Flex PCB vs. Rigid PCB: When to Choose Flexible Circuits for Your Electronics Project

When making electronics, choosing between Flex PCB vs. Rigid PCB is crucial. Flex PCBs are ideal for small, lightweight devices that require bending, while Rigid PCBs are more suitable for robust, straightforward setups and cost savings. Select based on your project’s needs, location, and budget for optimal results.

Key Takeaways

Pick Flex PCBs for designs that need to bend or fit small spaces. They work great for wearables and tiny gadgets.

Use Rigid PCBs for simple and steady projects. They are strong, affordable, and good for stable settings.

Think about Rigid-Flex PCBs for tricky projects. They mix the strengths of both types, giving flexibility and strength.

Understanding Flex PCB vs. Rigid PCB

Material Composition of Flex PCBs and Rigid PCBs

Flex PCBs and rigid PCBs use different materials. This affects how they work and where they are used. Flex PCBs are made from bendable materials like polyimide or polyester. These materials let them twist and bend without breaking. They are also lightweight and resist heat, making them great for small, moving designs. Rigid PCBs, however, use hard fiberglass-reinforced epoxy resin (FR4). This material is strong and stable, perfect for devices that stay still.

Aspect | Flexible PCBs | Rigid PCBs |

|---|---|---|

Durability | Need careful design to avoid breaking when bent. | Stronger because of their solid structure. |

Bend Areas | Sharp bends can break; smooth curves are better. | Sharp corners can cause problems; rounded edges are better. |

Cost | Cheaper but may need more parts. | |

Design Considerations | Needs special layouts for bending. | Easier to design but less flexible. |

Think about your project’s needs when choosing between flex and rigid PCBs. If your design bends a lot, flexible materials are a must to avoid damage.

Design and Structure Differences

Flex PCBs and rigid PCBs are built differently, which changes how they work. Flex PCBs are thin and can bend or fold to fit tight spaces. They often have layers of different lengths to make bending easier. A good rule is to add 1.5 times the layer thickness for better flexibility.

Rigid PCBs are flat and solid. They are made for stability and are easy to produce. While they are less flexible, they work well in simple electronics. But sharp corners in rigid PCBs can cause signal problems, so rounded corners are better.

Both types need careful planning. Flex PCBs must handle bending and heat to work well. Rigid PCBs need good layouts to avoid interference.

Manufacturing Process Comparison

Making flex PCBs and rigid PCBs is similar but has key differences. Both use copper layers to create circuits, but the materials and steps differ. Flex PCBs need special care because their materials are delicate. For example, polyimide layers must be carefully added to keep them flexible. Protective coatings are also used to stop damage during bending.

Rigid PCBs are easier to make. Their FR4 material is strong and simple to work with. Standard methods can be used, making them cheaper to produce in large amounts. Flex PCBs take longer and cost more to make because of their complex designs.

Both types benefit from modern tools and machines. These ensure high-quality results, no matter which type you choose.

Cost Implications

Cost is important when picking between flex and rigid PCBs. Flex PCBs can save money by removing the need for extra parts like connectors. They also combine many functions into one design, saving space and materials. But making flex PCBs costs more at first because of the special materials and steps needed.

Rigid PCBs are usually cheaper, especially for big orders. Their simple designs and easy production lower costs. However, they might need extra parts, like connectors, which can add to the price.

When thinking about costs, look at the long-term benefits. Flex PCBs may cost more upfront but save money in complex projects. Rigid PCBs are cheaper at first and work well for simple designs.

Advantages of Flex PCBs

Lightweight and Compact Designs

Flex PCBs are great for saving weight and space. They use light materials like polyimide, which are perfect for small devices. For example, satellites can be 30% lighter with flex PCBs. This makes them popular for aerospace and portable gadgets.

These PCBs also help make systems smaller. They can cut system size by over 60%, giving more room for creative designs. Flex PCBs remove bulky connectors, saving space and lowering costs.

Advantage | Description |

|---|---|

Flex PCBs make satellites 30% lighter. | |

Cost Savings | No bulky connectors, reducing assembly costs. |

Smaller systems save space and weight by 60%. | |

Improved Reliability | No mechanical connectors, boosting system reliability. |

Adaptability in Dynamic Applications

Flex PCBs work well in devices that move or bend. They are perfect for wearables, robots, and cars. You can bend or fold them to fit tight spaces. This keeps your designs working even in tough conditions.

For example, pacemakers use flex PCBs because they fit odd shapes. Cars also use them to handle vibrations and movement. Flex PCBs make sure your designs stay strong and reliable.

Flex PCBs improve reliability by removing weak mechanical connectors.

High-Density Interconnects

Flex PCBs allow more circuits in less space. Their layers make complex designs possible without making boards bigger. This is useful for modern devices that need to be small but powerful.

With flex PCBs, you can create designs rigid boards can't handle. They are ideal for smartphones, IoT gadgets, and military tools. Flex PCBs help you build advanced products for today’s tech needs.

Advantages of Rigid PCBs

Strong and Long-Lasting

Rigid PCBs are great for devices needing strength and reliability. Their solid build keeps them stable under stress or pressure. This makes them perfect for cars, planes, and factory machines. They don’t bend or break, even with shocks or vibrations. For example, their strong material helps them handle stress without failing. This ensures they work well for a long time.

Property | What It Means | Why It Matters |

|---|---|---|

Flexibility vs. Strength | Shows if the PCB can bend or must stay firm. | Important for devices needing strong, solid boards. |

Strength Under Tension | How well it resists breaking when pulled. | Needed for devices under heavy stress. |

Layers and Thickness | Impacts how strong and heavy the PCB is. | More layers add strength but may cost more. |

Rigid PCBs are dependable for devices that need to stay strong and last.

Affordable for Big Projects

Rigid PCBs are cheaper when making lots of electronics. Their simple design and common materials, like FR4, lower costs. They also need fewer extra parts, like connectors, making assembly easier. This makes them a smart choice for things like phones or TVs, where saving money matters.

For big projects, rigid PCBs give good performance without costing too much.

Handles Heat Well

Rigid PCBs are great for hot environments. Their materials, like fiberglass, resist heat very well. This helps them keep working even in high temperatures. Devices like power supplies and LED lights use them because they handle heat easily.

Choosing rigid PCBs means your devices can take the heat and still work reliably.

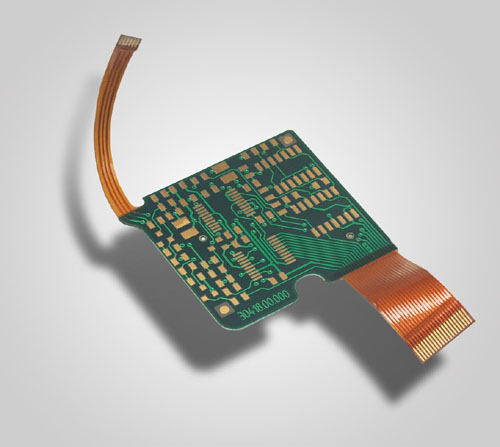

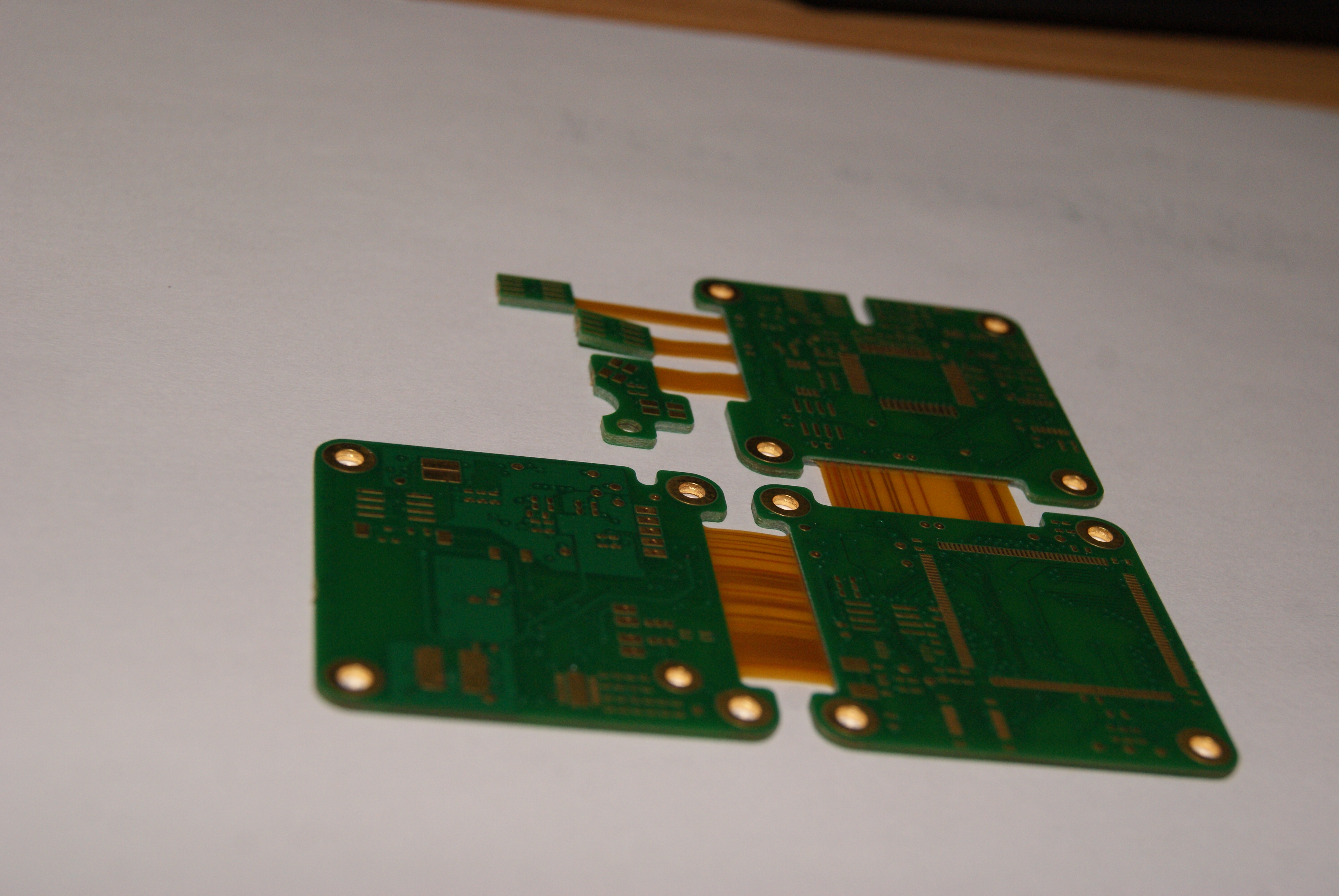

Exploring Rigid-Flex PCBs with LT CIRCUIT

Benefits of Combining Rigid and Flexible Elements

Rigid-flex PCBs mix rigid and flexible parts for better designs. They combine strong sections for stability and bendable parts for tight spaces. You can fold or twist them to fit small areas, making them great for compact devices.

These PCBs are also more reliable. Fewer connectors and solder points mean fewer chances of breaking. This keeps your devices working well over time. Rigid-flex PCBs also save money by needing fewer parts and less assembly work. They are tough and can handle heat, cold, and stress, making them perfect for hard conditions.

Benefit | Description |

|---|---|

Foldable design fits into small spaces easily. | |

Enhanced Reliability | Fewer connectors lower the risk of breaking. |

Cost Reduction | Saves money by reducing parts and assembly steps. |

Durability in Harsh Conditions | Works well in extreme temperatures and under stress. |

Design Flexibility | Allows creative shapes and 3D designs not possible with rigid PCBs. |

Versatility in Complex Applications

Rigid-flex PCBs work well in tricky designs where others fail. They are used in devices needing detailed layouts or working in tough places. For example, they are common in airplanes, medical tools, and military gear. These PCBs handle shaking, impacts, and temperature changes without losing performance.

Their ability to support 3D shapes helps create smart designs for small, powerful devices. Whether it’s wearable tech or advanced robots, rigid-flex PCBs give you the flexibility to make your ideas real.

LT CIRCUIT’s Expertise in Rigid-Flex PCB Solutions

LT CIRCUIT is a trusted maker of rigid-flex PCBs. They use top materials and modern tools to create high-quality boards. Their designs meet the needs of today’s electronics.

LT CIRCUIT focuses on accuracy and reliability. They help you build strong and efficient products. Whether for home gadgets or industrial machines, their innovative solutions ensure success. Check out LT CIRCUIT’s products to improve your electronic designs.

Choosing Between Flex PCBs and Rigid PCBs

Evaluating Project Needs

Your project’s needs decide the best circuit board type. Flex PCBs are great for designs needing movement or small spaces. They work well in wearables, robots, or aerospace devices. These boards bend and twist to fit tight areas without breaking.

Rigid boards are better for stable and simple designs. They suit devices like TVs, factory machines, or power supplies. Rigid boards are strong, reliable, and cheaper to make in large amounts.

Think about your design’s complexity when choosing. Flex PCBs handle detailed layouts and many connections. Rigid boards are better for simple designs where strength and cost matter most.

Thinking About Environmental Conditions

The environment affects how your circuit board works. Flex PCBs handle vibrations, bending, and movement well. They are perfect for wearables, car electronics, or medical tools. These boards stay strong under physical stress.

Rigid boards work best in steady environments. They resist heat and stress, making them good for hot or still setups. For example, they are used in LED lights and factory machines because they handle heat well.

For extreme conditions, rigid-flex boards are a good choice. They mix the strengths of both types, offering flexibility and toughness. These are ideal for aerospace or military projects needing high reliability.

Budget and Cost Factors

Your budget affects which PCB you pick. Flex PCBs cost more to make at first. But they save money later by needing fewer parts and steps. They also combine many functions into one board, saving materials.

Rigid boards are cheaper for big projects. Their simple design and common materials lower costs. If you’re making many devices, rigid boards are a smart, affordable option.

Rigid-flex boards balance cost and value. They cost more upfront but save on repairs and replacements. Their durability makes them worth it for projects with many uses.

Lifespan and Maintenance

How long your board lasts depends on its type and use. Flex PCBs are reliable in moving setups. They don’t need weak connectors, so they last longer in wearables, cars, and medical devices.

Rigid boards are best for still setups. Their solid build resists damage, making them great for factory machines and home electronics. They need little care and work well over time.

Rigid-flex boards mix the strengths of both types. They are durable and easy to maintain. If you need a long-lasting board, rigid-flex is a great choice.

Tip: Pick a board type that matches your project’s maintenance needs for long-term success.

Picking the right PCB depends on your project’s needs. Flex PCBs are light, handle shocks, and fit small spaces. They work well in medical devices and other tight designs. Rigid PCBs are strong, resist heat, and cost less to make. They are great for simple and steady setups. Rigid-flex PCBs mix both benefits. They are flexible and tough for tricky projects. Check out LT CIRCUIT’s solutions to make your ideas real.

FAQ

What makes flex PCBs different from rigid PCBs?

Flex PCBs can bend and fit small spaces easily. Rigid PCBs are flat and strong, perfect for stable setups.

Are flex PCBs good with high temperatures?

Yes, flex PCBs handle heat well because of their polyimide material. They work reliably even in hot conditions.

When are rigid-flex PCBs the best choice?

Use rigid-flex PCBs for small designs needing both strength and flexibility. They are great for aerospace, medical, or military uses.

See Also

Top 7 Benefits of Rigid Flex PCBs in Compact Electronics

Exploring Rigid Flex PCB Uses in Industrial and Medical Fields

A Comprehensive Guide to Rigid-Flex PCB Structures

Manufacturing Rigid PCBs: Key Materials and Quality Processes

Selecting the Right PCB Manufacturer for Your Business Needs