Finishing | ENIG gives a surface that is easy to solder |

Manufacturers also test boards for heat, bending, and how well they work with electricity. This helps stop problems and makes the boards last longer.

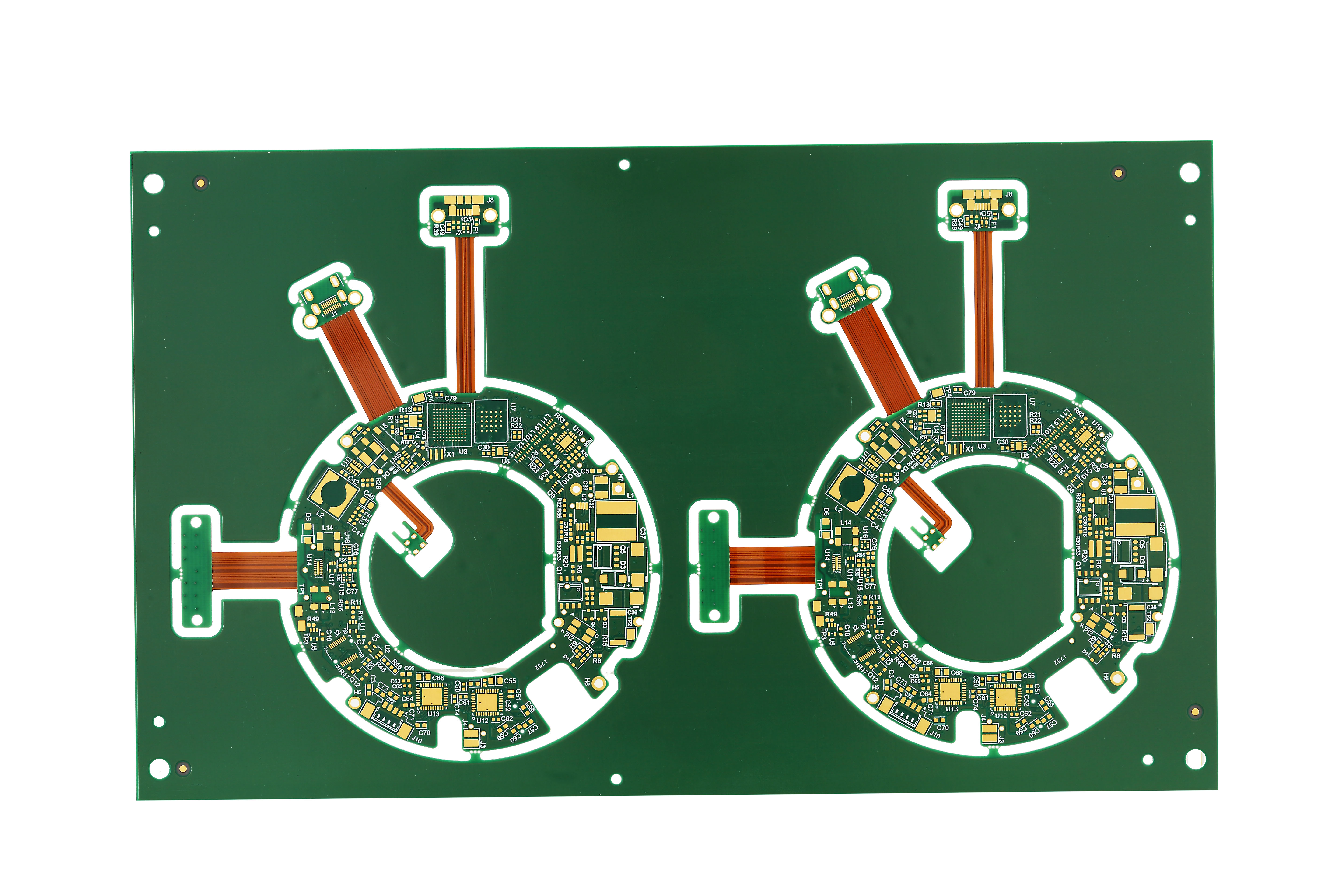

Layer Alignment

Getting the layers lined up right is very important in rigid-flex PCB making. Your manufacturer should follow IPC-2221 and IPC-2222 rules. These rules tell how to place layers and vias. Good alignment stops mistakes and keeps your circuits working.

Drilling must be exact to keep layers together.

Imaging must be clear so features match up.

A drill-to-copper gap of at least 8 mil helps avoid trouble.

Complex Designs

Complex rigid-flex PCBs need extra care. Your manufacturer should know how to handle bend radii, where connectors go, and how to stack materials. They must plan for 3D shapes and many bends. Good manufacturers use computer tools to check for stress and signal problems before making the boards. They test boards by bending them thousands of times to make sure they last.

Tip: Pick a partner who works with you from design to testing. Working together helps you avoid mistakes and makes sure your board is just right.

Material Selection

Performance Impact

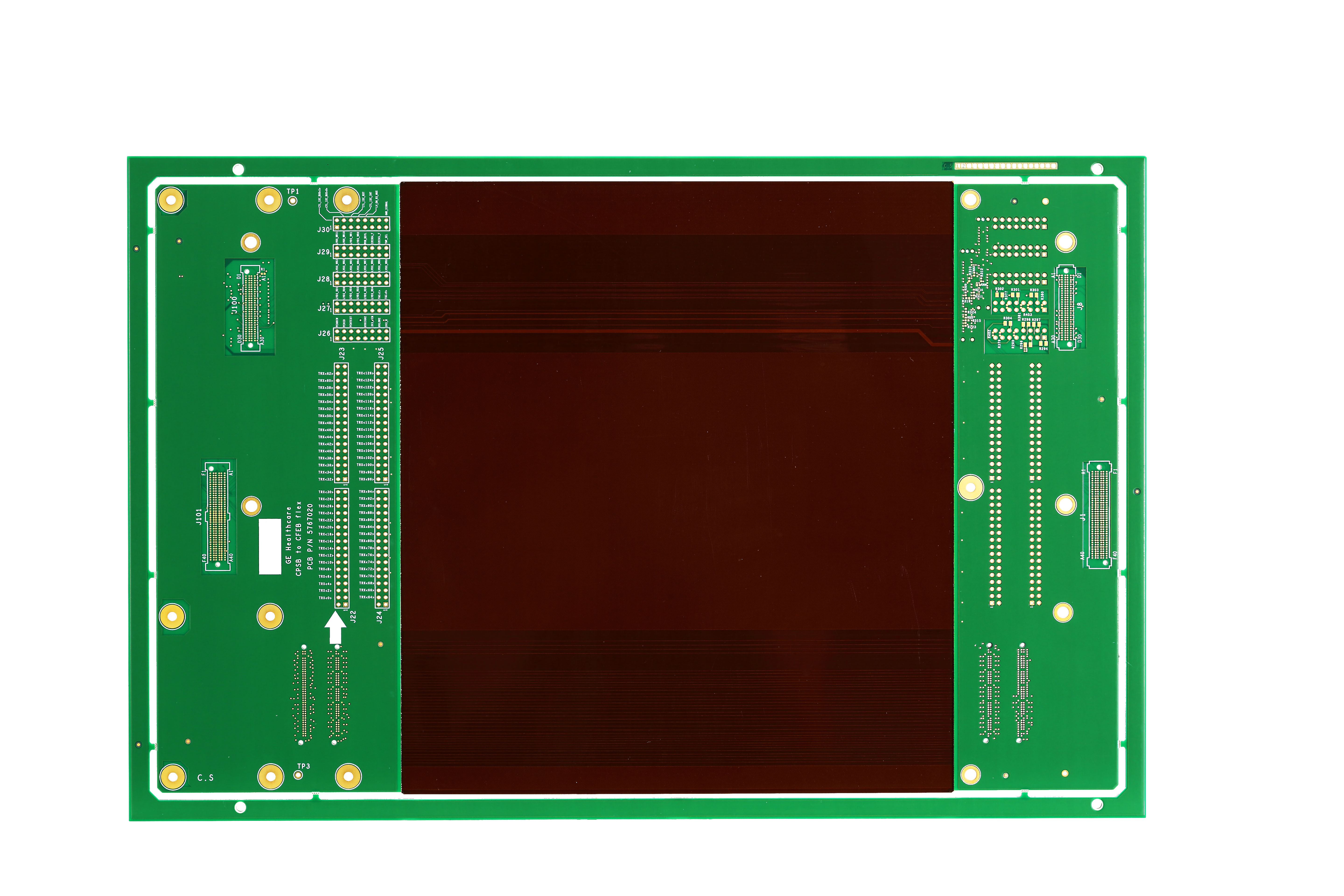

Picking the right materials is important for rigid-flex PCBs. The materials you use change how signals move on your board. They also affect how well your board works. Look at the table below to see what each material does:

Material Type | Common Materials | Impact on Electrical Performance and PCB Characteristics |

|---|---|---|

Flexible Substrate | Polyimide (PI), LCP, PET, PEEK | PI can handle heat, bends easily, and helps signals move well. LCP is good for fast signals. PET saves money and keeps things safe. PEEK stands up to chemicals and heat. |

Rigid Substrate | FR-4 (standard, high-Tg, low-Dk/low-Df), ceramics | High-Tg FR-4 does not warp in heat. Low-Dk/low-Df FR-4 keeps signals clear. Ceramics make boards strong. |

Conductive Layers | Copper (Rolled Annealed, Electrodeposited) | The copper you pick changes how much it bends and how much power it carries. This changes how well your board works. |

Adhesives | Acrylic, Epoxy | These glues hold layers together and help with heat. They also help keep signals clear. |

Coverlay Materials | Polyimide, LPI Solder Mask, Acrylic, Epoxy, TPU | These cover the board to stop water and damage. They help your board work well for a long time. |

Tip: Pick materials that fit your product’s speed, heat, and how much it needs to bend.

Durability and Reliability

The materials you choose help your rigid-flex PCB last longer. Good materials keep your board working in tough places and with lots of use. Think about these things:

High glass transition temperature (Tg) materials do not bend in heat.

Flexible materials that stretch do not crack when bent.

Polyimide flex layers handle heat and chemicals well.

No-flow prepregs and adhesiveless laminates stop glue from leaking and layers from coming apart.

Thick boards with more copper can take more shaking and carry more power.

Coatings like ENIG keep out water, salt, and chemicals.

Smooth changes between flex and hard parts stop weak spots.

Following IPC and RoHS rules keeps your board safe and high quality.

Work with your manufacturer to pick the best stackup for your board. This helps stop problems and makes sure your board works for a long time.

Industry Standards

Compliance

You must check if your rigid-flex PCB manufacturer follows industry standards. These rules help make sure your boards are strong and work well. They are important for things like airplanes and medical devices. If your manufacturer follows these rules, your boards will have fewer problems. This also saves money and helps your product work better.

Description | Key Focus Areas | |

|---|---|---|

Design standard for flex & rigid-flex PCBs | Layout, materials, routing, bending radius, transitions | |

IPC-6013 (C & D) | Performance specification for flex & rigid-flex PCBs | Testing, durability, environmental resistance, rigid-to-flex areas |

IPC-2226 | Design standard for HDI PCBs | Signal integrity, thermal management, EMI reduction |

IPC-6018 | Inspection/performance for flexible circuitry | Inspection criteria, performance requirements |

IPC-6010 | General performance for rigid PCBs | Quality assurance, reliability, testing methods |

IPC-4203 & 4204 | Materials standards for flexible printed boards | Material properties, adhesives, dimensional stability |

When a manufacturer follows these standards, your boards last longer. They also work better and break less often. This makes your project go smoother. Following rules helps you talk clearly with your supplier. It also makes sure your product fits new technology needs.

Tip: Always ask which IPC standards your manufacturer uses. This helps you avoid mistakes and keeps your project on track.

Traceability

You need full traceability for your rigid-flex PCB. This means you can follow every material and step from start to finish. Good traceability helps you fix problems fast and keeps your boards high quality.

Manufacturers use different ways to track everything:

Write down each material’s type, batch, and date.

Put QR codes or barcodes on every batch and board.

Scan these codes at each step to record details.

Save records of tests, materials, and steps.

Log quality data during the whole process.

Use trusted suppliers for good materials.

You can see every step in making your board.

You can find and fix problems quickly.

You know your product is reliable.

With good traceability, you know your boards meet standards. This helps you do better in tough markets.

Testing and Debugging

In-Process Testing

You need good in-process testing to find problems early. Visual inspection lets you see big solder or surface problems. But it cannot find small or hidden faults. Automated Optical Inspection uses cameras and software to check for missing parts. It also finds wrong placements and solder problems. In-Circuit Testing checks each circuit for shorts and opens. It also checks if parts are put in the right way. Flying Probe Testing works well for tricky or small batches of boards. It lets you test boards without needing special tools.

For deeper checks, you can use X-ray inspection to look inside the board. Scanning electron microscopy helps you find tiny or hidden problems. Thermal imaging shows hot spots that may mean something is wrong. Burn-in Testing puts the board under high heat and voltage. This helps find weak parts early. But you must be careful so you do not hurt good parts. Using all these tests together gives you a full look at your board’s quality.

Tip: Using many in-process tests helps you find more problems. This stops expensive surprises later.

Final Inspection

Final inspection is the last check before shipping. You should look for the most common problems:

Soldering problems, like cold joints or bridges, can cause shorts.

Wrong part placement or missing parts can make the board not work.

Drilling mistakes, like holes in the wrong place, hurt connections.

Plating and etching problems can make the board weak or break.

Solder mask and silkscreen issues can cause shorts or make assembly hard.

A manufacturer with good testing and debugging helps you avoid these problems. You save money by having fewer failures and repairs. Your product will last longer. Automated testing and expert checks help you fix problems fast. This keeps your project on time and your customers happy.

Pricing and Value

Transparent Costs

You need to know the real price from your rigid-flex PCB manufacturer. Clear costs help you plan your money and stop surprise fees. A good company gives you a quote that lists every cost. This should include materials, setup, testing, and shipping. When you see each part, you can compare companies and pick the best one.

Tip: Always ask for a full list of charges before you begin. This helps you find extra fees and keeps your project safe.

A clear quote helps you trust the company. You know what you pay for and can ask questions if something seems wrong. Being open about costs helps you avoid problems later.

Cost Drivers

Many things change the price of rigid-flex PCBs. You should know what makes the price go up or down. Here are the main things that change the cost:

If you order more boards, each one costs less. Small orders cost more because setup takes time.

More parts and hard assembly make labor and tools cost more.

Flexible materials like polyimide cost a lot more than regular ones.

More layers make the board cost more because it is harder to make.

Odd shapes waste material and make the price go up.

Thin traces and small spaces are harder to make and cost more.

Thicker copper needs more work and costs more money.

Small, exact holes take longer and cost more to drill.

Fancy finishes like ENIG cost more but last longer.

Special stiffeners, like aluminum or polyimide, add to the price for extra strength or heat control.

When you know these cost drivers, you can work with your company to get the best price and good quality. Picking the right design and materials helps you save money and still get a strong board.

Lead Time and Delivery

Production Schedules

It is important to know how fast your manufacturer can send your rigid-flex PCBs. Lead time changes when your project will finish and when you can sell your product. The best companies have different times for making boards, depending on how many you order and how hard they are to make. Some can send quick-turn prototypes in just 48 hours. Big or tricky orders might take up to two weeks. Look at the table below to see how long top U.S. suppliers take:

Manufacturer | Lead Time Range |

|---|---|

Wintech | |

Advanced Circuits | 5 to 10 days |

Sanmina Corporation | 10 to 15 days |

TTM Technologies | 7 to 12 days |

Sierra Circuits | 5 to 7 days |

Multek | 7 to 14 days |

Tip: Always ask your manufacturer for a clear schedule. This helps you get ready for building, testing, and shipping.

Pick a partner who can finish on time and handle rush jobs. Good suppliers tell you about delays early. This helps you avoid wasting time and money.

Packaging and Shipping

Good packaging and shipping keep your rigid-flex PCBs safe from harm. After testing, your boards need strong packaging to stop water, static, and bumps. The best suppliers use ESD bags, moisture barrier bags, desiccants, and humidity cards. These things keep your boards dry and safe while they travel.

ESD bags and foam stop static from hurting circuits.

Moisture barrier bags and desiccants keep water away, so boards do not get ruined.

Humidity cards show if there is too much water in the package.

Strong boxes and soft padding stop boards from bending or breaking.

Packaging is part of quality control. It makes sure your boards arrive safe and ready to use.

Shipping teams work with delivery companies to get your boards to you on time. This is very important for things like medical devices or electronics that need to be ready fast. Pick a manufacturer with good packaging and shipping to protect your boards and keep your project moving.

Communication and Support

Responsiveness

You need a manufacturer who answers you fast and clearly. Quick replies help you avoid mistakes and keep your project on track. In the rigid-flex PCB field, companies like Capel say fast answers are more important than exact reply times. If you wait too long for answers, your costs can go up. You might miss deadlines or hurt your business ties.

Good manufacturers use many ways to talk with you. You can call, email, chat online, or use video calls. Some companies give you one account manager. This person gives you updates and answers your questions quickly. When you get clear and fast info, you can make good choices.

Tip: Pick a manufacturer who uses many ways to talk and keeps you updated all the time.

Problem Resolution

Problems can happen while making or after getting your boards. You want a partner who fixes issues fast and helps you after you buy. Top companies like Shenzhen Capel Technology give strong technical help before and after your order. Their quick help lets you catch new chances in the market.

Good after-sales help builds trust and makes you want to come back. When a manufacturer helps you fix problems fast, you save time and keep your good name. Good support means you get answers and help when you need it most.

Find companies that have fixed problems well before.

Ask how they handle technical issues and returns.

Make sure they help you even after you buy.

If you look at all the important things before picking a rigid-flex PCB manufacturer, your project will do better. Checking everything closely helps you get better boards, have fewer problems, and get your order on time. You can use this checklist to help you choose:

Make sure the manufacturer has the right skills and certifications.

Compare prices, how fast they work, and how they help you.

Focus on what matters most to you so you can pick the best company for your project.

FAQ

What certifications should you look for in a rigid-flex PCB manufacturer?

Look for IPC, ISO 9001, and UL certifications. These mean the company uses strong quality and safety rules.

How do you verify a manufacturer’s experience with complex designs?

Ask to see case studies or samples of their work. Read what customers say about them. Ask how they make advanced rigid-flex layouts.

What is the typical lead time for rigid-flex PCB production?

Lead times can be as short as 48 hours for prototypes. Big orders may take up to two weeks. Always check the schedule with your manufacturer first.

See Also

Choosing Between Flexible And Rigid PCBs For Electronics Projects

Selecting A Reliable PCB Manufacturer For Your Business Needs

Top Benefits Of Rigid-Flex PCBs In Compact Electronic Designs

Industrial Rigid PCB Production: Materials, Processes, And Standards

Comprehensive Guide To Manufacturing Flexible Printed Circuit Boards