The Essential Steps in Fast Turnkey PCB Assembly

Fast turnkey PCB assembly is important in making electronics today. It helps with speed, reliability, and saving money, which are key to staying competitive. These services simplify design, buying parts, assembly, and testing. This means products are ready faster and take less time to develop. Automated Optical Inspection (AOI) finds mistakes with 99.5% accuracy. This improves production by up to 20%. LT CIRCUIT uses advanced technology and a clear process to provide great PCB assembly solutions made just for you.

Key Takeaways

Quick turnkey PCB assembly makes the process faster and cheaper.

Doing DFM and DFA checks early avoids errors and boosts quality.

AOI and X-ray checks find defects, making products more reliable.

Preparation Steps in Turnkey PCB Manufacturing

Design for Manufacturing (DFM) and Design for Assembly (DFA) Checks

Before making your PCB, check if the design works well. This includes Design for Manufacturing (DFM) and Design for Assembly (DFA) checks. These checks find problems early and make production easier.

DFM checks ensure your design fits manufacturing limits. This avoids mistakes and improves quality.

DFA checks make assembly simpler, reducing errors and defects. They also improve how your PCB works and lasts.

Fixing these issues early saves money, boosts reliability, and speeds up production. Finding design problems early prevents failures during assembly and makes production smoother.

Tip: Work with experts like LT CIRCUIT to do DFM and DFA checks. Their knowledge helps make your design ready for fast PCB assembly.

Bill of Materials (BOM) Review and Material Procurement

A detailed Bill of Materials (BOM) is key for smooth PCB production. Reviewing your BOM ensures all parts are listed and meet requirements. This step avoids delays and helps get materials on time.

Benefit | Description |

|---|---|

Lists all components, avoiding missing items during assembly. | |

Better teamwork | Improves communication between teams, helping product development. |

Faster production | Guides assembly, making production quicker with fewer delays. |

Accurate cost planning | Helps estimate costs by listing quantities and prices of parts. |

Good inventory control | Prevents having too many or too few parts in stock. |

Higher product quality | Ensures parts meet standards, improving the final product. |

Less waste and rework | Reduces mistakes and fixes during production, saving time and materials. |

Checking your BOM carefully helps avoid waste and keeps quality high. LT CIRCUIT can help find the best parts for your project.

PCB File Verification and Approval by LT CIRCUIT

After finishing your design and BOM, check your PCB files. This step makes sure your files are correct for production. LT CIRCUIT reviews your Gerber files, drill files, and other documents. They look for mistakes or problems that could affect manufacturing.

Once verified, LT CIRCUIT gives feedback and approval for production. This ensures your design is ready for fast PCB assembly. Their careful checks make the move from design to production easy.

Note: Working with LT CIRCUIT gives you a clear guide for file checks. This keeps your project on schedule and meets deadlines.

Assembly Process in Fast Turnkey PCB Assembly

Solder Paste Application

The first step is adding solder paste to the board. This paste helps parts stick and conduct electricity. A stencil, matching the board design, is used for accuracy. The stencil ensures paste goes only on specific spots, like pads for components.

Proper solder paste use lowers errors. Mistakes from bad paste application can drop by 60%-90% with better methods. Welding quality improves by 40%, and fixing costs go down by over 60%. These changes make products more reliable, with failures decreasing by 30%.

Metric | Percentage/Value |

|---|---|

Fewer soldering mistakes | |

Better welding quality | Increased by 40% |

Lower rework costs | Reduced by over 60% |

Higher product reliability | Increased by 30% |

Good solder paste application is key to making quality circuit boards.

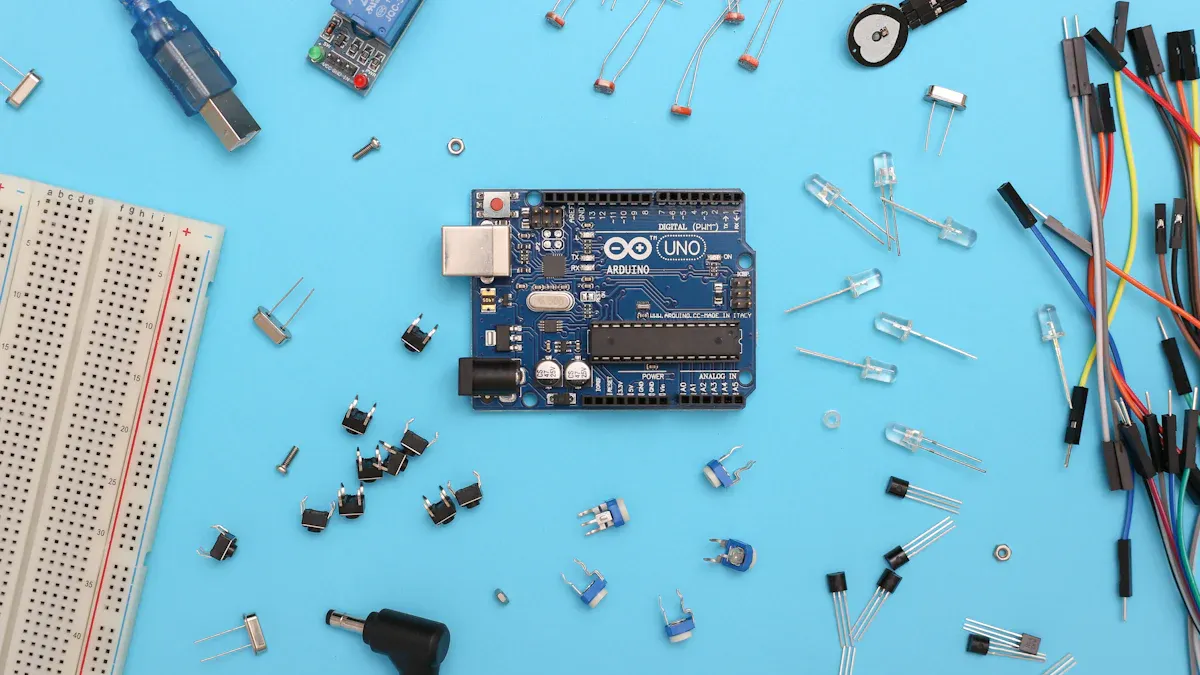

Component Placement Using Advanced SMT Technology

Next, components are placed on the board. Advanced surface mount technology (SMT) uses fast machines for this. These machines have many nozzles and move quickly, placing thousands of parts per hour.

SMT boosts speed and quality. For example:

A company saw a 60% rise in output after using smart SMT machines.

Defects dropped by over 30%, improving product quality.

This step ensures parts are placed correctly, reducing mistakes and speeding up assembly.

Reflow Soldering for Precision Assembly

Reflow soldering secures parts on the board. The board goes through a reflow oven, where heat melts the solder paste. This creates strong connections. Custom heat settings improve solder quality and reduce errors.

Aspect | Contribution to Precision Assembly |

|---|---|

Custom Heat Settings | Improve solder quality and reduce mistakes. |

Regular Thermal Checks | Keep the oven working well for consistent results. |

Automated Inspections | Find defects, improving assembly accuracy. |

Reflow soldering is vital for precise assembly. It ensures solder joints are strong and the product is defect-free.

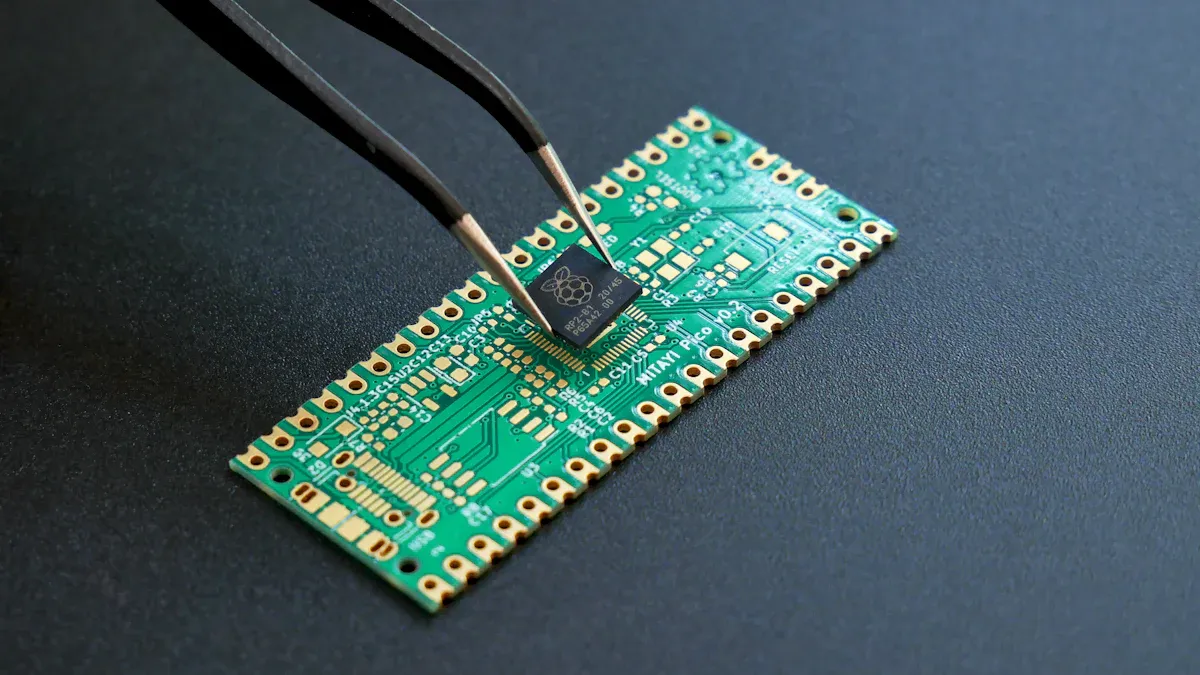

Manual Soldering for Specialized Components

Some parts need manual soldering, like connectors or special pieces. Machines can't handle these, so skilled workers do it carefully. This step ensures the board's quality.

Manual soldering adds flexibility for unique parts. It ensures every part meets high standards. Combining machine and manual work makes assembly smooth and efficient.

Inspection and Testing for Quality Assurance

Checking and testing are important steps in making a PCB. They make sure the PCB works well and meets quality rules. Finding problems early helps avoid fixing mistakes later and saves time. Here’s how these checks are done:

Automated Optical Inspection (AOI) for Finding Problems

Automated Optical Inspection (AOI) uses special cameras to spot surface problems on a PCB. It’s quick, accurate, and helps keep the assembly process smooth. AOI looks for:

Solder problems like too little, too much, or solder bridges.

Component issues like wrong placement, missing parts, or bad alignment.

Surface damage like scratches or dirt.

AOI systems are very reliable, with less than 2% false alarms and fewer than 1% missed errors.

Parameter | Industry Standard |

|---|---|

False Call Rate | <2% |

Escape Rate | <1% |

This technology helps make sure the PCB assembly is fast and accurate.

X-Ray Inspection for Hidden Problems

AOI checks the surface, but X-ray inspection finds hidden issues. This method spots problems like gaps in solder or cracks inside the board. Unlike cutting the board to check inside, X-ray keeps the PCB safe. It’s very useful for checking complex designs.

Functional Testing and Debugging by LT CIRCUIT

Functional testing checks if the PCB works as planned. LT CIRCUIT uses tools to measure signals, check performance, and find problems. Important checks include:

Description | |

|---|---|

Waveform Observation | Watches signals live to find problems. |

Signal Analysis and Measurements | Makes sure the circuit works as designed. |

Time-Domain Measurements | Finds timing problems like signal delays. |

Triggering Capabilities | Spots specific issues for closer checks. |

Advanced Features for In-Depth Analysis | Helps fix problems with digital signals. |

These tests make sure the PCB is ready to use without any issues.

Finalization in Turnkey PCB Manufacturing

Cleaning and Debris Removal

Cleaning is an important step in making PCBs. It removes dirt and leftover materials that could harm the board. Techniques like rinsing and brushing clean off flux, dust, and debris. A final rinse ensures all residues are gone, stopping them from causing problems later.

Leftover flux can attract water, leading to rust. Rust damages parts and PCB connections, making them less reliable. Ionic contamination can cause tiny growths called dendrites. These growths create unwanted paths for electricity, which may lead to leaks or short circuits. These issues can hurt how the PCB works.

Problem Description | Effect on PCB Quality |

|---|---|

Final rinse removes all flux residues from the board. | Stops residues from moving and causing problems in assembly. |

Acidic flux attracts moisture, leading to rust. | Rust harms parts and PCB connections, lowering reliability. |

Ionic contamination causes dendritic growth, creating unwanted paths for current. | Dendrites can cause leaks or short circuits, hurting PCB performance. |

Cleaning well improves the PCB’s quality and ensures it works properly.

Packaging for Protection and Delivery

Packaging keeps PCBs safe during shipping. Good packaging reduces damage by absorbing shocks and keeping the PCB still. Materials like bubble wrap and foam peanuts protect the PCB from scratches and bumps.

Protective packaging absorbs shocks and keeps the PCB secure.

Data shows well-packed items have fewer damages than poorly packed ones.

Bubble wrap and foam peanuts stop scratches and absorb impacts.

Studies prove cushioned packages have much lower damage rates.

Using these methods ensures your PCB arrives safely and ready to use.

Logistics Coordination by LT CIRCUIT

LT CIRCUIT handles delivery to make sure your PCBs arrive on time. They produce up to 50,000 square meters of PCBs each month, managing big orders easily. Certifications like UL, CE, RoHS, and ISO9001 show their focus on quality.

Their delivery process includes tests like flying probe checks and optical inspections. These tests ensure every PCB meets high standards before shipping. LT CIRCUIT’s organized logistics keep your production schedule running smoothly.

Fast turnkey PCB assembly makes the process easier and quicker. It covers everything from design to delivery. This method saves time, money, and improves reliability. Using one provider helps launch products faster and reduces costs.

Benefit Type | Description |

|---|---|

Speed | Turnkey PCB assembly shortens waiting times for faster launches. |

Cost-Effectiveness | Smaller orders lower upfront costs and offer more options. |

Efficiency | One provider avoids shipping delays and keeps things simple. |

Picking LT CIRCUIT ensures top-quality PCB assembly made just for you.

FAQ

What is the biggest benefit of turnkey PCB assembly?

Turnkey PCB assembly makes things easier. It handles design, buying parts, building, and testing. This saves time, lowers costs, and gives great results.

How does LT CIRCUIT deliver quickly?

LT CIRCUIT uses smart tools, good planning, and careful checks. These steps make sure your PCBs arrive fast and stay high-quality.

Can small orders be done with turnkey PCB assembly?

Yes, small orders are possible with turnkey PCB assembly. You can test new designs or make fewer items without spending too much or waiting long.

See Also

Advantages of Integrating SMT and THT in PCB Assembly

Essential Skills for Designing Multi-Layer PCB Layouts

Understanding the Manufacturing of Rigid-Flex Multilayer PCBs

Enhancing PCB Production Yields with Online AOI Technology

Importance of Vacuum Two-Fluid Etching in Precision PCB Manufacturing