HASL Finish PCB Manufacturing: Process, Benefits, and Applications in Industrial Electronics

HASL finish is important in PCB manufacturing. It adds a protective layer to help them work well and last long. This method is a cost-effective solution for industries needing strong circuit boards. Major sectors like automotive and medical equipment utilize HASL because it is both affordable and durable. LT CIRCUIT, focused on quality, produces excellent HASL-finished PCBs for industrial use.

Key Takeaways

HASL finishes are a cheap way to make PCBs. They work well for industries needing strong circuit boards.

The HASL process includes cleaning, adding flux, solder coating, leveling with hot air, and careful checking for quality.

You can pick leaded or lead-free HASL based on the environment and what the board is used for.

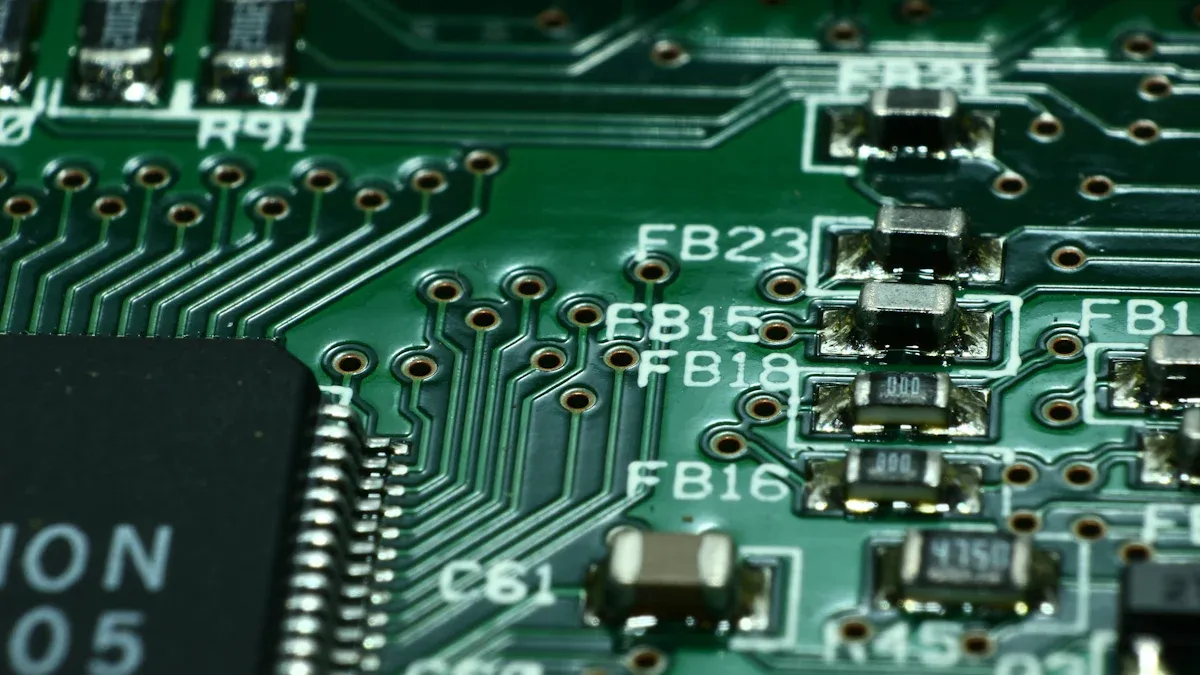

Understanding the HASL Process in PCB Manufacturing

What is HASL in PCB Manufacturing?

HASL, short for Hot Air Solder Leveling, is a common finish used in making PCBs. It covers the exposed copper parts of the board with solder. This protects the board from rust and keeps it easy to solder. Many people choose HASL because it is strong and affordable for protecting circuit boards.

Why is HASL so important? It helps make PCBs reliable and high-quality. The even solder layer improves connections during assembly. This makes it a top choice for industries needing durable and long-lasting PCBs.

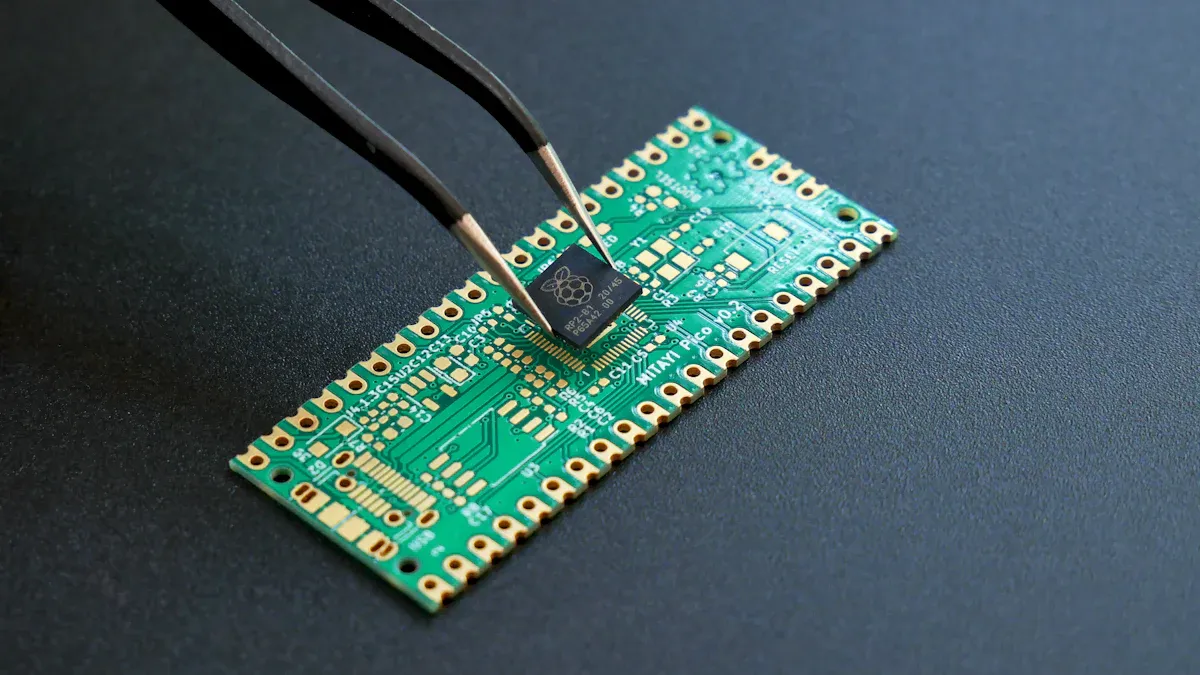

Step-by-Step Overview of the HASL Process

The HASL process has several steps to create a good finish. Here’s how it works:

Cleaning the PCB: The board is cleaned to remove dirt or grease. This helps the solder stick well to the copper.

Flux Application: A flux layer is added to stop oxidation. This improves how well the solder bonds to the board.

Solder Coating: The board is dipped into hot liquid solder. This coats the copper areas with solder.

Hot Air Leveling: Hot air blows off extra solder. This makes the surface smooth and even.

Inspection and Testing: The board is checked for problems and tested to meet quality rules.

Manufacturers check many things to keep the process consistent. For example, the process capability index (Cpk) should be over 1.33 to show good performance. The solder thickness must stay within 10% of the target. They also monitor solder coverage, thickness, and temperature. Standards like IPC-4552 ensure the boards meet industry rules.

Metric | Description |

|---|---|

Cpk | Shows process quality; must be above 1.33. |

Thickness Tolerance | Should stay within +/- 10% of the target thickness. |

Statistical Monitoring | Tracks solder thickness, coverage, and temperature. |

Inspection Standards | Uses IPC rules like IPC-4552 for quality checks. |

Leaded vs. Lead-Free HASL Finishes

When picking a HASL finish, you can choose leaded or lead-free. Each type works best for different uses.

Leaded HASL: This older option uses solder with lead. It is very reliable and solders well. But, because of environmental concerns, it is less popular now.

Lead-Free HASL: This newer option uses solder without lead. It is eco-friendly and follows RoHS rules. It works just as well but needs higher heat during processing.

Both finishes are cheap and solder well. But lead-free HASL is better for eco-friendly needs. The thicker solder layer in HASL works well with many PCB designs. However, HASL can have trouble with very small designs or multilayer boards.

Aspect | Details |

|---|---|

Cost | |

Solder Film Thickness | Thick solder layer works with wider design tolerances. |

Solderability | Great solderability with strong joints after many heat cycles. |

Limitations | Problems with very small designs and uneven soldering in multilayer boards. |

By knowing the differences between leaded and lead-free HASL, you can pick what fits your needs. Whether you want eco-friendly options or traditional reliability, HASL is a flexible and useful finish for PCBs.

Key Benefits of HASL in PCB Manufacturing

Cost-Effectiveness of HASL Finishes

HASL finishes are a cheap way to make circuit boards. This method gives good results without costing too much money. The process dips the board in hot solder, then uses air to remove extra solder. This simple method keeps costs low and protects the copper parts.

Several reasons make HASL affordable. First, it uses common materials, which are easy to find. Second, the high heat during the process shows problems early, like layers peeling apart. Fixing these issues early saves money later. But HASL might not work well for designs needing very smooth surfaces because it can leave uneven layers.

Why HASL is cost-effective:

Cheap for making many circuit boards at once.

Works well for simple designs or controlled environments.

Finds problems early, saving time and money.

Choosing HASL gives you a mix of low cost and good quality. That’s why many industries use it.

Durability and Reliability in Industrial Applications

HASL finishes are tough and last a long time. The solder layer protects against things like water and rust. This keeps circuit boards working well, even in bad conditions.

Numbers show how strong HASL finishes are. The solder layer is usually 0.8 to 1.5 mil thick. Special tools like X-ray gauges and AOI machines check the boards for problems. These checks make sure every board meets high standards.

Measurement Type | Specification |

|---|---|

Solder Thickness | 0.8–1.5 mil |

Inspection Method | X-ray thickness gauges |

Defect Detection | AOI (Automated Optical Inspection) |

With HASL, your circuit boards will work well in tough environments. Many manufacturers trust HASL for strong and reliable boards.

Compatibility with Industrial-Grade Electronics

Industrial electronics need finishes that handle tough conditions and solder easily. HASL does this by adding a thick solder layer for strong connections. It works for many uses, like car systems and power electronics.

HASL makes assembly and repairs easy, even after heating the board many times. This helps in factories where parts may need replacing or upgrading. The thick solder layer also works with many board designs, making HASL flexible.

Why HASL works for industrial electronics:

Strong solder joints for good connections.

Easy to fix and assemble, even after heavy use.

Works with many types of circuit board designs.

Choosing HASL means your boards can handle tough jobs. Its mix of strength, solderability, and low cost makes it a great choice.

Applications of HASL Finish in Industrial Electronics

Power Electronics and HASL-Finished PCBs

Power electronics need strong PCBs to handle high currents. HASL adds a solder layer that protects and strengthens these boards. The thick solder helps connections stay strong under heat and stress. HASL-finished PCBs work well in power converters, inverters, and motor controllers. Their easy soldering makes assembly simple and reduces connection problems.

Automotive Electronics and HASL Applications

Cars use HASL-finished PCBs for important systems like engines and ADAS. The solder layer protects boards from moisture and vibration damage. HASL works well with tough electronics, making it great for cars. It’s also cheap, so manufacturers can make many boards without losing quality.

Industrial Automation Systems and HASL Benefits

Factories need reliable PCBs for machines that run all day. HASL-finished boards have strong solder joints and last a long time. They’re used in robots, PLCs, and factory equipment. HASL handles heat cycles well, keeping machines working for years. Below is a table showing HASL’s uses in different industries:

Market Segment | Applications |

|---|---|

Telecommunications | Used in routers, modems, switches, and base stations. |

Medical Devices | Found in monitors, diagnostic tools, imaging machines, and lab equipment. |

Aerospace and Defense | Applied in avionics, radar, communication tools, and military electronics. |

HASL’s strength and flexibility make it a top choice for tough industrial jobs.

HASL finishes are important in making PCBs for industries. They protect boards, make soldering easy, and fit many designs. Companies like HASL because it is cheap and easy to get. Check out LT CIRCUIT’s great HASL-finished PCBs for your needs.

FAQ

What is the main benefit of hot air solder leveling?

Hot air solder leveling adds a solder layer to protect the board. This layer stops rust and helps make strong connections during assembly.

How is lead-based HASL different from lead-free HASL?

Leaded HASL uses solder with lead for strong connections. Lead-free HASL uses safer solder, follows RoHS rules, but needs more heat to process.

Can HASL finishes work for all PCB designs?

HASL fits most designs well. But it might not work for tiny or multilayer boards because the solder layer can be uneven.

See Also

Understanding The Steps In PCB Manufacturing Today

Exploring Materials And Standards In Rigid PCB Production

Unveiling Innovative Techniques For HDI PCB Prototyping

Advantages Of LDI Machines In HDI PCB Circuit Production

Utilizing Horizontal Copper Sinking Technology In PCB Manufacturing