How to Select the Right PCB Fabrication Manufacturer for Your Business

Choosing the right pcb fabrication manufacturer is crucial for your business. You need a pcb fabrication manufacturer you can rely on. They should maintain high quality standards and ensure timely delivery. Before making your decision, consider the following:

Can the pcb fabrication manufacturer produce the printed circuit boards you require?

Do they hold the necessary certifications and comply with industry regulations?

Is their customer support responsive, and are their prices transparent?

Does the pcb fabrication manufacturer meet all your project requirements?

Criteria | Why It Matters |

|---|---|

Project fit | The pcb fabrication manufacturer matches your project needs |

Reliability | Proven to be a dependable pcb fabrication manufacturer |

Key Takeaways

Make sure you know what your project needs. Write down the technical details, how many you need, when you need them, and how much you can spend. This will help you find a manufacturer that matches your needs. It also helps you avoid expensive delays.

Pick a manufacturer who has a lot of experience. They should have the right certifications. They need to check their work for quality. They should answer your questions quickly. This helps make sure your products are made well and arrive on time.

Try making a prototype first and talk clearly with your manufacturer. This helps you find design problems early. It also makes sure you know the real price. Doing this helps you trust your manufacturer and makes the whole process go smoothly.

Define Project Needs

Technical Requirements

Start by writing down what your pcb project needs. Different industries need different things. For example, cars, hospitals, and home gadgets all use different boards. The table below can help you figure out what you need:

Technical Requirement | Description / Importance |

|---|---|

Board Outline | Exact size and shape are needed for cutting and fitting. |

Hole and Slot Sizes | Holes must be the right size and in the right place. |

Copper Weights | Each layer needs the right amount of copper for strength and power. |

Board Thickness | The board must be thick enough and meet all needs. |

Choose from HASL, ENIG, Immersion Silver, OSP, and make sure it is RoHS safe. | |

Soldermask and Silkscreen | Pick the color and finish for how it looks and works. |

Special Processing Notes | This includes things like impedance control, blind/buried vias, via-in-pad, and special finishes. |

Fabrication Drawing Format | Use Gerber, PDF, AutoCAD, or ODB++ to show your design clearly. |

Panelization Details | Plan how boards are grouped, where marks go, and space for checking. |

Technical Contact Info | Give contact info so questions get answered fast and work does not stop. |

Tip: Give your manufacturer clear plans and early designs. This helps them know what you want and stops mistakes in your pcb project.

Volume and Timeline

Decide how many boards you need and when you need them. A big company is good for lots of boards and lower prices. Small companies are better for a few boards and quick jobs. Companies close to you can ship faster and talk with you easily. If one company does both making and putting together, it saves time and stops mistakes.

Note: Talk often and set clear goals. This helps you finish on time and not spend extra money.

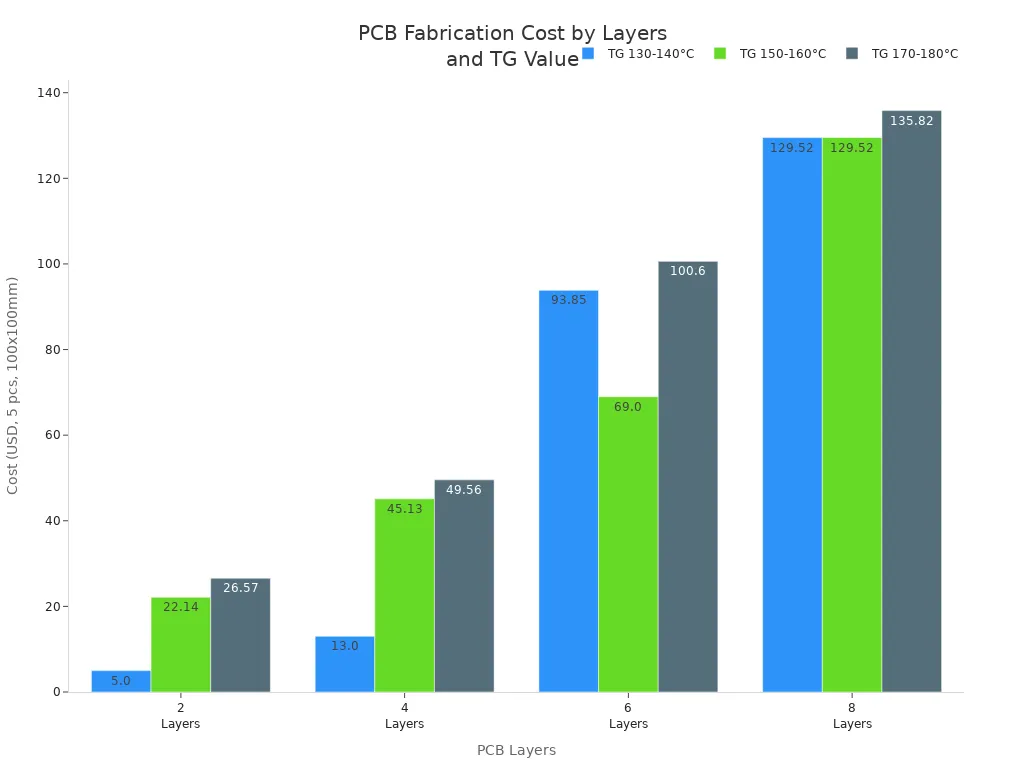

Budget

Your budget depends on how hard your pcb project is and how many you need. Prices change if you want more layers, special materials, or extra features. Use the table below to guess your costs:

Quantity Range | Lead Time | Tooling Cost | Materials | Production Process | Testing | Cost per Board | |

|---|---|---|---|---|---|---|---|

Prototype | 1-5 units | 5-10 days | Minimal | FR4 | Manual | Visual | Very High |

Low Volume | 10-100 units | 10-20 days | Moderate | Rogers 4003C | Automated | AOI | Moderate |

High Volume | 1000+ units | 4+ weeks | High | Rogers 4003C | Automated | AOI | Low |

Remember: If you do not set clear goals or a good budget, you might pay more or wait longer. Always know what you want before you begin.

Evaluate PCB Fabrication Manufacturer

Experience and Track Record

When you pick a pcb fabrication manufacturer, you want them to have lots of experience. Companies that have been around for many years are usually more stable. For example, TTM Technologies and AT&S have worked in this field for over 38 years. Viasion is newer but still has more than 18 years of experience. The table below shows how long some top companies and people have worked with pcb fabrication:

Manufacturer / Individual | Founded / Career Start | Years of Experience (as of 2025) |

|---|---|---|

TTM Technologies | 1978 | 47+ years |

AT&S | 1987 | 38+ years |

Viasion | 2007 | 18+ years |

Ross Feng (CEO of Viasion) | 2004 | 20+ years |

You should also check for other signs that show a good track record. If most customers are happy, that is a good sign. If they deliver on time almost every time, you can trust them. When customers come back for more orders, it means they like the service. Low numbers of broken boards mean they do good work. Companies that listen to feedback and make changes care about their customers.

Tip: Ask for stories from other customers. These stories help you see if the pcb manufacturer is reliable and makes good products.

Production Capabilities

A good pcb fabrication manufacturer should be able to handle your needs. You need to see if they have the right machines and enough workers. They also need enough space to make your order. Here are some things to check: Can they make the number of printed circuit boards you need? Do they use new machines like SMT lines and inspection tools? Are their engineers and workers trained for hard jobs? Do they check quality with visual checks and AOI? Do they have ISO 9001 and IPC certifications? Can they drill, cut, and print legends very well?

If your project needs special things, like tiny lines or special shapes, make sure they have done this before.

Turnaround Time

How fast you get your boards is important. You want your boards quickly, but you also want them to be right. Most pcb fabrication orders take 2 to 8 weeks. If your board is simple, some companies can finish in just 24 hours. Harder boards may take 24 to 72 hours for quick jobs, but big orders or special features can take longer.

Order Type | Typical Turnaround Time | Notes |

|---|---|---|

Standard PCB Fabrication | 2 to 8 weeks | Depends on complexity and workload |

Quick-turn (Simple Boards) | As fast as 24 hours | For 2-4 layer boards, low volume, prototypes |

Quick-turn (Complex Boards) | 24 to 72 hours | For multilayer boards; complexity and volume affect timing |

Overseas Manufacturers | ~24 hours for bare boards + shipping | Fast production, but shipping and communication may take longer |

Local Manufacturers | Faster shipping and communication | Usually higher cost, especially for complex boards |

Note: Always check how long it will take before you order. Ask if the pcb fabrication manufacturer can do rush jobs if you need them fast.

DFM and DFA Support

Design for Manufacturability and Design for Assembly help you find problems before making your boards. The best pcb fabrication companies give you tools and services to check your design. These checks catch mistakes early and save you time and money.

Many companies have online tools to check if your design is ready.

Engineers look at every order for DFM and DFA problems.

You can get help from experts about stack-up, materials, and layout.

Some companies have a customer portal so you can track your order and get feedback.

Fast jobs are possible when DFM and DFA checks are used.

Tip: Use free DFM tools and ask for an expert to check your design before you order a lot of boards.

Security and IP Protection

Your designs are important and need to be safe. You want a pcb fabrication manufacturer that keeps your data and ideas safe. Good companies use many ways to protect you:

They use safe channels to send your files.

Only certain people can see your designs.

Encryption keeps your files safe when sent or stored.

They check for problems with security often and use firewalls.

They check vendors and use blockchain to stop fake parts.

Data masking hides important details when sharing files.

They follow rules like ISO 27001 and ITAR for safety.

They store your data in safe places like encrypted cloud or special servers.

Workers get training so they do not make mistakes or leak info.

They have plans to get your data back if something bad happens.

Remember: Pick a pcb manufacturer in a country with strong IP laws if your design is secret. Always ask about their security rules before you send your files.

Quality and Support from Reliable PCB Manufacturer

Certifications and Quality Control

You should check for certification when picking a reliable pcb manufacturer. Certification shows the company follows strict rules and meets quality standards. Different certifications are important for different industries. The table below explains what each one means:

Certification | Industry/Application | Purpose/Quality Focus |

|---|---|---|

ISO 9001 | General manufacturing | Quality management system ensuring consistent high-quality products |

ISO 13485 | Medical devices | Quality management for safe and effective medical device PCBs |

AS9100 | Aerospace | Quality management for aerospace industry compliance and safety |

Safety and compliance | Ensures PCBs meet safety standards through rigorous testing (visual, electrical, thermal, mechanical) | |

IPC Certification | Electronics industry | Quality and reliability standards with classes for consumer (Class 1), industrial/medical (Class 2), aerospace/military (Class 3) |

ITAR | Military/Defense | Compliance with US export control laws for defense-related products, ensuring highest quality and security |

MIL Standards (e.g., MIL-PRF-31032, MIL-PRF-55110) | Military | Performance and qualification standards for rigid boards and laminate materials in harsh environments |

A reliable pcb manufacturer uses many steps to check quality. These steps help find problems early and make sure your boards work well. Some common ways to check quality are:

Automated Optical Inspection (AOI) uses cameras to spot missing parts or solder issues.

X-Ray Inspection looks inside the board for hidden problems.

In-Circuit Testing (ICT) checks for open or short circuits and tests if parts work.

Functional Testing makes sure the board works as planned.

Flying Probe Testing is good for small batches and finds electrical issues.

Environmental Stress Screening (ESS) tests boards in hot, cold, or shaking conditions.

Solder Paste Inspection (SPI) checks solder before putting on parts.

Visual Inspection finds scratches, bad alignment, or other damage.

Tip: Always ask for proof of certification and details about their quality checks. This helps you avoid mistakes and makes sure your boards are right for you.

Customer Support

Good customer support helps you finish your project and fix problems fast. A reliable pcb manufacturer has a team ready to help you at every step. Here is how a support team usually works:

Role | Responsibilities and Focus Areas |

|---|---|

Account Executive | Helps you with quotes, gathers design needs, and matches your budget and timeline. |

Business Manager | Answers your questions and handles requests during your order. |

Project Manager | Tracks your project from start to finish, reviews manufacturability, and plans delivery. |

Technical Project Manager | Talks with the factory, checks your design, and makes sure your board meets all requirements. |

Quality Control Engineer | Checks quality, writes inspection reports, and manages all inspections. |

Production Manager | Gives feedback on manufacturability, manages production, and works to improve quality and efficiency. |

You might have problems like assembly defects, design mistakes, or environmental issues. Common problems include:

Assembly defects like measling or delamination.

Design mistakes such as wrong part placement or bad heat control.

Environmental failures from dust, water, or temperature changes.

Manufacturing problems with resin, heat, or oxide layers.

Talking clearly with your manufacturer helps stop these problems. If you pick a company with bad support, you could have delays, spend more money, or hurt your business reputation. Good support means you get answers fast and avoid big mistakes.

Note: Test the support team by asking questions before a big order. Fast, clear answers show you can trust them.

Reputation and Reviews

You can learn a lot about a reliable pcb manufacturer by reading reviews and checking their reputation. Online reviews and stories show how well the company talks and solves problems. Look for these signs:

Customers say the company talks clearly and quickly.

Reviews mention on-time delivery and good technical help.

Case studies show how the company fixed real problems.

Third-party sites like Trustpilot and Google Reviews give honest feedback.

A strong warranty and good after-sales help show the company cares about your success.

Tip: Read reviews from businesses like yours. This helps you see if the manufacturer can handle your type of project.

Prototyping

Prototyping lets you test your design before you order a lot of boards. A reliable pcb manufacturer will help you at each step. Here is a simple process you can follow:

Pick a manufacturer with experience, certification, and good support.

Share your project goals and design details.

Send all needed files and parts.

Stay in touch during assembly to get updates and fix problems fast.

Check the prototype using visual inspection, AOI, and in-circuit tests.

Compare costs and services to make sure you get value for your money.

Watch for red flags like slow replies, missing references, or unfair prices.

Prototypes help you find design mistakes and test materials. If prototypes work well, you can expect good results in full production. If the manufacturer uses advanced testing and follows industry rules, you can trust them for bigger orders.

Remember: Always ask for a prototype before full production. This step protects your money and helps you avoid surprises.

Pricing Transparency

You need clear and honest pricing to plan your project budget. A reliable pcb manufacturer will explain all costs up front. Here are some things that help keep pricing clear:

Factor | Explanation |

|---|---|

Communication | Good communication stops hidden costs and delays. |

Quality and Reliability | Certifications and positive feedback show the company follows industry standards. |

Manufacturing Capabilities | Skilled workers and the right equipment mean accurate cost estimates. |

Lead Time and Delivery | Clear delivery times help you avoid rush fees or penalties. |

Post-sales Services | Extra services like testing or warranties are explained before you order. |

Hidden costs can happen if you do not check the details. Watch out for:

Manual review changes if your design files have errors.

More expensive parts if the originals are out of stock.

Extra charges for special testing or fast shipping.

Higher costs for non-standard board shapes or features.

Tip: Always ask for a detailed quote and check for extra fees. Keep a 10-15% budget margin for any surprises.

Picking the best PCB fabrication manufacturer takes some steps. First, see if they have lots of experience and good equipment. Make sure they have the right certifications. Next, look at how they test their boards and if they help customers well. Check if their prices are fair. You should also see if they can make enough boards for you and finish them on time. Find out if people trust them and if they can change plans when needed. Prototyping lets you find problems early. This saves you money and keeps your project safe.

FAQ

What files do you need to send to a PCB manufacturer?

You must send Gerber files, a Bill of Materials (BOM), and assembly drawings. These files show the manufacturer how to make your board the right way.

Tip: Check your files again before you send them.

How can you check if a PCB manufacturer is reliable?

You can look at customer reviews, ask for certifications, and get a prototype. Good manufacturers answer fast and show proof of their work.

Why is prototyping important before full production?

Prototyping lets you find design mistakes early. You can test the board and fix problems before you spend money on many boards.

See Also

Selecting a Reliable PCB Manufacturer for Your Company Needs

Key Questions To Discuss With PCB Fabricators Before Production

A Comprehensive Guide To The PCB Manufacturing Process

Understanding PCB Fabricator Strengths And LT CIRCUIT’s Complex Solutions