How to Choose a Reliable Multilayer PCB Manufacturer in China

Choosing a good PCB manufacturer for your china multilayer pcb projects requires a step-by-step approach. When working on china multilayer pcb projects, you may encounter challenges related to quality control, intellectual property protection, and effective communication with your china multilayer pcb supplier. Additionally, many companies face difficulties with complex technical processes, such as intricate lamination and maintaining precise alignment in their china multilayer pcb production.

Key Takeaways

Understand what you need for your multilayer PCB and pick a manufacturer who can meet your technical and certification needs. This helps make sure you get good quality and smooth production.

Look at the supplier’s experience, certifications, and how they check quality with testing and inspections. This helps you avoid problems and get products you can trust.

Choose a manufacturer who talks clearly, gives quick help, and shows prices openly. This keeps your project going well and helps you trust them.

Requirements

Multilayer PCB Specs

Before you start making multilayer pcb, know what you need. Some industries, like cars and phones, need very careful work. For example, 8 layer pcb boards are used in things like GPS, car computers, and phone repeaters. These need boards that can handle heat, are small, and keep signals strong.

Specification Aspect | Details/Values |

|---|---|

Layer Count | 4 to 60 layers (8 layer pcb is common for advanced designs) |

FR4, Rogers, Polyimide, Metal Core | |

Minimum Trace/Spacing | 2 mil / 2 mil |

Surface Finishes | HASL, ENIG, Immersion Silver |

Manufacturing Techniques | Laser drilling, direct imaging, AOI, X-ray, electrical testing |

Quality Standards | ISO 9001, UL, IPC Class 3 |

Vias | Through-hole, blind, buried |

Make sure your multilayer pcb needs match what the supplier can do. This helps the pcb fabrication go right for your project.

Certifications Needed

Certifications are important in pcb fabrication. You should pick manufacturers with the right certificates. These include ISO 9001 for quality, IATF 16949 for cars, and UL for safety. RoHS and REACH SVHC are needed for the environment and global rules.

Certification | Description |

|---|---|

ISO 9001 | Quality management system certification |

IATF 16949 | Automotive industry quality standard |

UL | Product safety certification |

RoHS, REACH SVHC | Environmental and chemical safety compliance |

A supplier with these certifications makes sure your multilayer pcb is safe and meets all rules.

Order Volume & Lead Time

Think about how many boards you need and how fast you need them. Top multilayer pcb makers in China let you order small amounts, even just one. This helps you save money on test runs or small orders. For 8 layer pcb, it usually takes 5 to 15 days for small orders.

Tip: Always check if your supplier can make enough boards on time. This helps you avoid waiting and keeps your pcb fabrication smooth.

When you match your needs to the supplier’s skills, your project does better. Check if they know how to make 8 layer pcb, have the right certificates, and can handle hard jobs. This helps you avoid problems and makes sure your product is good.

Research China Multilayer PCB Market

Supplier Experience

When you look for a good pcb manufacturer in China, check their experience first. The best multilayer pcb factories in China have worked for over ten years. For example, JHYPCB has made multilayer pcb for more than 15 years. This long time means they know how to make 8 layer pcb and can do hard jobs. Always pick a multilayer pcb factory that has made many good china multilayer pcb before.

Tip: Check online lists and reviews to learn about the manufacturer’s history and what people think about them.

Advanced Capabilities

A great multilayer pcb factory in China uses the newest technology. These manufacturers can make 8 layer pcb and other hard multilayer boards. The table below shows some special skills you should look for:

Manufacturer Name | Advanced Capabilities | Product Range | Industry Applications |

|---|---|---|---|

Shenzhen Kexin Electronics | Laser drilling, high-precision imaging | Rigid, multilayer, HDI | Automotive, telecom, medical |

Suzhou MTC Circuit | Automated quality control, fine pitch design | Multilayer, HDI, flexible | Consumer, automotive |

Fuyuan Electronics | HDI, flexible pcb, R&D focus | Multilayer, HDI, flexible | Telecom, electronics |

You need a pcb manufacturer that can make 8 layer pcb with small errors and special features.

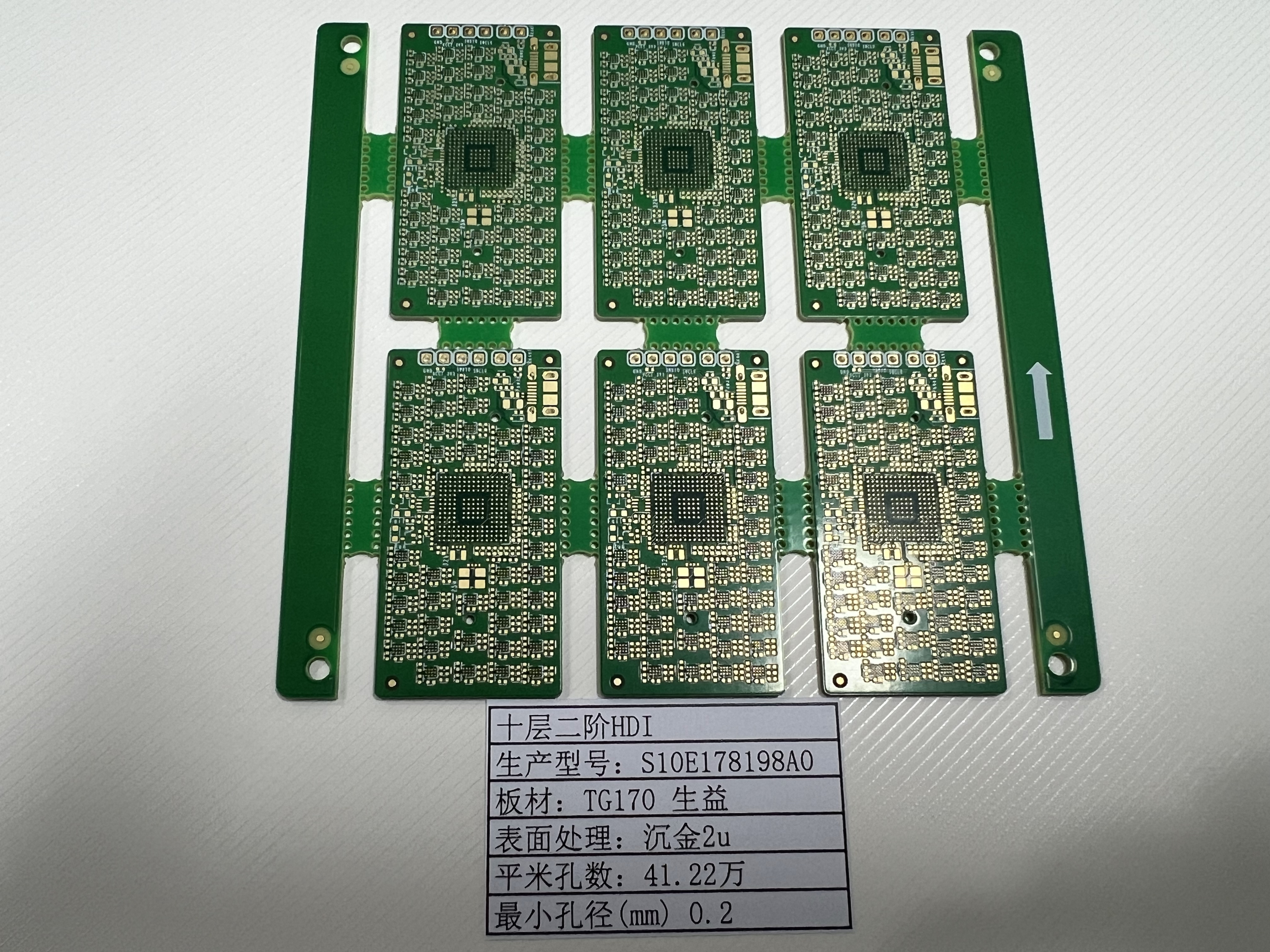

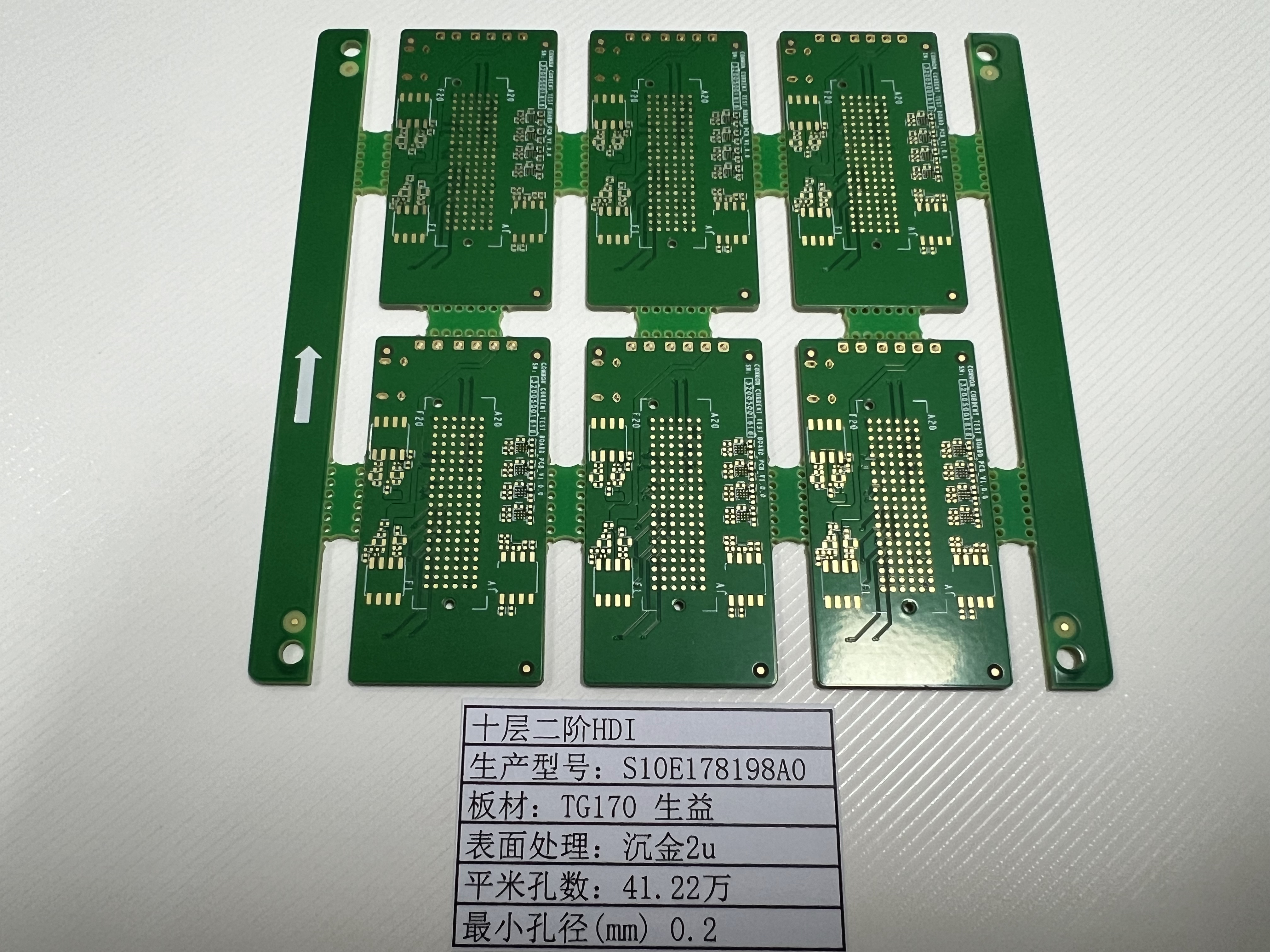

LT CIRCUIT Overview

LT CIRCUIT is a top multilayer pcb factory in China. They make many kinds of multilayer pcb, like HDI, rigid-flex, and high-density boards with up to 24 layers. LT CIRCUIT uses new machines like laser tools and automatic ink plugging to make every 8 layer pcb very exact. Many customers from other countries, like those in space and telecom, trust LT CIRCUIT for their china multilayer pcb. The company is known for good quality, great service, and helping customers fix problems. If you choose LT CIRCUIT, you get a manufacturer that spends money on better machines and quality. This makes them a great choice for 8 layer pcb and other multilayer boards in China.

Evaluate PCB Manufacturer in China

Quality Certifications

When picking a good pcb manufacturer in China, check their quality certifications. These show the company follows important rules for safety and quality. You want a pcb manufacturer that meets both world and Chinese standards. Some well-known certifications are ISO 9001, IATF 16949, UL, RoHS, and REACH. These rules help you trust the pcb fabrication and make sure your multilayer pcb is right for your needs.

Here is a table that lists common certifications and why they matter:

Certification | Description | Relevance to PCB Manufacturers in China |

|---|---|---|

ISO 9001 | Quality management system for consistent product quality | Essential for all manufacturers |

IATF 16949 | Automotive quality management system | Needed for automotive pcb fabrication |

ISO 13485 | Medical device quality management | Important for medical multilayer pcb |

ISO 14001 | Environmental management system | Shows environmental responsibility |

UL | Product safety certification | Required for North American markets |

RoHS | Restriction of hazardous substances | Needed for electronics in the EU |

CE | European safety and health standards | Required for European sales |

CQC | China Quality Certification | National quality and safety mark |

REACH | Chemical safety compliance | Ensures safe materials in fabrication |

Always ask the pcb manufacturer to show proof of these certifications. A good pcb manufacturer will give you this information easily. This step keeps your project safe and helps you avoid problems during pcb fabrication.

Production Capacity

Production capacity is very important when you check a pcb manufacturer in China. You need to know if they can make enough boards and deliver on time. A good pcb manufacturer has new machines and skilled workers. This helps them make both small and big orders for multilayer pcb projects.

You can check production capacity by asking questions like these:

How many multilayer pcb boards do you make each month?

What is your biggest daily output for hard multilayer designs?

Do you have enough machines for fast pcb fabrication?

Can you make more boards if my order gets bigger?

A strong production capacity means the manufacturer can help your business grow. You will not have delays and your supply chain stays smooth. Many top multilayer pcb factories in China use new machines for pcb fabrication. This helps them make good boards fast and meet tight deadlines.

Tip: Always visit the manufacturer’s factory or ask for a virtual tour. This lets you see their production capacity and how they check quality.

Customer Feedback

Customer feedback helps you see if a pcb manufacturer in China is reliable. You should read reviews and stories from other customers. Look for comments about multilayer pcb quality, pcb fabrication speed, and support from the manufacturer.

Here are some ways to find customer feedback:

Check online review sites and industry forums.

Ask the manufacturer for names of past customers.

Look for case studies or success stories on their website.

A good pcb manufacturer will have happy customers who talk about quality, on-time delivery, and good service. If you see many complaints about slow work or bad fabrication, look for another company. Good customer feedback means the manufacturer cares about quality and helps you with every step of pcb fabrication.

Note: If you see lots of good feedback, it is a strong sign the pcb manufacturer is reliable. You can trust them with your multilayer pcb projects in China.

High-Quality Products & Quality Control

Inspection Systems

Strong inspection systems help keep quality high at every step. Top multilayer pcb makers use both people and machines to check boards. The table below lists common inspection systems and what they do:

Inspection System | Description | Application in Multilayer PCB Manufacturing |

|---|---|---|

Manual Visual Inspection (MVI) | Workers look at boards with their eyes or magnifiers. | Works well for simple boards, not for complex multilayer boards. |

Automated Optical Inspection (AOI) | Cameras and software find surface problems and mistakes. | Great for quick, correct checks in big pcb fabrication jobs. |

X-Ray Inspection | X-rays show hidden problems inside the board. | Needed for multilayer pcb fabrication where layers are hard to see. |

Automatic Laser Test (ALT) | Lasers check board height and if things line up right. | Makes sure sizes are correct in the pcb fabrication process. |

Multisensor Measurement System | Uses optics, lasers, and probes to check all sizes. | Good for tricky, high quality multilayer pcb projects. |

Pick a manufacturer that uses these checks to keep boards good and mistakes low.

Sample Testing

Sample testing is an important part of making multilayer pcb. Makers take random boards from each group and test them for problems. These tests check if electricity flows right and if the board works. Some companies use special tests like flying probe and time domain reflectometry. These steps help find problems early and make the pcb fabrication process better. You want a partner who uses sample testing as part of their strong quality control.

Tip: Ask your supplier how they do sample testing. This shows if they care about quality control and the whole pcb fabrication process.

LT CIRCUIT Quality Standards

LT CIRCUIT is known for strong quality control and high-quality products. The company follows world rules like ISO 9001, UL, CE, IPC, and RoHS. You get advanced checks like AOI and X-ray, which cut mistakes by up to 40% in big pcb fabrication jobs. LT CIRCUIT uses special tools like Statistical Process Control and Pareto Analysis to find and fix problems early. They also use digital twin technology and AI to make quality and speed better. Every board gets many tests, like stress and weather checks, before shipping. LT CIRCUIT packs boards in anti-static and moisture-proof bags to keep them safe during delivery. When you pick LT CIRCUIT, you get high quality multilayer pcb with strong quality control at every step.

Communication & Support

Responsiveness

You want a pcb manufacturer who answers your questions fast. Top multilayer PCB suppliers in China give each client an account manager. This person watches your project and gives you updates. Customer service teams work in many time zones and speak different languages like English and Chinese. This way, you always get help when you need it. You can see how your order is going in real time. Picking a good pcb manufacturer means you get clear answers and great service.

Each client gets an account manager

Teams speak many languages

You get updates on your order

Quick replies to your questions

Technical Support

A good pcb manufacturer helps you with technical problems at every step. The best companies offer everything you need, like design, making, testing, and help after you buy. You can talk to engineers about making and putting together your boards. These experts use new machines to keep your boards high quality and on time. Many companies answer questions in less than a day and have easy return rules. The table below shows what help you can get:

Manufacturer | Technical Support Services Offered |

|---|---|

PCBasic | Engineering help, flying probe tests, welding, X-ray checks, first samples |

Shennan Circuits | PCB design, making, putting together, special orders |

Dongshan Precision | Careful PCB making, automatic SMT lines, test labs |

Unimicron Electronics | EMS help, design, testing, putting together, automation tools |

Kinwong Electronics | First samples, putting together, testing, new machines |

Shenzhen Depue Technology | Buys new machines and technology |

You should expect your pcb manufacturer to give you expert help and keep quality high.

Transparency

Being open and honest helps you trust your pcb manufacturer. Top suppliers use special systems to watch every step, from start to finish. You get updates often, sometimes every hour, about your order. Engineers are there to help with any problems during the process. Many companies have customer service all day and night, so you can always ask about your order. You can track your order in real time and know the return rules. These steps help you feel sure about your order and get good products.

Tip: Pick a pcb manufacturer who is open and keeps you updated at every step.

Compare Costs & Terms

Pricing Structure

When you look at multilayer PCB suppliers in China, check their prices. The price of your boards changes with the number of layers. It also depends on how hard the board is to make and how many you order. For example, a simple 4-layer PCB can cost $2 each if you buy a lot. An 8-layer board with special features can cost up to $20 each. The table below shows some price examples:

Layer Count & Complexity | Typical Price Range (per board) | Example Scenario |

|---|---|---|

4-layer, simple, high volume | $2 per unit | Prototyping, 1000+ units |

6-layer, standard automotive | $12-$16 per unit | Automotive modules |

8-layer, complex, ENIG finish | $15-$20 per unit | 5G modules |

The size of the board, special materials, and certifications can change the price too. You can save money by making your design better or ordering more boards.

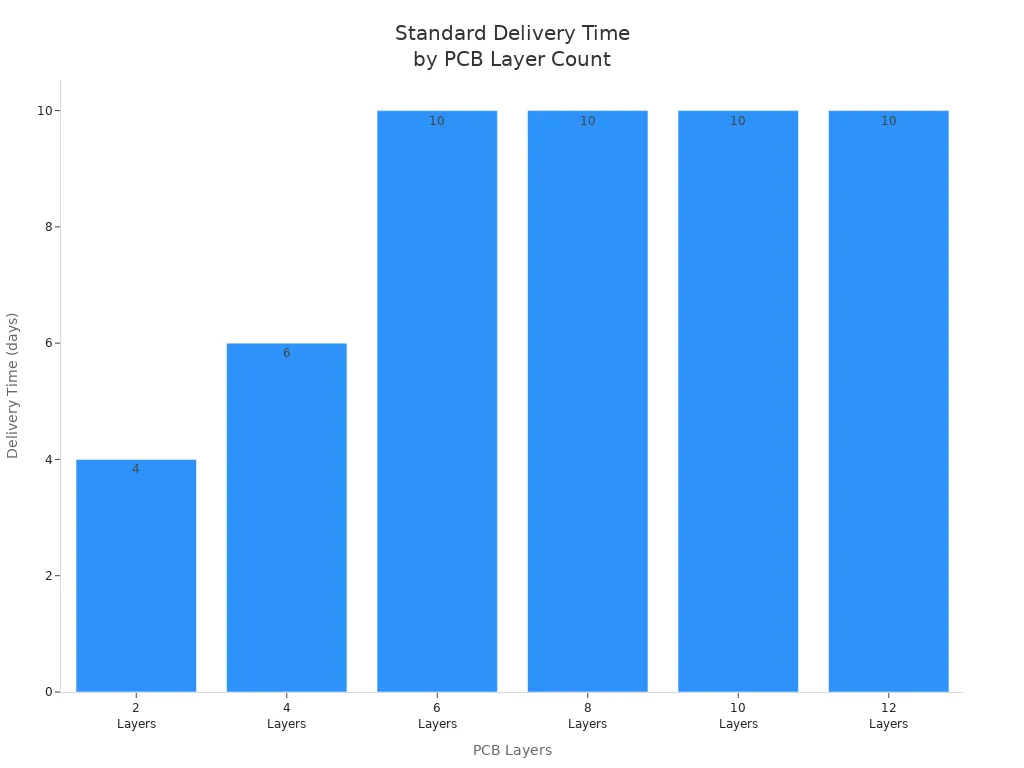

Delivery Times

Getting your boards on time is very important. Top Chinese multilayer PCB makers can ship simple boards in 1 or 2 days. Harder boards take longer to make and ship. The more layers your board has, the longer it takes. The chart below shows how delivery times go up with more layers:

A 4-layer PCB might need 10-12 days to make and 4-6 days to ship. An 8-layer board could take up to 18 days to make and 7-10 days to ship. If you need your boards faster, you can pay for express shipping. This makes the boards arrive sooner but costs more.

Contract Terms

Always read the contract before you order. Most Chinese multilayer PCB makers list what materials they use and any limits on the process. The table below shows some common contract topics:

Notice Topic | Description |

|---|---|

Only certain materials available for heavy copper boards | |

Default Layer Stackup | Standard stackup used unless you request otherwise |

V-scoring Limitations | Restrictions for thin boards |

Soldermask & Silkscreen | Color rules and defaults |

Additional Charges | Extra cost for large gold areas or special requests |

You must agree to these rules when you order. Makers can change the rules, so check them often. Clear contract terms help you know the cost and get your boards on time.

How to Choose a Reliable PCB Fabrication Partner

Decision Checklist

Picking the right partner for pcb fabrication is very important. The right pcb manufacturer helps your project succeed. You need someone who gives good quality and supports you all the way. Use this checklist to help you decide:

Communication Quality

See how fast the manufacturer answers your questions. Quick and clear replies mean they are good at talking with you.Customer Support Availability

Make sure you can reach support in many ways. Good pcb manufacturers help by phone, email, or chat.Technical Expertise

Check if the engineers have good skills and experience. Skilled teams can handle hard pcb fabrication and fix problems.Turnaround Time

Make sure the manufacturer delivers on time. Good pcb manufacturers finish work when they say they will.Quality Assurance Processes

Look for certificates like ISO 9001 and IPC-A-610. These show the manufacturer follows strong quality rules.Cost Transparency

Be sure you know all the prices. Good pcb manufacturers tell you every cost and do not hide fees.Reputation and Reviews

Read what other customers say. Good reviews and stories show the manufacturer is trustworthy.Production Capabilities

Check if the manufacturer can make the amount you need. Modern machines and big factories are important.Testing and Inspection

Ask if they test boards in their own factory. Good pcb manufacturers use special checks to find problems early.Sample and Prototype Policy

Ask for samples before you order a lot. This helps you see if the boards are good.Intellectual Property Protection

Make sure the manufacturer keeps your designs safe.Environmental and Ethical Practices

Pick a partner who follows green and fair rules.

Tip: Do not pick the cheapest option just to save money. Do not skip sample tests or rush your choice. Take your time, compare companies, and ask for proof of certificates.

LT CIRCUIT as a Trusted Option

If you want to know how to choose a reliable pcb fabrication partner, LT CIRCUIT is a great pick. You get a reliable pcb manufacturer with a strong record in quality and advanced pcb fabrication. Here is why LT CIRCUIT matches every point on your checklist:

Strong Communication:

You get quick answers from account managers. LT CIRCUIT tells you what is happening at every step of pcb fabrication.Expert Support:

The engineers have lots of experience. You can talk about design, testing, and making your boards.On-Time Delivery:

LT CIRCUIT always works on schedule. You can trust them to send your boards when you need them.Quality Assurance:

The company has ISO 9001, UL, and RoHS certificates. Every board gets AOI, X-ray, and electrical checks. You get good quality every time.Transparent Pricing:

You see all prices with no hidden costs. LT CIRCUIT explains every charge before you order.Modern Production:

The factory uses new machines for multilayer pcb fabrication. You can order small or big amounts and get the same quality.Customer Reputation:

Many big brands trust LT CIRCUIT. You can read stories and reviews that show they are reliable.Sample and Prototype Services:

You can ask for samples to check quality before big orders. This makes sure your design works well.IP Protection:

LT CIRCUIT keeps your files and designs safe with secure systems.Ethical and Green Practices:

The company follows strict green and fair rules.

If you want to know how to choose a reliable pcb fabrication partner, LT CIRCUIT is a smart choice. You get a reliable pcb manufacturer who cares about quality, helps you, and supports your business.

First, know what you need for your project. Then, look at each china multilayer pcb supplier’s background and how long they have worked.

Make a simple list to check their certificates, how they keep boards good, and if they help customers well.

Pick a partner such as LT CIRCUIT. They use new machines, follow strong rules, and send boards on time for great multilayer PCB work.

FAQ

What certifications should you check when choosing a PCB manufacturer?

Look for ISO 9001, UL, and RoHS certificates. These prove the company follows important safety and quality rules.

How can you verify a manufacturer’s production capacity?

Ask how many boards they make each month. You can also ask for pictures or a tour of their factory. Good suppliers will show you this information.

Why is sample testing important before placing a large order?

Sample testing lets you check if the boards are good. You can find problems early and stop big mistakes in your main order.

See Also

Selecting a Reliable PCB Manufacturer for Your Company

Exploring Multilayer PCB Uses in Various Sectors

A Full Guide to Manufacturing Multilayer Ceramic PCBs

Step-By-Step Breakdown of Multilayer PCB Production

Essential Skills Needed for Designing Multilayer PCB Layouts