Designing High-Performance PCBs for LED Applications

High-performance PCBs are important for LED systems to work well. Good PCB design helps LEDs last longer by controlling heat. Too much heat can shorten LED life and raise repair costs. Strong high-performance PCBs also reduce breakdowns, cutting repairs and making users happier. This is why PCB design is key for LED setups.

Key Takeaways

Keeping LEDs cool is very important for circuit boards. Use metals like aluminum or copper to stop overheating and make LEDs last longer.

Manage current with good tools like LED drivers. These protect LEDs from power spikes and help save energy.

Arrange PCB parts carefully for better performance. Put similar parts together and use thicker lines to avoid electrical problems.

Key Design Considerations for LED Circuit Boards

Effective Thermal Management

Managing heat is very important for LED circuit boards. LEDs make heat when they work, and too much heat can lower their lifespan and performance. To handle this, use materials like aluminum or copper. These materials move heat away from LEDs, keeping them bright and reliable.

Heat stress often causes electronics, like LEDs, to fail. Knowing how heat affects reliability helps you predict how long LEDs will last. For example, some methods to measure current use resistors that create extra heat. This makes designs harder and needs better heat control. Fixing these problems early helps build strong PCBs for long-lasting LED systems.

Current Regulation for LED Systems

Controlling current is key to keeping LED systems safe and efficient. LEDs can get damaged by sudden power surges or plugging in while hot. To stop this, use good current control tools like LED drivers. These drivers send steady current to LEDs.

You can check how well your current control works using these:

Driver Efficiency: Shows how well power is turned into light.

Luminaire Efficacy: Measures how much light comes from energy used.

Power Factor: A high score means the driver works well.

Transient Over-Current Events: Tests how the system handles sudden power changes.

By focusing on these, you can make LED systems that save energy and work reliably.

Layout Optimization for High-Performance PCBs

The layout of LED circuit boards affects how well they work. Placing parts in the right spots helps reduce electrical problems and manage heat better. Put high-power parts, like LEDs and drivers, where heat can be handled easily. Grouping similar parts together makes designs simpler and improves performance.

Trace width and spacing matter too. Wider traces help current flow better, which is important for high-power designs. Enough space between traces stops short circuits and keeps the board safe. Using layers in the PCB layout spreads power and ground better, lowering noise and improving signals.

Following these layout tips helps make LED boards that work well and meet strict standards. This makes designs more useful, cost-effective, and reliable for many uses.

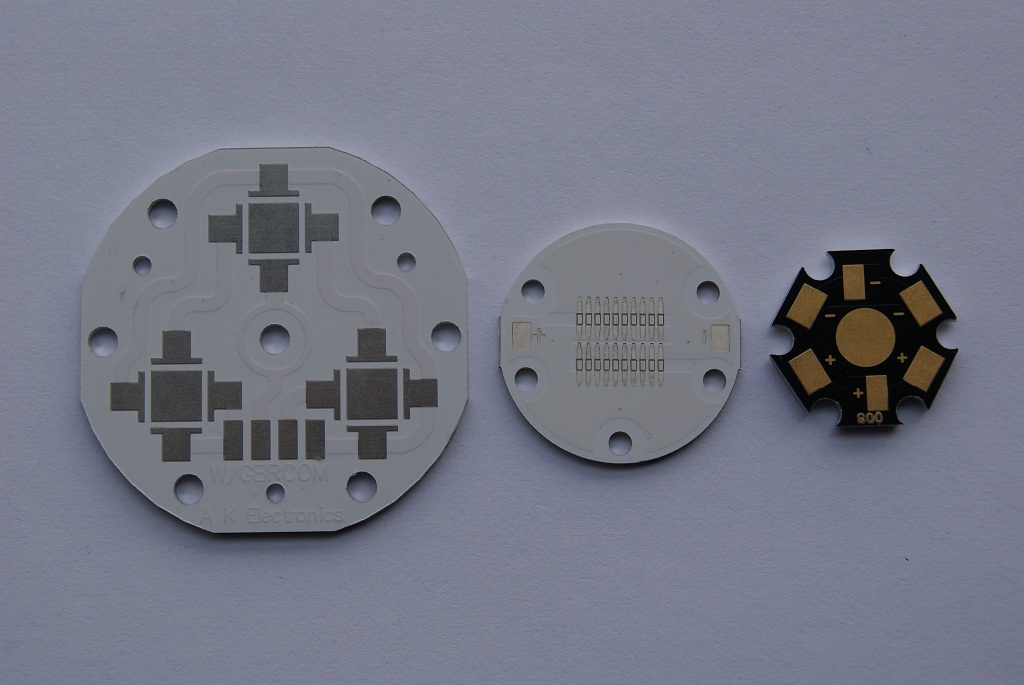

Material Choices for LED PCB Design

Picking the right material for LED boards is very important. Different materials work better for different uses, like bright lights or everyday lighting.

Why Aluminum PCBs Are Great for LEDs

Aluminum PCBs, also called Metal Core PCBs (MCPCBs), are popular for LED boards. They handle heat well because they have a special layer and aluminum base. This design keeps LEDs bright and lasting longer, especially in powerful LED systems.

Why Aluminum PCBs Are Special:

They have low thermal resistance, about 0.09°C in²/W.

They stop overheating, helping LEDs last longer.

Perfect for tough jobs like factory lights and car headlights.

Aluminum PCBs are great at cooling down LEDs. This makes them a top pick for strong LED systems that need to work in tough places.

FR4 PCBs for LED Boards

FR4 PCBs are a cheaper option for LED boards. They are made of fiberglass and epoxy, which are strong and safe. While they don’t cool as well as aluminum, they work fine for less powerful LED systems.

Why Choose FR4 PCBs:

They cost less and are easy to find.

They work with many LED board designs, like single or multi-layer boards.

Good for lights that don’t get too hot, like home lamps.

If your design doesn’t need a lot of cooling, FR4 PCBs are a good, affordable choice.

Copper PCBs for Powerful LED Boards

Copper PCBs are the best for high-power LED boards. They have thick copper layers that carry electricity well and cool down heat quickly.

Why Copper PCBs Are Best for Strong LED Systems:

They cool LEDs well, keeping them bright and steady.

Thick copper handles more power, great for strong LED designs.

Ideal for bright outdoor lights and big displays.

Copper PCBs help LEDs stay cool and work better. They are perfect for systems needing lots of power and long-lasting performance.

PCB Layout Tips for LED Applications

Placing Components

Putting parts in the right spots is very important. Start by making a simple plan to keep signals clear and avoid problems. Group parts with similar voltage and current to make the design easier and work better. For example:

Put surge protectors near signal connectors to stop voltage spikes.

Keep ground areas separate in digital sections to reduce noise.

Arrange parts to stop signal crossing and improve how they work.

Good placement also helps lights shine evenly and avoids shadows. This is especially useful for LED boards used in lighting. By following these tips, your designs will be brighter and more reliable.

Trace Size, Spacing, and Layers

The size and space of traces affect how well LED boards work. Wider traces carry more current, which is needed for powerful LED boards. Use these tips to pick the right trace size and spacing:

Situation | What to Do |

|---|---|

High-Frequency Signals | Use >4x trace width |

Sensitive Parts | Use >2x-3x trace width |

High Current | Use 3x-4x trace width |

Power | Use 4x-5x trace width |

Paired Signals | Use 0.1x-0.3x trace width |

Tough Conditions | Use >2x-3x trace width |

Extra Safety | Add 10-20% more space |

Ground Signal Gap | Keep at least 2x trace width |

For strong LED boards, use a 4-layer design. This helps spread heat and current evenly, making LEDs work better.

Power and Ground Design

A good power and ground setup is key for LED boards. Use a separate ground area to keep signals clear and reduce noise. This is very important for strong LED boards that need steady power.

A strong ground area also helps manage heat. It spreads heat out, stops overheating, and makes LEDs last longer. Adding heat sinks and thermal vias can make cooling even better.

By focusing on power and ground design, you can make LED boards that shine bright and work well in many situations.

Manufacturing and Testing with LT CIRCUIT

Advanced Assembly Methods for LED PCBs

Using smart assembly methods makes LED boards strong and reliable. LT CIRCUIT uses modern tools to build high-power LED PCBs. These tools make the process faster and reduce mistakes, improving how LED lights work.

Advantages | Performance Metrics | |

|---|---|---|

Automated Pick-and-Place | Quickly places parts with accuracy, lowering human mistakes | Better quality and fewer errors |

Automated Optical Inspection | Spots and fixes part placement issues early | Higher overall board quality |

Reflow Soldering | Great for SMDs, giving steady and exact results | Stronger solder connections |

Wave Soldering | Works well for through-hole parts, speeding up production | Faster assembly |

Functional Testing | Checks if boards work as planned | Matches design needs |

In-Circuit Testing (ICT) | Finds problems during assembly | Ensures good quality |

Burn-in Tests | Tests boards under stress to find weak spots | Shows possible failures |

These methods help make LED boards that meet strict quality rules. They are perfect for lights needing steady brightness and performance.

Quality Control Processes at LT CIRCUIT

Quality checks are key to making good LED boards. LT CIRCUIT uses both machines and people to inspect boards carefully.

AOI (Automatic Optical Inspection): Uses images to find flaws early, so only good boards move forward.

Flying Probe Test: Measures small details like resistance and capacitance for tight designs.

Manual Inspection: Checks for problems like bumps or bends at every step.

X-Ray Testing: Looks inside boards for hidden issues like broken circuits.

Two-Dimensional Measurement: Makes sure sizes are correct to avoid shape problems.

FCT/ICT Testing: Tests boards in real-life setups to confirm they meet customer needs.

These steps make sure every LED PCB from LT CIRCUIT works well and lasts long.

Testing Techniques for Reliable LED Circuit Boards

Testing is important to make sure LED boards are strong and work well. LT CIRCUIT uses different tests to check high-power LED PCBs.

Thermal Testing: Measures heat levels to see how long LEDs will last.

ICT (In-Circuit Testing): Checks if all parts work properly, reducing bad boards.

Functional Testing: Mimics real-world use to ensure the board works as designed.

ESS (Environmental Stress Screening): Puts boards in tough conditions to find hidden problems.

These tests make sure LED boards work well in hard jobs, like factory lights or outdoor signs.

Advanced Techniques in LED PCB Design

Multi-Layer Designs for High-Performance PCBs

Multi-layer PCBs make LED boards work better. Stacking layers allows more circuits on smaller boards. This design fits more parts while keeping good performance. Multi-layer boards also make devices lighter and easier to carry. For LEDs, this means smaller systems with brighter lights. These designs also improve signals and reduce interference. This helps LED systems work reliably in tough conditions.

EMI/EMC Compliance in LED PCB Design

Electromagnetic interference (EMI) can cause LED boards to fail. To fix this, follow EMI/EMC rules when designing. Use ground planes and route traces carefully to block interference. Place parts smartly and leave enough space between traces. These steps lower EMI and keep LED boards working well. Even in areas with lots of electromagnetic activity, these designs stay reliable. By focusing on EMI/EMC, your LED systems will shine brighter and last longer.

Cost-Effective Routing Strategies for LED Light PCBs

Good routing saves money and improves LED board designs. Use wider traces for power lines to handle more current safely. Group similar parts together to make designs simpler and cheaper to build. Avoid using too many vias, as they make production harder. For LED boards, smart routing gives steady power and bright lights. These tips make your designs better and more affordable.

Making high-performance PCBs for LEDs needs smart planning. Focus on heat control, picking the right materials, and good layouts. Working with experts like LT CIRCUIT helps you get new ideas and top skills. Teamwork improves energy use, makes systems last longer, and saves money. This makes LED systems stronger and better for many uses.

FAQ

What materials are best for powerful LED boards?

Aluminum and copper are great for strong LED boards. They handle heat well, keeping LEDs bright and lasting longer in tough jobs.

How do you manage heat better in LED boards?

Use heat sinks, thermal vias, and aluminum materials. These help cool down the board, stop overheating, and make LEDs last longer.

Why is EMI/EMC important for LED board design?

EMI/EMC rules help LED boards work well near interference. They stop signal problems and improve how the boards perform overall.

See Also

Key Strategies for Creating High-Current Copper PCBs

Comprehensive Guide to Heavy Copper Multilayer PCB Production

Understanding LED PCBs and Their Impact on Lighting

Frequent PCB Design Challenges and SMT Processing Solutions

Ten Effective Strategies to Reduce Custom PCB Production Costs