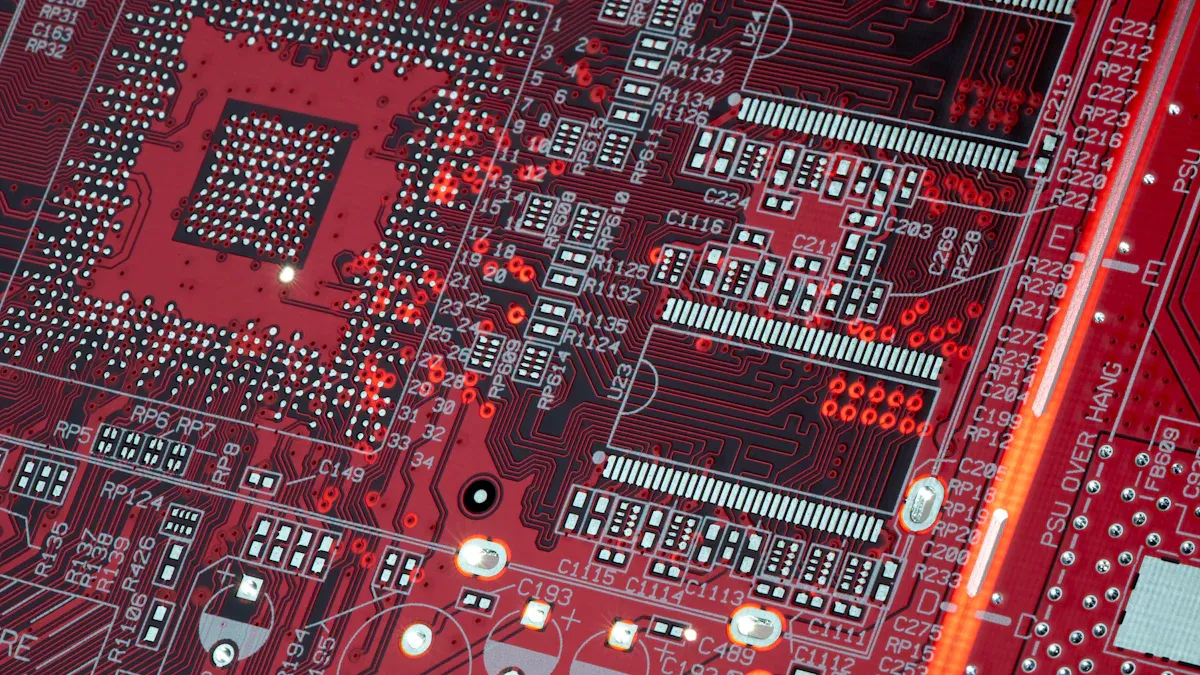

High TG FR4 Laminate PCBs: Superior Performance for Extreme Temperature Applications

High TG FR4 laminate PCBs work great in very hot places. They stay strong even when heated and cooled many times.

Tests show their glass transition temperature (Tg) is about 175 °C. This makes them very reliable.

Even when heated, they stay stiff, showing great stability.

Their Tg only drops by 2 °C, proving they are tough.

Industries like cars, airplanes, and green energy use these PCBs. They are needed for engine controls, airplane systems, and solar power devices because they handle heat well.

Key Takeaways

High TG FR4 laminates handle very high heat well. They are great for cars, planes, and factories.

These laminates stay strong and stable even with heating and cooling many times. This helps them last a long time.

Using High TG FR4 laminates can save money over time. They are tough and need less fixing.

Understanding High TG FR4 Laminate PCBs

Key Properties of High TG FR4 Laminate

High TG FR4 laminates are made to handle very high heat. They stay strong and stable, even in tough conditions. This makes them perfect for jobs where heat resistance is very important.

Thermal Stability: These laminates keep their shape and strength in heat. They don’t bend or warp easily.

Dielectric Properties: Their dielectric constant, between 3.3 and 4.8, stays steady. This helps signals stay clear in high-frequency circuits.

Electrical Insulation: With a breakdown strength of about 20 kV/mm, they protect circuits from electrical problems.

Standard Thickness: Usually 1.57 mm thick, they fit many PCB designs.

These features make High TG FR4 laminates a top pick for cars, planes, and industrial electronics.

The Importance of Glass Transition Temperature (TG)

The glass transition temperature (TG) shows when a material changes from hard to soft. For regular PCBs, this happens around 130 °C or less. High TG FR4 laminates have a TG of about 170 °C or more, making them better at handling heat.

Why is this important? During manufacturing, PCBs face very high heat, like in wave soldering. Regular materials can break or weaken under this heat. High TG laminates stay strong and keep working well, even under stress.

Studies show High TG materials last longer. For example:

Short heat exposure above TG can change regular materials, but High TG laminates resist this.

Long-term heat below TG can weaken regular materials, but High TG laminates stay stable.

Choosing High TG FR4 laminates means your PCBs can handle tough manufacturing and working conditions.

How High TG Enhances PCB Performance

High TG FR4 laminates make PCBs work better in hot conditions. They stay strong and stable, helping circuits work well for a long time.

Here’s how High TG laminates improve PCBs:

Reduced Thermal Expansion: They don’t expand much in heat, avoiding cracks or part misalignment.

Improved Signal Integrity: Their low loss tangent keeps signals clear and reduces interference.

Enhanced Durability: They handle repeated heating and cooling without breaking, great for cars and factories.

The table below shows the main features of High TG FR4 laminates:

Property | Measurement |

|---|---|

Glass transition temperature | ~170 °C (high-Tg laminates) |

Dielectric constant | |

Breakdown field strength | Approximately 20 kV/mm |

Standard thickness | 1.57 mm |

Using High TG FR4 laminates in your PCBs gives you a strong, reliable option that works well, even in tough environments.

Advantages of High TG FR4 Laminate PCBs

Strong Heat Resistance and Dependability

High TG FR4 laminate PCBs stay strong in very hot conditions. They don’t soften or bend when heated, keeping them reliable. This makes them perfect for jobs where heat is a big problem.

These laminates handle quick temperature changes during soldering. They keep signals clear and steady, even in high-frequency circuits. This reduces the chance of system problems, making them trustworthy for important tasks.

Less Thermal Expansion and No Layer Separation

Heat can make PCBs crack or parts move out of place. High TG FR4 laminates stop this by expanding evenly when heated. This lowers stress on the board.

Sometimes, PCB layers can peel apart in high heat. High TG FR4 laminates prevent this with better bonding and surface treatments. The table below shows how they solve heat-related problems:

Problem | Solution |

|---|---|

Materials Expand Differently | Use low-CTE materials like Arlon 85N and balanced designs to stop warping. |

Weak Bonds Cause Layer Peeling | Improve surface prep, use custom prepregs, and control pressure for strong bonds. |

By fixing these issues, High TG FR4 laminates keep PCBs strong and working well, even in tough conditions.

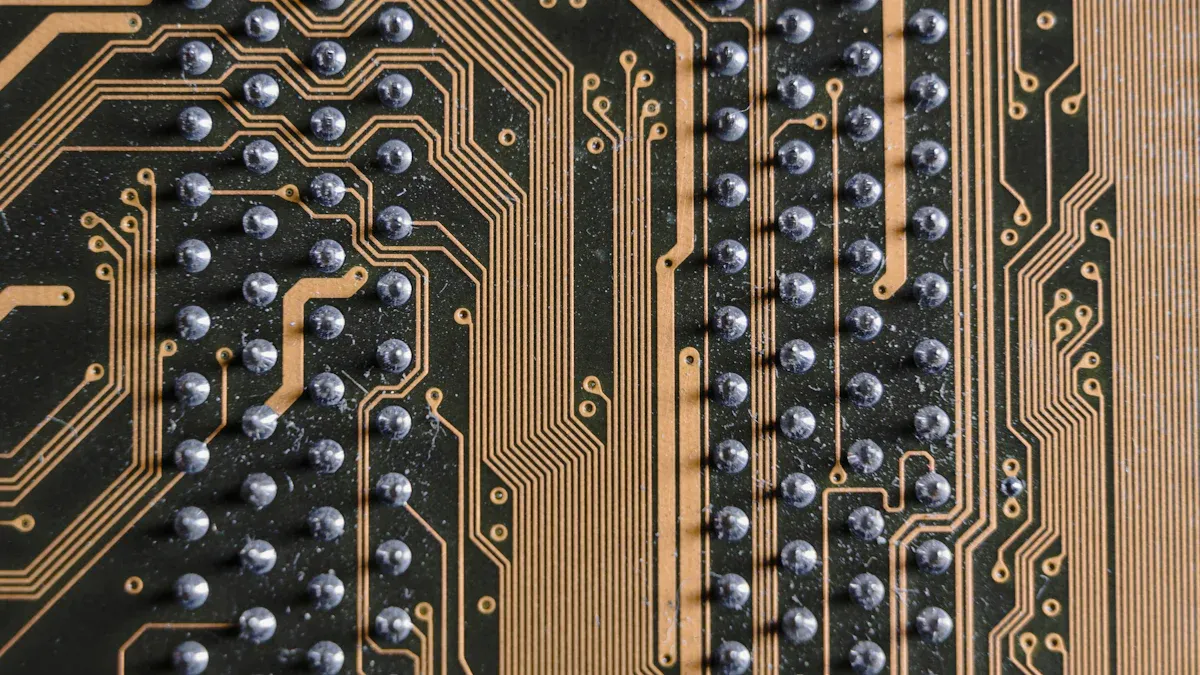

Long-Lasting in Tough Places

High TG FR4 laminate PCBs last a long time in harsh places. They survive heating and cooling many times without breaking or losing strength. This makes them great for cars, planes, and factory machines.

These laminates also resist water and chemicals, making them even tougher. Their strong build keeps devices working well, even under stress. Choosing High TG FR4 laminates means you get a durable and reliable solution for your needs.

High TG FR4 Laminate PCBs vs. Standard PCBs

Differences in Materials and Performance

High TG FR4 laminates and standard PCBs are very different. High TG laminates use special materials that handle more heat. Standard PCBs use materials that can’t take as much heat. This affects how well they work in tough conditions.

High TG laminates stay strong, expand less, and resist heat better. Standard PCBs might bend or soften when it gets too hot. For example, standard PCBs have a TG of about 130 °C. High TG laminates have a TG over 170 °C. This makes High TG laminates better for tough jobs.

Why High TG Works in Extreme Heat

High TG FR4 laminates are great for very hot places. They don’t crack or break during soldering or long heat exposure. This keeps them from peeling or failing.

They also keep signals clear in high-frequency circuits. Their low dielectric loss helps devices work well in harsh conditions. Whether in cars or factories, these PCBs are very reliable.

Long-Term Savings and Value

High TG FR4 laminates cost more at first but save money later. They last longer and need fewer repairs than standard PCBs. This lowers maintenance costs over time.

These PCBs also make devices last longer. They handle heat and stress without breaking. This makes them a smart choice for industries needing strong, reliable parts.

Applications of High TG FR4 Laminate PCBs by LT CIRCUIT

Automotive and Aerospace Innovations

High TG FR4 laminates are changing cars and airplanes. These PCBs work well in hot places and stay strong under tough conditions. They are perfect for engine controls, airplane systems, and advanced sensors.

They stay reliable in heat, lowering the chance of breaking.

Smaller and packed designs use these laminates without losing performance.

They help new tech like self-driving cars and satellite devices by keeping signals clear.

Using High TG FR4 laminates gives you smart solutions for cars and planes that need to handle heat and stress.

Industrial and Power Electronics Solutions

Factories and power systems need PCBs that handle heat and high energy. High TG FR4 laminates are strong and work well in these areas.

Category | Details |

|---|---|

Growth Factors | More electronics, better tech, and lower costs |

Challenges and Restraints | Competing materials, changing prices, and eco rules |

Emerging Trends | Smaller designs, faster signals, and better heat control |

Growth Catalysts | Electronics growth, new ways to make PCBs, and need for strong computing |

Market Projection | $15 billion by 2025, growing 5% yearly to $22 billion by 2033 |

These laminates help control heat, keeping power systems and green energy devices working well. They don’t crack or peel, making them last longer.

High-Performance Consumer Electronics

High TG FR4 laminates are key for high-tech gadgets. You’ll find them in gaming consoles, medical tools, and communication devices.

Their strength helps them last longer under stress.

They allow small designs with complex circuits, fitting modern trends.

FR4 Tg150 materials resist chemicals, stay stable, and keep signals clear. These features make them great for devices that need to work in tough conditions. Adding these laminates ensures your gadgets stay reliable and meet industry needs.

High TG FR4 PCBs are very strong in hot places. They work well in extreme heat without losing reliability. LT CIRCUIT makes these PCBs with great care and skill. Their designs help industries needing tough and long-lasting solutions.

FAQ

What does "High TG" mean in High TG FR4 laminates?

High TG means the glass transition temperature. It shows the heat level when the material softens. This helps PCBs stay strong in high heat.

Are High TG FR4 laminates suitable for all industries?

Yes, they work in cars, planes, factories, and gadgets. Their ability to handle heat makes them great for tough jobs.

How do High TG laminates improve PCB durability?

They stop boards from expanding too much in heat. They also keep layers from peeling and survive heating many times. This makes PCBs last longer in hard conditions.

See Also

Comprehensive Guide to Heavy Copper Multilayer PCB Production

The Advantages of Ceramic PCBs for Effective Heat Management

Integrating Rogers Material and TG170 in Hybrid PCB Designs

Essential Materials and Processes for Rigid PCB Manufacturing

Creating Efficient PCBs Tailored for LED Technology Applications