What is a Heavy Copper PCB and Where is it Used

You use a heavy copper pcb when you need extra durability and power.

The PCB industry considers 3 or more ounces of copper on any circuit board layer as heavy copper.

Standard boards usually have less copper. Heavy copper pcb options handle more current and heat than standard types.

Current Capacity (amps) | Trace Width (mils) | |

|---|---|---|

1 | 4.5 | 100 |

3 | 9 | 100 |

6 | 8 | 50 |

You find heavy copper pcb manufacturers in industries that need strong and reliable circuit boards.

Key Takeaways

Heavy copper PCBs have at least 3 ounces of copper per square foot, providing increased strength and current capacity for demanding applications.

These PCBs excel in thermal management, effectively spreading heat to prevent overheating and ensuring reliable performance in high-power environments.

LT CIRCUIT offers high-quality heavy copper PCBs tailored for industries like automotive and aerospace, ensuring durability and customization for specific needs.

Heavy Copper PCB Features

Copper Thickness

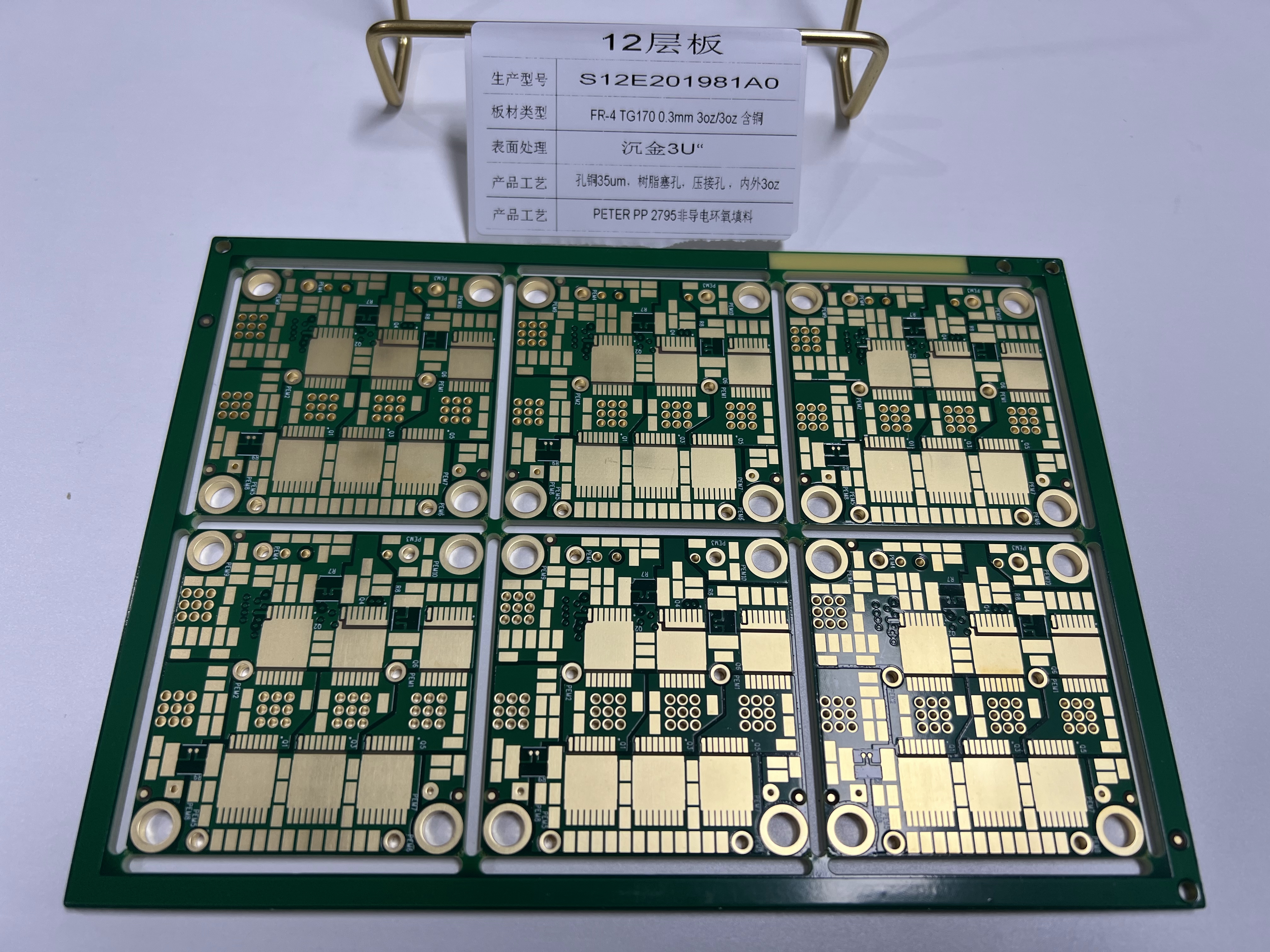

You can identify a heavy copper PCB by its copper thickness. Standard PCBs usually have 1 ounce of copper per square foot. Heavy copper PCBs start at 3 ounces per square foot, which equals about 105 micrometers (µm). Some designs use up to 20 ounces per square foot, exceeding 200 µm.

Copper Thickness (oz/ft²) | Thickness (µm) |

|---|---|

3 | 105 |

20 | >200 |

This extra thickness matters. It gives your board more strength and better performance.

The importance of copper thickness in PCB manufacturing cannot be ignored because it directly affects the conductive performance, heat dissipation performance, mechanical strength and signal integrity of the circuit board.

When you choose a heavy copper PCB, you get a board that can handle more current and heat. This makes it ideal for demanding applications.

Performance Benefits

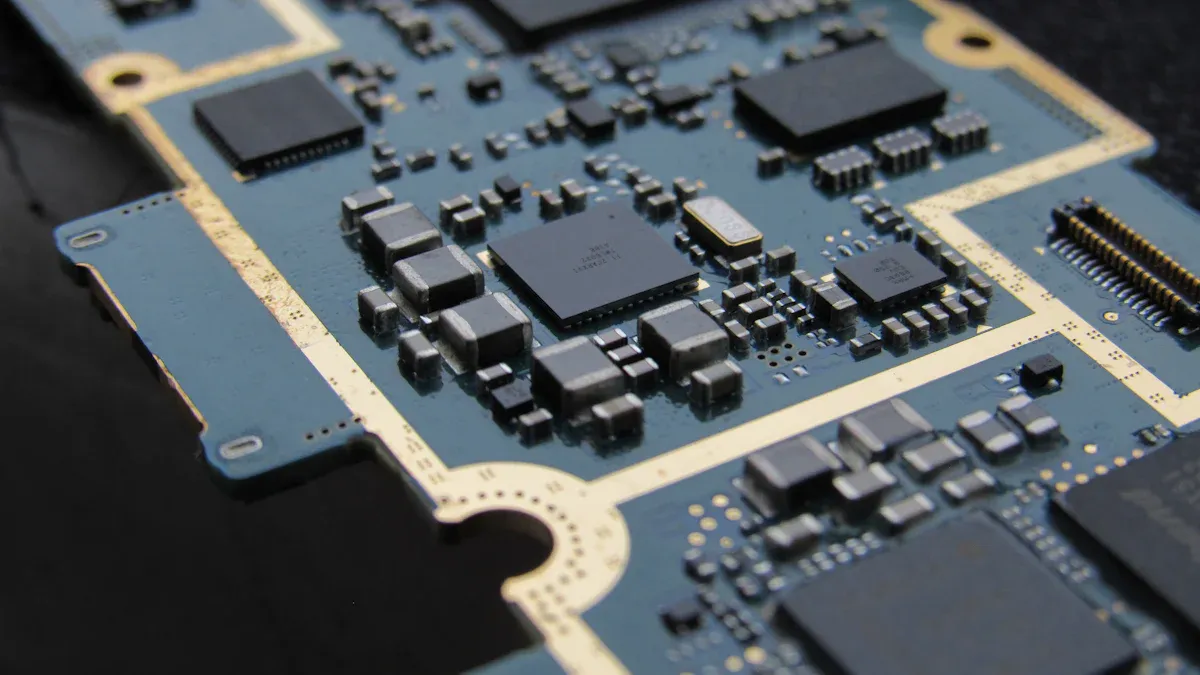

Heavy copper PCBs offer several key advantages. You will notice these benefits most in high-power or industrial settings.

Benefit | Description |

|---|---|

Heavy copper PCBs can handle higher currents without overheating, making them ideal for power electronics. | |

Superior Thermal Management | They act as heat sinks, spreading heat evenly and reducing hot spots, crucial for high-power applications. |

Enhanced Mechanical Strength | The added copper weight provides structural integrity, making them resistant to mechanical stress. |

Improved Reliability for Repeated Thermal Cycles | Designed to endure thermal stresses, ensuring fewer failures and lower maintenance costs. |

You will see improved current carrying capacity, which means your board can safely deliver more power. Superior thermal management helps your devices stay cool. Thicker copper layers spread heat more effectively, reducing the risk of hot spots that can damage components.

Increased copper thickness in a PCB enhances its mechanical strength and reliability, making it less prone to warping or bending, which is particularly important for applications subjected to mechanical stress or environments with vibration or impact.

You also get better reliability. Heavy copper PCBs last longer and resist wear and tear.

Thicker copper layers provide better resistance to wear and tear, improving the overall lifespan and reliability of the PCB.

Standard vs Heavy Copper

You might wonder how heavy copper PCBs compare to standard boards. The differences are clear when you look at electrical performance and durability.

Feature | Standard PCBs | Heavy Copper PCBs |

|---|---|---|

Current Capacity | 5-10 amps | |

Thermal Management | Moderate | Excellent |

Mechanical Strength | Standard | Enhanced durability |

Signal Integrity | Standard | Improved |

Design Flexibility | Limited | Increased flexibility |

Standard PCBs work well for low-power devices. Heavy copper PCBs excel in high-power and high-stress environments. You get higher current-carrying capacity and much better thermal management. This means your board can handle more demanding tasks without overheating or failing.

Heavy copper PCBs also give you more design flexibility. You can create complex circuits that need both power and control signals on the same board.

Heavy copper PCBs have thicker copper layers, which enhance thermal conductivity. This increased thickness allows for more effective heat spreading and release. The design reduces the risk of hot spots that can damage electronic components.

LT CIRCUIT specializes in producing high-quality heavy copper PCBs. You can rely on their expertise for advanced designs that require excellent current carrying capacity and thermal performance. Their boards deliver the durability and reliability you need for critical applications.

Heavy Copper PCB Manufacturers: LT CIRCUIT

When you look for heavy copper pcb manufacturers, LT CIRCUIT stands out as a leader in the field. You get high-quality boards that meet strict industry standards. LT CIRCUIT holds certifications such as ISO9001-2000, UL, CE, and ISO:TS16949, which guarantee quality and safety for every product.

Certification/Standard | Description |

|---|---|

ISO9001-2000 | Quality control system authentication |

UL | Certification for safety and quality |

ISO:TS16949 | Automotive quality management standard |

CE | Health, safety, and environmental protection standards |

EU SGS lead-free product | Certification for lead-free manufacturing |

Industry Applications

You find heavy copper pcb manufacturers serving many industries. LT CIRCUIT supplies boards for:

Military applications

Power supply and control converters

Welding tools

Solar board production

These applications demand reliability and durability. LT CIRCUIT uses advanced multilayer technology and precision manufacturing to meet these needs. You also get customization options, including design consultation, material selection, and rigorous testing.

Power Electronics

In high power applications, you need heavy copper pcb manufacturers who understand your requirements. LT CIRCUIT delivers PCBs with copper thickness from 3 oz to 20 oz. This allows your boards to carry more current and manage heat better. You see improved thermal management, less risk of hot spots, and greater mechanical strength. These features make LT CIRCUIT a top choice for power electronics.

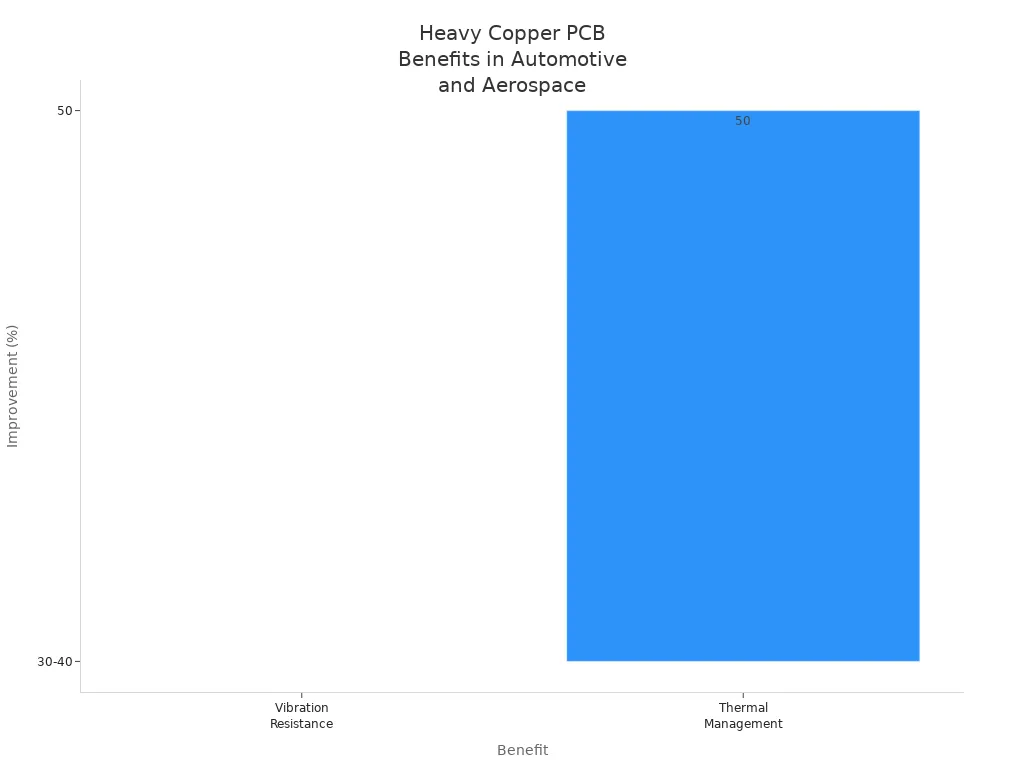

Automotive and Aerospace

Automotive and aerospace applications require boards that can handle extreme conditions. LT CIRCUIT’s heavy copper PCBs withstand high temperatures, strong vibrations, and mechanical stress. You benefit from:

Benefit | Description |

|---|---|

Vibration Resistance | Thick PCBs show a 30-40% improvement in withstanding vibration-induced fatigue. |

Thermal Management | A 4 oz/ft² copper layer reduces thermal resistance by up to 50%. |

Mechanical Strength | Thicker substrates provide greater strength and reduce the risk of damage. |

Environmental Protection | Specialized coatings protect against humidity and corrosion. |

You can trust LT CIRCUIT to deliver boards that meet the strict demands of these industries. Their commitment to quality and customization ensures your applications run safely and reliably.

You gain strong performance and reliability when you choose a heavy copper pcb. These boards feature thick copper layers, excellent thermal management, and high durability. Industries like automotive, communications, and industrial equipment rely on heavy copper pcb solutions. LT CIRCUIT delivers quality, fast production, and custom options for your advanced projects.

FAQ

What makes a PCB "heavy copper"?

You see a heavy copper PCB when copper thickness reaches 3 ounces per square foot or more. This extra copper boosts strength and current capacity.

Where do you use heavy copper PCBs?

Power electronics

Automotive systems

Industrial equipment

Aerospace devices

You choose heavy copper PCBs for high-power and high-temperature environments.

Why should you choose LT CIRCUIT for heavy copper PCBs?

Feature | Benefit |

|---|---|

Quality | |

Customization | Tailored solutions |

Expertise | Advanced technology |

You get durable boards and expert support from LT CIRCUIT.

See Also

Key Strategies for Creating High-Current Copper PCBs

Comprehensive Guide to Heavy Copper Multilayer PCB Production

Utilizing Panasonic Copper-Clad Laminates in PCB Fabrication

Exploring Horizontal Copper Sinking Techniques in PCB Manufacturing