What Are Flexible PCBs and Their Key Applications

Flexible PCBs are circuit boards that can bend and fit into different shapes. This makes them perfect for small and creative designs. They are very important in modern electronics because they save space and are very useful.

The flexible PCB market is expected to grow a lot, reaching $61.75 billion by 2032.

In 2024, the global market was worth $23.89 billion, with a growth rate of 13.7% expected from 2025 to 2030.

Rigid-flex PCBs are also growing, valued at $22.1 billion in 2023, with a growth rate of 10.9% through 2032.

Flexible PCBs remove the need for big connectors. This helps devices like smartphones and wearables stay light and work better. They can fold and fit into small spaces, improving connections and lasting longer. This makes them very important in new technology.

Key Takeaways

Flexible PCBs can bend and fit in tight spaces. This makes them important for modern gadgets like smartphones and smartwatches.

These boards are light and strong, helping devices work better. They also last longer in tough conditions.

Picking the right flexible PCB is very important. Think about what your device needs before choosing one.

Types of Flexible PCBs by LT CIRCUIT

Flexible PCBs come in different types for various needs. LT CIRCUIT provides many options to help you find the right one.

Single-Sided Flexible PCBs

Single-sided flexible PCBs are the easiest type to make. They have one copper layer and a bendable base. These are great for simple designs in small spaces. You can see them in things like calculators or LED lights. They are light, cheap, and work well for basic electronics.

Double-Sided Flexible PCBs

Double-sided flexible PCBs have copper layers on both sides. This lets you create more detailed circuits while staying flexible. They are used in devices needing more features, like cameras or car dashboards. LT CIRCUIT makes sure these PCBs are reliable and perform well.

Multilayer Flexible PCBs

Multilayer flexible PCBs have several copper layers with insulation in between. This design helps make very complex circuits for advanced uses. They are ideal for small gadgets like smartphones or medical tools. These PCBs handle tough designs while staying flexible, making them great for modern devices.

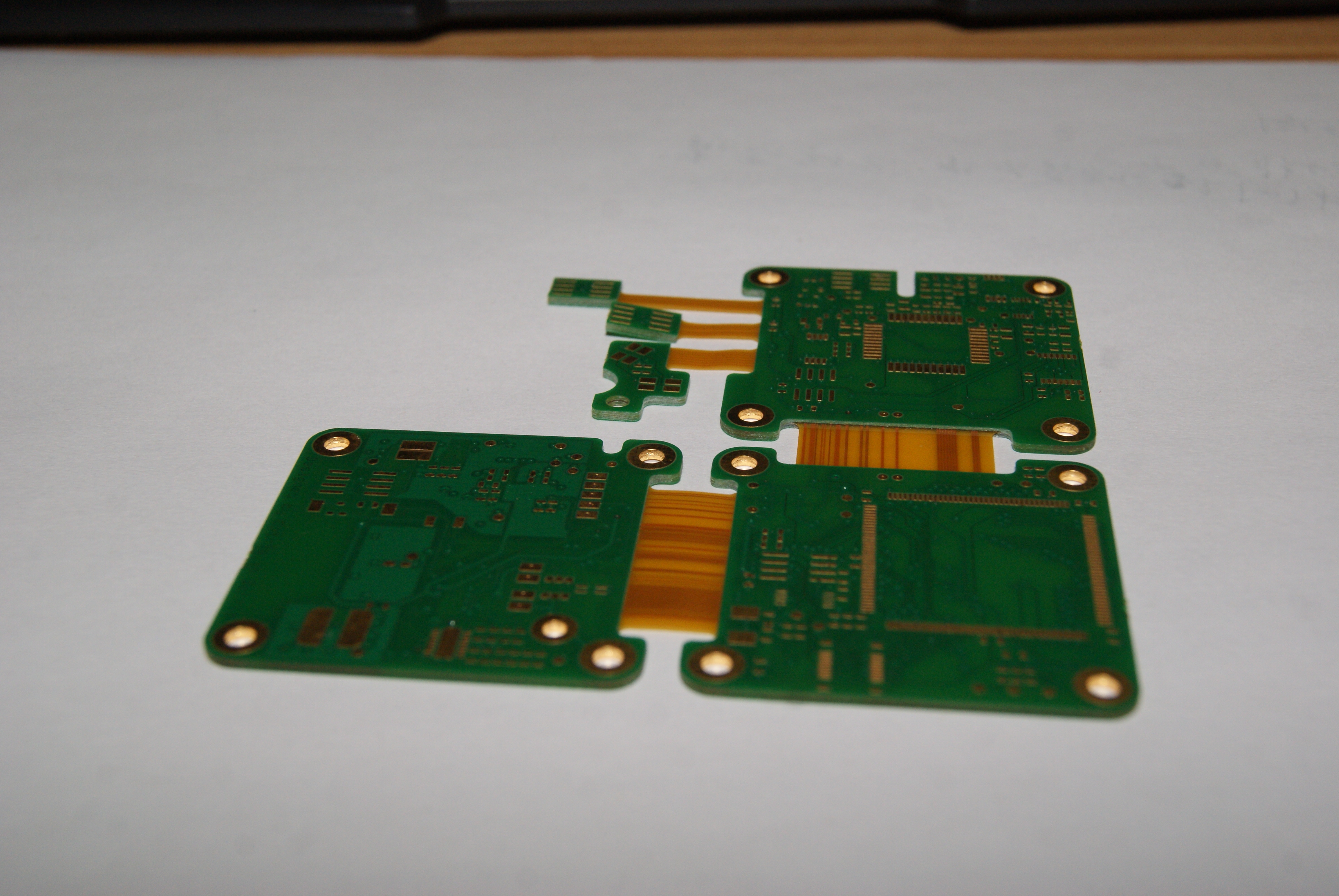

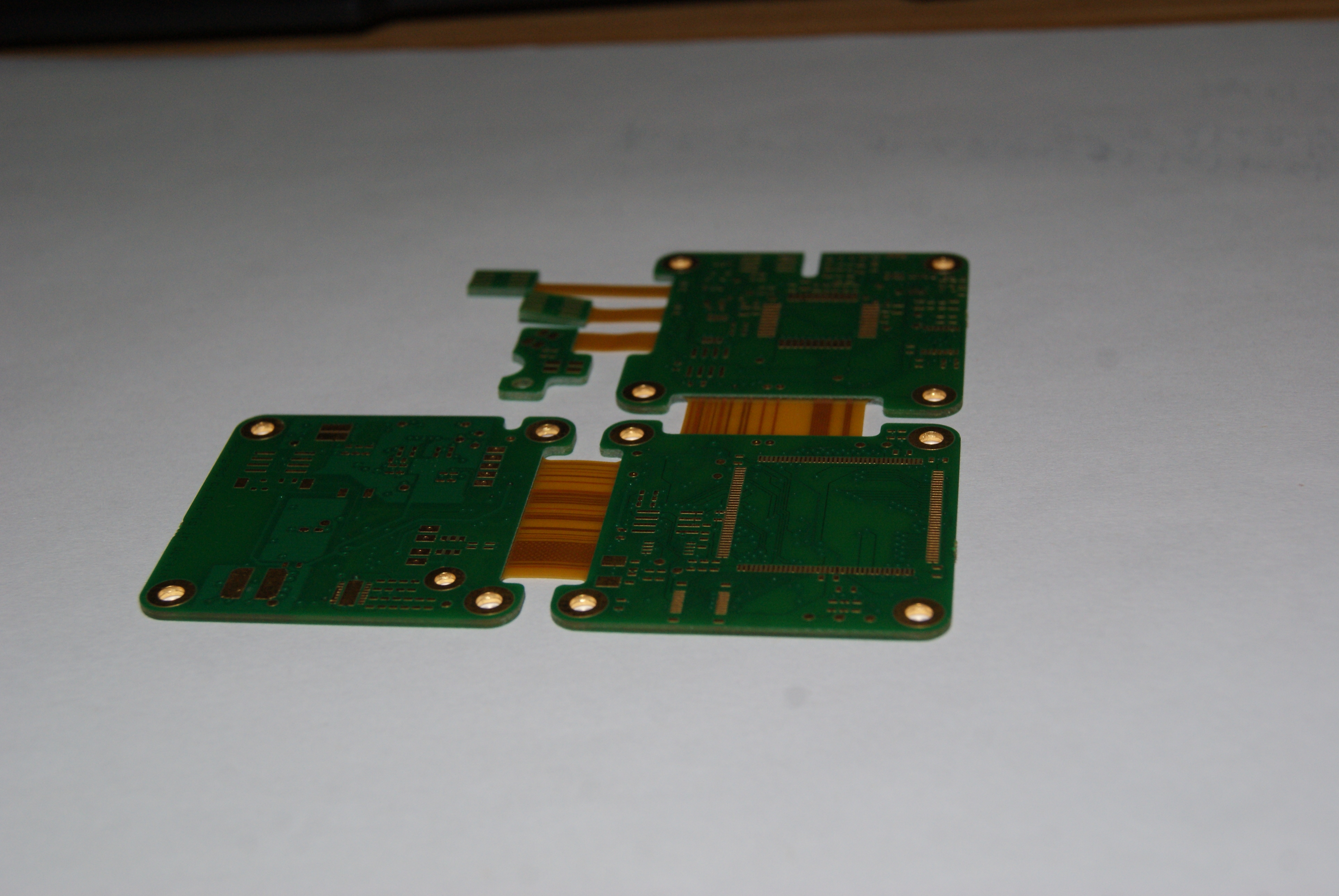

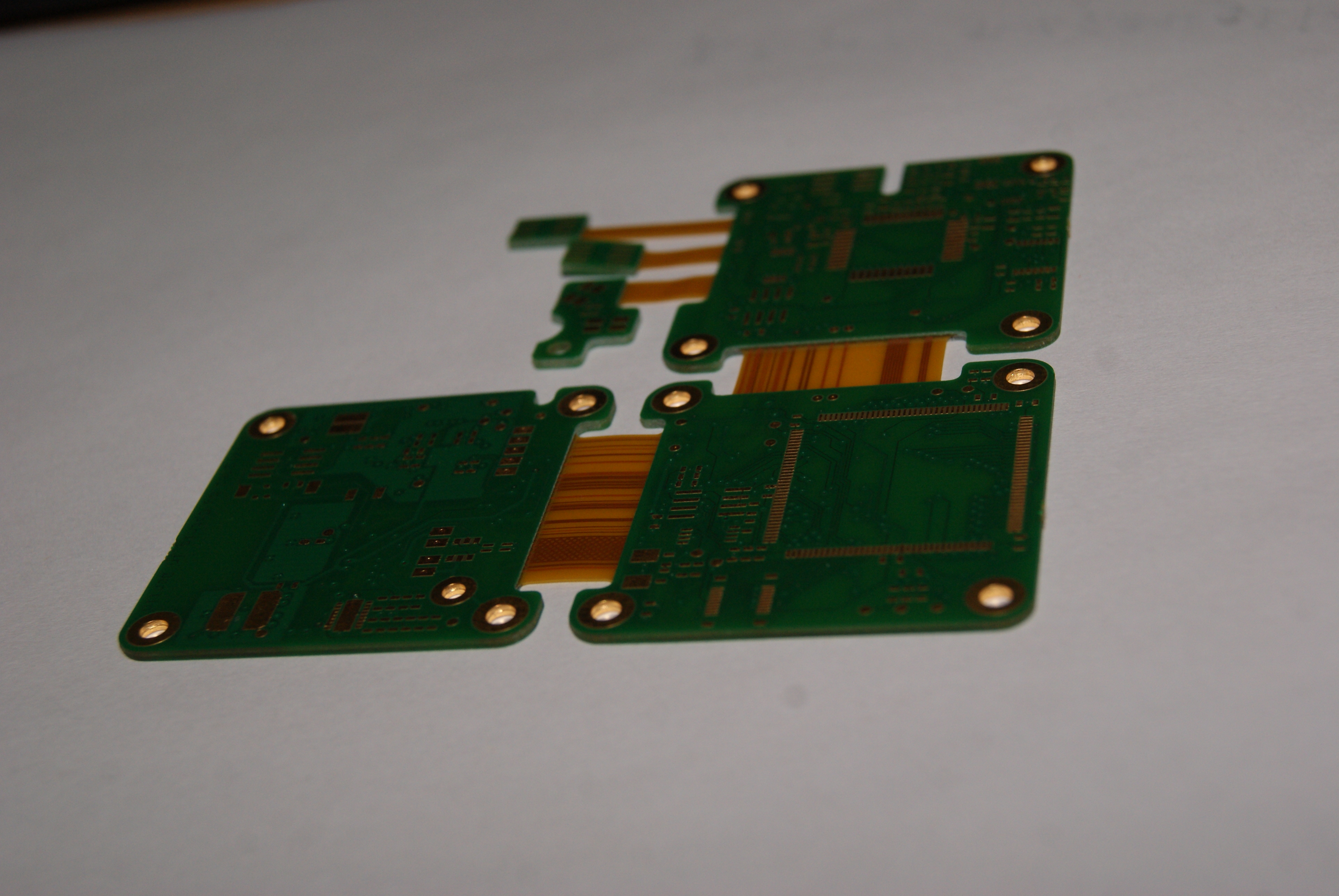

Rigid-Flex PCBs

Rigid-flex PCBs mix stiff and bendable parts. The stiff parts hold components, and the flexible parts can bend. This type is perfect for strong and adaptable devices like space systems or wearables. LT CIRCUIT ensures these PCBs are high-quality and dependable.

Tip: Pick the right flexible PCB based on your device's needs. Think about how complex, small, or strong it needs to be.

Advantages of Flexible PCBs

Flexible PCBs have many benefits for modern electronics. They help create small, light, and reliable designs for today’s technology.

Space Efficiency

Flexible PCBs are great for small devices with limited space. They can bend, twist, or fit into odd shapes. This helps organize the inside of devices better. They are used in wearables, phones, and airplane systems.

Flexible PCBs make devices smaller by combining rigid boards and wires into one compact piece.

Feature | Details |

|---|---|

Material | Made from bendable, strong materials like polyimide. |

Flexibility and Strength | Can bend or twist to fit tight spaces and handle stress. |

Space and Weight Saving | Combine multiple boards and wires into a lighter, smaller design. |

This space-saving feature is vital for industries like aerospace, where every bit of space matters.

Lightweight Design

Flexible PCBs use thin, light materials like polyimide films. This makes them lighter than traditional boards. Reducing weight is important for wearables and mobile devices.

Engineers use flexible PCBs to make lighter electronics.

They stay functional even with less weight, making them ideal for advanced designs.

Flexible PCBs are key in reducing weight while keeping performance high.

Durability and Reliability

Flexible PCBs are made to handle tough conditions. They resist heat and physical stress, making them great for cars, planes, and factories.

They stay strong under stress, lowering the chance of breaking.

They work well even in extreme heat or vibrations.

Benefit | Details |

|---|---|

Reliability | Fewer wire failures mean better overall performance. |

Temperature Range | Can handle high or low temperatures for tough environments. |

This toughness makes flexible PCBs perfect for long-lasting electronics.

Enhanced Design Flexibility

Flexible PCBs allow creative and complex designs. They combine many functions into one board, removing the need for connectors and improving signals.

Rigid-flex PCBs can bend to fit tight spaces, saving room.

Without connectors, they have better signal quality and less interference.

Improvement Type | Details |

|---|---|

Space-saving | Rigid-flex PCBs bend to fit small spaces, saving room. |

Weight Reduction | Their flexibility helps reduce device weight. |

Enhanced Reliability | Stay strong under stress, lowering failure chances. |

Improved Signal Integrity | No connectors mean better signals and less interference. |

This flexibility helps create innovative designs, making flexible PCBs essential for modern technology.

Key Applications of Flexible PCBs

Flexible PCBs have changed technology by allowing creative designs. They can bend, twist, and fit into small spaces. This makes them very useful in many industries. Let’s see how they are improving key areas.

Consumer Electronics

Flexible PCBs are important in gadgets like phones and wearables. These devices need to be small and do many things. Rigid-flex PCBs combine stiff and bendable parts. This helps fit complex circuits into tiny spaces. They make devices work better and last longer.

For example, thinner smartphones need flexible PCBs. These PCBs remove big connectors, making devices lighter and easier to carry. They also help add advanced features. This means you get powerful, portable, and stylish gadgets.

Automotive Industry

Cars use flexible PCBs to improve performance and reliability. They are found in displays, lights, and control systems. Their flexibility and strength offer many benefits.

Better Quality: Fewer connectors mean fewer electrical problems.

Lower Costs: Easier assembly saves money during production.

Creative Designs: Compact layouts save space in vehicles.

For example, car dashboards use flexible PCBs for smooth operation. They work well even in heat or vibrations. This makes them a trusted choice for cars.

Industry Sector | Key Trends and Adoption Statistics |

|---|---|

Automotive | More use in displays, lights, and electronics to improve performance and reduce weight. |

Medical Devices

Flexible PCBs help create new medical tools that improve care. Their small and light design is perfect for wearable devices and portable tools. They also allow real-time health tracking, helping remote care.

Flexible PCBs go through strict tests to ensure safety. For example:

AOI Testing checks for visual flaws.

Heat Testing ensures they work in extreme temperatures.

Environment Testing checks durability in medical settings.

Testing Protocols | Description |

|---|---|

Automated Optical Inspection (AOI) | Checks the PCB's visual quality. |

Electrical Testing | Confirms the PCB works correctly. |

Thermal Stress Testing | Tests how it handles very hot or cold conditions. |

Environmental Testing | Ensures it lasts in tough medical environments. |

These tests make sure flexible PCBs meet high medical standards. They are essential for modern healthcare tools.

Aerospace and Defense

Aerospace and defense need strong parts for tough conditions. Flexible PCBs are perfect for satellites, planes, and military gear. They are durable and adaptable.

To prove their strength, flexible PCBs are tested:

Heat Cycle Test: Checks if they handle temperature changes.

Peel Test: Measures how well layers stick together.

Aging Test: Simulates long-term use in harsh conditions.

Test Type | Description |

|---|---|

Thermal Cycling Test | |

Peel Strength Test | Checks how strong the bond is between layers. |

Aged Sample Test | Simulates years of use in tough environments. |

These tests show flexible PCBs are reliable for aerospace and defense needs.

Industrial Electronics

In factories, flexible PCBs are tough and efficient. They are used in machines, robots, and control systems. They handle stress and extreme temperatures well.

A wearable with a flexible PCB was tested for durability. Weak spots were found and fixed with stronger materials. This improved its reliability, showing how design changes help in tough environments.

Flexible PCBs also save space and weight, which is great for small industrial tools. They resist moisture and temperature changes, making them last longer. This is why they are popular in industrial electronics.

Flexible PCBs are very important in today’s electronics. They help save space, are lightweight, and last a long time. These PCBs are used in healthcare, aerospace, and gadgets. These industries need creative and advanced designs. LT CIRCUIT provides strong and dependable PCBs. They make sure your devices work well and improve technology.

FAQ

What are flexible PCBs made of?

Flexible PCBs are built using polyimide or polyester films. These materials are bendable, strong, and resist heat. This makes them perfect for advanced electronics.

How do flexible PCBs improve device performance?

Flexible PCBs remove the need for many connectors. This improves signal strength and makes devices more reliable. Their lightweight build also helps devices be portable and efficient.

Can flexible PCBs handle extreme environments?

Yes, flexible PCBs can handle heat, vibrations, and moisture. They are tough and work well in aerospace, cars, and factories.

Tip: Pick flexible PCBs tested for your device's environment.

See Also

A Comprehensive Guide To Rigid-Flex PCB Structures

Exploring The Fundamental Concepts Of PCB Printed Circuit Boards

Key Functions And Features Of IC Substrate PCBs

An Overview Of Manufacturing Multilayer Rigid-Flex Circuit Boards

Ceramic PCBs: Their Role And Applications In Today's Industries