HASL Finish in PCB Manufacturing: Process, Applications, and Quality Control

HASL, or Hot Air Solder Leveling, is a common finish used in PCB manufacturing. It protects copper lines from rust and aids in the soldering process. This technique ensures strong connections and maintains optimal performance in electronics. It is essential for producing high-quality devices.

Key Takeaways

HASL, or Hot Air Solder Leveling, keeps copper safe and helps solder stick better on PCBs.

Good cleaning and careful soldering are important for a strong HASL finish.

Lead-free HASL is better for the environment, works well, and costs less.

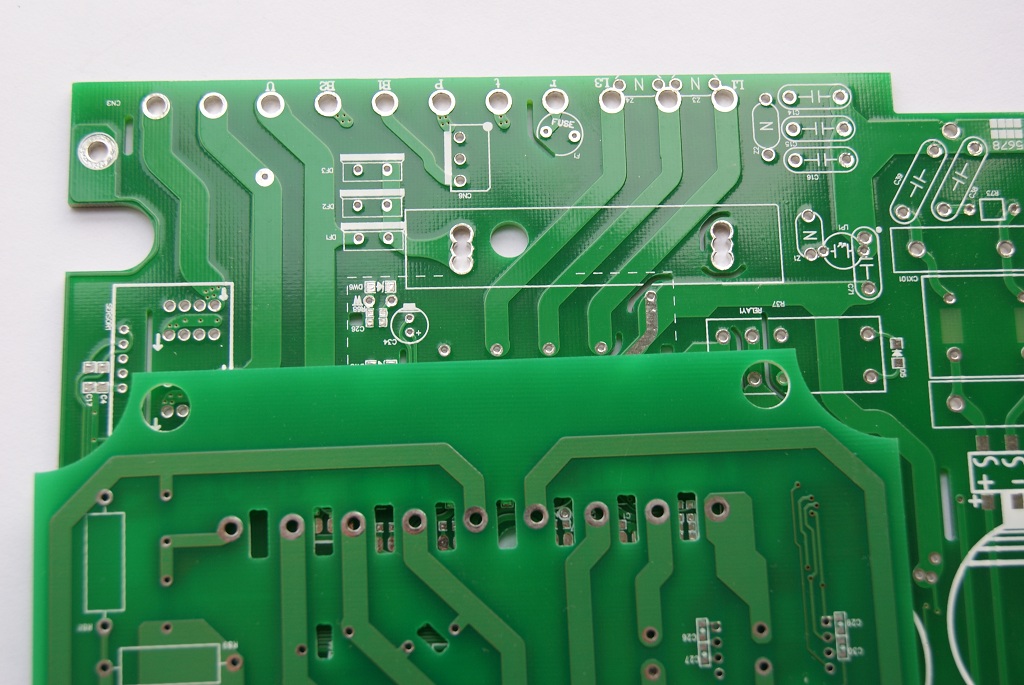

Understanding the HASL Process in PCB Manufacturing

The HASL process is important for making good circuit boards. It uses specific steps to create a smooth finish. This finish helps solder stick better and protects copper parts. Let’s look at the main steps of this process.

Surface Preparation for HASL

Before adding the HASL finish, the PCB must be cleaned well. Cleaning removes dirt, grease, and rust from the surface. A clean board helps the solder stick properly.

After cleaning, a flux coating is added to the copper parts. Flux stops rust and helps the solder spread evenly. If the surface isn’t prepared right, the solder won’t stick well. This can cause problems in the final board.

Solder Application Techniques

Adding solder is the most important part of HASL. The PCB is dipped into hot liquid solder. This covers the copper and protects it from rust. It also makes strong connections for assembly.

Several things affect how well the solder works. For example, choosing the right solder paste is important. Adjusting heat levels during soldering also helps. The table below shows some techniques and their effects:

Technique | What It Does |

|---|---|

Picking the right paste improves strength and coverage. | |

Changing heat levels keeps solder joints strong. | |

Pad Type | NSMD pads make connections more reliable. |

Underfill Processes | These methods add strength but cost more. |

Surface Finish | Different finishes affect strength and durability. |

Good stencil design and cleaning are also key. A good stencil spreads solder evenly. Cleaning reduces problems like extra solder balls. These steps help make a strong solder finish.

Cooling and Leveling in HASL

After soldering, the PCB is cooled and leveled. This step makes the surface smooth and even. Hot air blows off extra solder as the board is lifted out.

Cooling hardens the solder and keeps it in place. Leveling stops bumps or solder bridges that can cause issues. Careful cooling and leveling make the PCB reliable and easy to solder.

Applications of HASL Finish in PCB Manufacturing

Common Uses of HASL in PCB Production

HASL is a popular finish for circuit boards. It is used in electronics, industrial tools, and communication devices. People choose it because it is cheap and easy to solder.

For projects with tight budgets, HASL is a smart choice. It works well for simple and complex boards. It also makes strong connections for through-hole parts. Its thicker solder layer adds strength and durability.

Compared to ENIG, HASL costs less. ENIG has a smoother surface, but HASL is better for projects that don’t need fancy designs or high-frequency use.

Feature | HASL | ENIG |

|---|---|---|

Cost | More expensive | |

Solderability | Very good | Good |

Surface Smoothness | Less smooth | Very smooth |

RoHS Compliance | Sometimes | Always |

Best Use | Low-cost projects | High-tech projects |

Advantages of HASL Surface Finish

HASL has many benefits for making circuit boards. First, it protects copper lines from rust. This keeps the board working well for a long time.

Another benefit is its great soldering ability. HASL makes strong connections during assembly. This is helpful for boards with through-hole parts.

HASL is also flexible. You can pick leaded or lead-free options. Lead-free HASL is good for meeting eco-friendly rules.

Finally, HASL is affordable. It costs less than finishes like ENIG. While it’s not as smooth, it’s still a reliable choice for many uses.

Lead-Free HASL and Environmental Compliance

Lead-free HASL is becoming more common due to strict rules. It doesn’t use lead, so it follows RoHS standards.

This type of HASL protects copper and solders well, just like regular HASL. But it also helps reduce electronic waste and pollution. Choosing lead-free HASL means your boards meet modern eco-friendly rules.

Lead-free HASL is safer for workers too. It lowers exposure to harmful materials, making factories healthier.

If you want a finish that is good for the planet, lead-free HASL is a great option. It balances cost, performance, and environmental care.

Quality Control Measures for HASL Surface Finish

Thickness Testing and Standards

Checking thickness is key to making good HASL boards. The solder layer must meet rules to keep boards reliable. The IPC-6012 rule says HASL finishes need at least 1 μm thickness. It also needs 95% coverage to protect copper and help solder stick well.

To check this, factories test samples with special tools. They measure many spots on the board to ensure even solder. This step stops problems like uneven layers, which can hurt soldering and durability.

Ensuring Uniformity in HASL Coating

Even coatings are important for good soldering results. Uneven layers can cause weak connections or bad soldering. To fix this, focus on cooling and leveling steps. Leveling removes extra solder and smooths the surface.

Final checks include looking at the board and measuring it. These checks find any coating problems early. Fixing them improves board quality and lowers the chance of defects.

Defect Prevention and Reliability Assurance

Stopping defects is crucial for great HASL boards. Common problems include too much tin, uneven layers, or bad soldering. Tests like heat checks and solder tests can find these issues. These tests make sure solder sticks well and connections are strong.

Good quality control also means cleaning and testing the board’s function. These steps aim for no defects and better reliability. By improving the process, factories can make top-quality HASL boards every time.

The HASL finish is important in making PCBs. It keeps copper safe and helps solder stick well. You now know its steps, uses, and checks for quality. LT CIRCUIT makes strong PCBs with HASL finishes. They use smart methods and strict rules to ensure great quality and performance.

FAQ

What does a HASL finish do?

A HASL finish keeps copper from rusting. It also helps solder stick well during assembly. This makes your PCB last longer.

How is lead-free HASL different from regular HASL?

Lead-free HASL uses tin solder without lead. It follows RoHS rules and is safer for workers. It protects copper and solders well, just like regular HASL.

Can you use HASL for high-frequency PCBs?

HASL isn’t great for high-frequency PCBs because it’s not smooth. For smoother finishes, try ENIG or immersion silver instead.

See Also

Understanding HASL PCB Manufacturing: Key Processes And Advantages

An Overview Of The PCB Manufacturing Process

Achieving Excellence In Quality Control For PCB Production

Exploring Rigid PCB Manufacturing: Key Materials And Standards