HDI PCB manufacturer showdown who delivers the best

Choosing the right hdi pcb manufacturer is crucial for shaping the future of electronics. The global HDI PCB market is projected to reach $22.3 billion by 2025, driven by increasing demand for innovative electronics and automotive applications.

Source | Projected 2025 Market Size (USD Billion) |

|---|---|

Allied Market Research | 22.26 |

Coherent Market Insights | 19.59 |

Maximize Market Research | Slightly above 16 |

Every hdi pcb manufacturer must leverage advanced PCB technology, adhere to strict quality standards, and foster innovation. Engineers and procurement specialists are constantly seeking the best PCB solutions for HDI applications. As compact electronic devices gain popularity, the need for reliable hdi pcb manufacturer options continues to grow. To remain competitive, each hdi pcb manufacturer must deliver exceptional service and cutting-edge solutions.

Key Takeaways

Pick an HDI PCB manufacturer that uses new technology. Make sure they check quality well. They should deliver fast. This helps you get strong and good circuit boards.

LT CIRCUIT is special because it brings new ideas. It gives custom choices. It checks quality very carefully. The company helps customers a lot. This makes it the best for hard and big HDI PCB jobs.

Think about what your project needs. Look at how many you need to make. Check the technology level. Think about the cost. See how fast you need a sample. This helps you pick the best manufacturer for good results.

Evaluation Criteria

To pick the best HDI PCB manufacturer, you need to look at some important things. These things help engineers and buyers choose a good company for advanced pcb projects.

Technology & Innovation

Manufacturers should use new technology to keep up with modern electronics. Advanced pcb methods like laser-drilled microvias and sequential lamination help make smaller and stronger devices. New ideas like embedded parts and rigid-flex pcb designs let devices move data faster and do more things. These changes make signals better, lower noise, and make multilayer pcb manufacturing more dependable.

Production Capacity

How much a manufacturer can make affects how fast you get your order. Big factories can make lots of boards and finish orders quickly. Skilled workers and good machines help make even hard pcb designs without problems. Good teamwork between design and manufacturing teams stops mistakes and saves time.

Quality & Certifications

Quality is very important in pcb manufacturing. Top manufacturers use strong quality checks like AOI, X-ray inspection, and electrical testing. Certifications like ISO 9001, ISO 14001, and ipc compliance show they care about high standards. Following rules like IPC-6012 and RoHS makes sure pcb products are safe and work well.

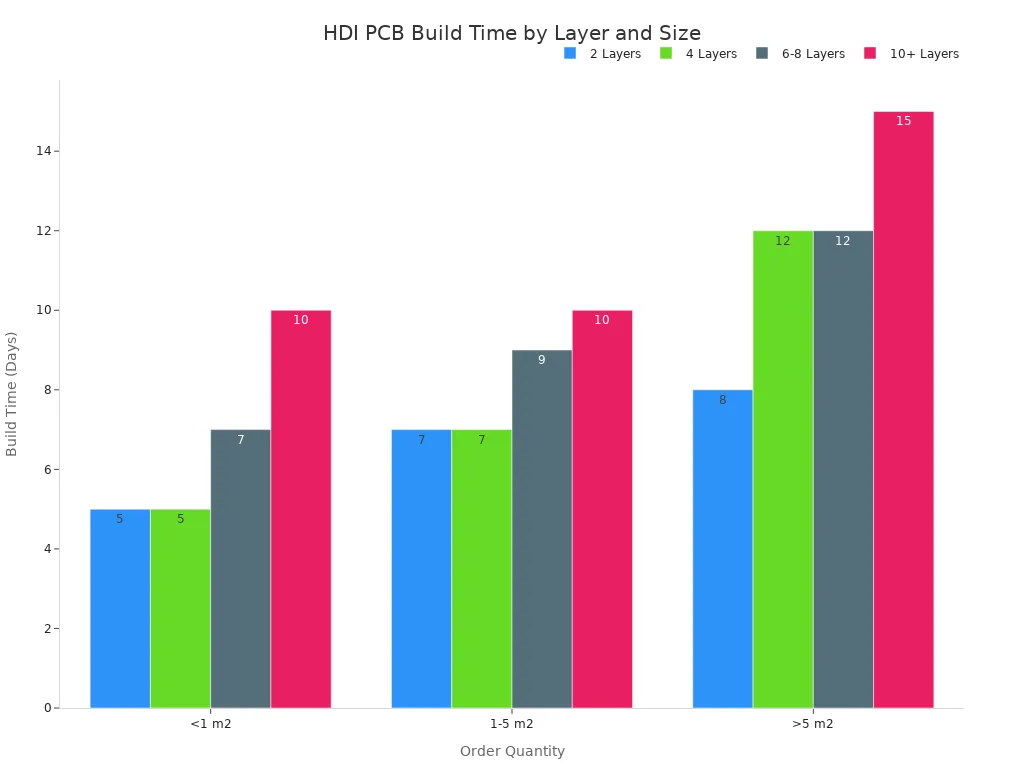

Lead Time & Service

Getting your order fast and on time is very important for your project. Most HDI pcb orders take 5 to 15 days, depending on how many layers and boards you need.

Manufacturers with good customer service and clear answers help you finish your project on time.

Pricing

The price for HDI pcb depends on how many boards you order and how hard they are to make. If you order a lot, each board costs less because of economies of scale. If you order just a few or need a prototype, each board costs more. HDI pcb usually costs 25-50% more than standard pcb because it uses better technology and stronger quality checks.

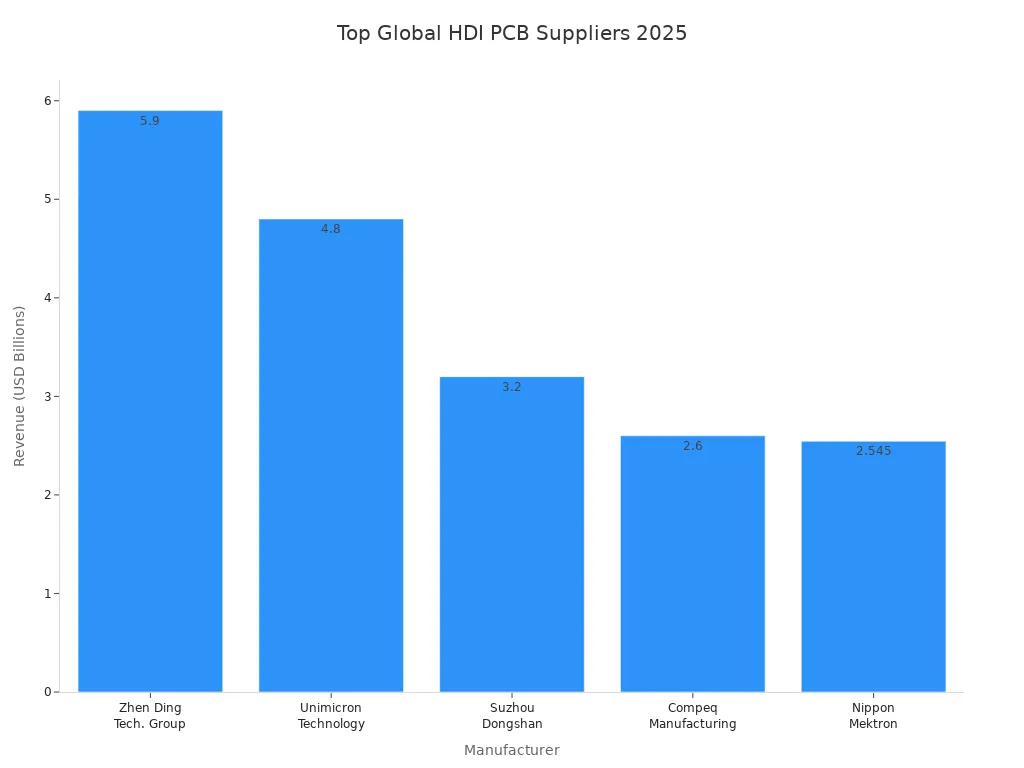

Leading HDI PCB Manufacturers 2025

The global HDI PCB market has many top manufacturers. Each company has special skills and strong abilities. These companies help electronics grow by making high-quality board products. They serve many different uses. Here is a look at the best HDI PCB manufacturer choices for 2025.

Top Global HDI PCB Suppliers in 2025:

LT CIRCUIT

AT&S

Compeq Manufacturing

TTM Technologies

Rayming Technology

APCT

LT CIRCUIT: Innovation & Quality

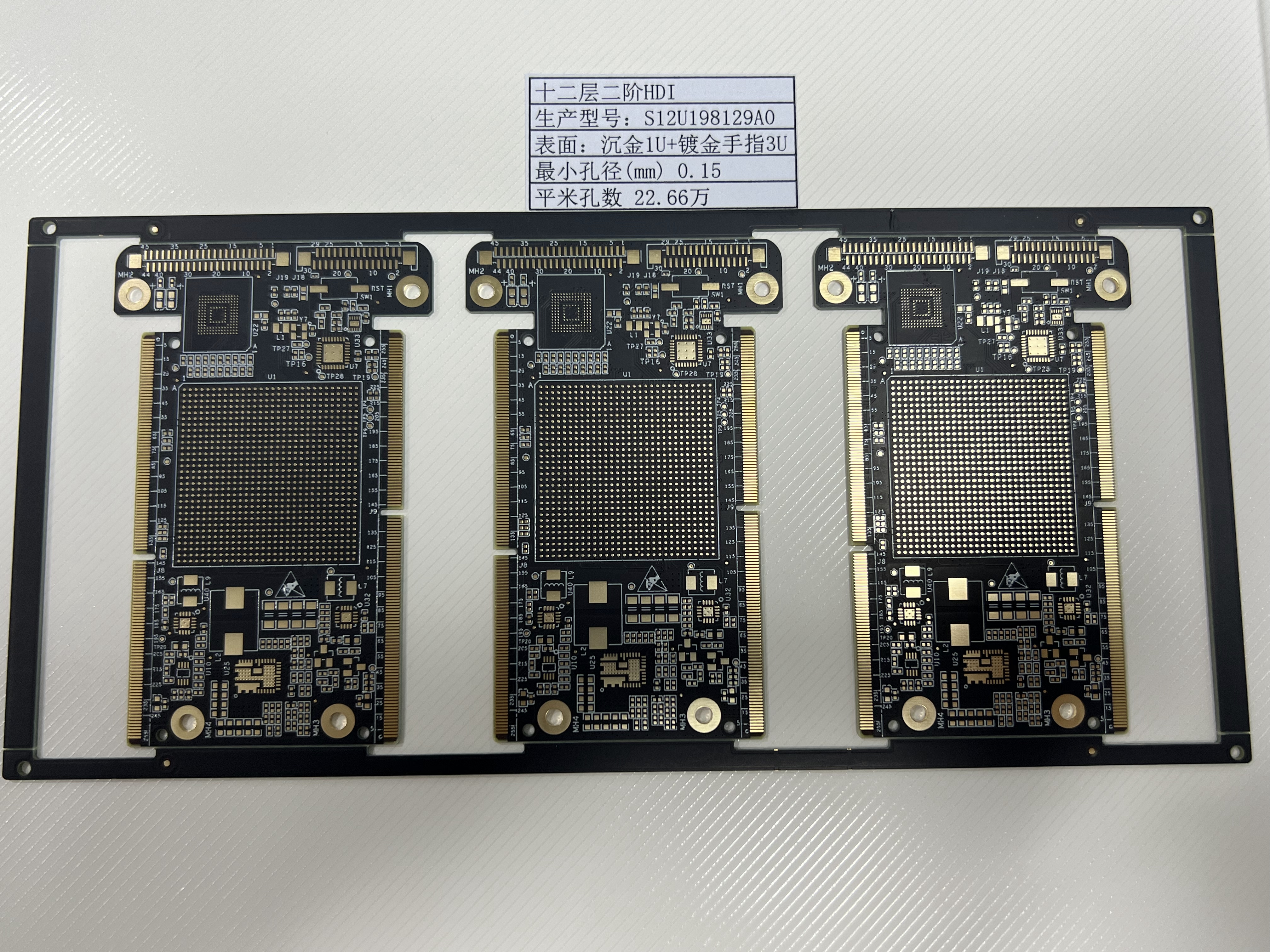

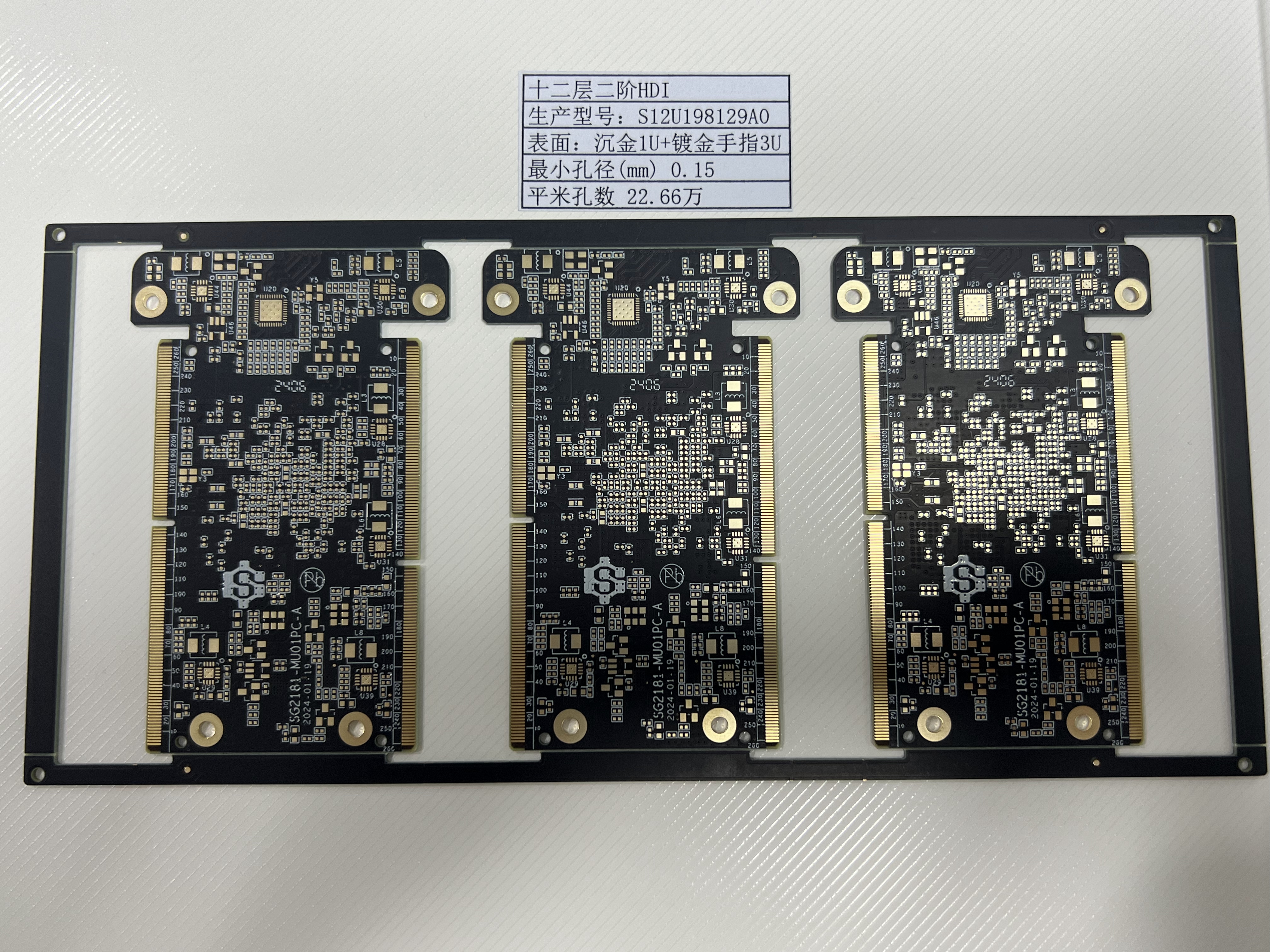

LT CIRCUIT is a top hdi pcb manufacturer. It is known for new ideas and great quality. The company makes high-density interconnect boards and any-layer HDI products. LT CIRCUIT can build up to 12-layer multi-layer printed circuit boards. They use laser direct imaging and microvia drilling. Their engineers are good at stack-up design, picking materials, and layout planning. The company uses modern tools like statistical process control and AI-driven models. These tools help make high-quality pcbs. LT CIRCUIT gives custom options like different surface finishes, solder mask colors, and small built-in parts. Their tests include flying probe and electrical tests. They have certifications like ISO 9001, UL, and CE. Automated optical inspection and X-ray inspection lower defects by 40% in big orders. LT CIRCUIT serves telecommunications, aerospace, medical, and industrial fields. They deliver reliable pcbs and green pcb options.

Technological Strengths | Details |

|---|---|

HDI PCB Specialization | High-density interconnect (HDI) boards, any-layer HDI products |

Multilayer PCB Capability | Up to 12 layers, 8.0 mm thickness |

Advanced Manufacturing Techniques | Laser direct imaging, microvia drilling for fine features |

Engineering Expertise | Stack-up design, material selection, layout optimization |

Modern Process Tools | Statistical Process Control (SPC), AI-driven models, Digital Twin Technology |

Custom Solutions | ENIG, HASL, immersion silver, solder mask colors, embedded components |

Testing Methods | Flying probe tests, electrical tests (E-tests) |

Quality Assurance Certifications | ISO 9001, UL, CE certifications |

Inspection Techniques | AOI, X-ray inspection (40% defect reduction in high-volume production) |

Industry Applications | Telecommunications, aerospace, medical, consumer electronics, industrial sectors |

Unimicron Technology Corporation

Unimicron Technology Corporation is one of the biggest hdi pcb manufacturer companies. They make high-end HDI PCBs, flexible pcb solutions, and rigid-flex boards. Unimicron’s products are used in electronics, healthcare, and fast communications. The company uses advanced pcb manufacturing and fine-line technology. They also make high-frequency pcbs. Unimicron’s quality checks and certifications make sure their products work well for tough jobs.

AT&S

AT&S is in Austria and is a top maker of high-tech HDI and high-speed pcb products. They supply multi-layer printed circuit boards for phones, medical tools, and car electronics. AT&S uses new materials and methods, like sequential lamination and built-in part technology. The company works on new ideas and makes high-quality board products for small and complex designs.

Compeq Manufacturing

Compeq Manufacturing is a big hdi pcb manufacturer with strong skills in multi-layer and HDI PCB making. Their factories run at over 80% capacity, showing high demand and good work. Compeq makes high-quality pcbs for phones, tablets, networks, and telecom systems. The company cares about quality and reliability. They serve big electronics brands with advanced pcb solutions.

Zhen Ding Technology Group

Zhen Ding Technology Group is a leader with strong production and many customers, including Apple. The company makes FPC, SLP, HDI PCB, IC substrate, and rigid-flex pcb products. Zhen Ding’s large factories support phones, computers, wearables, AR/VR, and smart home devices. The company focuses on quality and new ideas. This helps them lead the global pcb market.

TTM Technologies

TTM Technologies is a well-known hdi pcb manufacturer in the United States. They serve aerospace, military, and high-reliability pcbs markets. The company makes advanced HDI and multi-layer pcb solutions for important jobs. TTM Technologies uses green pcb processes and offers full assembly services. They help many electronics and industrial customers.

Fastprint

Fastprint is in Shenzhen and leads in HDI and flexible pcb solutions. The company works hard on new ideas and low-cost pcb making. Fastprint serves tough markets like electronics and cars. Their focus on quality and fast delivery makes them strong in the global HDI PCB market.

Rayming Technology

Rayming Technology uses advanced ways to make HDI PCBs. The company uses laser drilling for microvias, plasma cleaning, and electroless copper plating. They use sequential lamination and any-layer HDI technology for complex designs. Rayming supports coreless HDI construction, via-in-pad technology, and very thin trace widths. The company follows IPC-2581 standards for accurate and reliable pcb making. Rayming makes high-frequency pcbs and high-quality board products for many uses.

Laser drilling for microvias makes small, exact holes.

Plasma cleaning gets microvia holes ready for plating.

Electroless copper plating puts copper inside microvias.

Sequential lamination builds the PCB layer by layer.

Any-layer HDI technology allows microvias on any layer.

Coreless HDI construction helps with thickness and heat.

Via-in-pad technology supports fine lines and high-density connections.

Blind, buried, and microvias help with electrical work and small size.

Fine trace widths and spacing go down to 1.5 mil and holes as small as 2 mil.

Up to 4 lamination cycles for multilayer HDI PCB making.

Follows IPC-2581 standard for data sharing.

APCT

APCT helps with fast prototyping for HDI PCBs using a full process. The company has seven factories in different places to make complex HDI boards quickly and well. APCT makes HDI boards with blind, buried, and stacked vias. They offer fast service even for hard designs. The company gives design help with IPC-certified designers and uses FreeDFM to avoid delays. APCT can make both small and big orders, helping from start to finish. Their quick schedules and full assembly services make them a good choice for fast projects and turnkey assembly.

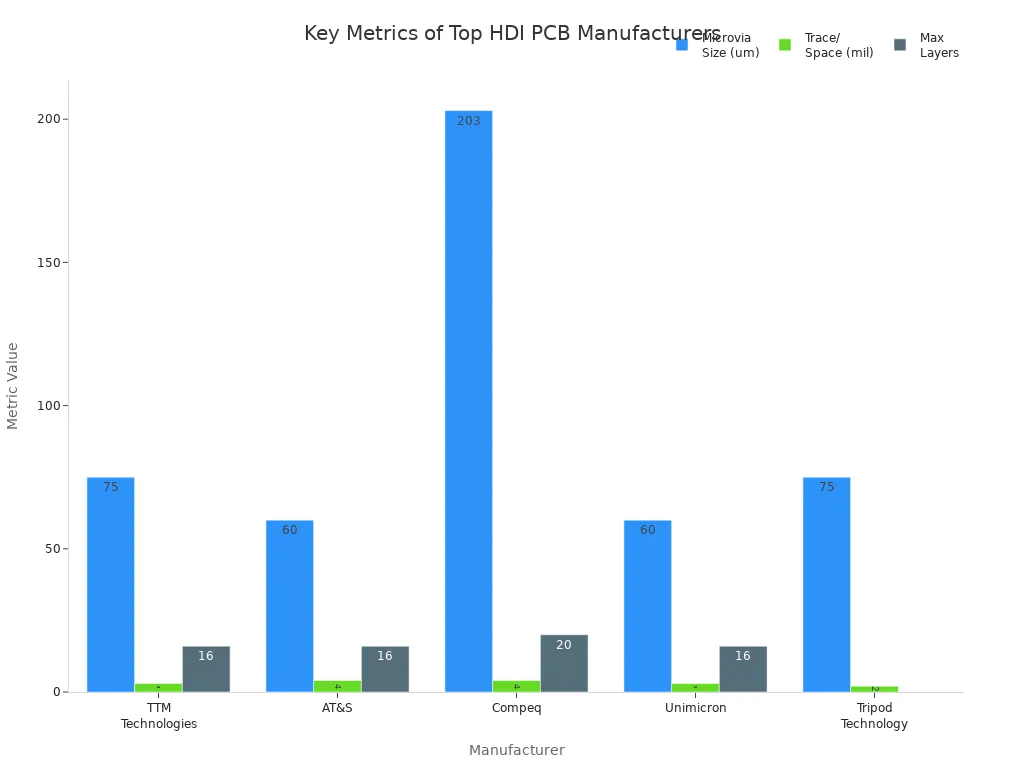

Key Metrics Overview

Picking the right HDI PCB manufacturer is important. Engineers and buyers look at many things. They check technology, how much a company can make, and service. The table below shows how top companies do in these areas. LT CIRCUIT is special for new ideas, great support, and high quality.

Manufacturer | Microvia Size | Trace/Space Resolution | Max Layers | Services Offered | Industry Focus |

|---|---|---|---|---|---|

LT CIRCUIT | Laser microvias to 60um | 3/3 mils | 12 | Custom HDI, any-layer, fast prototyping, engineering support, advanced testing | Telecom, aerospace, medical, industrial, consumer |

TTM Technologies | Laser microvias to 75um | 3/3 mils | 16+ | Quickturn prototyping, high volume, RF applications | Aerospace, medical, computing, networking, telecom |

AT&S | Laser microvias to 60um | <4 mils | 16 | Prototyping, rigorous testing, HDI design | Automotive, medical, industrial, aerospace |

Compeq | Microvias to 8 mils | 4 mils | 20 | Design, quickturn, RF boards, flex/rigid-flex | Communications, consumer, automotive, IoT |

Unimicron | Laser microvias to 60um | 3/3 mils | 16 | HDI design, quickturn, RF, flex, rigid-flex | Automotive, telecom, consumer, medical |

Tripod Technology | Laser microvias to 75um | 2/2 mils | N/A | Turnkey assembly, design, quickturn, flex/rigid-flex | Communications, computing, consumer, automotive |

Tip: LT CIRCUIT uses special laser tools and microvia drilling. These help make very exact and packed boards for new electronics.

LT CIRCUIT’s engineers work with customers on every step. They help with stack-up design, picking materials, and planning layouts. They use digital twin technology and AI to keep quality high. Special inspections like AOI and X-ray help catch problems early. LT CIRCUIT lets you pick different surface finishes and solder mask colors. Their support team answers fast and helps from start to finish.

Other companies like TTM Technologies and AT&S make boards with lots of layers and serve special markets. Compeq and Unimicron are good at making boards quickly and for RF jobs. Tripod Technology is best at making very thin lines. Each company has something special, but LT CIRCUIT mixes new ideas, quality, and good service in every job.

Best HDI PCB Manufacturer 2025

Top Choice & Why

Picking the best HDI PCB manufacturer in 2025 takes careful thought. Experts want companies with strong skills, new technology, and good customer help. LT CIRCUIT is the top pick for many reasons.

LT CIRCUIT has lots of experience with HDI and tricky PCB designs.

The company has important certifications like ISO 9001 and UL. They follow tough industry rules.

LT CIRCUIT uses the latest machines and smart inspection tools.

The team checks quality at every step of making PCBs.

LT CIRCUIT gives flexible choices and custom options for special projects.

The company can make boards fast and handle bigger orders as needed.

LT CIRCUIT keeps quality high but prices fair.

Customers get great help and clear answers from start to finish.

LT CIRCUIT always works on new ideas and stays reliable. This makes them a favorite for engineers and buyers. The company quickly follows new trends like making things smaller and using more machines. Every project meets the newest technology needs.

Industry Recognition

Industry leaders and customers notice LT CIRCUIT for doing a great job. The company gets praise for its strong HDI skills and always making good products. Many electronics makers trust LT CIRCUIT for important jobs in telecom, aerospace, and medical fields. Awards and good reviews show the company cares about doing well and making customers happy. LT CIRCUIT’s good name keeps growing as it sets new records in the HDI PCB world.

Recommendations by Need

High-Volume Production

Manufacturers making lots of boards need special machines and strong checks. They use laser drills to make tiny microvias, even smaller than 100 μm. Factories have plating lines for HDI boards that work both sideways and up and down. Clean rooms keep the air and temperature just right for good pcb quality. Laser direct imaging helps make small, exact patterns. Companies like LT CIRCUIT, Unimicron, and Compeq know how to make many boards at once. Their teams check every step, from plating to imaging, to stop mistakes. LT CIRCUIT is great because they can make lots of boards fast and help with engineering.

Laser drills make tiny microvias

Clean rooms keep boards safe from dust

Fast plating lines help make boards quickly

Teams check each step for mistakes

Good design rules help make many boards at once

LT CIRCUIT’s factories can handle big orders and special designs. This makes them a good pick for making lots of boards.

Advanced Technology

Some projects need the newest tools and smart workers. LT CIRCUIT is a leader here. They make HDI pcbs with up to 12 layers and any-layer connections. Their engineers use digital twin and AI to make each pcb better. Laser imaging and microvia drilling help make tiny and tricky designs. AT&S and Rayming Technology also have advanced options, but LT CIRCUIT is best for new ideas and custom work. Their team helps with design, picking materials, and planning layouts for hard projects.

Manufacturer | Max Layers | Technology Highlights |

|---|---|---|

LT CIRCUIT | 12 | Digital twin, AI, any-layer HDI |

AT&S | 16 | Sequential lamination, fine lines |

Rayming | 10 | Coreless HDI, via-in-pad, microvias |

If you want the newest pcb technology, LT CIRCUIT gives top solutions that meet tough standards.

Cost Efficiency

Saving money is important for some projects. Manufacturers must keep quality high but prices low. LT CIRCUIT uses smart designs to cut extra layers and microvias. Their team helps pick materials that work well and cost less. Making more boards at once lowers the price for each one. JHYPCB and Fastprint also have good prices, but LT CIRCUIT is best for flexible orders and clear costs.

Check all costs: setup, materials, making, testing, shipping

Use simple designs and DFM to save money

Order more boards to pay less for each

Pick certified makers for good quality

Stay away from companies with bad service or old tools

LT CIRCUIT’s way helps you save money and still get strong boards.

PCB Prototype Manufacturer

Picking the right pcb prototype maker helps you test ideas fast. LT CIRCUIT makes quick prototypes with advanced services. Their engineers help from design to testing. You can choose different finishes and solder mask colors. LT CIRCUIT checks each pcb with flying probe and electrical tests to make sure they work well. APCT and JHYPCB also make fast prototypes, but LT CIRCUIT is best for custom work and quick help.

If you need fast and good pcb prototypes, LT CIRCUIT gives speed, choices, and strong boards. Their help lets you bring new ideas to life quickly.

The 2025 HDI PCB manufacturer review shows LT CIRCUIT is best for new ideas, good quality, and helpful service. Every pcb supplier has something special. Picking the right company for your project gives you the best outcome. Here are some important points:

Flexible pcb materials work well in wearables, cars, and medical tools.

Good certifications and quick delivery are very important when picking a pcb.

The industry now wants fast prototypes and eco-friendly pcb options.

Use this guide to check out different pcb makers. If you need help or want a technical check, contact LT CIRCUIT or another top pcb supplier.

FAQ

What makes an HDI pcb different from a standard pcb?

HDI pcb has microvias and very thin lines. This lets more parts fit in a small area. Engineers pick HDI pcb for new and advanced electronics.

How does LT CIRCUIT ensure pcb quality?

LT CIRCUIT uses special machines to check each pcb. They use optical inspection and X-ray tests. Their team checks every step to find problems early. This helps make the pcbs work better and last longer.

Can customers request custom pcb solutions?

Yes. LT CIRCUIT lets customers pick custom pcb choices. You can choose finishes, solder mask colors, and how to test the boards. The team helps with special project needs.

Tip: Always talk to your manufacturer about your pcb needs to get the best results.

See Also

Explore Cutting-Edge Methods For HDI PCB Prototyping

Essential Design Tips For Trustworthy HDI PCB Production

The Process Behind Designing And Making HDI Multi-Layer PCBs

Save Project Expenses With Fast Turnaround HDI PCBs In 2025

Advantages Of LDI Exposure Technology In HDI PCB Circuit Production