What Are Double Sided IMS PCBs and Where Are They Used

You’ll find double sided ims pcb in many modern electronics because they feature metal substrates and two conductive layers, enhancing both performance and reliability. This unique structure gives double sided ims pcb exceptional thermal conductivity, durability, and vibration resistance. The table below highlights the key benefits:

Advantage | Description |

|---|---|

Superior heat transfer thanks to a specialized polymer layer. | |

Lightweight | Metal boards are lighter than traditional ceramic options. |

Durability | Metal substrates in double sided ims pcb offer longer lifespan and better conductivity than other PCB materials. |

Non-toxic and Recyclable | Made with environmentally friendly metals. |

Vibration Resistance | Robust core design minimizes vibration and keeps components securely in place. |

LT CIRCUIT provides advanced double sided ims pcb solutions tailored to meet the evolving needs of the electronics industry.

Key Takeaways

Double sided IMS PCBs offer superior thermal management, keeping electronics cool and reliable in high-power applications.

These PCBs are lightweight and durable, making them ideal for demanding environments like automotive and LED lighting.

Choosing IMS technology supports eco-friendly practices, as many boards use recyclable materials and non-toxic metals.

Double Sided IMS PCB Basics

What Is an IMS PCB

You may hear the term "ims" often in electronics. It stands for insulated metal substrate printed circuit board. This type of pcb uses a metal core instead of the fiberglass found in traditional boards. The metal core pcb design gives you better thermal management and higher durability.

Here is a table that shows how an ims pcb compares to a traditional pcb:

Feature | IMS PCB | Traditional PCB |

|---|---|---|

Base Material | Metal core (aluminum/copper) | Fiberglass epoxy |

Thermal Conductivity | High | Lower |

Heat Dissipation | Superior | Less effective |

You can see that an insulated metal substrate pcb stands out for its ability to handle heat and provide strong support for components. This makes it a popular choice for high-performance board designs.

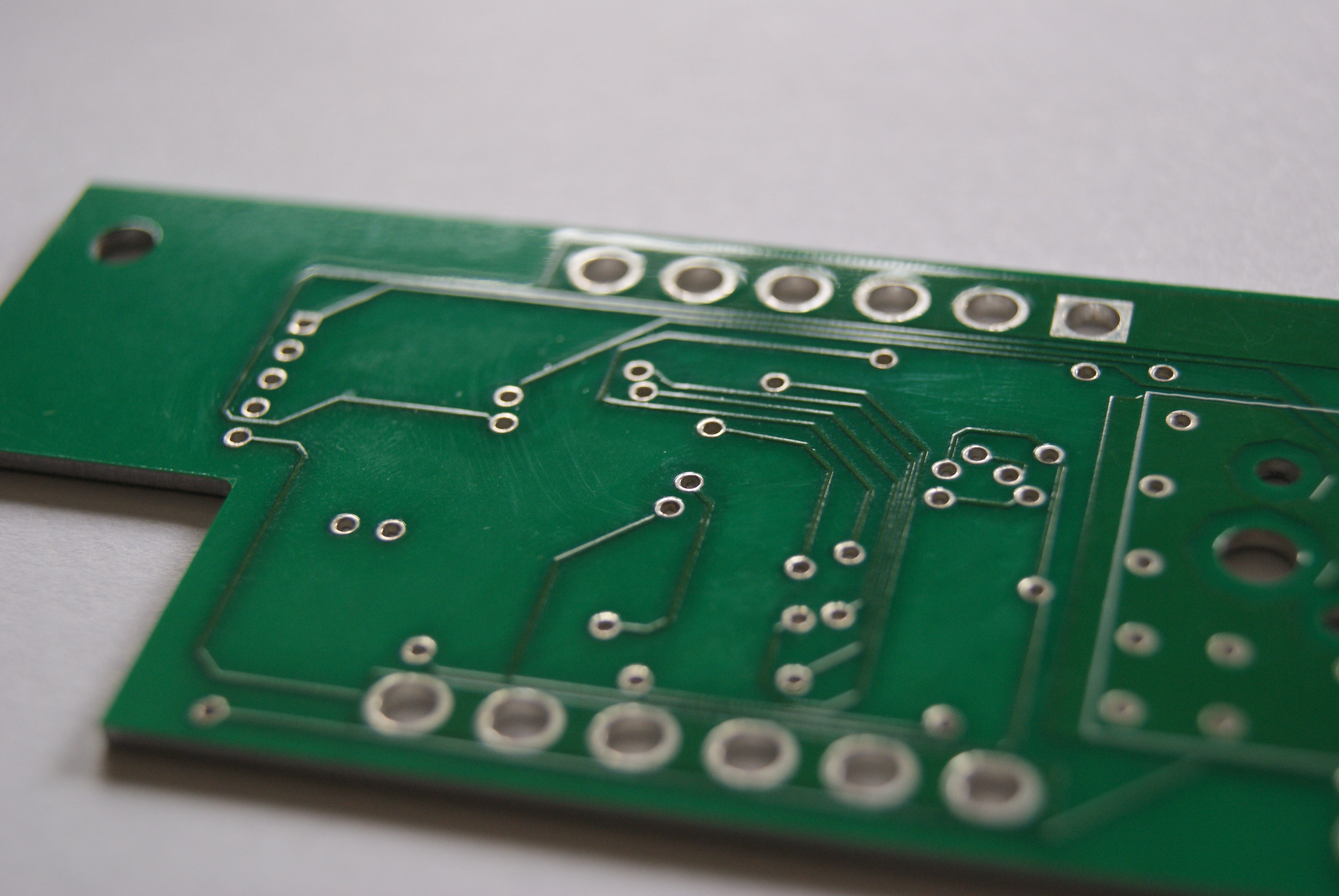

Structure and Function

A double sided ims pcb has a unique structure that sets it apart from other types of pcb. You will find three main layers in this board:

Copper Circuit Layer: This layer uses high-purity copper foil. It carries electrical signals and helps collect heat from components.

Thermal Insulating Layer: Made from ceramic-filled epoxy resin, this layer separates the copper from the metal substrate. It transfers heat while keeping electrical parts safe.

Metal Substrate Layer: This layer is usually aluminum or copper. Aluminum offers good thermal conductivity (about 200 W/m·K), while copper provides even higher thermal performance (about 400 W/m·K). Some designs use steel or alloy for extra strength.

Here is a table that breaks down the materials and their roles:

Layer | Material | Thermal Conductivity (W/m·K) | Function |

|---|---|---|---|

Copper Circuit Layer | High-purity copper foil | N/A | Electrical conduction and component mounting, heat collection |

Thermal Insulating Layer | Ceramic-filled epoxy resin | 1 - 8 | Electrical isolation, heat transfer from copper to metal substrate |

Metal Substrate Layer | Aluminum | ~200 | Acts as heat sink and structural support |

Copper | ~400 | Suitable for high-power designs | |

Steel or alloy | N/A | Used in scenarios with high mechanical strength requirements |

A double sided ims pcb lets you mount components on both sides. This design uses thermal vias to move heat from both sides of the board to the metal core. You get better heat dissipation and more flexible layouts than with a single-sided ims pcb. This structure helps you manage thermal loads in demanding applications.

Tip: If you need a pcb for high-power or high-temperature environments, an insulated metal substrate printed circuit board is a smart choice.

Key Benefits

When you choose a double sided ims pcb, you gain several important advantages:

Superior Thermal Management: The metal core pcb design quickly moves heat away from sensitive parts. This keeps your devices running cooler and more reliably.

Enhanced Durability: The strong metal substrate resists vibration and physical stress. Your board lasts longer, even in tough conditions.

Efficient Heat Dissipation: The combination of copper layers, thermal vias, and a metal base ensures excellent heat dissipation. This is vital for power electronics and LED lighting.

Compact and Flexible Design: You can place components on both sides of the board. This saves space and allows for more complex circuits.

Environmental Benefits: Many ims boards use recyclable metals. This makes them a greener option for your projects.

Manufacturers face challenges when making double sided ims pcb, especially for boards longer than 1.8 meters. They must use special tools and advanced technology to keep the board strong and reliable. Strict quality control ensures that each insulated metal substrate pcb meets high standards for performance and safety.

You will find that an ims pcb gives you a powerful solution for managing heat and supporting high-performance electronics. The unique structure and materials make it a top choice for many modern applications.

Double Sided IMS PCB vs Other PCB Types

Main Differences

When you compare a double sided ims pcb to other types of pcb, you notice several important differences. An ims pcb uses a metal core, while traditional boards rely on fiberglass. This metal core gives the ims pcb much better thermal conductivity. You can use both sides of a double sided ims pcb for mounting components, which increases circuit density and design flexibility. In contrast, single-sided ims boards only allow components on one side.

Manufacturing costs also differ. Double-sided pcbs require more assembly steps because you need to process both sides of the board. You also need extra solder stencils, which adds to the cost. Single-sided pcbs cost less to assemble since they only need one pass through the assembly process. However, when you look at the overall production costs, board size and material type play a big role. More complex layouts in double-sided designs often lead to higher expenses.

Note: The most significant cost drivers include board size, material choice, layer count, and build complexity. Features like microvias, thicker copper, and advanced surface finishes can also raise costs.

Unique Advantages

You gain several unique advantages when you choose an ims pcb, especially for demanding applications. Double-sided aluminum pcbs stand out for their excellent thermal management. The metal core acts as a heat sink, pulling heat away from components and lowering the risk of thermal damage. This makes them ideal for high-power uses like LED lighting and power supplies.

Metal core pcbs, such as those with aluminum or copper, offer superior thermal conductivity. This feature helps keep your circuit components cool, even in high-temperature environments. As a result, your system becomes more reliable and lasts longer.

Here is a quick comparison:

Feature | Double Sided IMS PCB | Traditional PCB | Single Sided IMS PCB |

|---|---|---|---|

Thermal Conductivity | Excellent | Low | Good |

Component Mounting | Both Sides | Both Sides | One Side |

Heat Dissipation | Superior | Limited | Good |

Durability | High | Moderate | High |

You can see that an ims pcb gives you a strong edge in thermal management, durability, and design flexibility.

IMS Applications and LT CIRCUIT Solutions

Common Uses in Industry

You see ims pcb technology in many industries because it solves tough problems with heat dissipation and thermal management. These boards help you keep your electronics cool and reliable, even in high-power applications. The double sided ims pcb stands out in areas where you need strong heat dissipation and excellent thermal performance.

Here are some of the most common applications for ims boards:

Application | Description |

|---|---|

LED lighting | Keeps high-brightness LEDs cool, extending their life. |

Automotive electronics | Used in headlights, sensors, battery modules. |

Power converters | Manages heat in inverters and converters. |

You find ims pcb solutions in led lighting because they handle the intense heat from high-brightness LEDs. Good heat dissipation means your lights last longer and stay brighter. In automotive electronics, ims boards support headlights, sensors, and battery modules. These parts need strong thermal management to work safely in harsh conditions. Power modules and converters also use ims pcb technology to control heat and improve reliability in power electronics.

Other important applications include:

Solar inverters, where efficient heat dissipation keeps systems running smoothly.

Industrial control systems, which need stable thermal performance for long-term operation.

5G and high-frequency electronics, where low-loss and high-speed signals depend on advanced thermal management.

You benefit from these applications because ims pcb technology gives you better heat control, longer product life, and safer operation in demanding environments.

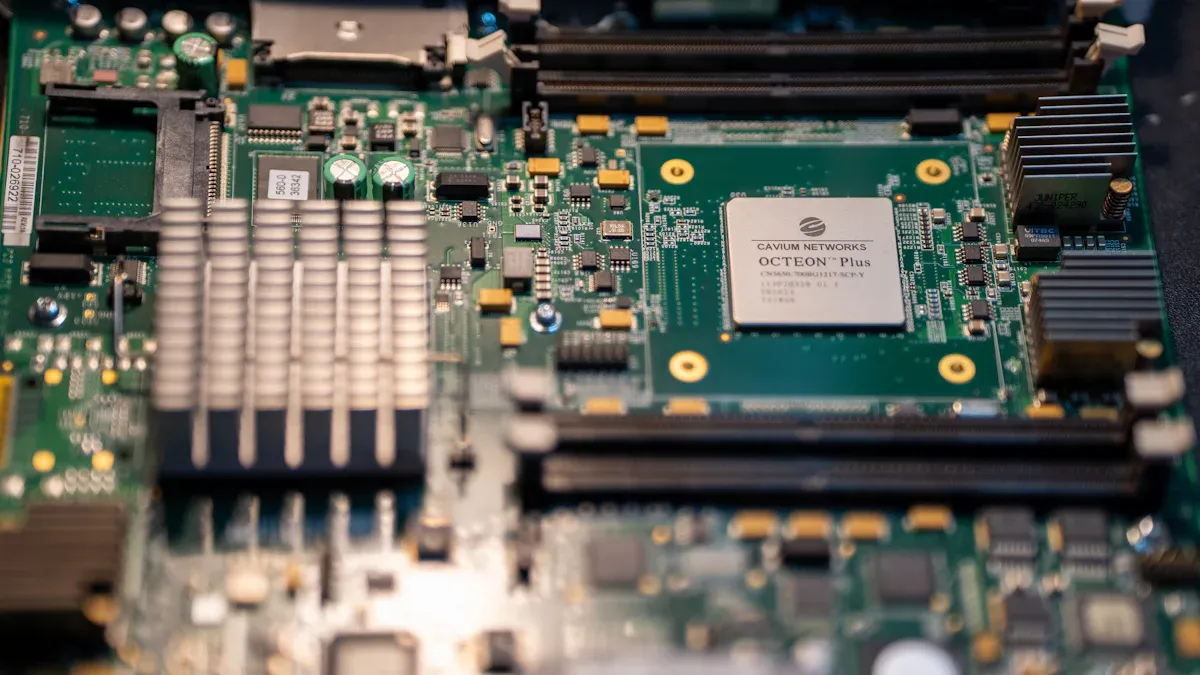

LT CIRCUIT’s IMS PCB Expertise

When you choose LT CIRCUIT, you get access to advanced ims pcb solutions designed for modern electronics. LT CIRCUIT offers a wide range of products, including double sided ims pcb, HDI boards, and multilayer pcb options. You can customize your board with different materials, solder mask colors, and surface finishes to fit your specific needs.

LT CIRCUIT uses the latest advancements in ims pcb design and manufacturing. You see high-thermal-conductivity ceramics like AlN and BeO for extreme heat dissipation. Miniaturization techniques, such as microvias and HDI technology, allow you to build compact boards for automotive and 5G applications. Smart pcb designs now include embedded sensors for real-time thermal monitoring and AI-driven optimization. LT CIRCUIT also focuses on sustainable manufacturing by using lead-free, halogen-free materials and recyclable metal cores.

Here are some recent technological advancements you can expect:

Advancement Type | Description |

|---|---|

Use of ceramics like AlN and BeO for extreme heat dissipation. | |

Miniaturization Techniques | Microvias and HDI for compact designs in automotive and 5G. |

Integration with AI and IoT | Embedded sensors for real-time thermal monitoring and AI-driven design. |

Automotive & EV Focus | High-power ims pcb for inverters, battery management, and motor drives. |

Sustainable Manufacturing | Lead-free, halogen-free, and recyclable metal cores. |

High-Frequency Applications | Low-Dk materials for 5G/mmWave RF and EMI shielding. |

LT CIRCUIT has achieved several milestones in ims pcb technology. You benefit from innovations like loading resonance diagnosis, which helps identify and solve heat and signal issues in complex circuits. The company has extended frequency headroom up to 67 GHz, supporting the latest high-speed data standards. LT CIRCUIT also speeds up product cycles by reducing connector optimization time from days to seconds.

Here are some key achievements:

Key Achievement | Description |

|---|---|

Loading resonance diagnosis and circuit transformation | Identified the root cause of loading resonances and interpreted 3D EM wave transmission/resonances in 1D circuit counterparts. |

Frequency headroom | Extended validated bandwidth from 40 GHz (2021) to 67 GHz (2024), adequate for 1.6 TbE and upcoming PCIe 7.0. |

Speed | Reduced connector optimization loops from days to seconds, accelerating product cycles. |

Awards | DesignCon 2024 Best Early-Career Paper Finalist, IEEE EPS Travel Award (ECTC 2025). |

You can see LT CIRCUIT’s expertise in these industry recognitions:

2023: DesignCon – "Distributed-Physical-Based TL Model of PCIe 5.0 Connector for SI Fast Diagnosis" showed a new model with high accuracy and speed.

2024: DesignCon – "m-TL Circuit Model of 5/6 G Connectors for Fast Resonance Crosstalk Analysis" expanded the model to multi-pair circuits.

2025: IEEE T-MTT – "PCIe 5.0 Connector Distributed Physical-Based Circuit Model with Loading Resonances for Fast SI Diagnosis & Pathfinding" enabled design pathfinding for PCIe 6.0 and 7.0.

You can trust LT CIRCUIT for quality and reliability. The company follows ISO 9001:2015 standards, which means every ims pcb meets strict quality requirements.

Certification/Standard | Description |

|---|---|

ISO 9001:2015 | Adherence to strict quality standards in production. |

LT CIRCUIT’s commitment to innovation, quality, and customer satisfaction makes it a leader in the ims pcb industry. You get advanced solutions for all your power electronics, led lighting, and high-power applications.

You see double sided IMS PCB technology driving progress in many fields. These PCBs help renewable energy and industrial automation grow.

Sector | IMS PCB Impact |

|---|---|

Automation | Boosts energy management and system reliability. |

Renewable Energy | Supports solar and wind power systems. |

Eco-friendly Focus | Uses sustainable materials. |

R&D and Innovation | Advances thermal management solutions. |

The demand for PCB power solutions rises with more solar inverters and energy storage systems.

Government incentives encourage you to use green technology.

LT CIRCUIT leads with quality, innovation, and advanced PCB solutions.

FAQ

What makes double sided IMS PCBs better for heat management?

You get faster heat transfer with a metal core. This design keeps your electronics cooler and helps prevent overheating in high-power devices.

Tip: Use double sided IMS PCBs for LED lighting or power modules to boost reliability.

Can you customize IMS PCBs with LT CIRCUIT?

Yes, you can choose materials, solder mask colors, and finishes. LT CIRCUIT offers custom solutions to fit your project’s needs.

Where do you usually see double sided IMS PCBs used?

You often find them in LED lighting, automotive electronics, solar inverters, and industrial control systems. These boards work well in places that need strong heat control.

See Also

Understanding The Differences Between PCB Types: Single, Double, Multilayer

Exploring The Diverse Uses Of Multilayer PCBs In Various Sectors

Defining IC Substrate PCBs And Their Essential Roles

An Overview Of High-Speed PCBs And Their Importance

Essential Design Factors For Reliable HDI PCB Manufacturing Processes