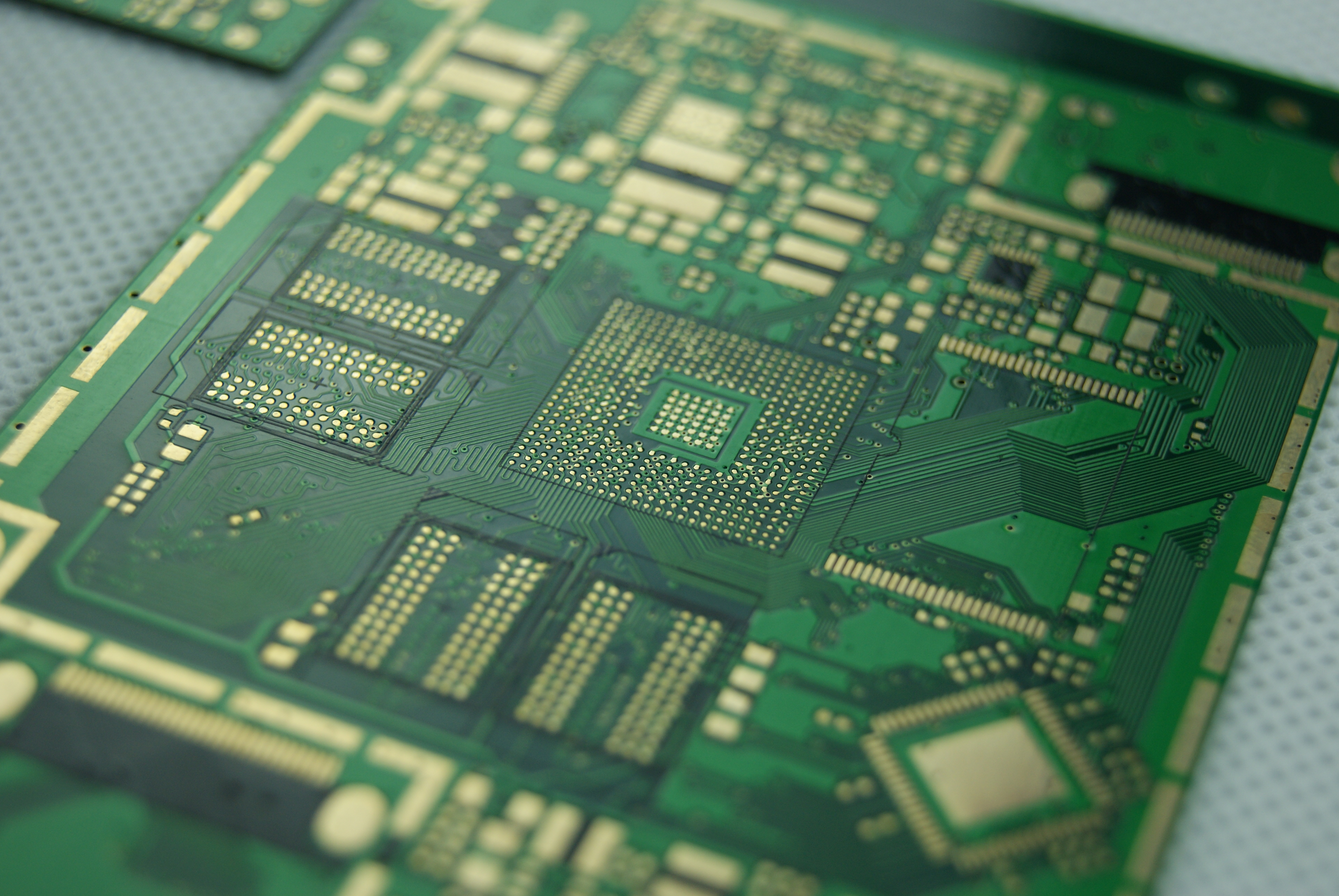

ENIG vs. Other PCB Surface Finishes: Why Immersion Gold Is Preferred for High-Reliability Applications

Printed circuit boards (PCBs) for important uses need strong finishes. These finishes stop rust, improve work quality, and handle pressure well. Immersion Gold (ENIG) is the best choice because it lasts long and fights corrosion. In airplanes and space systems, ENIG helps electronics survive tough conditions. It also works for medical devices since it is safe and dependable, making it great for long use.

Key Takeaways

Immersion Gold (ENIG) stops rust and damage, keeping parts working well for a long time in important uses like airplanes and medical tools.

ENIG's flat surface makes soldering easier, creating strong connections and good electrical work, especially in tight designs.

LT CIRCUIT makes top-quality ENIG PCBs that follow strict rules, making them a reliable pick for important fields like phones and airplanes.

The Importance of Immersion Gold in PCB Surface Finishes

Protecting PCBs from Oxidation and Corrosion

PCBs need protection from damage caused by the environment. Immersion gold adds a shield over the copper to stop oxidation. This keeps the PCB working well and dependable for a long time. Research shows immersion gold is better than palladium at stopping oxidation. It also fixes problems like "black pad," which happens from nickel corrosion, using better plating methods.

ENIG coatings are made to fight corrosion, including galvanic corrosion. The nickel and gold layers work together to protect the PCB. This makes ENIG a top choice for industries needing durable and reliable PCBs.

Enhancing Solderability and Electrical Performance

Immersion gold gives a smooth surface that helps with soldering. It creates strong solder joints, even for tiny parts. Tests show ENIG has great flatness and resists corrosion, making it perfect for dense designs.

The nickel layer in ENIG slows down intermetallic compound (IMC) growth. This makes solder joints stronger and less likely to break. ENIG also passes tough solderability tests, proving it works well for electrical tasks.

Durability for Long-Term and High-Stress Applications

Immersion gold helps PCBs handle tough conditions. Manufacturers test them with strict rules like tape tests and microsection checks to ensure strength. Gold Finger PCBs, which use immersion gold, perform well in cars and heavy machines.

Studies show PCBs with immersion gold stay good for 20 years if stored right. They can also handle 1,000 connection cycles without failing, showing they last in heavy use.

Why ENIG Stands Out Among Surface Finishes

Key Advantages of ENIG Over HASL and OSP

When comparing ENIG to other finishes like HASL and OSP, it stands out. ENIG is better for durability, soldering, and lasting performance. HASL can leave bumpy surfaces, but ENIG is smooth and flat. This makes it great for small, packed components. OSP is cheaper but doesn’t resist rust or last as long as ENIG.

Here’s a simple comparison of ENIG with other finishes:

Feature | ENIG | HASL | OSP |

|---|---|---|---|

Flat Surface | Yes | No | Yes |

Long Shelf Life | Yes | No | No |

Corrosion Resistance | Yes | No | No |

Lead-Free Compliance | Yes | Yes | Yes |

ENIG stops rust and keeps soldering easy over time. This makes it the best choice for important uses like airplanes and medical tools.

The Role of Nickel and Gold Layers in Reliability

The nickel and gold layers in ENIG make PCBs work better. Nickel protects copper from rust and helps make strong solder joints. Gold keeps the nickel from rusting and helps with soldering, even after long storage.

Here’s how these layers help:

Nickel Layer: It is added evenly and blocks harmful growth on metals.

Gold Layer: It doesn’t rust and keeps the nickel clean for soldering.

Gold also spreads heat well, which is important for powerful devices. Together, nickel and gold make PCBs strong and reliable, even in tough conditions.

Flat Surface for High-Density and Fine-Pitch Components

A flat surface is key for modern PCBs with tiny parts. ENIG’s smooth finish helps place parts correctly and avoids soldering mistakes.

For things like BGA and SMT designs, ENIG gives the flatness needed for success. Studies show smooth surfaces improve soldering and make designs more reliable.

Surface Finish Type | Benefit for Fine Pitch/BGA Components |

|---|---|

ENIG | Excellent planarity and solderability |

HASL | Uneven surface, not ideal for fine pitch |

OSP | Limited shelf life, less reliable for dense designs |

Choosing ENIG means your PCBs will work well for advanced designs. Its smooth surface and strong nickel and gold layers make it the best for reliable electronics.

LT CIRCUIT’s Expertise in High-Reliability ENIG Solutions

Advanced PCB Technologies with Immersion Gold

LT CIRCUIT is a leader in making advanced PCBs. They use top-notch immersion gold technology to improve conductivity and stop rust. This helps devices work well, even in tough conditions.

Here’s what LT CIRCUIT offers:

Feature | Description |

|---|---|

Surface Finish | Immersion gold gives great conductivity and stops oxidation. |

Design Capability | |

Application Range | Used in electronics, medical tools, aerospace, and cars. |

Reliability | Immersion gold boosts performance in harsh environments. |

Production Efficiency | Fast production and quick prototypes for your needs. |

These features make LT CIRCUIT a trusted choice for industries needing strong PCBs. Whether for small gadgets or critical aerospace systems, their immersion gold PCBs deliver precision and dependability.

Applications in Aerospace, Medical Devices, and Telecommunications

LT CIRCUIT’s immersion gold PCBs are perfect for industries needing high reliability. They are used in satellites, medical monitors, and 5G networks.

Sector | Application Example | Benefits |

|---|---|---|

Aerospace | Satellites with immersion gold PCBs | Better electrical performance and no signal loss. |

Medical Devices | Heart monitors with immersion gold boards | Reliable readings and long-lasting safety for patients. |

Telecommunications | Servers for fast data with immersion gold PCBs | Strong signals and smooth data transfers for 5G. |

In aerospace, these PCBs handle extreme heat and heights. For medical tools, they are safe and last long. In telecom, they keep connections stable, even in busy 5G systems.

📊 Did you know? Over 60% of ENIG is used in electronics. In aerospace, it meets strict military rules. For medical tools, ENIG use has grown 18% yearly since 2020.

Commitment to Quality and Environmental Compliance

LT CIRCUIT focuses on quality and protecting the environment. Their PCBs meet top standards like ISO 9001 and IATF 16949.

Certification/Standard | Description |

|---|---|

MIL-PRF-31032 | Military standard for circuit boards. |

AS 9100 | Quality system for aerospace. |

ITAR | Rules for international arms trade. |

IPC 6012 & IPC 6018 | PCB design and manufacturing standards. |

NADCAP | Aerospace and defense accreditation. |

IATF 16949 | Quality standard for cars. |

ISO 9001 | Global quality management standard. |

ISO 14001 | Environmental management standard. |

ISO/IEC 17025 | Testing and calibration requirements. |

TL 9000-H | Telecom quality management system. |

Bellcore Compliance | Meets Bellcore standards. |

OHSAS | Safety and health management. |

Automotive TS 16949 | Car industry quality standard. |

Medical ISO 13485 | Medical device quality system. |

These certifications prove their PCBs are reliable and eco-friendly. LT CIRCUIT uses advanced tools and methods to ensure top quality.

🌱 Sustainability Matters: LT CIRCUIT cares about the planet. Their ISO 14001 certification shows they reduce harm to the environment while making great products.

ENIG is the most reliable choice for advanced PCB designs. It lasts long and works best for important applications.

Surface Finish | |

|---|---|

ENIG | Best |

ENEPIG | Similar to ENIG |

ImAg | Least |

With LT CIRCUIT’s skill, you get custom-made PCBs. These PCBs are built to last and stay dependable.

FAQ

Why is ENIG better than other PCB finishes?

ENIG resists rust, has a smooth surface, and lasts long. These qualities make it perfect for important uses like airplanes and medical tools.

How does ENIG help with soldering?

The gold layer stops rust, making soldering easy. The nickel layer makes solder joints strong and slows harmful growth, keeping connections reliable in tight designs.

Is ENIG good for the environment?

Yes, ENIG follows eco-friendly rules like ISO 14001. It has no lead and supports green manufacturing, making it a smart choice for eco-friendly industries.

💡 Tip: Keep ENIG PCBs in a dry place to make them last longer and work better.

See Also

How Tin Immersion Affects Solder Mask Stability in PCBs

Vacuum Two-Fluid Etching Machines: Key to Precision PCB Manufacturing

Utilizing Horizontal Copper Sinking Technology for PCB Manufacturing

Creating High-Performance PCBs Tailored for LED Technologies

Key Guidelines for Designing Heavy Copper PCBs for High Currents