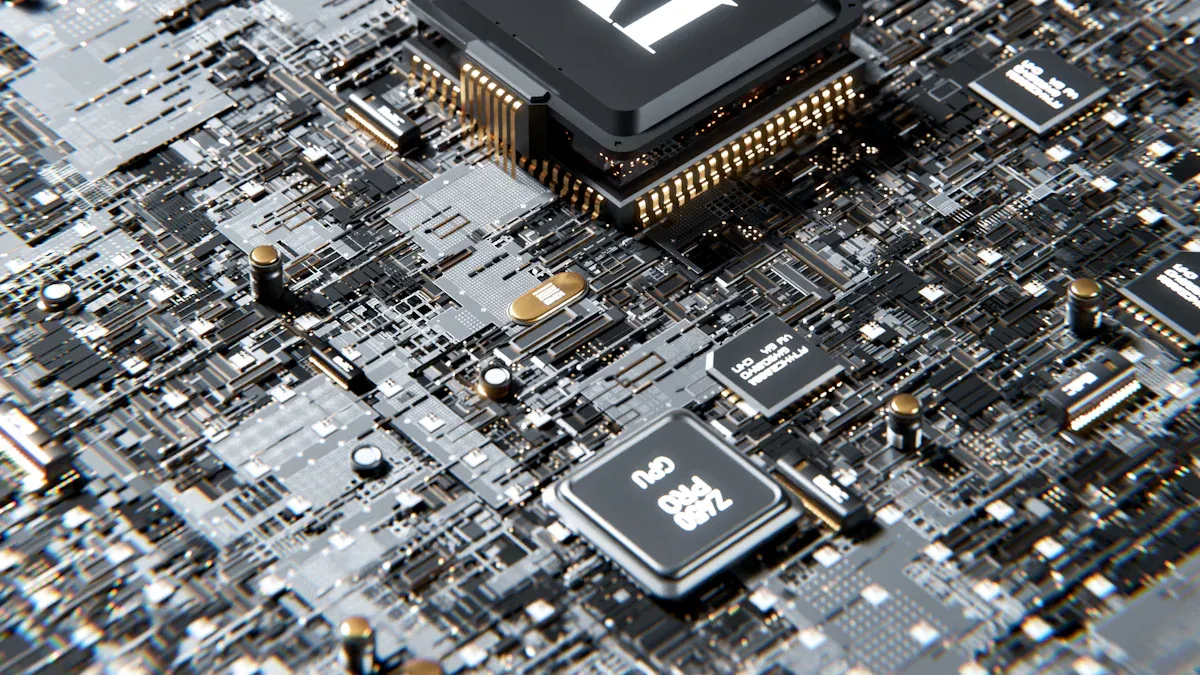

Smart, Strong, Small: HDI Rigid Flex PCBs

HDI Rigid Flex PCB technology is revolutionizing the future of electronics. Its innovative designs cater to the demand for smaller, more efficient devices. This transformation is particularly evident in industries like aerospace and consumer electronics, which are rapidly advancing with groundbreaking innovations. The ability to incorporate advanced features into compact spaces makes HDI Rigid Flex PCB a game-changer.

Key Takeaways

HDI rigid-flex PCBs help make smaller and better devices. They are important for industries like space tech and electronics people use daily.

Using better materials and new methods makes rigid-flex PCBs stronger. It also helps them handle heat and send signals clearly.

Companies like LT CIRCUIT offer custom options for these PCBs. This helps them fit project needs and work better and longer.

Latest Advancements in HDI Rigid-Flex PCB Technology

Innovations in Microvia and Layering Techniques

Microvia technology has changed how HDI rigid flex PCBs are made. Smaller vias help create tighter connections, making designs smaller and more efficient. Layering methods have also improved a lot. Manufacturers now stack layers carefully using special lamination steps. This process makes sure layers connect well, which is important for devices that need high performance.

New investments in electroplating have made these methods even better. These upgrades boost production and add new technologies for future use. For instance, the AOS system helps make structures with 7µm lines and spaces. This reduces wasted materials and improves production results, making the process faster and smarter.

Improvement Description | Impact |

|---|---|

Investment in electroplating facilities | More production capacity and better technology for future processes |

Implementation of AOS system for finishing | Creates structures with 7µm lines/spaces, cutting waste and boosting yield |

Cutting-Edge Materials in Flex PCB Technology

Materials for flex PCBs have greatly improved. Flexible bases like polyimide now handle heat better and are stronger. These materials let circuits bend and twist without losing their function. Advanced adhesives and copper foils also make them more durable and conductive.

Reports show rising demand for these materials. The HDI PCB market, worth USD 12.3 Billion in 2024, is expected to grow at 7.5% CAGR from 2026 to 2033, reaching USD 22.6 Billion by 2033. This growth shows the need for small, powerful electronics in industries like cars, phones, and medical devices.

The HDI PCBs market was valued at USD 12.3 Billion in 2024.

It is expected to grow at a CAGR of 7.5% from 2026 to 2033, reaching USD 22.6 Billion by 2033.

Demand for small, high-performance electronics drives this growth in many industries.

Precision Manufacturing for Rigid-Flex PCBs

Making rigid-flex PCBs requires very careful manufacturing. New materials, built-in features, and automated designs help achieve better accuracy. These improvements allow for detailed designs and reliable circuits.

Rigid-flex PCBs are now common in wearable devices. In 2023, over 61% of new wearables used rigid-flex designs. This shows their importance for lightweight and small devices. Their use in advanced medical tools and military systems also grew by 29% last year. These examples show how precise manufacturing meets modern technology needs.

Over 61% of new wearable devices in 2023 used rigid-flex designs.

Use of rigid-flex boards in medical tools and military systems grew by 29% last year.

Benefits of HDI Rigid-Flex PCBs

Space-Saving Designs for Compact Devices

HDI rigid-flex PCBs help make smaller devices. They shrink parts but keep them working well. Tiny components and special packaging, like System-in-Package (SiP), save space. Multi-layer boards fit more parts in less room. Features like microvias and blind vias connect layers without using extra space.

Main benefits of space-saving designs:

Smaller parts for tiny devices.

Stacked parts to use less area.

Lightweight sensors for compact designs.

These features are perfect for wearables and medical tools, where size matters.

Better Strength and Heat Control

Strength is very important for flex PCBs. Adhesiveless polyimide makes them stronger by stopping expansion. Flexible designs let them bend without breaking. Rounded corners and even thickness add extra strength.

Heat control is another big benefit. High-density connections spread heat evenly, stopping overheating. This makes rigid-flex PCBs great for tough jobs, like in cars and planes, where they must work under extreme conditions.

Design Feature | Benefit |

|---|---|

Adhesiveless polyimide | Makes boards stronger and stops expansion. |

Rounded corners | Prevents weak spots and adds durability. |

Even thickness | Helps boards last longer in moving devices. |

Great Signal Quality and Performance

HDI rigid-flex PCBs keep signals clear and strong. They stop signal loss and interference, making them reliable. These boards handle high-frequency signals with less noise. Better power flow makes them work efficiently in advanced devices.

Performance Feature | Benefit |

|---|---|

Keeps signals strong and reduces distortion. | |

Less electromagnetic noise | Stops interference that can mess up signals. |

High-frequency support | Works well for devices needing fast signals. |

With small designs, strong materials, and great performance, HDI rigid-flex PCBs meet modern tech needs.

LT CIRCUIT's Role in Advancing HDI Rigid-Flex PCB Technology

Expertise in High-Density Interconnect Solutions

Modern electronics need HDI solutions to work efficiently. LT CIRCUIT specializes in creating advanced HDI rigid-flex PCBs. These designs improve performance and ensure reliable signal quality. Using the latest methods, LT CIRCUIT makes sure every PCB works perfectly.

Their skill is in placing microvias and layering effectively. These techniques reduce signal interference and improve clarity. This makes them great for devices needing high-frequency signals. Whether for small wearables or strong industrial systems, LT CIRCUIT’s HDI designs fit your needs.

Tip: Use HDI rigid-flex PCBs for small designs needing top performance.

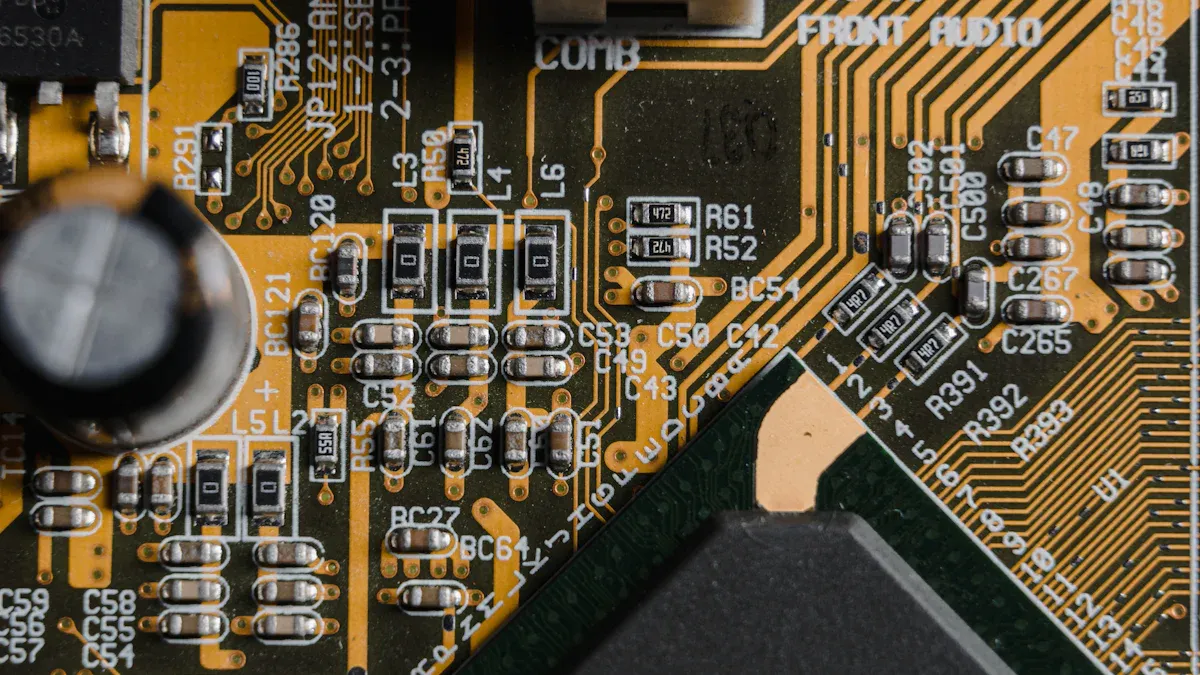

Customization and Quality Assurance in Rigid-Flex PCBs

Custom designs are important for new technology. LT CIRCUIT offers options to match your project’s needs. You can pick materials, solder mask colors, and finishes to create the perfect PCB.

Quality checks are a big part of their process. Every PCB is tested carefully with flying probes and E-tests. This ensures they work well, even in tough conditions.

Feature | Benefit |

|---|---|

Material customization | Matches your project’s needs. |

Rigorous testing | Ensures strong and reliable boards. |

Flexible design options | Fits unique project requirements. |

Innovations Driving the Future of Flex PCB Technology

LT CIRCUIT uses new technologies to stay ahead. Materials like gallium nitride (GaN) and silicon carbide (SiC) improve flex PCB performance. They handle heat better and waste less power, making them ideal for advanced devices.

The rigid-flex PCB market is growing fast. It will rise from USD 25.7 billion in 2024 to USD 77.7 billion by 2034, with a CAGR of 11.70%. In China, the market will grow at 12.4% CAGR, reaching USD 3.62 billion by 2024. This shows the rising need for better flex PCB technology in industries like healthcare and cars.

Key trends shaping the future:

New materials like GaN and SiC.

Better signals with HDI technology.

Fast market growth from new innovations.

By using HDI in its designs, LT CIRCUIT creates top-quality PCBs. These advancements help make smaller, smarter, and stronger devices for the future.

HDI rigid-flex PCBs are changing modern electronics in big ways. Their small size and strong performance make them key for new tech. LT CIRCUIT drives this change with smart, custom solutions. Learning about these updates helps you stay ahead in a fast-moving world.

FAQ

Which industries use HDI rigid-flex PCBs the most?

HDI rigid-flex PCBs are used in many fields. These include aerospace, healthcare, cars, and electronics. Their small size and strength make them great for advanced uses.

How do HDI rigid-flex PCBs boost device performance?

These PCBs make devices work better by stopping signal problems. They handle heat well and support fast signals. Their design helps them work reliably in tough conditions.

Can LT CIRCUIT make custom HDI rigid-flex PCBs?

Yes, LT CIRCUIT can create custom PCBs for your needs. You can pick materials, finishes, and designs to match your project. This ensures the best performance and dependability.

Tip: Reach out to LT CIRCUIT for help with custom PCB designs.

See Also

A Comprehensive Guide to Rigid-Flex PCB Structures

Unveiling Cutting-Edge Techniques for HDI PCB Prototyping

The Design and Production Process of HDI Any Layer PCBs