Essential Guide to Flex PCB Manufacturing

Flex PCB manufacturing is important for today's electronics. It helps make circuits that are light, small, and fit odd shapes.

Flexible PCBs are used in cars, healthcare, and gadgets. These industries need parts that bend and last long.

The flexible PCB market might grow to USD 20 billion by 2029. This shows how useful they are for tiny devices and powerful systems. Knowing how they are made can help you save money, improve reliability, and make better electronics.

Key Takeaways

Flex PCBs are light and bendable, perfect for gadgets like smartwatches and phones.

Special materials and careful testing make flex PCBs strong and dependable in harsh environments.

Picking a full-service company like LT CIRCUIT simplifies production, saves money and time, and keeps quality high.

Understanding Flex PCBs

What is a Flex PCB?

A flex PCB is a special circuit board that can bend and twist. Unlike stiff boards, it uses soft materials like polyimide to fit tight or odd spaces. These boards are important for modern gadgets because they are light and flexible.

Strict rules ensure flex PCBs work well and last long. Below is a table showing key standards and their uses:

IPC Standard | Purpose | Examples of Use |

|---|---|---|

IPC-6013 | Checks quality and performance. | Used in testing for heat and bending strength. |

IPC-2223 | Guides how parts are connected. | Helps in wearables and smart devices. |

IPC-9204 | Tests flexibility and stretch. | Ensures durability for foldable phones and health gadgets. |

IPC-9257 | Tests electrical functions. | Confirms circuits work before making them in bulk. |

IPC-TM-650 | Sets testing methods for materials. | Keeps production consistent and reliable. |

IPC-TM-650 2.6.21B | Measures heat resistance of materials. | Helps pick materials for hot environments. |

These rules make sure flex PCBs meet the needs of industries that require strong and reliable circuits.

Key Characteristics of Flex PCBs

Flex PCBs have unique features that make them different from stiff boards:

They use soft, high-quality materials like polyimide for flexibility.

They can bend or fold to fit small or odd spaces.

They combine many boards into one, making devices lighter.

They handle bending and shaking without breaking.

They keep working well in moving parts or tough conditions.

They resist heat and shaking, making them great for cars and planes.

These features make flex PCBs popular for industries needing strong and flexible designs.

Applications of Flex PCBs in Modern Industries

Flex PCBs are used in many industries because they are flexible and reliable. Here are some examples:

Wearable Devices: Used in fitness bands and smartwatches for comfort and strength.

Automotive Electronics: Found in car dashboards, sensors, and lights. They handle heat and shaking well.

Healthcare: Used in medical tools like sensors and implants for their small size and flexibility.

Consumer Electronics: Help make thin smartphones, tablets, and laptops.

Aerospace: Reduce weight in planes and spacecraft while working in extreme conditions.

As technology improves, flex PCBs are being used more and more. Their demand is growing as industries need lighter and stronger electronics.

Materials in Flexible PCB Fabrication

Common Base Materials (Polyimide, Copper Foil)

Flexible PCBs use strong materials to work well. Polyimide is a popular choice because it handles heat and bends easily. This makes it great for tough jobs. Copper foil is the part that carries electricity, making sure circuits work properly.

These materials are used where strength and accuracy are needed. Polyimide stays strong in hot places, and copper foil keeps electricity flowing. Together, they help flexible PCBs bend and twist without breaking or failing.

Adhesives and Coverlays in Flex PCB Manufacturing

Adhesives and coverlays protect flexible PCBs from damage. Adhesives stick layers together, keeping them stable during use. Coverlays shield circuits from things like water and dirt.

Different adhesives work for different needs. Acrylic adhesives stick well, while epoxy adhesives last longer. Coverlays, often made of polyimide, add extra protection. They help flexible PCBs work even in rough conditions.

Advanced Materials for Specialized Applications

New materials are improving flexible PCBs. Special polymers handle heat better in tough environments. Sensors can now be built into the PCB, making it more useful.

These changes allow custom designs for special uses. For example:

Improved materials make polyimide even better.

Built-in sensors add new features to modern devices.

As technology grows, these advanced materials help make flexible PCBs stronger and more useful.

Flexible PCB Manufacturing Process

Design and Prototyping in Flex PCB Manufacturing

Designing and testing are key steps in making flex PCBs. First, you create a design that fits your needs. Special software helps map circuits for good performance and easy production.

Testing the design with prototypes is important before making many boards. Early tests check if the circuit works. Later tests improve details for better production. Final prototypes match the real product to ensure they meet all rules.

Here’s how prototypes are tested:

Methodology | Description |

|---|---|

Tests how circuits work and checks if they perform well. | |

Makes sure the design can be made and works as planned. | |

Testing and Validation Services | Runs tests to check if the prototype is strong and reliable. |

Prototypes also show what the product will look like. This helps everyone understand the design better. Testing and designing are needed to make flex PCBs that work well.

Material Preparation and Lamination

Getting materials ready is the first step in making flex PCBs. You pick strong materials like polyimide and copper foil. These must be clean because dirt can ruin the board.

Lamination joins the layers into one piece. Layers are stacked in order, starting with copper. Heat and pressure are used to stick them together. This makes the PCB strong and flexible.

Clean the layers to remove dirt.

Stack the layers in the right order.

Use heat and pressure to bond them.

Let the board cool and harden.

Check for mistakes and fix them.

Lamination affects how the PCB works and how strong it is. It’s an important part of making flex PCBs.

Etching, Drilling, and Plating

Etching, drilling, and plating are careful steps in making flex PCBs. Etching removes extra copper, leaving the circuit design. This step must be accurate to avoid mistakes.

Drilling makes holes for connecting parts. The holes must be in the right spots. Mistakes can cause bad connections or short circuits. Machines and tools must be set up carefully for good results.

Plating adds a metal layer to the holes. This helps electricity flow and makes the PCB stronger. Together, these steps create the main structure of flex PCBs.

Assembly and Testing in Flexible PCB Fabrication

Assembly means putting parts on the PCB and soldering them. This step needs care to avoid errors. Flex PCBs need special methods because they bend easily.

Testing checks if the PCB works and lasts. Common tests include:

In-circuit testing (ICT): Finds problems in the circuit.

Functional testing: Makes sure the PCB works as it should.

Automated optical inspection (AOI): Looks for mistakes in the design.

Quality checks are very important. They include looking at the board, testing electricity, and simulating tough conditions. X-ray tests find hidden problems. These steps ensure the PCB meets industry rules.

By following these steps, you can make flex PCBs that are strong and reliable for modern devices.

Benefits of Flex PCBs

Space-Saving and Design Flexibility

Flex PCBs save space and offer flexible designs for devices. They replace thick wires, making assembly easier and reducing mistakes. Their light weight also makes gadgets easier to carry.

Flex PCBs save room by removing the need for many wires.

They allow small designs, perfect for wearables and portable devices.

Their bending ability helps fit them into tight spaces.

These features make flex PCBs great for smartphones, medical tools, and airplanes, where saving space and weight is important.

Enhanced Durability and Reliability

Flex PCBs are strong and work well in tough conditions. They go through tests to handle stress, shaking, and extreme weather.

Purpose | |

|---|---|

ESD/EMP Testing | Stops damage from static electricity and electromagnetic pulses. |

Vibration Testing | Checks if they work after shaking or movement. |

Thermal Cycling Testing | Makes sure they survive changing temperatures. |

Moisture Resistance Testing | Protects against water damage. |

These tests prove flex PCBs last a long time. This makes them useful for cars, planes, and factory machines.

Cost-Effectiveness in Long-Term Applications

Flex PCBs save money over time by making production simpler. They don’t need extra connectors or wires, cutting down on labor costs.

Compared to stiff PCBs, flex PCBs provide:

Space savings with foldable designs.

Fewer connections, which means fewer repairs.

Lightweight builds, lowering shipping costs for portable items.

These benefits make flex PCBs a smart choice for industries needing reliable and efficient electronics.

Challenges in Flex PCB Manufacturing

Tackling Design Complexity

Making flexible PCBs is tricky and needs careful planning. You must balance how circuits work with how they bend. Transparent flex PCBs are even harder to design. They need special materials that are clear and conduct electricity. For example:

Clear materials must work for both looks and electricity.

Layers and parts must be placed carefully to avoid mistakes.

Signals must stay strong while keeping the circuit neat.

These challenges show why advanced tools and skilled makers are needed for good results.

Handling Material Costs

The cost of materials affects how much flexible PCBs cost to make. Polyimide and special glues are expensive. Costs are higher in industries like aerospace and defense. Important factors include:

Labor costs, which make up 40-45% of production costs in places like the U.S. and U.K.

Suppliers raising prices to deal with changing material and labor costs.

To save money, you can buy in bulk, design smarter to waste less, and work with manufacturers who offer good deals without lowering quality.

Keeping Quality Consistent

Making sure flexible PCBs are always high quality takes effort. You need methods to reduce mistakes and improve reliability. Common ways include:

Strategy | Description |

|---|---|

Following International Standards | Ensures products are good and builds trust with certifications. |

Improving Processes Over Time | Updates methods to meet customer needs and reduce errors. |

Using IoT and Automation | Makes production faster, reduces mistakes, and gives live data for better control. |

Statistical Process Control (SPC) | Uses numbers to check and fix production problems, keeping quality steady. |

Lean Manufacturing | Cuts waste and improves efficiency, making production smoother and better. |

By using these methods, flexible PCBs can meet industry rules and work well in many devices.

Best Practices for One-Stop Flexible PCB Fabrication

Working with LT CIRCUIT for Expert Help

Picking the right company for flexible PCB making is key. LT CIRCUIT offers a one-stop solution that makes the process easier and more accurate. By handling everything in one place, you save money and time.

LT CIRCUIT’s skills in PCB making ensure top quality. Their advanced management system checks every step to meet industry rules. Teams focus on choosing materials, improving designs, and making sure your PCB works well in tough situations.

Benchmark | Description |

|---|---|

Combining services saves money on shipping and materials. | |

Shorter lead times | Getting parts and making PCBs at the same time avoids delays. |

Guaranteed quality | Careful management and strict checks keep quality high. |

Choosing LT CIRCUIT gives you access to modern tools and a smooth process, helping you turn your ideas into reality.

Why Testing and Inspection Matter

Testing and checking are important to make sure flexible PCBs work well. Careful quality checks confirm your PCB is strong and reliable. Each test finds problems early, so they can be fixed before production.

LT CIRCUIT uses strict testing methods to meet industry standards. From checking by eye to testing in tough conditions, every step ensures the PCB performs under stress.

Testing Method | Purpose |

|---|---|

Visual Inspection | Spots visible problems in parts and circuits. |

Dimensional Testing | Makes sure sizes and limits are correct for assembly. |

Electrical Testing | Checks if the PCB works by testing electricity flow. |

Flexibility Testing | Tests if the PCB can bend without breaking. |

Environmental Testing | Checks if it lasts in extreme heat or moisture. |

Reliability Testing | Tests how long and stable the PCB will be. |

X-ray Inspection | Looks inside the PCB to find hidden issues. |

These tests make sure your flexible PCB is strong and dependable.

Using Advanced Tools for Accuracy

Modern tools are important for making precise flexible PCBs. LT CIRCUIT uses advanced machines and automation to improve production and reduce mistakes.

High-tech inspection tools like AOI and X-ray systems find defects with great accuracy. These tools catch more errors and avoid false alarms, ensuring your PCB meets top standards.

Metric | Improvement |

|---|---|

Defect detection rates | Better by up to 99.5% |

False positive rates | Lowered to under 1% |

Inspection time | Cut down by 80% |

Overall production yield | Increased by 15-20% |

By using these technologies, LT CIRCUIT makes sure your flexible PCB is made with care and precision, ready for complex uses.

Flex PCBs are key to today’s electronics. They help make smaller devices, last longer, and improve signals.

Feature | Explanation |

|---|---|

Uses | Found in smartwatches, medical tools, car systems, and foldable gadgets. |

Saves Space and Weight | Fits parts tightly for smaller and lighter electronics. |

Strong and Flexible | Bends easily without breaking, perfect for moving parts. |

Better Signal Quality | Fewer connectors mean stronger and faster signal flow. |

Cost-Effective | Easier to assemble, saving money on complex designs. |

Working with LT CIRCUIT ensures accurate and high-quality flex PCBs. Their skills make production easier, cheaper, and dependable.

📈 Exciting future uses for flex PCBs include:

Helping 5G networks grow.

Making wearables and medical tools even smaller.

Supporting eco-friendly technology.

Discover how flex PCBs can bring new ideas to life for your projects.

FAQ

What industries use flex PCBs the most?

Flex PCBs are common in cars, healthcare, planes, and gadgets. These industries need parts that are strong, bendable, and save space.

How do flex PCBs make products more reliable?

Flex PCBs handle shaking, heat, and water well. Their tough design keeps them working in hard places like cars or factory machines.

Can flex PCBs help lower production costs?

Yes, flex PCBs make assembly easier by using fewer wires. This cuts labor costs and improves efficiency, saving money over time.

💡 Tip: Working with experts like LT CIRCUIT ensures top-quality flex PCBs made just for you.

See Also

Understanding The Process Behind PCB Manufacturing Techniques

An In-Depth Look At The PCB Fabrication Process

Key Materials And Processes In Rigid PCB Manufacturing

Selecting A Reliable PCB Manufacturer For Your Business Needs

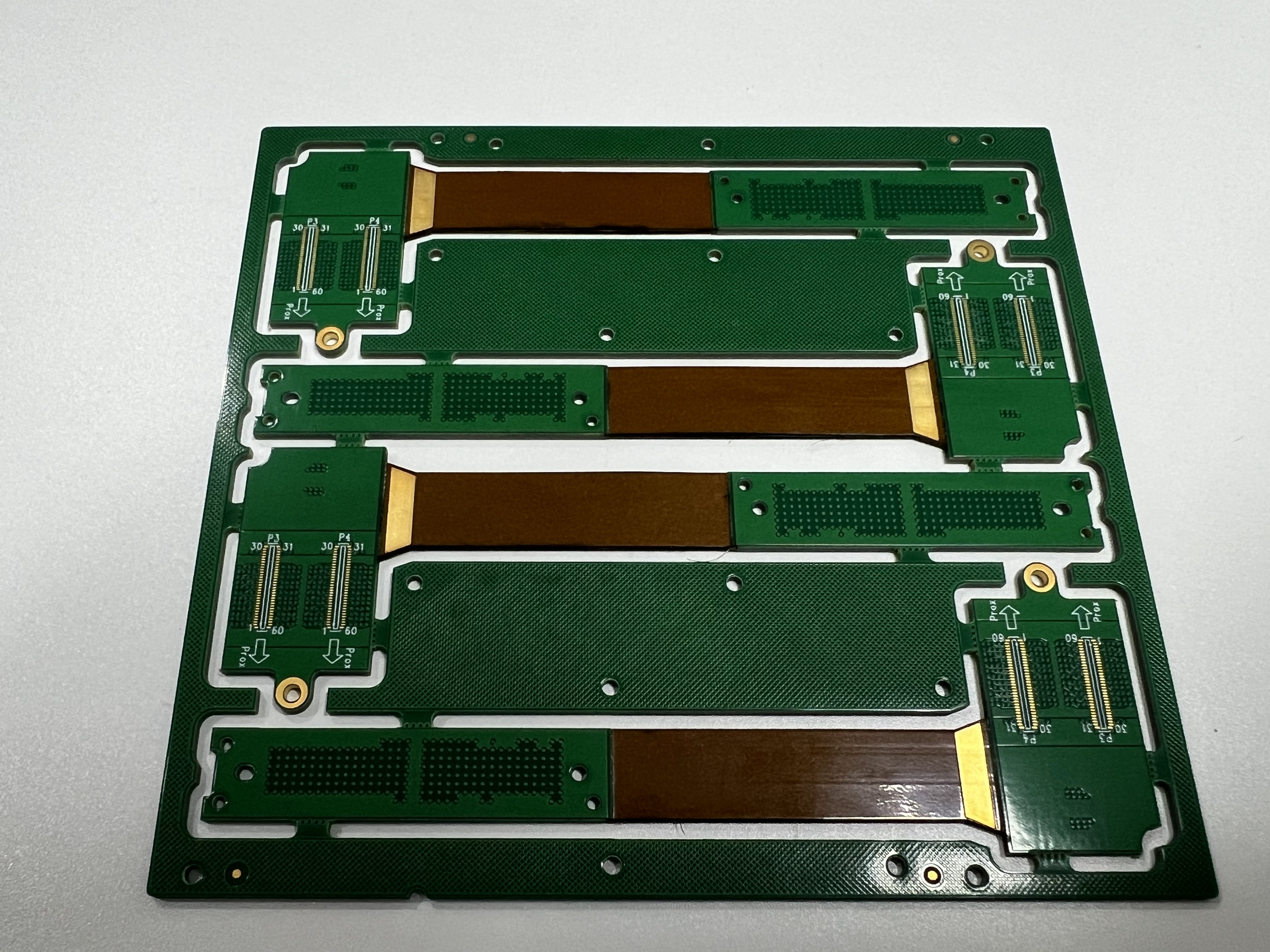

Exploring The Production Methods For Multilayer Rigid-Flex Boards